Glued the steering wheel together on the back porch, since a lot of epoxies smell like the glue factory just tossed the whole dead horse in the blender. I was pleasantly surprised to find the JB Plastic Weld wasn't quite as horrible.

If I change my mind, the wheel will probably fetch a bit more money if I can sell it in one piece.

Yesterday I ordered a Grant wheel from Summit and a turn signal switch from Daniel Stern Lighting. Dan is generally the go-to guy for knowing what Mopar repair parts are good and what's cut too many corners.

I went with the black foam version of the wheel Crankwalk posted. I've driven cars with both foam and wooden Grant wheels, and the foam grip is a bit more comfortable.

The turn signal switch is under the dash and too large to pull through the steering column. So I need to depin it first.

Then I tied a wire to one of the wires before pulling the switch out.

Unfortunately, pulling the wires on the new switch back through the column is a lot harder. Still trying to figure that part out...

Finally making progress on the turn signal wiring. I first tried tying all eight wires to one string. Didn't work. So I used the one string to pull eight wires through the column and tie each string to a wire.

Better, but they still got stuck. Hmmm, maybe if I tape the ends and pull the wires into the column one by one?

Success!

In reply to MadScientistMatt :

Where there is a will, there is a way!

The Grant steering wheel in place...

Confirmed that the lights all work, but I've got a bit of cleaning up to do before I can take it back on the road.

Id be sorely tempted to color match tge spokes

Dusterbd13-michael said:

Id be sorely tempted to color match tge spokes

That sounds like a great idea!

The red interior screams for red or silver spokes. I'd go red, black hardware, and see if grant still makes the chrome button with the pentastar. Would blend it all well, oem+ look. Id also trim back how far down the spokes the foam goes to get a good visual break of spoke and rim.

So, I thought I'd take the car for a longer shakedown trip. Nope.

The car ran hot and stalled on less than a mile. Thanks to some help from my wife, several bystanders, and a downhill grade, I managed to bring it home.

Turns out the water pump belt had jumped off my idler pulley setup. The coolant did boil over, but the engine isn't seized. Looks like I need to give that idler setup a closer look, and check if the head gasket survived.

Given how many other setbacks I've run into, before taking the Dart back on the road I want to answer a few questions:

1. What went wrong?

2. Did it cause any other damage?

3. How can I make sure this doesn't happen again?

To answer 1, it looks like when I fixed the problem with the belt rubbing on the lower radiator hose, the hose was what kept the belt from jumping off the pulley. So I was driving with nothing to spin the alternator or water pump.

Next, assessing damage. Compression check has 120 psi on all six cylinders. Next, I'll need to see if I have any coolant leaks...

And I have some thoughts on what to do about that idler pulley - as well as some mods to make cold starts better.

After a few false starts, I decided to remove the idler pulley. Shortening the alternator strut...

...and a shorter belt gives just enough clearance for the radiator hose and crank trigger.

Started it up and there's no sign of liquid leaks. There does seem to be an ignition miss - will need to check the plug wires, as they have been on there well over a decade. Maybe I broke one checking compression.

And I definitely have an exhaust leak at the manifold flange to turbo up-pipe. Again. I'll need to find a better long term fix that just putting in another parts store exhaust gasket.

Remflex is the go to choice for exhaust gaskets in the slant six world. Got their gasket installed and so far, so good.

Next concern, tighten the loose steering. There is one adjustment on the point where the steering column joins the box, but that appeared good. So I adjusted the sector shaft screw on the top of the steering box...

Only to find the bolts holding the steering box to the K-member allowed the box to wiggle slightly. So I tightened those down too. Was a little late for a test drive tonight, but I can tell a big difference already.

Today I wanted to resolve the speedometer problem by swapping to the junkyard speedometer I picked up several years ago through either this forum or slantsix.org. First, I opened it up to see if I could get the odometer to match, and...

... I don't think it is supposed to look like this.

