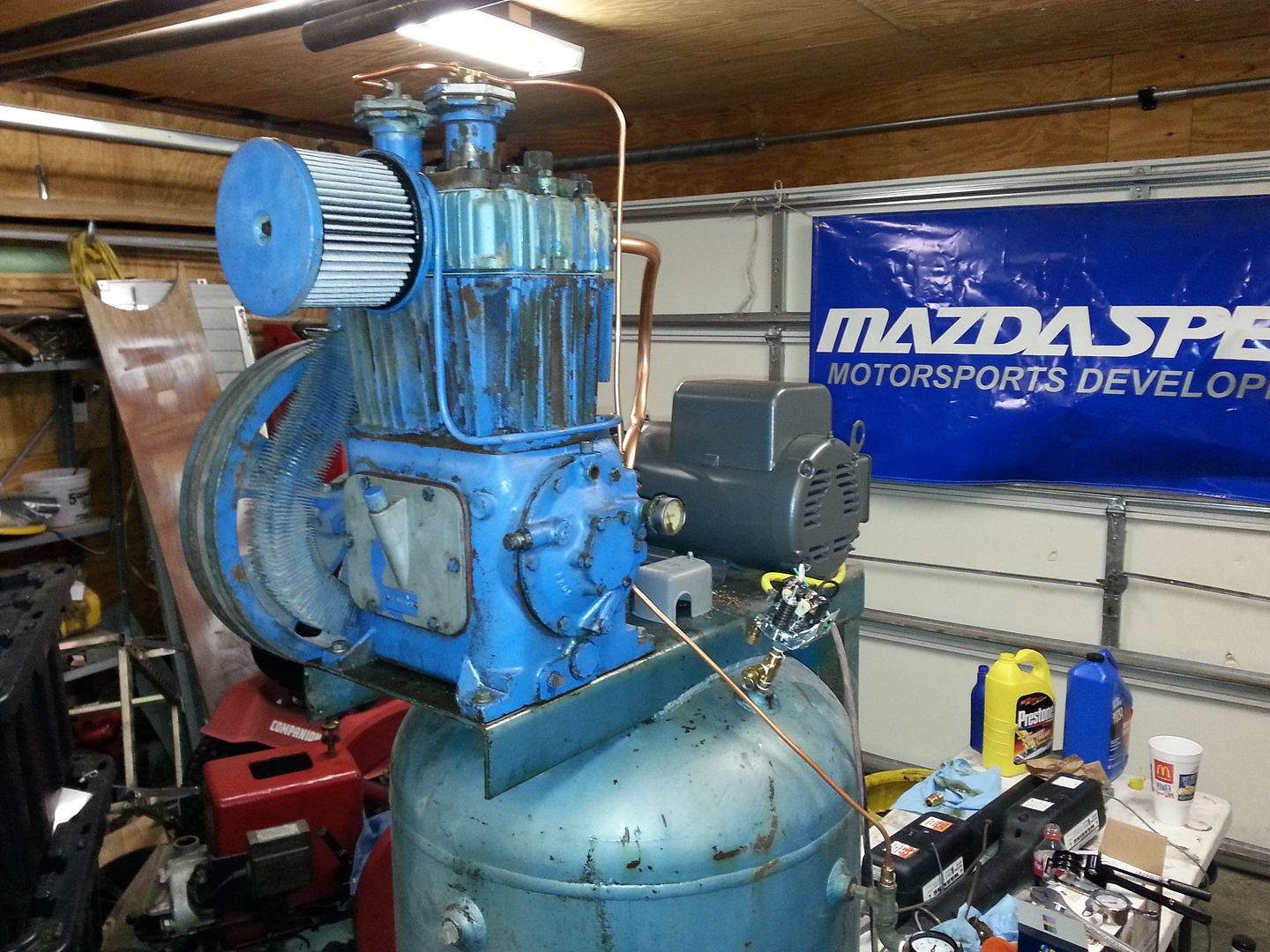

I haven't had much time to work on the thing, but I did get to it today.

Here are a couple of answers first.

