Sharing my build in the hopes that people find it interesting and useful.

Hi, I'm Dan and I'm an alcoho- car fanatic. I've been an SCCA member since 2009, started autocrossing my genesis coupe, then moved on to a 94 miata, then bought a supercharged miata, which I parted out and gave its organs to my first real build. My 1995 Merlot M edition miata. That car sports a Flyin Miata Ubercharger, rx7 intercooler, civic half radiator, coolant reroute, lightweight flywheel, racing beat header, racing beat resonated catback, megasquirt MSPNP2. It's 227whp/193wtq at 9psi. Awesome car, but its my sunday driver and it was basically composed of bolt ons.

After buying the original supercharged miata that would later get parted out, I took some time off from racing because the local autocross scene was getting... not fun. A friend invited me to rallycross and I was hooked. So I bought an 91 325is and broke it after 2 runs. I hated that car. Terrible steering wheel, terrible seating position, uninspiring motor (powerful, but just didn't seem eager). So I bought 1986 Toyota MR2 that was probably in way too good of shape to race on dirt.

I raced the mr2 for 2 seasons of rallycross. In Prepared RWD I took 1st place at the 2016 Central Rallycross challenge, and later that year battled for 1st at rallycross nationals losing to another local colorado rallycrosser in his Toyabaru by .7s. The motor was extremely tired, and smoking at high rpm. It wouldn't pass emissions. In 2017 the SCCA made a rule disallowing cracked windshields. Between a tired motor and an illegal windshield, the car sat. I needed a new motor. I bought a spare 4AGE and got ready to rebuild it and turbo it. I spend lots of time in the research stages of projects. During that research, I realized rebuilding and turboing the 4AGE was about a $2k prospect and the motor might only last 2 more seasons (mid/rear engine cars need really good filtration, especially at the very dusty colorado venues).

So, I decided to instead do a V6 swap. Toyota OEM reliability, and they're a dime a dozen at the junkyard. 1MZ it is. But, I wanted the extra power, so I decided to pick the 1MZ VVTI from a 2000 avalon. VVTI power bump, cable actuated throttle body, A/T ECU but supposedly isn't affected by the codes generated. S54 transmissions from the Mk2 NA MR2's have axles that are compatible with AW11 hubs. Also, it uses the C52/C56/C60 LSD's, which is great because I had bought an LSD for the AW11's C52 transmission.

Out with the 4AGE:

So much room! Yet... not enough...

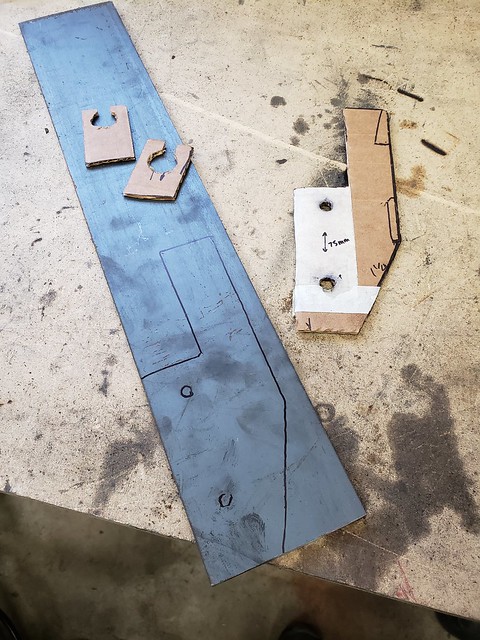

Those that V6 swap AW11's talk about how cramped the motor is in the engine bay. Want to change the spark plugs? Drop the motor. Accessory belt? Drop the motor. Alternator? Drop the motor. Check the dipstick- drop the motor. Ha. Kidding. You actually cut an access hole in the interior so you can pull the dipstick out. So, knowing this, and knowing the car was going full race car, I read the rules and realized I could remove non-essential components. So, being a race car, I decided a trunk was a very non-essential item. So I started cutting out sheet metal.

Per the rules I'll need to reinforce the chassis, so I will be putting in a bolt in tube crash structure. This will allow the structure to be unbolted and the entire engine lifted out the top (when it needs to come out, which should be less with all the increased maintenance access). I'll need to reattach the plastic bumper skin and lights as well to remain legal. The tube structure will also help with the need to add a skidplate. One of the first things I had to reinforce was that big seam of metal I had cut out along the length of the subframe. I am not the best tig welder by any stretch, but sometimes I can glue metal together.

Oh yeah, exhaust. I'm doing something weird and I hope it won't hurt performance too bad. There's clearance issues with the rear bank to the engine mount. Also the engine likes equal length headers. So, I'm using two front bank exhaust manifolds on either side of the motor. I'll cut the precat off (my donor was a california model and had 3 cats vs the normal 1 cat) and create a new y pipe with v-band clamps to gain some clearance.

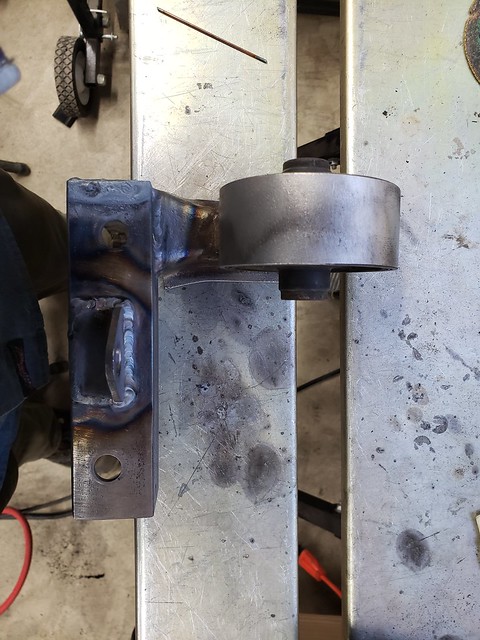

Rear exhaust manifold is very close to the motor mount

Heres the front bank exhaust manifold

The exit angle will be good once the precat is cut off and replaced with piping. It should easily clear the axle

Anyway, it's been a longer than expected project to get to this point, and there was plenty of steps before getting to this point, but this post has rambled long enough. I have the motor prepped with transmission and a proper tune up. Wiring harness was completed last week. In the coming weeks I'll be working on engine mounts, chassis bracing, and exhaust.

[/url]

[/url]