So, will I:

1. Decided this is not important since nobody else in Atlanta checks their speedometer?

2. Send it out for repair?

3. Try to make one working speedometer out of two dead ones?

4. Program a microcontroller to drive a LED sweep for a gauge?

To be continued....

While I'm still pondering exactly how I will handle the gauges, I'm going about working on putting an IAC valve in there. My go-to is the mid 1990s VW 4 cylinder IAC thanks to its barbed connections. Unfortunately, they're sized for some sort of metric hose, I think. A 3/4" hose is just perfect for the inlet. The outlet is a bit bigger, but 3/4" hose is convenient enough that I'll see if I can use my favorite short cut for just-a-little-too-small hoses:

...dish soap! It took a while, but I was able to get the heater hose and a fitting on the IAC.

Now to find a location for the valve...

The best bet is probably going to be to relocate the PCV fitting and put the IAC right there. I'll probably bring the elbow in to work and use a drill press on my lunch break for that.

Meanwhile, looking at the dash, the speedometer is a 6" bar graph...

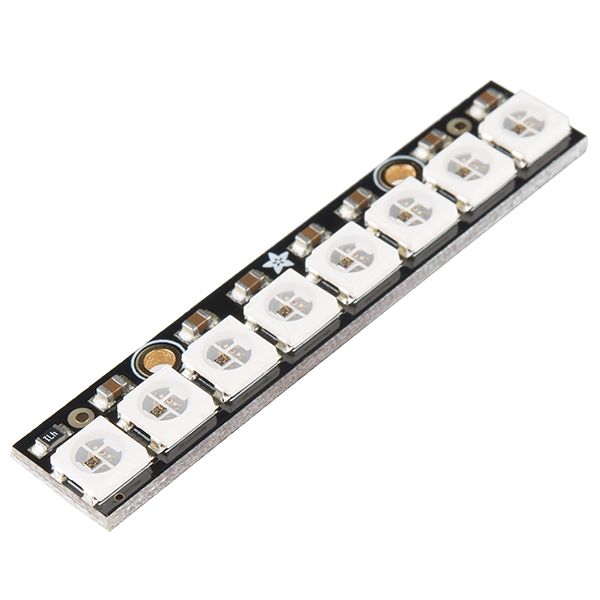

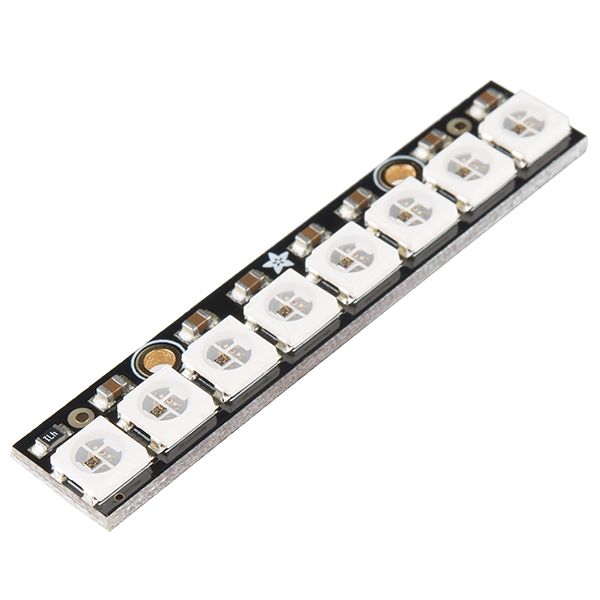

Hmmm... wonder if three of these would be about right?

The other gauges have about a 2" x 1/2" opening...

