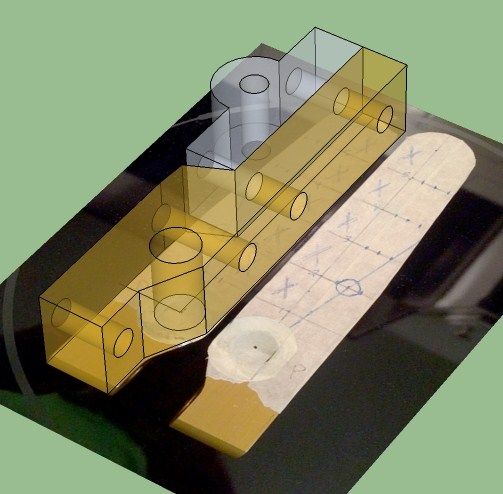

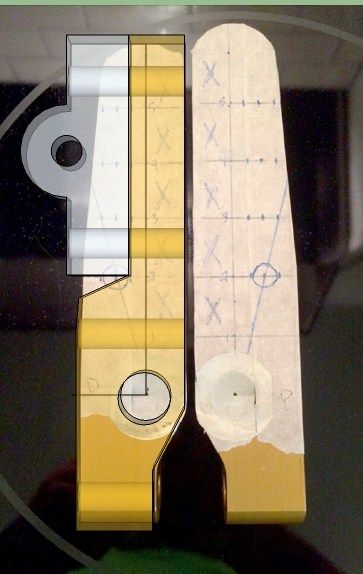

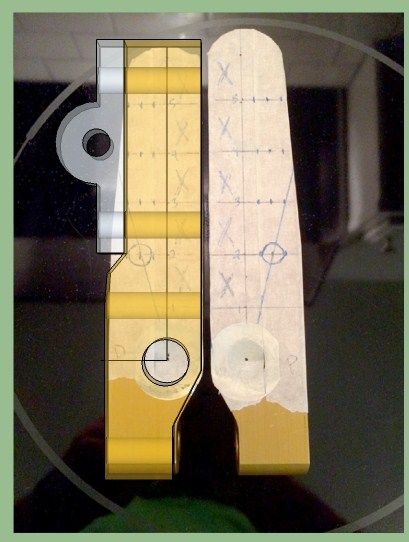

So are you telling the software you want in your first example 30.78* of steering on the left wheel and then it computes the other wheel? I can't quite decipher what you are inputting for steering anlge to determine what the software is doing.

If your arms are actually 1.5" below LBJ and you are running 10* KPI you need to move them another .3" ouboard per side to get close to 100% Ackerman. I would expect if you took the first model and put them .3 per side further outboard(seems to be the 26.5 number?) You would get really close to ideal Ackerman.

Your 3 runs have different total degrees of f turn. It does not appear the software corrects for that so your error is simply lowest in the run that had the least steering angle. It looks like your 3 runs just increased the lenght of the steering arms but left the distance from centerline the same. I'm very confused why the x dimension on the upper and lower are the same.. This software clearly works with a strange method of dimensional input.

