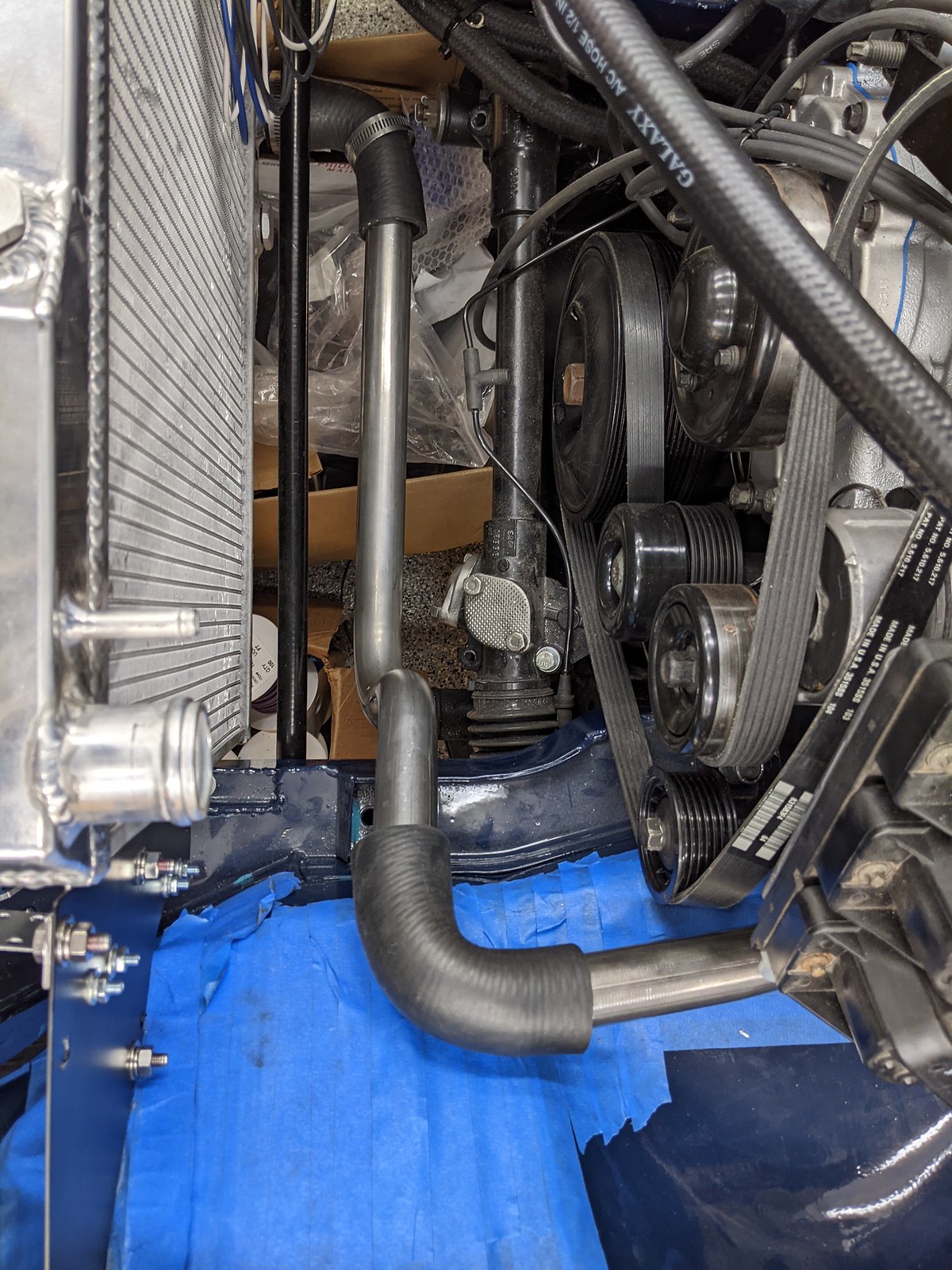

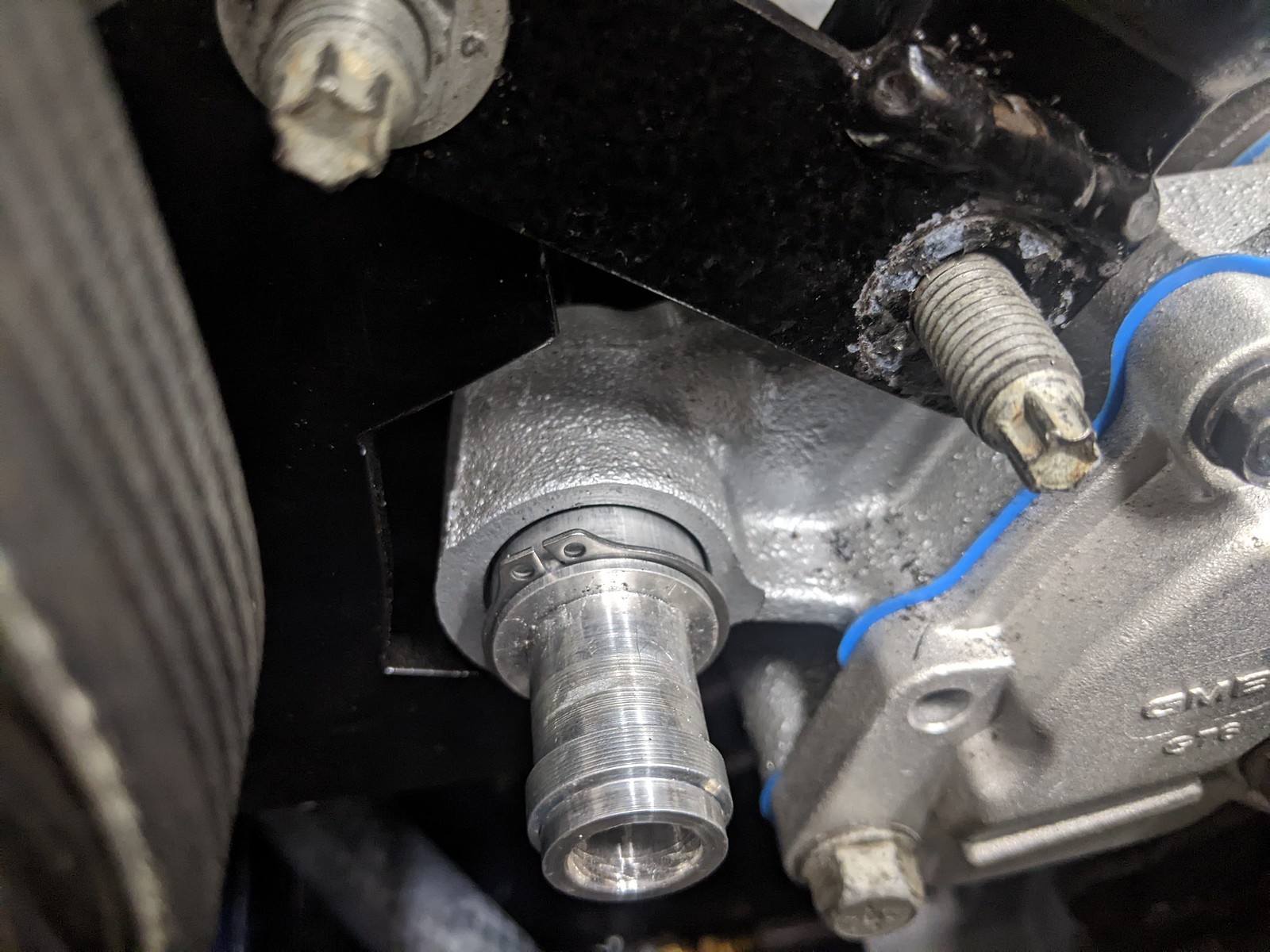

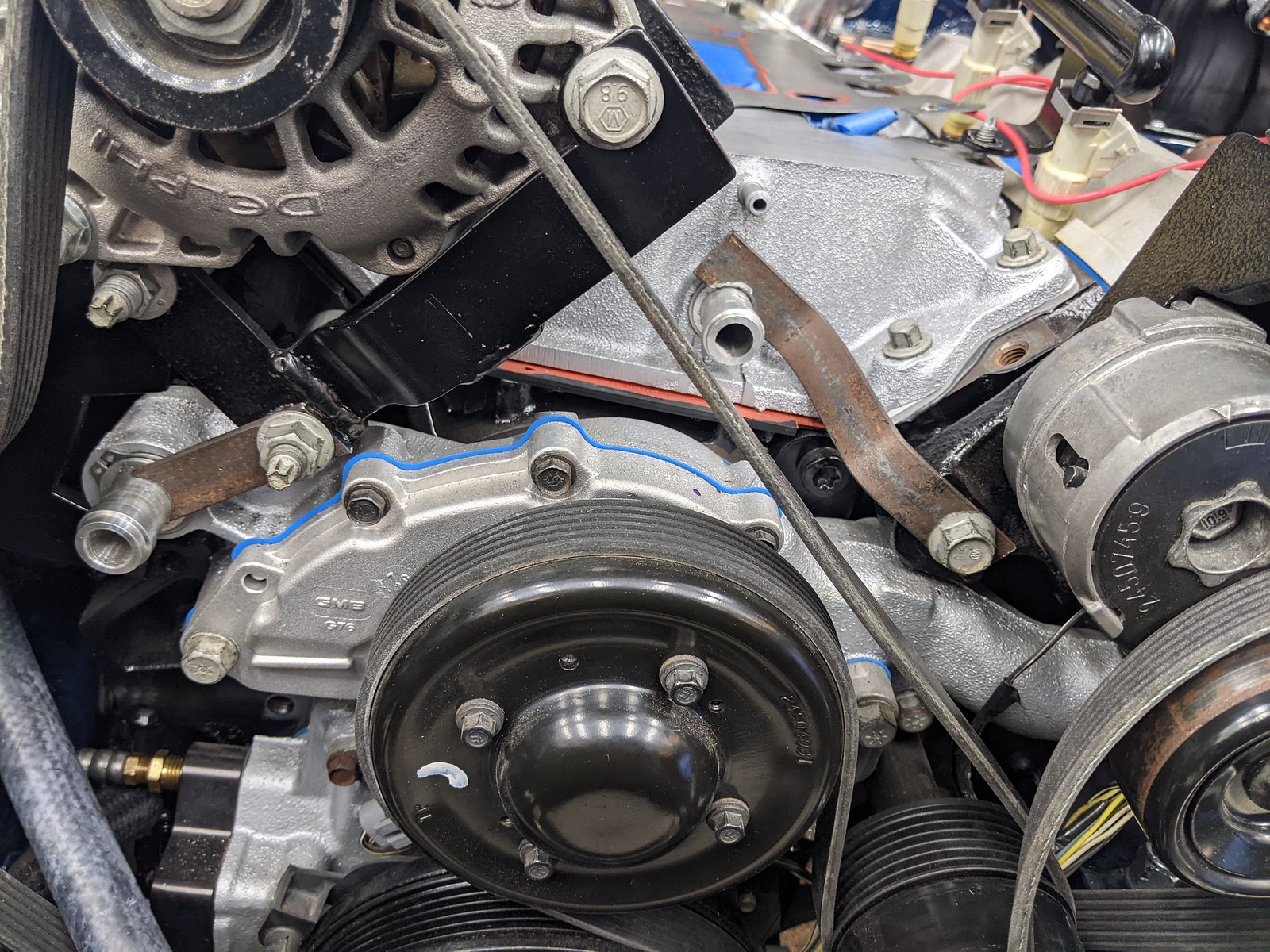

Progress has been good, finally. Steady and smooth. Im actually enjoying working on this beast at the moment, even with everything left to be done. Wiring is coming along nicely. Heater block off plate finally made. Just need to punch a hole for the engine bulkhead connector. Gonna leave the plate natural, not paint it. This way I dont have to worry about it being scratched. Ill just clean it up and clear coat it.

