Great video! Love the tuxedo!!!

So the dyno was... less of a success.

In short, the Holley Sniper unit started acting very strange, and began running very lean under no load and part throttle, no matter what my tuner threw at it. It should hopefully be going back to Holley soon for some sort of solution. Unit has less than two hours run time on it.

So, we are badly in need of an update here, so I'll do my best.

Let me start by saying that I have all the faith in the world in my tuner, and after this experience, the same goes for Holley. Excellent customer service from both, especially considering all the strange things this car can introduce.

So, to get folks caught up. When we first dyno'd the car it would run hard to 6500, then go suddenly rich and fall on its face. You can hear and see it here

The tuner and I looked at a lot of stuff, and ultimately determined (well, guessed, really) that we were having a spark issue up top. To solve this, and to open up a little more of a tuning window, we removed the locked out MSD Pro Billet distributor (which was set up for EFI per Holley's instructions) and replaced it with their Dual Sync distributor. The big difference here is the Dual Sync is designed for EFI, with both cam and (simulated) crank sensors. Because the car was in the tuner's shop, I had him order and install it. After he installed it, we ran into an issue were at part throttle, no load, the car would suddenly go super lean. Because I didn't want to pay shop rate to further diagnose things, I loaded up the car and took it home to figure things out.

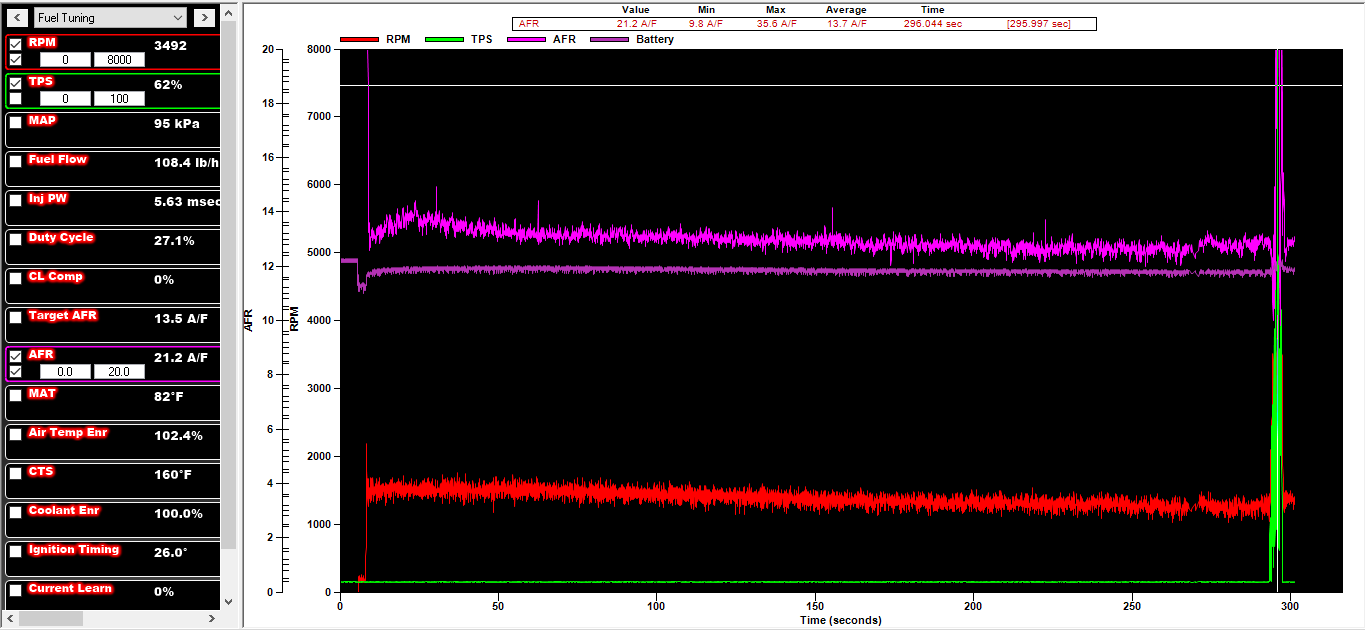

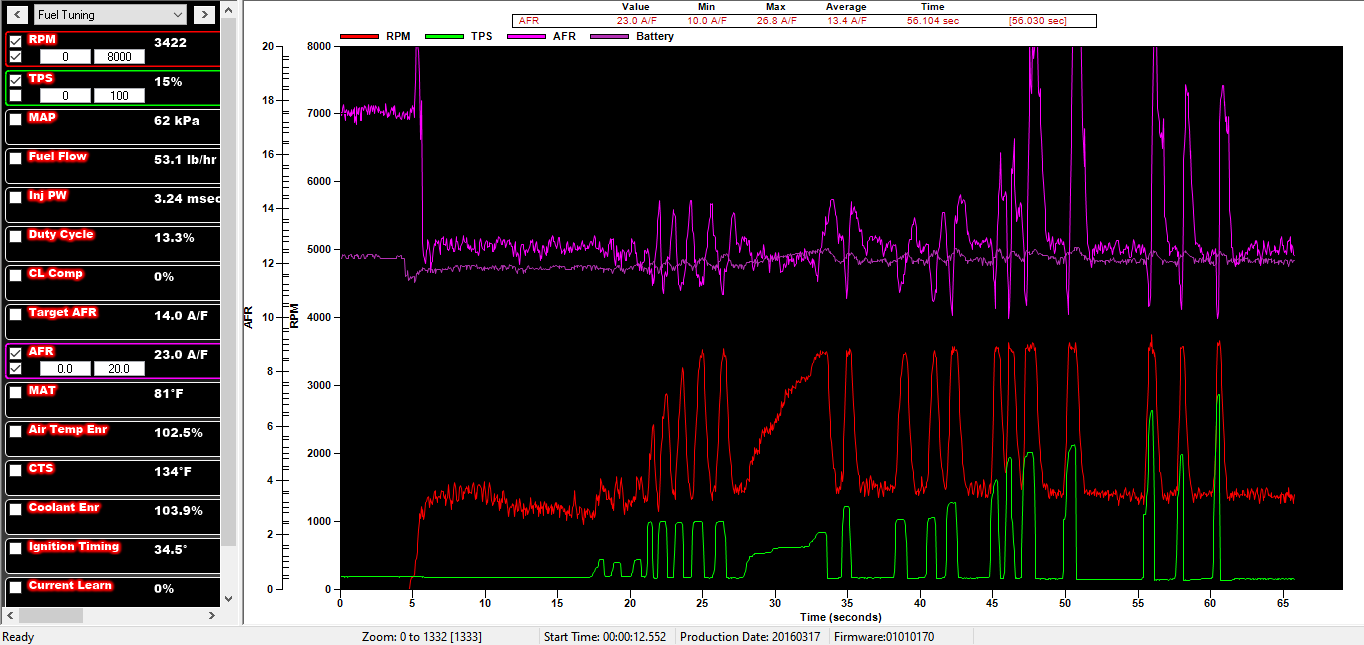

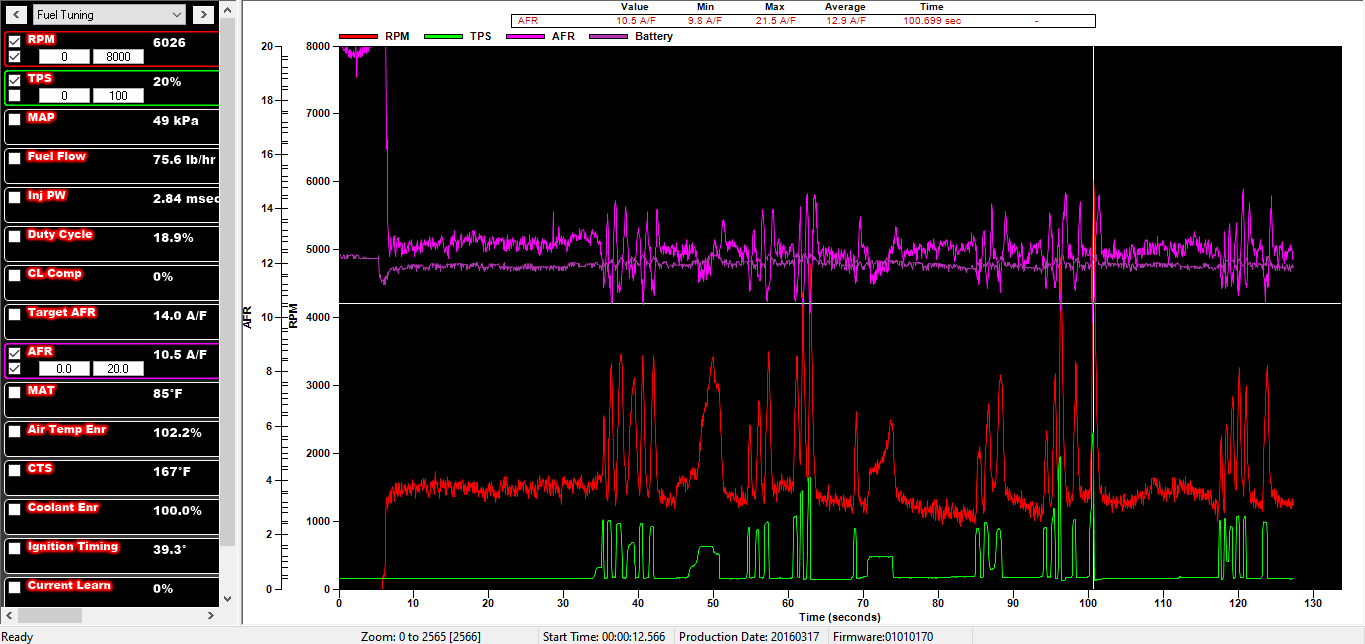

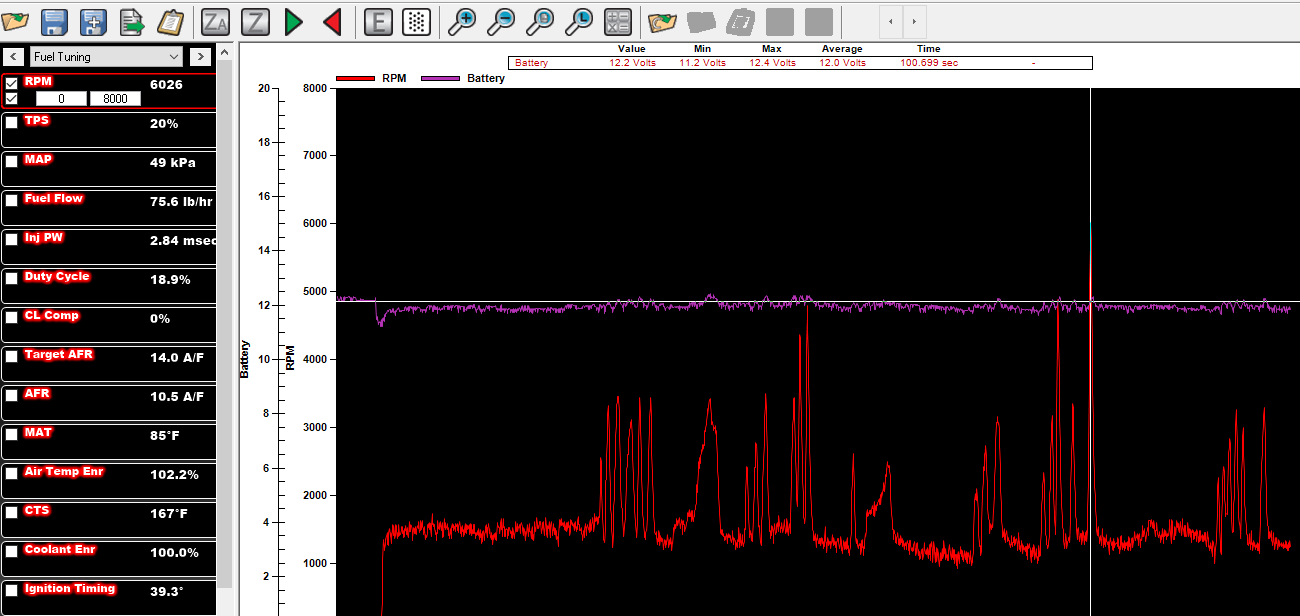

Data log sent to me by the tuner showing the lean issue

Data log sent to me by the tuner showing the lean issue

That brings us to where I left off.

