While we're breaking records, here is my dad's studebaker lark. 10.92 at 122 mph.

pres589 wrote: They look good.

Yeah. It's what I wanted to put on the car from the beginning. Now I just need to clean and paint the brakes behind them, so they look better in the sun.

The conversion to fuel injection begins. I plan to use the stock pcm, to manage it. I was thinking about buying a kit, but ended up deciding to use what I have and make it happen. I already have a harness that I was running on another car. My plan with this conversion is to get everything ready off of the car, without disabling it, and then spend a weekend throwing parts at it and hopefully have it done by the end if it.

I began by preparing the intake. It was a mess when I started. I wish I had gotten a before picture, but I forgot. If any of you have messed with one of these engines you know how dirty they get when pulled from a truck after a lot of miles.

It is a later truck intake, without the egr. I decided to go with the truck intake because it was that or a car intake, and truck intakes make more power.

I wanted to run the fuel line to the front right of the engine because that is where the fuel line is situated currently. Therefore I took the fuel rails and switched sides. This required a little clearancing so that the fuel line would be able to fit.

I will not be running the pcv system, so I tapped and plugged the port.

The injectors are 42 pound FAST injectors (I think). The guy we bought them from said they were 85 pounds injectors, but they are definately not. Does anyone know how to identify the size of the injectors. I tried looking up the part number, and it said they could be 4 different sizes. I have assumed that they are 42 pound injectors because I had to double the VE value I had in the car I was trying them in just to get the thing to idle. It would be nice to know for sure though.

I think I have figured out what size fuel injectors I have. They are 39 pound injectors.

39 pound injectors have no dot.

50 pound injectors have an orange dot.

65 pound injectors have a yellow dot.

85 pound injectors have a white dot.

pres589 wrote: Why not run the PCV system?

Coming from a cabureted small block chevy background, I assumed it was needless complexity.

When I was making the wiring harness, I saw the pcv system and determined that it did not make the car faster so I removed it. Since this is going to be a street/race car, maybe it would be nice to have, but I have aleady made it impossible to reinstall. Oops.

In summary I didn't really think about it, and the last car was a more all out race car, so my mind was still in that mode.

I started cleaning up the harness that I made 2 years ago. I have found a couple mistakes in it that I have now fixed. Turns out I mixed up some of the injectors, so 3 of the injectors on the left side of the engine were rearranged... oops.

I am slowly making progress on it. I am so glad this is not a challenge car anymore. It's nice to be able to just buy what I need. Look forward to pictures shortly.

I am about 75% done with the harness rework. I am very happy with the results so far.

This is the harness that I started with.

When I originally made the harness, I made it so that wires ran on either side of the engine rather than over top of it. To do this I cut as few wires as possible in order to minimize the chance of a mistake. Now that I realize it is not that difficult I am cutting the wires down and splicing them to the correct length. It is much cleaner and uses less wire. It is coming out very well so far. Here are some pictures of the progress thus far.

Also for this project I picked up a label maker. It was $30 at home depot, and it works great. It has been very helpful in keeping everything straight even though I pretty much know every connector by heart. I would highly recommend one if you are doing this type of project.

That's all for today. I hope to have the harness done tomorrow, and start throwing parts at the car on Saturday. Wish me luck.

Well I got a bit done tonight, but not what I said I wanted to get done. I got a little side tracked in a good way.

The wiring harness is not complete, but I have decided that it is probably better that I complete it on the car, so that I get all of the lengths perfect.

Here is a picture of it currently.

Also, I was able to piece together a cold air intake setup. I was not able to try it on the car, so here's hoping it will fit. I have a good feeling about it. I need to get a larger cone filter for it, so it does not neck down and back up. Pretty good for junk lying aroind, huh?

That's all for today.

I did not accomplish my goal for the weekend. I only have one picture to show because I was so busy thrashing that I never slowed down to get more. I ran into a couple of roadblocks.

The first was the one headers o2 bung is poorly located, so I was unable to install the o2 sensors.

The second road block was the weather. It started out great. I was literally in shorts. There was very little wind and the sun was shining, but then I saw this ominous black cloud slowly moving in. The wind began to pick up and the temperature dropped about 30 degrees that night, and it snowed. I tried to get as much done as I could today, but it was COLD!

So here's where I am at:

Fuel system is done.

Wiring is about an hour or two from completion.

The cold air intake fit beautifully.

I have to remove the exhaust to install an o2 bung.

I have to adapt a throttle cable to the pedal that is in the car.

I need to write the tune I found on the internet onto the car, and modify it as needed.

So much for a weekend install. I was at least able to grab the tune off of the computer, so now I get to start playing with it.

It's been a while since I've updated you guys. I'm almost ready to put the car on the road. The tuning is nearly complete as well. The car starts and idles fantastic. I am very happy with it. I plan to take it drag racing this weekend. I just got the bumper mostly mounted.

The sun was at just the right angle for this shot.

https://bangshift.com/bangshift1320/kids-first-car-v8-swapped-studebaker-built-2000-absolutely-rips/#comment-154706

So, I had to do this

because I saw this

which was caused by this

but luckily we have more of these

specifically this

So we rolled this to an area that I could work on it the other day. The LS1 did not work out. A couple of the cylinders were filled with water. I was not willing to risk it at the time, but I am to the point now that I just want to get it back together so I can drive it. So I'm throwing a bunch of junk at it.

