Moving slowly but surely. I put a little bit of time today.

- Removed the front sprockets

- Secondary tensioner

- Primary tensioner

- Primary sprocket

- A couple of coolant hoses connected to the head.

I first marked everything just in case, then removed (4x) E10 screws from the exhaust sprocket and (3x) 10mm nuts from the intake sprocket.

I used Dykem pens to mark the chain/sprockets. Not sure it will help but it makes me feel better.

On the intake sprocket there is a plate and a spacer that looks like a giant bellville washer. Becareful when removing the nuts, I loosened them a little at a time each.

As it all came off, I tried to keep it together and zip tied it all in position.

Next the secondary tensioner comes off by removing (4x) 10mm bolts. Be careful as it will come apart.

Zip tied the tensioner together as well:

Once all that is off, the primary tensioner comes off using a 32mm socket. Its on the side exhaust side of the head.

Becareful here when removing and keep the chain taught. You do not want to mess up here as that means removing the oil pan.

With the tensioner off you can remove the inner exhaust sprocket. I also marked this one just in case:

Keep some zip ties handy to hold the chain. I zip tied it to the washer bottle bracket for now while I loosen the head bolts.

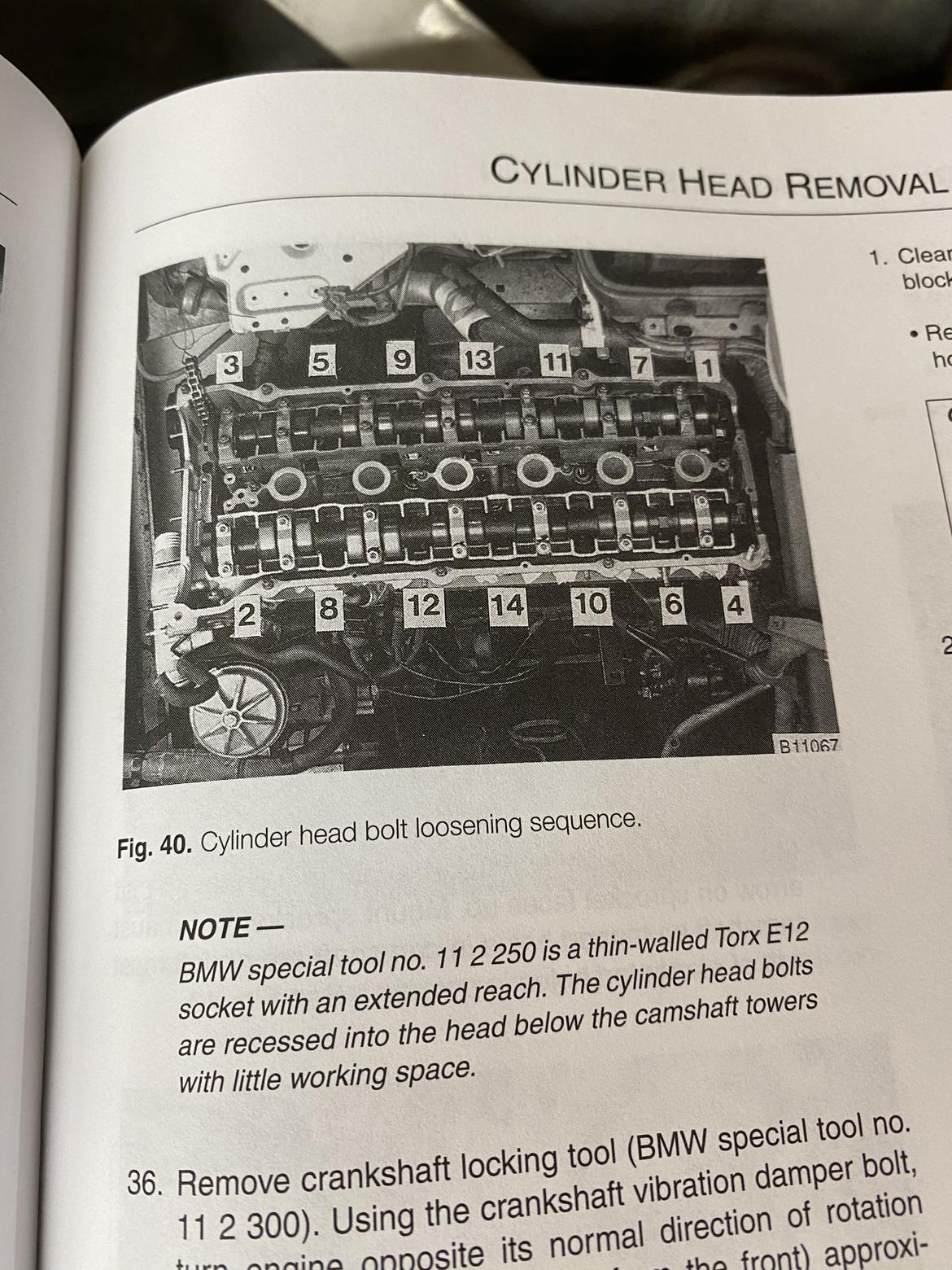

Here is the headbolt loosening sequence:

I did the first one and the tool would not fit on the second bolt due to clearance issues. I am going to machine the OD of the tool tomorrow.