I reached out to Holley, who took a look at the logs. They tweaked some small things, but didn't notice anything in there that should be causing the issue. So I loaded up their new tune and did a little data logging to see if we were still having issues.

Damn. Same problem. Car, under part throttle, not under load, would go lean hard and couldn't seem to rev over 3500rpms. F***

BUT WAIT! 3500rpm. That's way too "perfect" of an RPM. Then it hit me - when we were trying to figure out the first issue (going way rich over 6500) we set the limiter on the MSD 6AL box under the dash to (drumroll) 3500rpms. I set the limiter to 7500, and ran another log.

Well, wasn't that stupid? Let me crystal clear - I do not blame my tuner for missing this at all. It was not set that low when he first dyno'd the car, he didn't build it, you can't see it from the driver's seat, and he was troubleshooting without me there (and hell, I even missed it the first few times).

IMPORTANT NOTE - earlier in this thread, I installed a progressive throttle linkage. If you are using the Sniper Stealth system, like me, THIS DOES NOT WORK. The injectors don't fire as expected. I have removed this setup.

So, since my season is over, and his is busy with a lot of tuning business, we are now waiting to finish the dyno tuning and get final numbers. The good news, this is giving me time to figure out and fix a few other issues I was having.

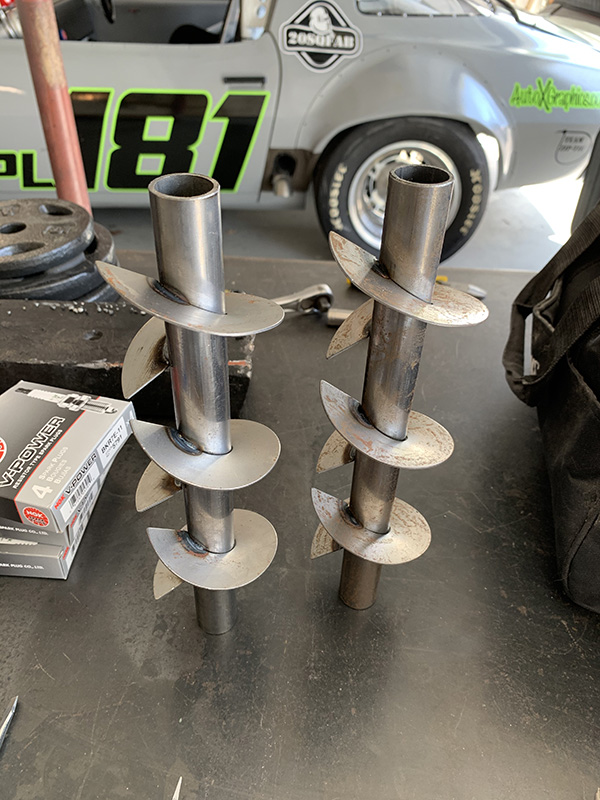

First thing on my list was to remove the spiral exhaust inserts that I had installed after Dixie. Truth is, lots of people had problems with sound at that event, so I suspect a meter and not my setup. These little guys are pretty restrictive, so if I'm going back to the dyno, I don't want them in there.

When I pulled the exhaust, I found a couple pin hole leaks ahead of the O2 sensors (not good for tuning), so it was off to Larry's to get those plugged up.

I also noticed something else when the car was running, and did a little logging to confirm:

The alternator wasn't charging (not great for EFI). Hindsight, when we raced in Dixie the battery died before my final run. I thought we just were running the fans too hard and the single battery couldn't keep up (which is why I added the second). I am willing to bet, now, that it wasn't working back then. A new regulator fixed things up.

One more thing that needed fixing - the gas pedal. I will NEVER accuse my tuner of not flooring the car on the dyno. In fact, he floored it so much, the gas pedal bent. I had previously bent it using heat, so I'm sure I softened some of the metal. In order to prevent that, and relieve some stress on the throttle cable, I built a quick and dirty throttle stop from some scrap and a hood bumper.