The LS1 is usable, but with the recent sale of a vehicle, we have an engine that does not have a destiny... until now. The engine is another LQ4. We originally bought it for very little money, and installed it in the Datsun (the SR-71D) when it still had the turbo setup. Long story short, we ran it down the track and the boost got out of control, we ran out of injector, and it did the damage seen below.

30 pound of boost on a stock bottom end is a recipe for disaster. Surprisingly none of the bearings were spun. We had a set of LQ4 rods and pistons that a friend gave us, so I took all of the old ones out and threw the new ones in. While I was at it, I threw on some ported LS1 heads, and an LS2 cam. This was going to be a challenge engine, but we decided it would be better for this car. So here is where we sit: More compression, higher flowing heads, better intake, larger throttle body, smaller cam. Should still make more horsepower than the old setup.

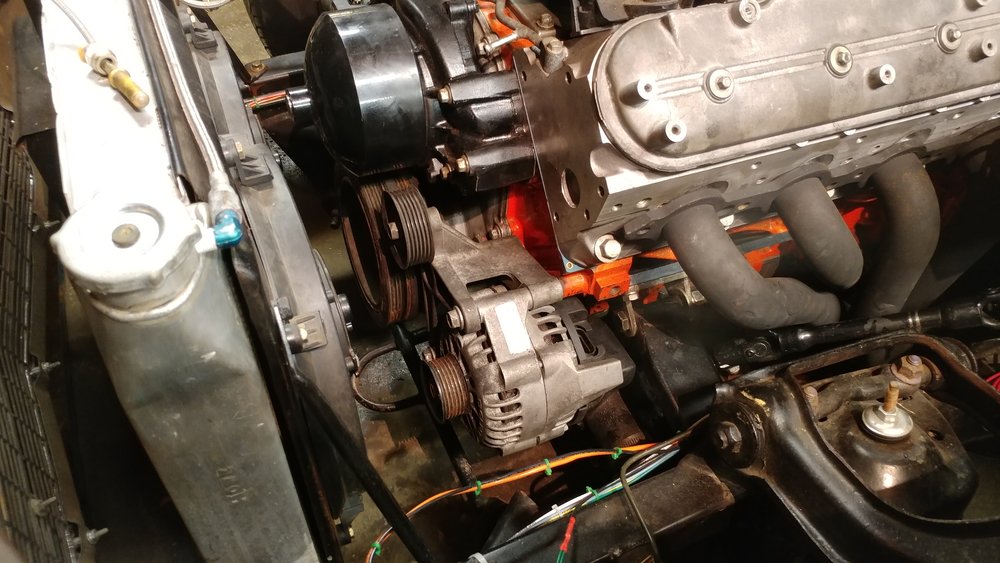

I threw it in the car today, hence the update.

I am also changing to a mechanical pump, so there is less to think about. There will be no switches to remember to turn on. Fire it up and go! I am very happy with how well the F-body accessories are fitting as well.

I'm really hoping it will hold together for a while, so that I can put together something a little more serious.

It's been a while since I've touched this car. I took it to a couple of shows, and drove it around.

Something that we discovered about F body oil pans is they have been the cause of several engine failures that we have had. The oil pickup is located in the front of the oil sump. Under hard acceleration, the oil runs away from the pickup, the engine oil starves and starts destroying stuff. This is likely the reason that the old engine that I had in the car spun a couple of main bearings. We have since found a solution to this issue and have over 30 drag passes (many over 135 mph) on one of our latest combos.

After discovering the issue with the F body oi pan, I stopped driving this car. It is too much risk to ruin more good parts. I say good parts, but almost every part of the engine has been through a blowup in the past. That being said, it has 40psi of oil ressure at idle, and runs really well.

After hearing that drag week was going to be in our area, i devised a plan. I was kind of getting bored of the LS engine, and let's face it, I'm a turbo guy. I love all the wooshy whistly sounds they make. So the tranformation has begun.

Out came the 6.0L

It is going to be sooooo nice to clean up the wiring on this car.

Next, I drug this out of the corner, yanked the oil pan, and weighed it.

Drum roll please... no oil pan, no intake, no exhaust manifold, no accessories, and no oil....

Not bad. To put this into perspective, an LS iron block short block with rotating assembly weighs about this much.

Also, I looked at the bottom end. As some of you may know, finding info on these engines is rather difficult. Even just finding a picture of a connecting rod is challenging. I was pleasantly surprised to find a beefy bottom end.

The connecting rods look almost identical to gen IV LS rods.

Some comparison shots.

Now in the car.

With the front end.

Many of you are probably thinking, why not put a turbo on the LS, and fix the oil pan. IMHO this combo is going to be way cooler.

Also, Some of you may be asking what happened to the F100. I still have it. It will likely get an LS. I really wanted to put the Atlas engine into a car anyways. What better car than this?

Also, I picked up a welding jig/mock block. Somebody had their engine destroyed by a dealer that didn't put oil back into their engine, so they made into a table.

$50 later, and I had a welding jig.

I pulled it apart tonight. Check out how they did the piston oil squirters.

I like that you're going with the Atlas engine over the LS. In terms of displacement it's similar to the Ford Barra six that is popular down under. I'd love to swap a turbo six into my old station wagon, just to be different.

In reply to Nitroracer :

Thanks. It's actually very similar dimensionally to a Barra 6 cylinder. On this that is annoying are the cam sprockets are huge and really increase the height of the engine. As far as bore and stroke, they are very similar too. They are like the Barra of America.

The only thing is America doesn't have the same love for inline 6 cylinders that Australia does, so finding aftermarket parts is borderline impossible.

I can't wait to see what these engines are capable of with boost.

You'll need to log in to post.