Clem, the parts came from http://www.compressorpartsstore.com/. This is the first time I've ordered from them, but they were pretty fast about getting the stuff out the door. Their prices were better than anyone else including Quincy and Ebay. As far as info, Google is your friend. There isn't a compressor forum that I can find. I did find a guy on YouTube that has some pretty good videos for the Quincy owners. Mostly it's a lot of digging.

Cuda, There is always a risk of tank failure. I'd probably trust an old tank as much as I would a new one though. It was pressure tested to 300psi when it was new, it has no damage that I can see and I'm only going to run it at 125psi. I'm confident it will be fine and it will be sitting behind my shop rather than in the same room if it isn't. If I was going to run it at max pressure, I'd get it hydro tested.

On to the update.

I got all the holes in the system plugged, installed a gauge and fired it up. It made a whopping 40psi and quit pumping.  I could hear air leaking so I started tracking down the leaks. This is the worst and it's going to require ordering more parts.

I could hear air leaking so I started tracking down the leaks. This is the worst and it's going to require ordering more parts.

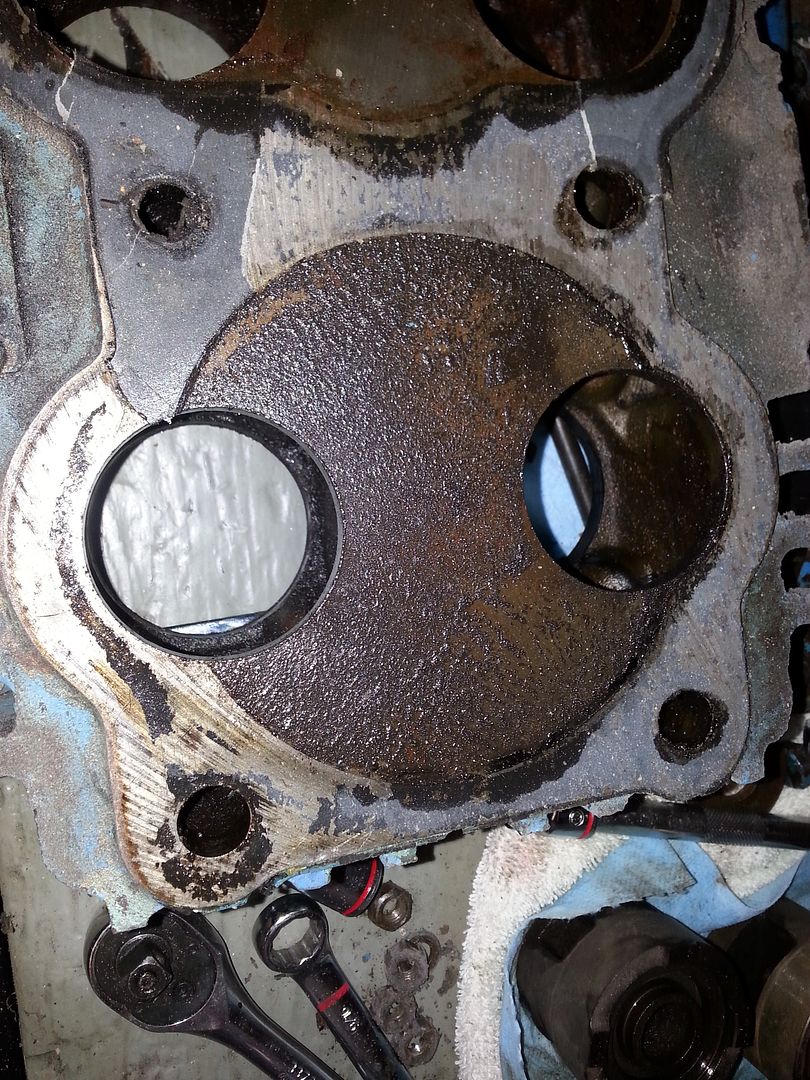

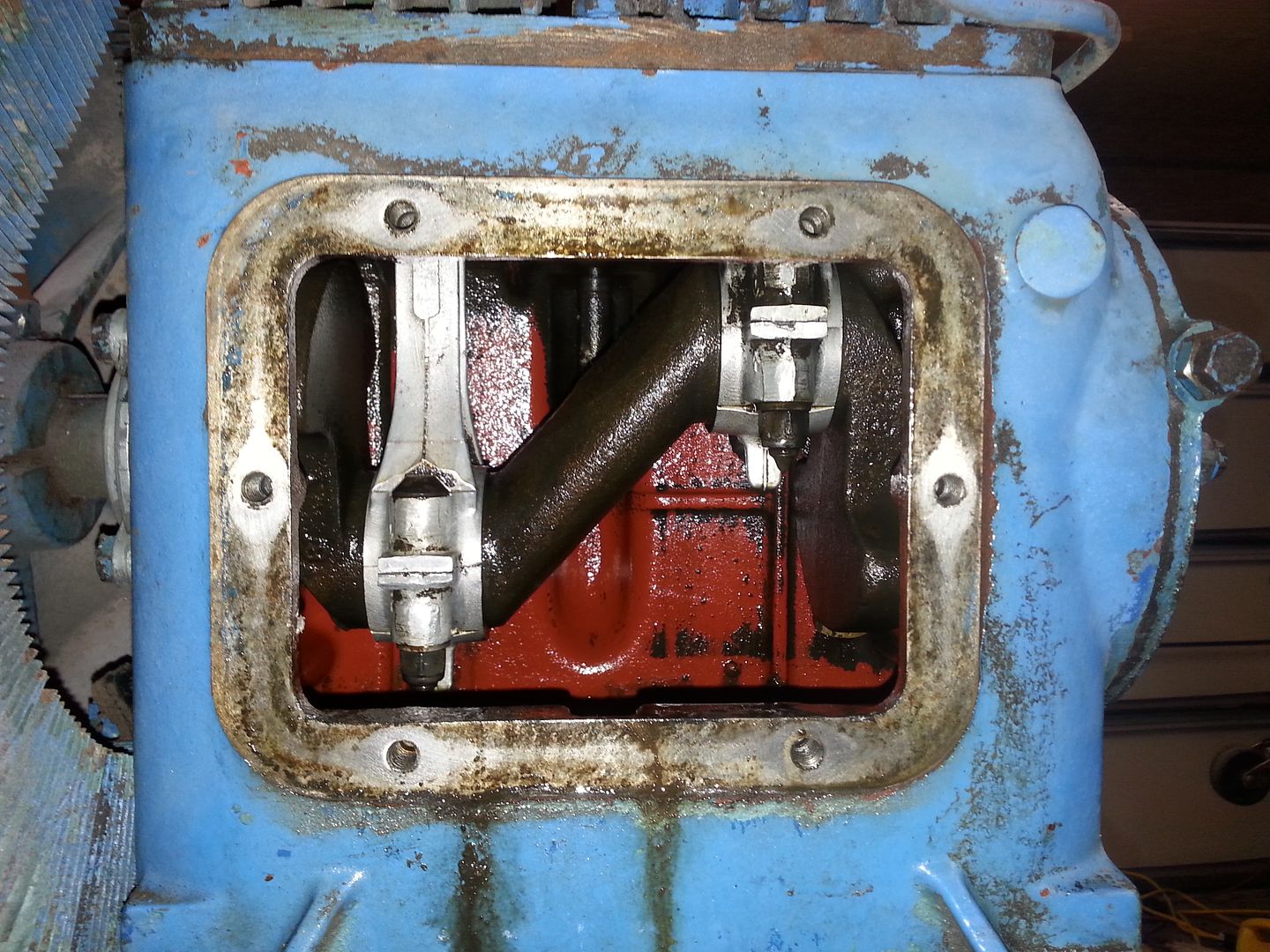

This is the base for the unloader on the high pressure cylinder. I pulled it off and pulled the valve assembly while I was at it. They look pretty ugly.

I went ahead and pulled all the valves, both high side valves were gross, the low side weren't too bad.

Quincy doesn't use reed valves like every other compressor I've ever worked on. They use what looks like a big washer. There is a new one in the below picture. The old ones were in pretty bad shape. It rides in the cylinder looking thing.