So, that's where things are at the moment. I'm going to do an oil change, inspect the filter, and get ready to hit the rollers again soon, hopefully besting the number we made last time.

Other than all of this, I've just spent some time doing some social distance hangs, including trying out my new truck tent. I love this thing.

Just did an oil change and, aside from a little too much gas in the oil from running too rich at first, it was all good news. Hopefully back on the rollers soon.

Some CamAERO stuff happening over here - https://grassrootsmotorsports.com/forum/aerodynamics-presented-nine-lives-racing/prepared-rear-spoiler-how-badly-am-i-compromising/176944/page1/#post3118110

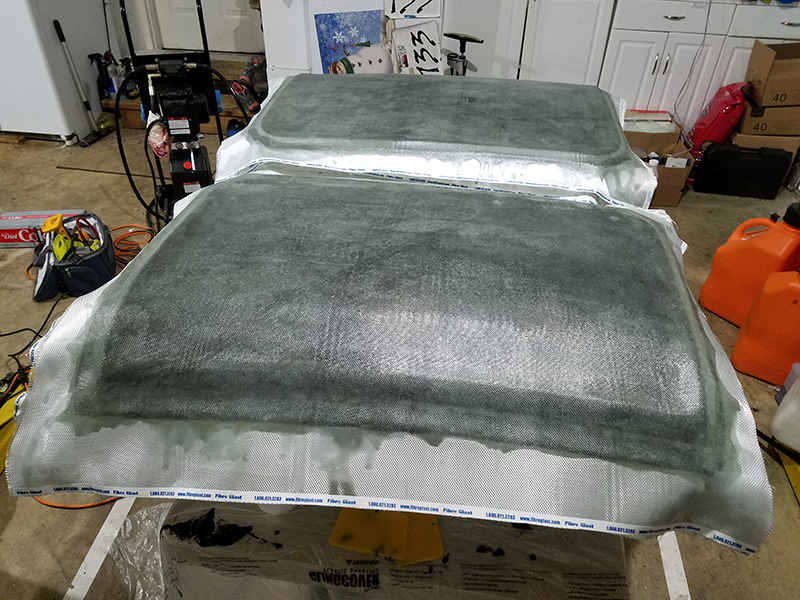

Still working on a video update, but in the meantime, my very talented friend Jay has been working on something for me...

More images here - https://flic.kr/s/aHsmS3RrDc

81cpcamaro said:Video isn't working, keeps getting an error, here and on YT.

Youtube is broken at the moment

Saw the video, good job. How on earth did Holley, who has made carbs for decades and knows well about progressive linkages, design that system that way. What a cluster.

81cpcamaro said:Saw the video, good job. How on earth did Holley, who has made carbs for decades and knows well about progressive linkages, design that system that way. What a cluster.

What's even more strange to me is that it works correctly on the non-Stealth units. The only difference should be the exterior case.

Got another update from Jay. I'm incredibly excited how they turned out. Once trimmed, they should be about 3lbs each.

this is something we talked about over in Robbie's aero discussion, thing. but, you might want to think about painting/wrapping those is a relatively light color.

The black of carbon fiber can absorb enough heat from sunlight that it can set the epoxy off again, and make it all melty. Depending the type of epoxy used.

In reply to sleepyhead the buffalo :

From Jay - "[I] Used West System 105 resin w/ 207 hardener, which is designed to be clear, and the hardener supposedly has UV inhibitors also"

He has made a carbon fiber dash and door for his Miata, and so far they have held up to the heat of the sun, but it is something to consider.

Automotive clear-coat with it's UV-inhibitors can work very well. I've done that to good effect.

