The vacation and home improvement project are over....but before we continue with the aero mods, lets see what else is brewing.

....................berkeley DIS!

....................berkeley DIS!

At this point I'm not sure what has me more confused... the GM DIS or the pokemon phenomenon. I ain't got time for the later so let's do something about the DIS.

The GM DIS is awesome in so many ways. cheap and simple.... but in the end it serves two masters....and we cant have that. The GM DIS has the ability to receive timing pulses from the ECM or it can use its built in timing curve. The problem is, I'm not 100% certain what mode the DIS is in and any given point. A five volt bypass signal is used to force the DIS to use ECM timings signals, however if the ECM signals arrive at the wrong time the DIS will fall back and use its built in curve. Its actually quite simple with the single exception that there is relatively no setup info available on the Megasquirt forums. There are a dozen or so ways to configure the DIS for satisfactory results, but so far i haven't really settled on what works best.

The GM DIS is awesome in so many ways. cheap and simple.... but in the end it serves two masters....and we cant have that. The GM DIS has the ability to receive timing pulses from the ECM or it can use its built in timing curve. The problem is, I'm not 100% certain what mode the DIS is in and any given point. A five volt bypass signal is used to force the DIS to use ECM timings signals, however if the ECM signals arrive at the wrong time the DIS will fall back and use its built in curve. Its actually quite simple with the single exception that there is relatively no setup info available on the Megasquirt forums. There are a dozen or so ways to configure the DIS for satisfactory results, but so far i haven't really settled on what works best.

The Ford EDIS4 appears to be the the go-to device for all the cool kids, so in this instance I will chose not to take the road less traveled and go ahead and do something sort of normal.

The Ford EDIS4 appears to be the the go-to device for all the cool kids, so in this instance I will chose not to take the road less traveled and go ahead and do something sort of normal.

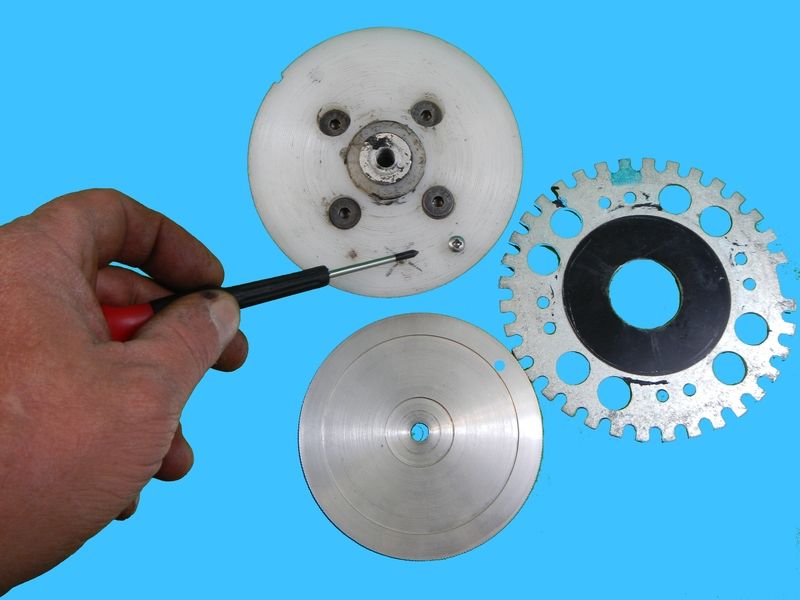

The EDIS4 was pulled from a 90's vintage Escort during a past pick & Pull adventure. The EDIS cost twenty something bucks. A 36-1 wheel was sourced from Ebay for a mere $32.00. At the same time I also scored a set of Denso plug wires for $19.00 and a Deutsch 2x3 connector set for $12.00.. not too shabby.

The 36-1 EDIS wheel is a few thousandths larger than the GM 7X DIS wheel... sweet! Unfortunately the hub center ain't even close...

The 36-1 EDIS wheel is a few thousandths larger than the GM 7X DIS wheel... sweet! Unfortunately the hub center ain't even close...

An adapter was ginned up on the lathe to get the 36-1 wheel to fit the custom hub on the B3 engine. I love it when a plan comes together

An adapter was ginned up on the lathe to get the 36-1 wheel to fit the custom hub on the B3 engine. I love it when a plan comes together

An additional slug of aluminum was machined to hold everything together.

An additional slug of aluminum was machined to hold everything together.

A SAM's membership card is used to set the gap for the crankshaft sensor. The 36-1 wheel is positioned nine teeth ahead of the missing tooth with the engine at TDC. This position will put the ignition at 10 degrease BTDC with zero offset in the Megasquirt setup panel. All this info was readily available on the Internet so no guessing was required.

A SAM's membership card is used to set the gap for the crankshaft sensor. The 36-1 wheel is positioned nine teeth ahead of the missing tooth with the engine at TDC. This position will put the ignition at 10 degrease BTDC with zero offset in the Megasquirt setup panel. All this info was readily available on the Internet so no guessing was required.