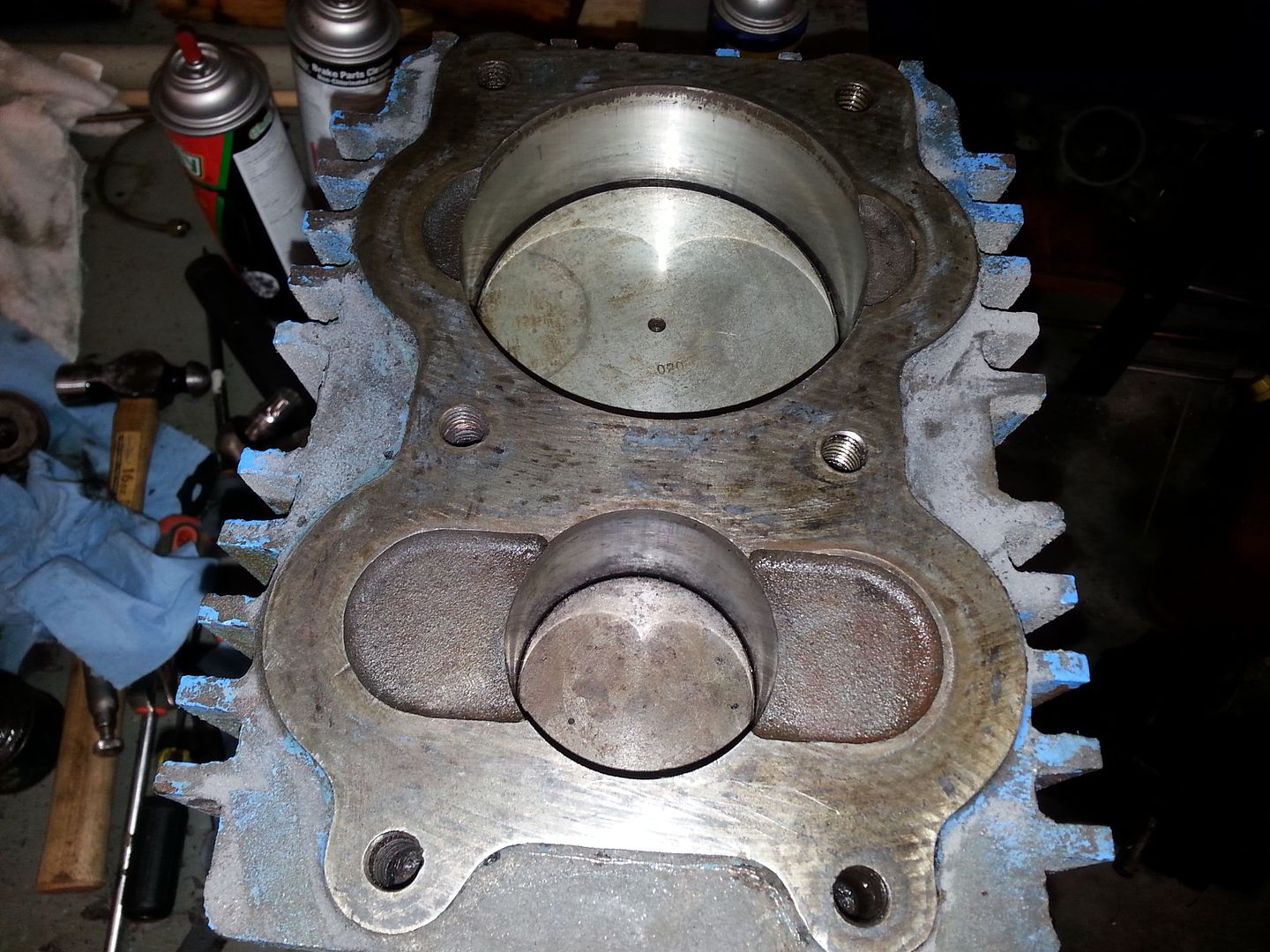

These pictures are looking down at the top of the pistons. As you can see, everything in the top end is nasty and will have to be cleaned.

