First, the backstory: The car is a 1997 Dodge Neon Sport with the 2.0 DOHC that I bought and built as a $2005 Challenge car (epic fail) and brought back as a $2012 Challenge car (good mid-pack finish). From about 2011, I've been campaigning it in regional RallyCross events and it's done pretty well for me the last couple years. As of right now, it's sitting on stock springs with KYB blacks in the front and oranges in the rear and that's the project I should be tackling first, but doing things that make sense is rarely as much fun!

As soon as I bought the car back in '05, I found an SRT-4 turbo setup as a take-off from an 04 model, so it's equipped with the SRT-4 injectors, turbofold, and intercooler and it's been making plenty of power running about 8 pounds of boost. I used MegaSquirt'n'Spark (now MSExtra/1) with an MS1 unit on a 2.2 board, so my upgrade options there are basically nonexistent.

Last year, I found a PT Cruiser in the local pick'n'pull with the turbo-lite motor -- it's the same engine as is found in the SRT-4 and PT Cruiser GT, but it's detuned at the ECU to run less advance and lower boost so that it doesn't require 93 octane fuel. Factory rating was about 180HP versus over 200 for the SRT-4, if I remember that right. The car wasn't beat up, so it was in there for a motor or trans problem more than likely, but the oil and coolant both looked good. The crank pulley bolt was completely gone, but the timing belt was still in place. It's a non-interference engine, though, so that didn't worry me too much. So, I spent a very cold St. Valentine's Day with a couple good friends pulling the engine out.

Rebuilding the motor and putting it in to the car was supposed to be my winter project, but I kind of procrastinated a bit and didn't start to take the motor apart until early Feb of this year. Oops. At any rate, I've got the whole motor torn down and I found the problems with the motor:

First off, the tops of the valves were just coated with oil and carbon. They were a total mess, but the intake tract was completely devoid of oil, so new guides and seals fixed that. All the oil went in to the cylinders, though, and left the pistons just caked in carbon. Once the head was off, there were literally sheets of carbon coming out of the engine. Total mess.

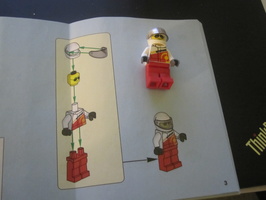

It's hard to make out, but this is the look through the intake ports:

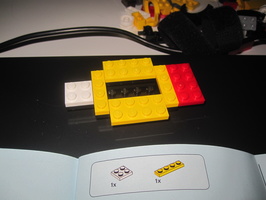

The block:

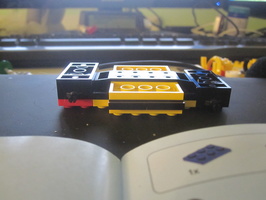

When I pulled the pistons out, they all pretty much looked like:

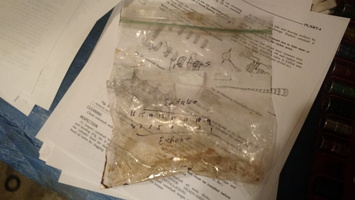

The car was in the junkyard, though, because of what I found on the timing belt:

It looks like the timing belt was so old, that it basically started to disintegrate and the teeth were basically scraped off. Hooray for non-interference engines!

At this point, everything is back from the machine shop -- new guides and seals, .005" worth of decking, and honing of the cylinders, std/std/std, and cleaned up a bit. I've hung the block on the engine stand and tackled the job of cleaning up the pistons while I wait for the parts to arrive.

Internet suggestions ranged from ATF to acetone and a few other weird things inbetween. I finally bought a $20 can of Berryman's Chem-Dip and dropped the pistons in. They were cleaned up a lot after an hour, and I've left them in since yesterday evening with an occasional removal to wipe down and scrape the lands a bit. I'm thinking that I'll be able to pull them out tonight and they'll be ready to have a couple nicks taken out and then re-ringed.

Meanwhile, I've found rod bolts on eBay -- Ford Duratec 1.8L con rod bolts from ARP are apparently correct -- and I stopped in the local dealer yesterday and got some bedplate sealant. My concern on that is that I keep reading that the "red stuff" is no good because it will create a gap that throws off the mains clearance and that there exists some mythical "green stuff" that has a 0 gap cure. According to Mopar, the red stuff supersedes the part number for the green stuff and I can't find the green stuff anywhere. So, here's hoping.