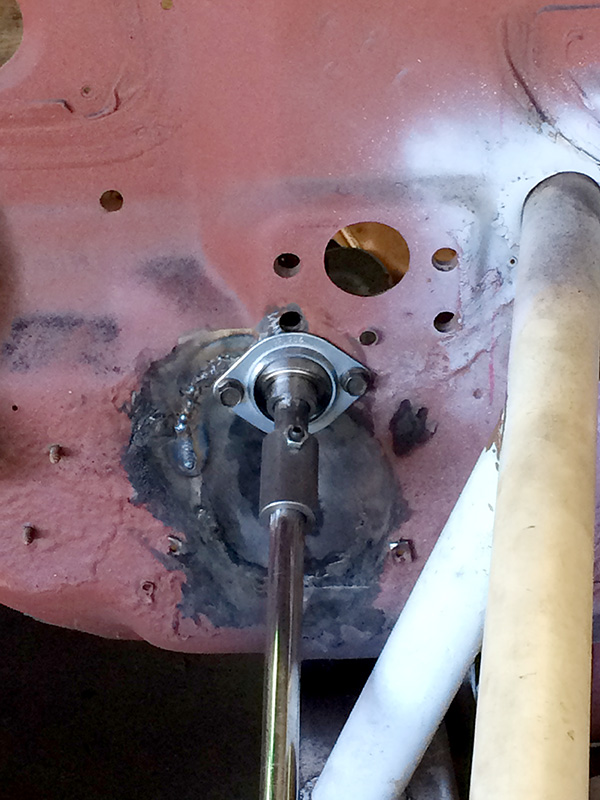

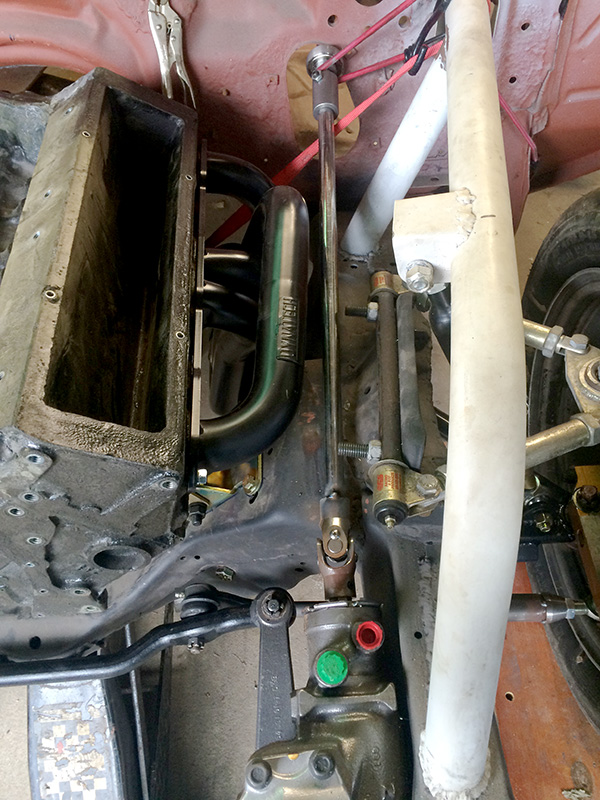

The splined u-joint attached to the steering box put up a HUGE fight going on, so I decided I should have another breakpoint in the linkage to get things apart. If you look towards the firewall, you'll see another splined coupler just before the firewall bearing (which will be put in for good, not just bungeed there, next time when I patch the firewall). This will let me get the column, with the firewall bearing, out from the inside if I need to.

The splined u-joint attached to the steering box put up a HUGE fight going on, so I decided I should have another breakpoint in the linkage to get things apart. If you look towards the firewall, you'll see another splined coupler just before the firewall bearing (which will be put in for good, not just bungeed there, next time when I patch the firewall). This will let me get the column, with the firewall bearing, out from the inside if I need to. You can see here where it comes through the firewall. I'll patch the original steering hole next time, and mount the firewall bearing for good.

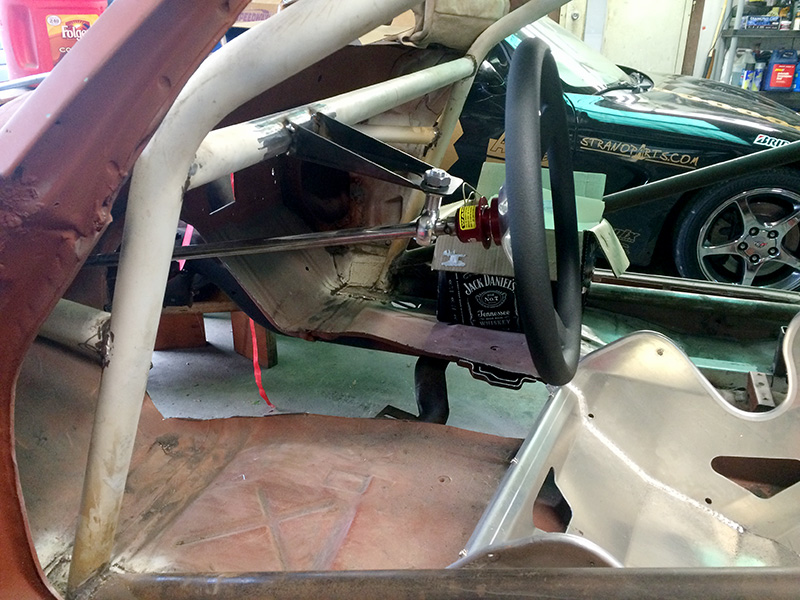

You can see here where it comes through the firewall. I'll patch the original steering hole next time, and mount the firewall bearing for good. And finally - input. I had to flip the bracket I bought for the steering wheel to get wheel low enough. It was hard to take a picture of what you see, but the top of the steering wheel is about 1/2" tops above the dash in the line of sight. Should be perfect.

And finally - input. I had to flip the bracket I bought for the steering wheel to get wheel low enough. It was hard to take a picture of what you see, but the top of the steering wheel is about 1/2" tops above the dash in the line of sight. Should be perfect.