A custom sub harness was fabricated to mate the EDIS4 to the wiring previously set up for the GM DIS. The rest of the Megasquirt harness required no additional modifications.

A custom sub harness was fabricated to mate the EDIS4 to the wiring previously set up for the GM DIS. The rest of the Megasquirt harness required no additional modifications.

The EDIS module nests neatly on one of the stock Miata brackets

The EDIS module nests neatly on one of the stock Miata brackets

The EDIS coil pack mounts the the bracket previously occupied by the GM DIS. Note the capacitor was also poached from the Escort. The capacitor helps to shunt any EMF that may develop.

The EDIS coil pack mounts the the bracket previously occupied by the GM DIS. Note the capacitor was also poached from the Escort. The capacitor helps to shunt any EMF that may develop.

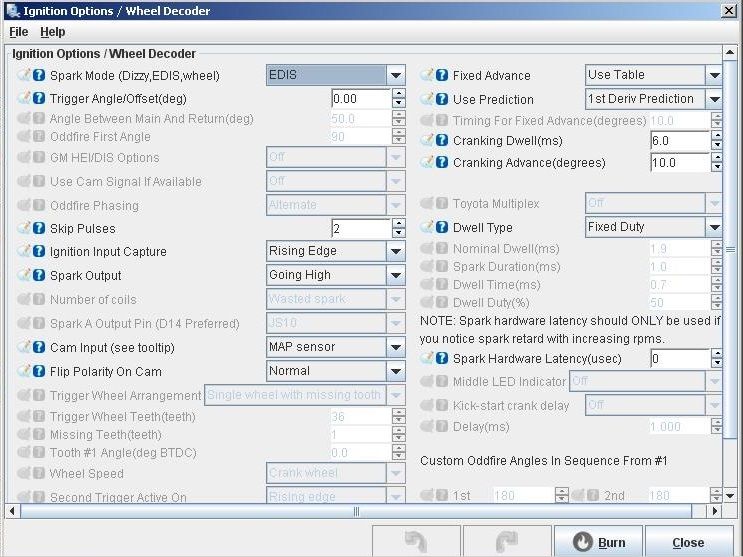

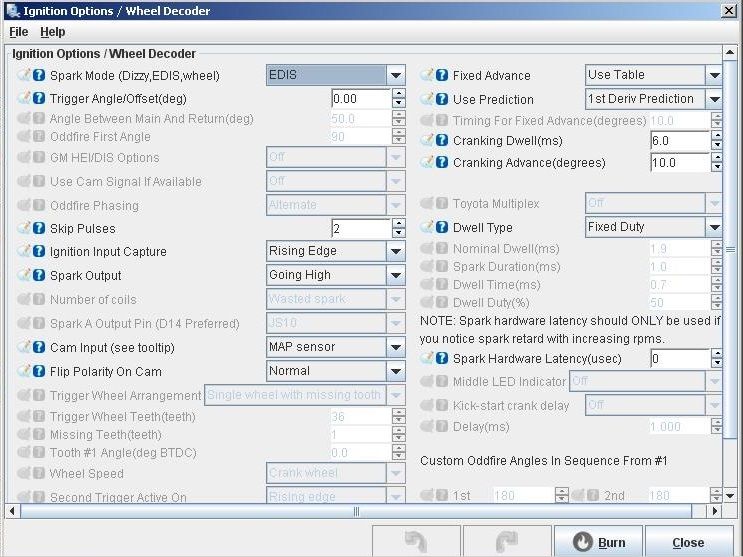

The EDIS was configured in tunerstudio with a few clicks of a mouse. At this point all that was left to do was twist the ignition key and see if this montage of parts work as expected....Yep!, the engine started right up.

The EDIS was configured in tunerstudio with a few clicks of a mouse. At this point all that was left to do was twist the ignition key and see if this montage of parts work as expected....Yep!, the engine started right up.

Stay tuned!

![]()

....................berkeley DIS!

....................berkeley DIS!  The GM DIS is awesome in so many ways. cheap and simple.... but in the end it serves two masters....and we cant have that. The GM DIS has the ability to receive timing pulses from the ECM or it can use its built in timing curve. The problem is, I'm not 100% certain what mode the DIS is in and any given point. A five volt bypass signal is used to force the DIS to use ECM timings signals, however if the ECM signals arrive at the wrong time the DIS will fall back and use its built in curve. Its actually quite simple with the single exception that there is relatively no setup info available on the Megasquirt forums. There are a dozen or so ways to configure the DIS for satisfactory results, but so far i haven't really settled on what works best.

The GM DIS is awesome in so many ways. cheap and simple.... but in the end it serves two masters....and we cant have that. The GM DIS has the ability to receive timing pulses from the ECM or it can use its built in timing curve. The problem is, I'm not 100% certain what mode the DIS is in and any given point. A five volt bypass signal is used to force the DIS to use ECM timings signals, however if the ECM signals arrive at the wrong time the DIS will fall back and use its built in curve. Its actually quite simple with the single exception that there is relatively no setup info available on the Megasquirt forums. There are a dozen or so ways to configure the DIS for satisfactory results, but so far i haven't really settled on what works best.  The Ford EDIS4 appears to be the the go-to device for all the cool kids, so in this instance I will chose not to take the road less traveled and go ahead and do something sort of normal.

