Out of stock already, but this pricey desktop ornament is fueled by fog machine fluid.

That's entertaining. I am going to propose we buy a few at work to undercut the full size tunnels we are currently using ![]()

In reply to stafford1500 :

So, how much info as a hobby racer can we get from putting a model of our car in one of these?

TR7 said:In reply to stafford1500 :

So, how much info as a hobby racer can we get from putting a model of our car in one of these?

The big issue (pun intended) with scale models is that the viscosity of air plays a disproportionately large role when you scale down. Basically the air is just as viscous but has far less momentum and therefore viscosity seems way higher.

This is a wordy way of saying the Reynolds Number (Re) is not applicable (Re is just the ratio of viscous effects and momentum). Water tunnels are used because they can get the Reynolds number closer to full-scale, and you can do neat stuff like embedding particles in the water to track the flow. Re is a big motivator though.

TR7 said:In reply to stafford1500 :

So, how much info as a hobby racer can we get from putting a model of our car in one of these?

Exactly zero, unless you are trying to make promotional videos for potential sponsors. Then you can say you have done some wind tunnel testing. Smoke tunnels in general only give a basic introduction to flow behaviors. The speeds I have used smoke wands at for full size vehicles is in the 30mph range, with me standing in the flow near the car.

Seriously though, the speed to get the smoke traces to work well is no where near the 'correct' Reynolds number. The scale also works against you as Reynolds number is a measure of the size, speed, and viscosity effects. At this size you would be better using water as the fluid medium to get the right sort of reactions.

Cyow posted at the same time as me... saying the same things.

You can seed air with particles and get the types of info he refer to for water tunnels. It is referred to as PIV (Particle Image Velocimetry). It requires some significant hardware and software to generate data, but produces real world flow field data that is more typically seen with CFD results. Think of the streamlines in simulation images. That can be generated with enough PIV data.

stafford1500 said:TR7 said:In reply to stafford1500 :

So, how much info as a hobby racer can we get from putting a model of our car in one of these?

Exactly zero, unless you are trying to make promotional videos for potential sponsors. Then you can say you have done some wind tunnel testing. Smoke tunnels in general only give a basic introduction to flow behaviors. The speeds I have used smoke wands at for full size vehicles is in the 30mph range, with me standing in the flow near the car.

Seriously though, the speed to get the smoke traces to work well is no where near the 'correct' Reynolds number. The scale also works against you as Reynolds number is a measure of the size, speed, and viscosity effects. At this size you would be better using water as the fluid medium to get the right sort of reactions.

I'll be more generous and say not exactly zero, especially if you are just beginning your understanding of aero. As long as you keep in mind that the Re is wrong and what this means, you can still learn some qualitative things, especially if you are a more visual learning person. High-level concepts like how canards can interfere with rear wings or what really happens when drafting can still be seen with this toy, and, I'll be honest, I really want one, haha.