Front turn signals I ended up stealing a pigtail from the original tail lamps. Cleaned up the lenses and surrounds, they came out really good. The tail lights...I didnt wanna buy new ones. I bought new lenses when I started the project. But the chrome was too badly pitted...so I ended up just pulling the trigger on new ones. I went with the older style tail lamps. More rounded, more flush, and about $100 cheeper. Basically all moss parts. Well, fit is ok, just ok. Left side fits better than the right, the right needs a little tweaking. Also the light to body gaskets it came with, moss ones were nice and thick, but not cut properly. The ones I got from rimmer bros, thinner, are actually cut correctly. Effin aftermarket garbage, all of it. At least the lenses are Lucas, but even so, eh. It is what it is. They look good in the end. They are stuffed with LED bulbs as well. Headlights id love to do LEDs from vintagecarled, but a pair of sealed beams will cost almost nothing, so thats what it will get. Also had to basically rebuild the hazard switch with some bits from the replacement. The new one had round pins, but it had the light up rocker. I had no connector for the round pins (later car connector) The correct one has typical flat spade quick disconnects, but had a solid plastic rocker, no light. Well all my junk has to light up haha. So mix and match, cleaned up all the internal bits and made a 'new' switch.

Dash has been dropped off at the interior place to have the eyebrow built. Just gotta keep moving on the wiring and get that all squared away. Need to make an ECU mounting bracket next.