The Ford EDIS4 appears to be the the go-to device for all the cool kids, so in this instance I will chose not to take the road less traveled and go ahead and do something sort of normal.  The 36-1 EDIS wheel is a few thousandths larger than the GM 7X DIS wheel... sweet! Unfortunately the hub center ain't even close...

The 36-1 EDIS wheel is a few thousandths larger than the GM 7X DIS wheel... sweet! Unfortunately the hub center ain't even close... An adapter was ginned up on the lathe to get the 36-1 wheel to fit the custom hub on the B3 engine. I love it when a plan comes together

An adapter was ginned up on the lathe to get the 36-1 wheel to fit the custom hub on the B3 engine. I love it when a plan comes together An additional slug of aluminum was machined to hold everything together.

An additional slug of aluminum was machined to hold everything together.  A SAM's membership card is used to set the gap for the crankshaft sensor. The 36-1 wheel is positioned nine teeth ahead of the missing tooth with the engine at TDC. This position will put the ignition at 10 degrease BTDC with zero offset in the Megasquirt setup panel. All this info was readily available on the Internet so no guessing was required.

A SAM's membership card is used to set the gap for the crankshaft sensor. The 36-1 wheel is positioned nine teeth ahead of the missing tooth with the engine at TDC. This position will put the ignition at 10 degrease BTDC with zero offset in the Megasquirt setup panel. All this info was readily available on the Internet so no guessing was required.  A custom sub harness was fabricated to mate the EDIS4 to the wiring previously set up for the GM DIS. The rest of the Megasquirt harness required no additional modifications.

A custom sub harness was fabricated to mate the EDIS4 to the wiring previously set up for the GM DIS. The rest of the Megasquirt harness required no additional modifications.  The EDIS module nests neatly on one of the stock Miata brackets

The EDIS module nests neatly on one of the stock Miata brackets  The EDIS coil pack mounts the the bracket previously occupied by the GM DIS. Note the capacitor was also poached from the Escort. The capacitor helps to shunt any EMF that may develop.

The EDIS coil pack mounts the the bracket previously occupied by the GM DIS. Note the capacitor was also poached from the Escort. The capacitor helps to shunt any EMF that may develop.  The EDIS was configured in tunerstudio with a few clicks of a mouse. At this point all that was left to do was twist the ignition key and see if this montage of parts work as expected....Yep!, the engine started right up.

The EDIS was configured in tunerstudio with a few clicks of a mouse. At this point all that was left to do was twist the ignition key and see if this montage of parts work as expected....Yep!, the engine started right up.

Thumbs up for the EDIS-4

Thumbs up for the EDIS-4  Although I'm on the tail end of the experiment, the sweet spot looks to be about 1 tick retarded on the camshaft. I have no idea what this translates to in degrees.

Although I'm on the tail end of the experiment, the sweet spot looks to be about 1 tick retarded on the camshaft. I have no idea what this translates to in degrees.

The stock Festiva throttle body allows coolant to flow through the device and will raise the air temperature going into the engine. What effect this heat had on performance and fuel economy was something I wanted to find out.

The stock Festiva throttle body allows coolant to flow through the device and will raise the air temperature going into the engine. What effect this heat had on performance and fuel economy was something I wanted to find out.

The culprit that disabled the car turned out to be the 36-1 crank wheel had slipped and the ignition timing was all berkeleyed up. This would have been and easy roadside fix, but not enough coffee to get the thinker going and a tow truck was required to get the car home.

The culprit that disabled the car turned out to be the 36-1 crank wheel had slipped and the ignition timing was all berkeleyed up. This would have been and easy roadside fix, but not enough coffee to get the thinker going and a tow truck was required to get the car home.  While we are looking at pictures, here is a shot of the power steering delete setup. I pulled the bracket off a Mazda 323 but a Ford Festiva or Aspire bracket would have worked. These parts would also work on the 1.6 and the 1.8 engine.

While we are looking at pictures, here is a shot of the power steering delete setup. I pulled the bracket off a Mazda 323 but a Ford Festiva or Aspire bracket would have worked. These parts would also work on the 1.6 and the 1.8 engine.  The only thing that kept the 36-1 crank wheel from slipping was friction...... So I drilled out a few parts and put a small screw in to keep the wheel from slipping again.

The only thing that kept the 36-1 crank wheel from slipping was friction...... So I drilled out a few parts and put a small screw in to keep the wheel from slipping again.  This is sort of how it all fits together, this time the little screw will keep the wheel from moving and upsetting the ignition timing.

This is sort of how it all fits together, this time the little screw will keep the wheel from moving and upsetting the ignition timing.  All back together and running again

All back together and running again