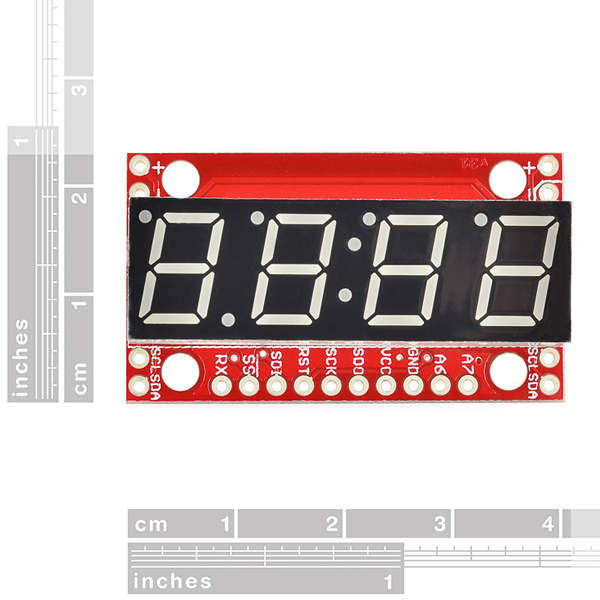

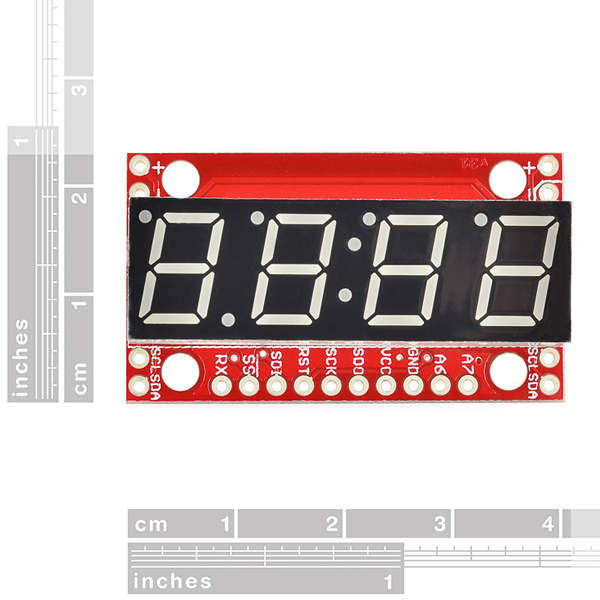

And there's this...

Sparkfun: You can even program it for stand-alone operation since the ATMega328 comes pre-loaded with the Arduino bootloader!

What the dash looks like now.

Rendering of what it might look like with digital gauges, with the front lenses intact.

What do you think? (Of the gauges, not my terrible photo editing skills!)

Regarding the IAC, I remember them being a constant failure item on VWs.

Hyundais used a similar valve for a long time and I don't recall ever having issues with them.

Right now I'm just sorting various issues. There was a pronounced rattle when stopped that went away when moving. I added another exhaust hanger and that noise quited down. However, there's a pretty noticeable gasoline smell when driving it, and I also smell a lot of gasoline after filling the tank. There is no obvious sign of fuel leaking under the hood, but I'd like to have this figured out before taking it out of the neighborhood.

On the good news, some tweaks to the cranking pulse widht and ASE have a lot better cold starts. Still has a tendancy to stall when shifted into gear when cold though.

More minor issue chasing. Took it on a somewhat longer test drive without a huge amount of fuel smell, so that is probably done. However, the throttle tends to feel a bit stuck in the closed position and I often had to give it a good stomp. (Fortunately, it closes just fine!) So I took a while to oil the throttle and kickdown cables, and that's better. No big news to report, just feeling a bit more confident about the car and getting the small stuff dealt with.

Throttle sticking when shut takes me back to the days before everything was drive by wire. It usually indicated that the throttle body was dirty and the blade was jamming in the crusties, but in aftermarket installs it also meant that the base throttle opening was too low or the throttle plate was not centered in the bore with the plate shut.

Some work on those gauges. Swapped the black boost gauge for one that matches the not yet wired up AFR gauge.

And it was pretty easy to take apart the tach. Let's see if putting the needle back on the correct side of its stop gets this working...