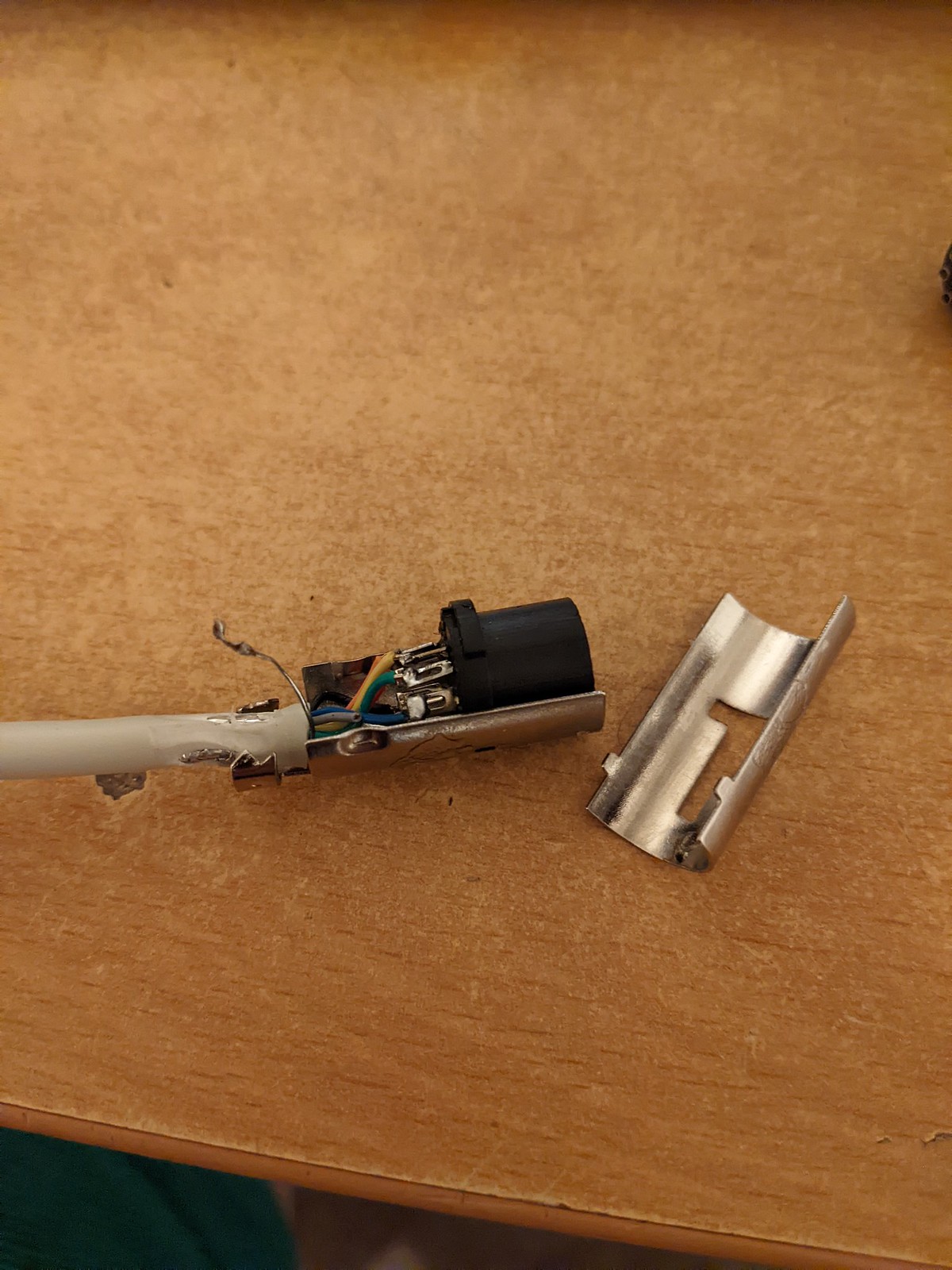

Also, after hours and hours and hours, days and days looking at vintage car radios on Ebay, I pulled the trigger on one. This is one of the harder decisions for me. First off, Im an audio guy, has to sound good. Second, I cant just put a modern headunit in this. It will look completely out of place, has to be a shaft radio, and not a digital one. Speakers I dont want to cut new paid for interior panels to fit either. And while I prefer a sub and amp to power everything, well we are gonna keep it a bit more skimmed down. I settled on finding a vintage Blaupunkt. Back in the day their headunits were high end. Now I think its a Chinese company that bought the name and they basically make junk. It also had to be stereo, and I have to be able to add a bluetooth streaming function. I ended up with a console from a late MGB which has a mid 80s Japaneses made Frankfurt. Manual tuner, not digital, but 4 channel, with bass and treble controls, not just a tone control. No tape deck either. I dont have it yet but it has a DIN plug, though im pretty sure there is no audio input on this one. Its most likely an amp hookup, should have all 4 channels and a remote/ground in the DIN plug. It does have a 16 pin 2 row connector though, not a DIN type connector. I have no idea what it is, maybe for an external tape deck? Hopin I can find some info on it and use that as the input, otherwise Ill have to get more creative. Also I hope the near 40 year old radio works, I bought it untested. I will do a hidden antenna probably in the cowl under the cowl vent opening. Plan is 2 small speakers, probably 3.5s, but if I can fit em 5.25s in the sides of the console. Ideal location? No way haha, but it will work. Only other option would be under the dash pointing at the floor, with a set of carefully placed tweeters to preserve some kinda of sound stage. In the rear, 6x9s in the side panels. Since I have to make the sail panels, and the lower bits as well I have no issues leaving space for speakers in panels Im making. Also I have some tricks to make a clean looking grill. When I was as Icon I was the one that came up with the stainless mesh behind the panel idea, a very clean way to have a transparent covered speaker that doesnt look totally out of place with a modern grill.

So thats this weekends update

Crappy fit seals from Moss that came with the lights

Decent fitting seals that were from Rimmer Bros