Not sure if I am taking quarantine extremely well or completely going crazy but it is allowing me to wrap up a few small tasks and re-re-redo others.

First things first. no more oil leaks! I am finally bone dry! (no photo needed because its a boring photo) and I managed to install the plastic splash guard and make a few new splash guards for other areas, hopefully this also will resolve my tossing belt issue. I think when I cut off too much from the balancer it had the serpt belt angle a bit wonky so one touch of water with a tip in of the throttle and off she goes. Need to find a big puddle and test thing theory now...

in other news, I'm re-re-re-doing the PCV system AGAIN! I thought I had it correct with the 1/2" bungs welded on but it seemed to want to fill the catch can in a 200 mile tow (or less) I think the placement of the driver side valve cover bung was too close to the rocker and was basically sucking up E36 M3 tons of oil. Part of the rear most rocker arm looked dry even...

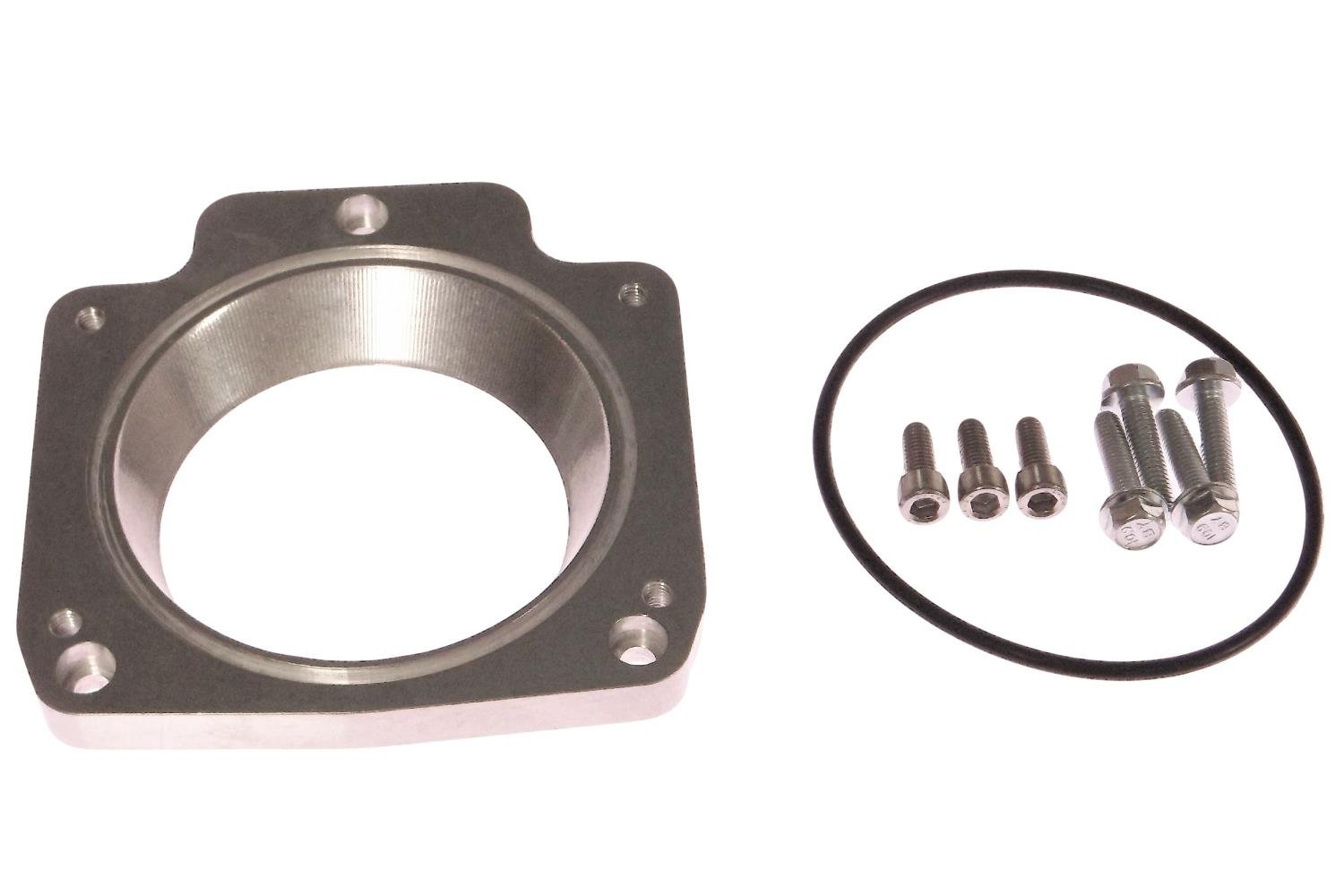

so in brings this fancy ass bling to the rescue (hopefully) as this has been an awful experience since there are so many correct ways to do a catch can setup correctly and cans with some steel wool are incredibly expensive for no reason but I digress....

these have a double baffle system but placement is trickey, they advise that you can put these in nearly any location on the valve cover (where it fits) so I was able to find a spot in-between the rocker and the valve cover mounting hole:

so while were here it looks like im cleaning and re-painting then re-doing the valve cover gaskets again... *sigh*

but this gives me hope as the gen six 454s have PCV ports in their valve covers in a similar location, but here is the snazy motionworks kit installed:

however this is a -12ORB which is huge and I have to neck down 3/4" piping to 3/8s across the system so I am not an airflow expert here but maybe this is something to do with PCV system issues?

can't quite test it yet as I keep fumbling with adapters and tubing and with COVID delays in shipping its like building cars in the 90s/00s again... we all have grown impatient that's for sure. maybe finally after this I can get it retuned properly and for the last time.

so while I wait on these pieces I did some electrical updates to the truck, "needed" to replace the batteries so I went with an AGM style (turns out I was just leaving the dome light on in the back) but they were 5+ years old and mismatched lead acid so I figured it was a good time to do that, more robustness is always good and I am moving towards self sustainable service/camping adventure vehicle.

re mounted the battery isolator better and had to make a bracket for the large between battery fuse but the engine bay looks better, with this done I was able to wire up the inverter I installed many months ago...

I went with 1/0 gauge wire. its 4KW unit but I don't plan on running a refrigerator for 24 hrs so this should be fine, there is no safe place to put it under the hood and with the airbox out of the way it is a perfect spot for an air compressor! however when it arrived it was missing parts so I'm going through an exchange on that currently so that will have to be installed later (soon).

I was originally going to do bulkheads but it looks like the City of Chicago (prior owners) had already pierced the main grommet so I just ran the thick cables through there and headed towards my high amperage posts... when in Rome I guess -

I only have 1 area of visible wire and I ran it between the center console and driver seat, only a little bit of gaffer tape needed to conceal, but take a look, everywhere else is pretty easily route-able and hidden!

you can spot the black wire if you have a keen eye, but the real hero for the backseat is this weathertech floor mat, it conveniently hides the large wires and works really good as a floor mat so theres that.

then the wire runs through the rear seats and under this clever panel:

flip the back seats up and everything is well reachable, (makes for easy fire extinguisher mount too) here is what it looks like under the panel.

and when its all buttoned up!

inverter tested and works good, now I have a high amperage lead that is connected to the secondary battery should I want to wire up anything goofy back there.

Now to finish up the PCV system and install the air compressor when the missing parts arrive.