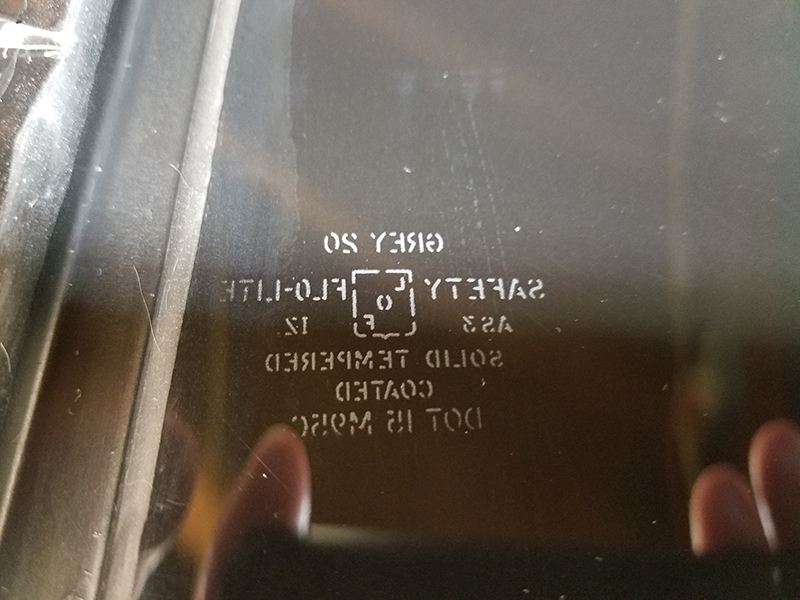

Did he make a mold off of the glass? And then mount the carbon part in the frame/gasket?

Looks sweet!

Keep in mind, the UV inhibitors have to do with the UV weakening the epoxy matrix over time... often times causing "browning", irrc

But, what I'm talking about is the temperature of the epoxy and the reinforcing mat exceeding the Transition Glass Temperature (Tg). It looks like 205 has a higher Tg than 207, around 130degF instead of 117degF. It's been 20 years since I was doing this stuff... so I don't recall if it was 205 or 207 we used to build a 10ft carbon twill over a blue foam core flying wing model. We were out on the outer shore of MD sitting on an asphalt tarmac, and the epoxy got rubbery. It didn't fail, but it didn't have the strength it had before. I don't recall if it harden back up again afterwards. Maybe it being a top, and no windows, the tops will get enough airflow, and without a foam core (?) the epoxy/carbon won't retain as much heat, and you'll be fine.

ymmv, but it might be good to check the temp on the tops when you check the tire temps; and if you decide to "check" if it's rubbery... do so with a nitrile glove on, so you don't begin getting sensitized to epoxy.

TVR Scott (Forum Supporter) said:Automotive clear-coat with it's UV-inhibitors can work very well. I've done that to good effect.

Did he make a mold off of the glass? And then mount the carbon part in the frame/gasket?

Looks sweet!

Yup, made the mold right off the glass. That's why the tempered glass logo transferred into the part. I think it's a really cool detail.

sleepyhead the buffalo said:Keep in mind, the UV inhibitors have to do with the UV weakening the epoxy matrix over time... often times causing "browning", irrc

But, what I'm talking about is the temperature of the epoxy and the reinforcing mat exceeding the Transition Glass Temperature (Tg). It looks like 205 has a higher Tg than 207, around 130degF instead of 117degF. It's been 20 years since I was doing this stuff... so I don't recall if it was 205 or 207 we used to build a 10ft carbon twill over a blue foam core flying wing model. We were out on the outer shore of MD sitting on an asphalt tarmac, and the epoxy got rubbery. It didn't fail, but it didn't have the strength it had before. I don't recall if it harden back up again afterwards. Maybe it being a top, and no windows, the tops will get enough airflow, and without a foam core (?) the epoxy/carbon won't retain as much heat, and you'll be fine.

ymmv, but it might be good to check the temp on the tops when you check the tire temps; and if you decide to "check" if it's rubbery... do so with a nitrile glove on, so you don't begin getting sensitized to epoxy.

This is great advice. Thank yiou. I will absolutely keep tabs on it. While I'd hate to hide the carbon, goopy t-tops over my head sounds like a bad idea.

This just sounds like it's time to get an enclosed trailer with an awning so the car can sit in the shade between runs

Patrick (Forum Supporter) said:This just sounds like it's time to get an enclosed trailer with an awning so the car can sit in the shade between runs

Great... now I'm my car's umbrella girl.

You'll need to log in to post.