I've been reading and re-reading the NASA-PT rulebook like every day. And for quite a while, it felt like it was every day that I was discovering something else in the rules that affects my build. Hopefully it's all under control at this point.

Publishing your points budget and detailed write-ups of modifications isn't always going to help you... for example, Vorshlag's wonderfully detailed and illustrated C4 Corvette TT build may have inspired rules changes in response to the build, as well as protests based on the information that was published. I'm not a professional shop doing the build, but like the Vorshlag team, I'm eager to learn of any mistakes I've made here and now, rather than when a class win is immediately disqualified. I'll be pleasantly surprised if I'm actually competitive anyway.

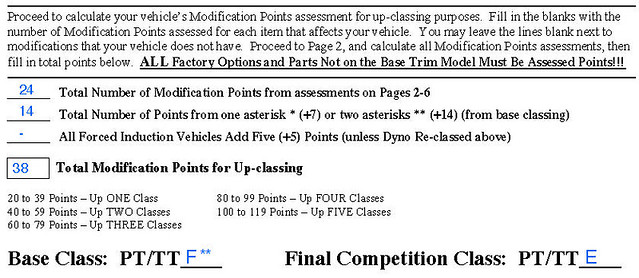

In Performance Tuning, your car is placed in a base class. You can make unlimited "no-points mods" to your car, and you can make modifications that cost points. Up to 19 points, you stay in the class. From 20-39 points, you move up one class. And from 40-59 points, you move up two classes.

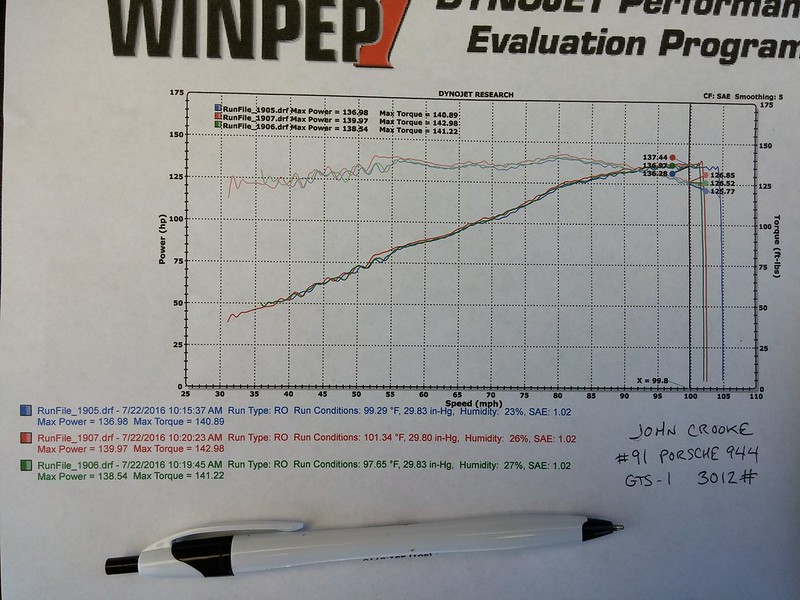

The Porsche 944 NA's base class is PTF**. Those two asterisks mean that I get assessed 14 points right off the bat. So to stay in PTF, the budget would be 19-14 = 5 points' worth of mods. Not realistic. To compete in PTE, my points budget is 39-14 = 25 points.

Budget: 25 Points

5 points: Tire composition: Toyo Proxes RR

7 points: Tire width: 245mm width (215 base class + 30mm)

3 points: Exhaust modifications (not including headers)

3 points: modified shocks/struts/dampers

2 points: modified coil springs or torsion bars

2 points: add,replace,remove or modify anti roll bars

2 points: modified brake calipers / brackets / rotors

Total assessed points: 24 Points

No points modifications (that have been done to the car):

Sunroof mechanicals removed

Floor mat removal

Jack and Spare tire removal

a/c system removal

air filter upgrade

alternator relocation

oil systems and coolers other than dry sump

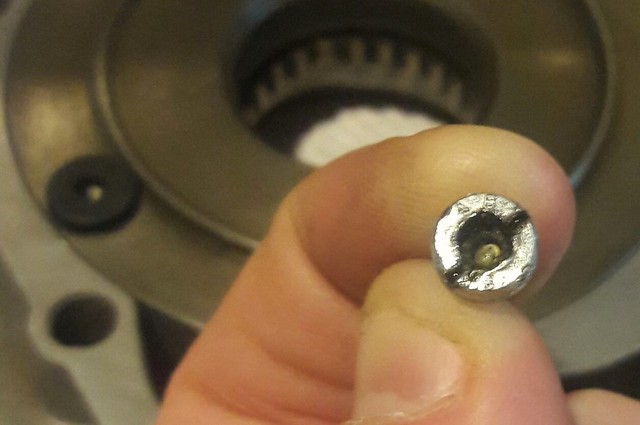

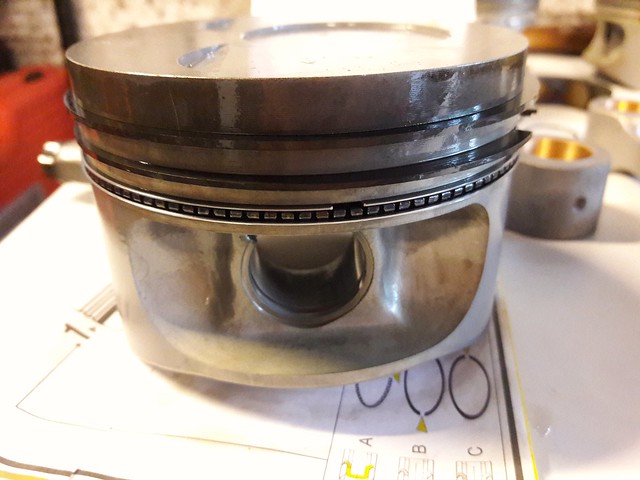

engine rebuild with forged internals of equal weight to BTM

non-BTM fuel lines

wheels, hub modifications (to accommodate brake modifications)

lightweight flywheel

ride height adjustment

shock mount modification

camber/caster plates

brake duct addition or modification

front strut tower bar

steering wheel replacement

mirror addition, and replacement

seat harnesses

driver’s seat

accelerator, brake, and clutch pedal modification

headlamp removal

data acquisition system

dashboard modification

No points modifications (that I’d like to do at some point)

battery replacement/lightweight battery

lexan windows and windshield

ECU reprogramming via chip

exhaust piping / header external wrapping

emergency brake removal

relocated battery

aero hood pins

Points modifications that are possible:

1 point: LSD

1 point: Manual Steering Rack Conversion (including removal of P/S pump and pulley)