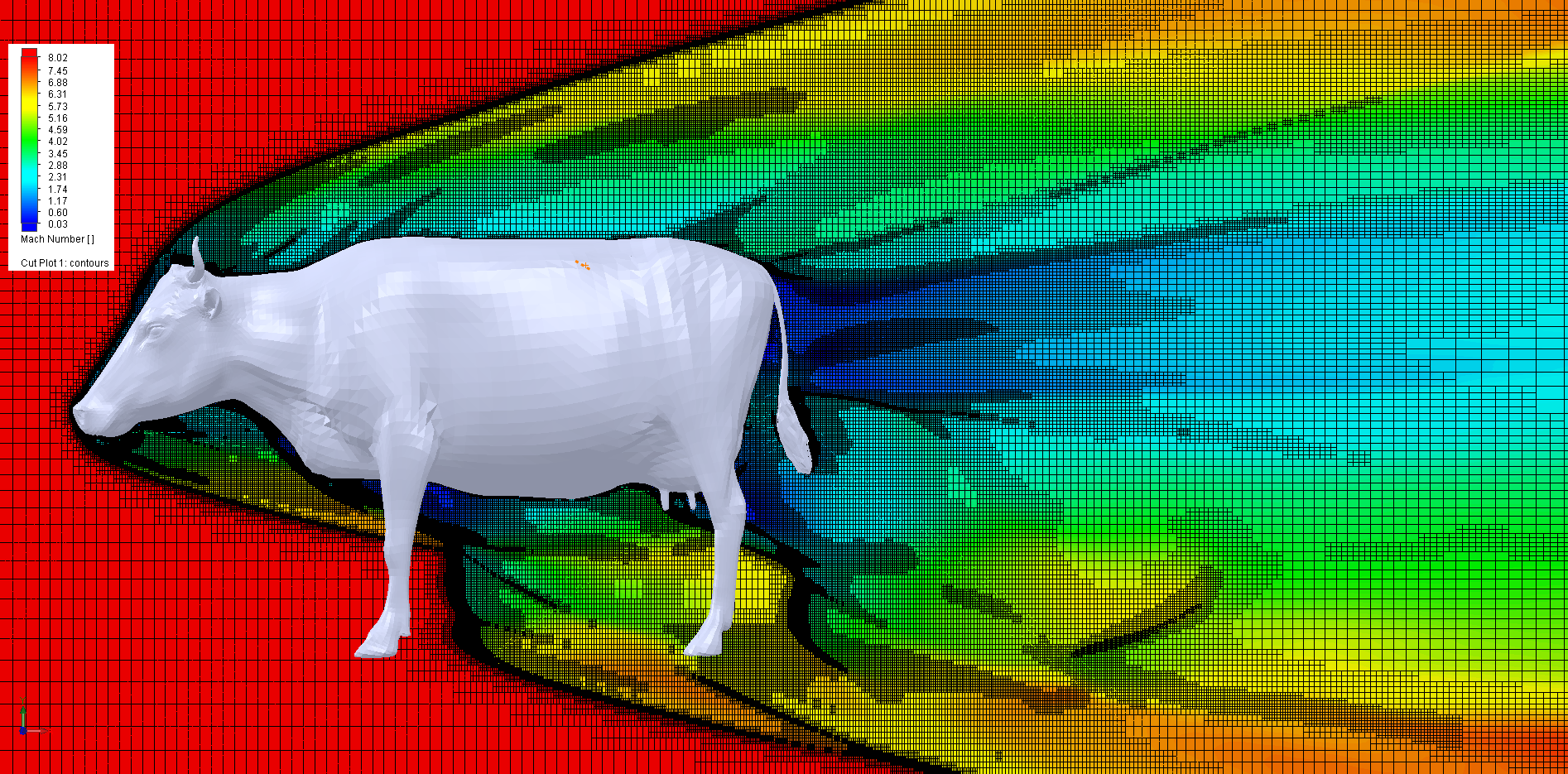

Colin Wood said:I know what I'd put in there: The little toy cow my daughter has so I can recreate this:

There is another image out there showing a cow at mach 8 or so...

Not sure the desktop unit is capable of that though.

In reply to cyow5 et al.:

OK, so just for some brain exercise; could you put the unit under vacuum sufficiently to scale viscosity? And would a small unit under vacuum behave better than water (considering air is compressible but water is, I think for this purpose, not)?

You would need to go the other way and pressurize the system to increase the Reynolds number via increasing the density of the air. That is the reason for moving to water, higher density.

There was a full size F1 tunnel that was pressurized, with bulkheads at the test section ends, so the techs could work on the car while the rest of the tunnel was under pressure. The entire tunnel did not pass certification and the welds all had to be ground out and redone. The advantage was to reduce test speed and still get the Reynolds number up to the right range.

we had to do a water tunnel lab in my undergrad work

one of my classmates taught all of us an important lesson about the peril of water tunnels when they misplaced the test section into the tunnel "just so" that the leading edge of the close-out panel dropped into the running/oncoming flow. fortunately, all the test apparatus were in the basement of that engineering building... still took a while for it dry out after pumping a couple hunderd gallons out in the space of a minute or two before they got it shut down.

TR7 said:In reply to cyow5 et al.:

OK, so just for some brain exercise; could you put the unit under vacuum sufficiently to scale viscosity? And would a small unit under vacuum behave better than water (considering air is compressible but water is, I think for this purpose, not)?

Without doing the math (which is fairly basic but I'm not free right now enough to google parameters), your best Hail Mary would be to increase the temperature. As long as viscosity drops more than density does, you might get closer but still way off. And who knows, the fog machine might no longer fog at that temperature and then it is all moot.

If scale air testing could be done by a small tweak like pressure or temperature, water tunnels wouldn't be needed. That tells me the swings you'd need aren't doable.

You'll need to log in to post.