High pressure cylinder:

Low pressure cylinder:

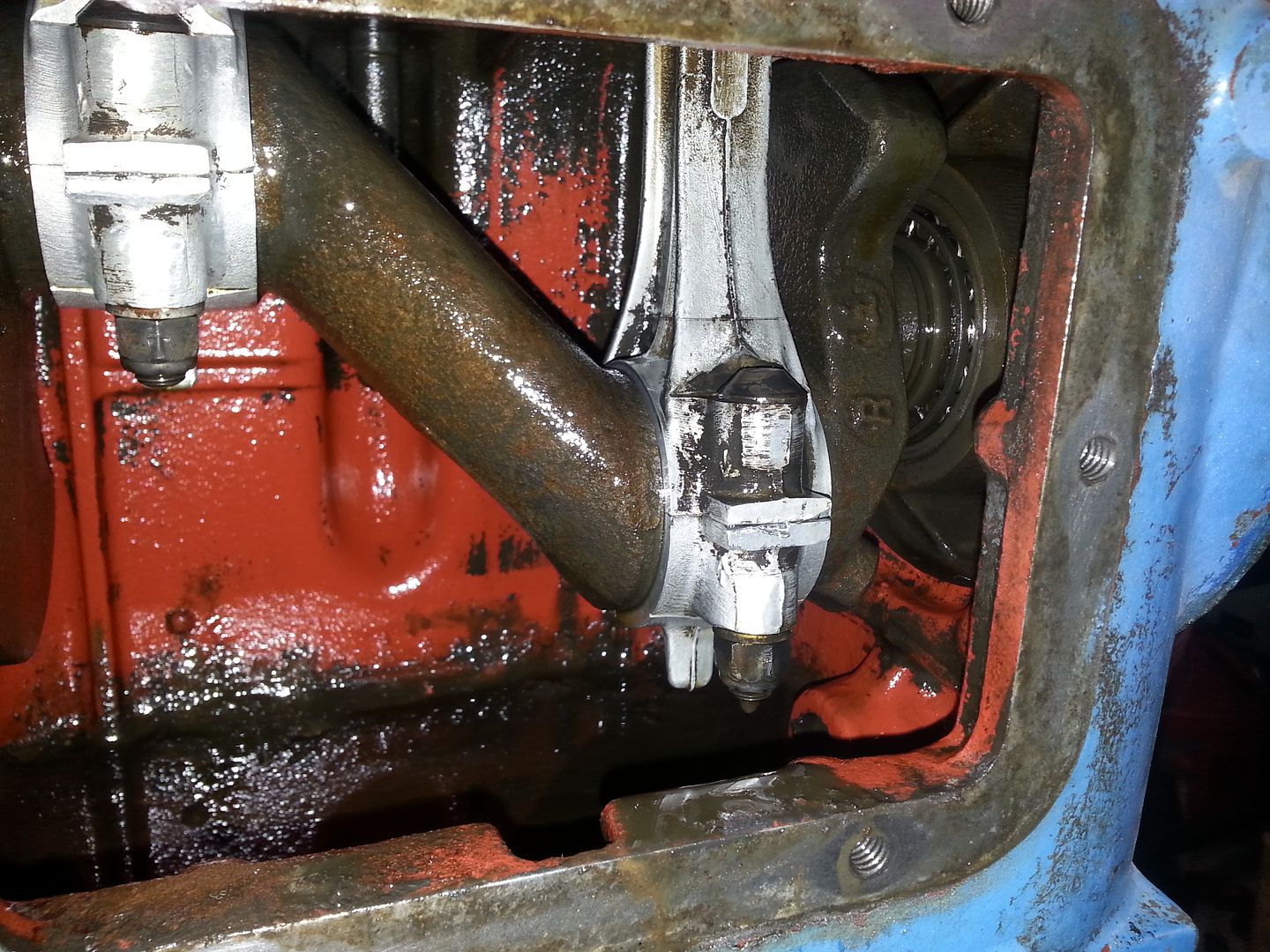

My only other problem is oil pressure. No matter how I adjust the pressure relief valve, I can't get over 11psi. I need it to be 18-20psi for the unloaders to work properly. A little digging on the internet gave me some places to look for problems. I did pull the pump cover to make sure all the vanes were moving free and to make sure the reversing valve assembly wasn't stuck. No pictures of that yet, but I'll get some when I go into it next time to find where I'm loosing pressure.

More updates as they happen.