RE Title: SCORE!!!!

bgkast wrote: Fobs will be here early next week. I want to test them before I sell any. I will get back to everyone soon. GRM price will be $10 each

At that price, I'll take the later 9-3 key. One of my best friends would love to have it.

Congrats on the title!

Just enjoy the glory of having a title on a car you bought for $50!!

No sense trying to rub it in.

bgkast wrote: Fobs will be here early next week. I want to test them before I sell any. I will get back to everyone soon. GRM price will be $10 each In other news:Mine, all mine! Also note nothing listed under brands

Is it wrong to send this picture to the jackhole at the state licensing department?

It sort of works. Some of the pixels are out.

My 39 mpg high dropped to 33.5 after I got into the boost a few times and got off the freeway, but I was impressed by that number.

This weekend it gets new (used) axles installed.

Rusted_Busted_Spit wrote: Glad you got it running. When you are ready get some thin wall 3 inch PVC and open up the airbox, put in a MBC and smile big.

Tell me more about the PVC airbox mod...

Key fob thread here: https://grassrootsmotorsports.com/forum/200x-classifieds/miscellaneous-keyless-fobs-support-the-50-saab/103500/page1/

PMs sent to those who have already expressed interest.

In reply to bgkast:

I will try to explain but if it goes really badly I will try to get some pictures of the one I did from my brother.

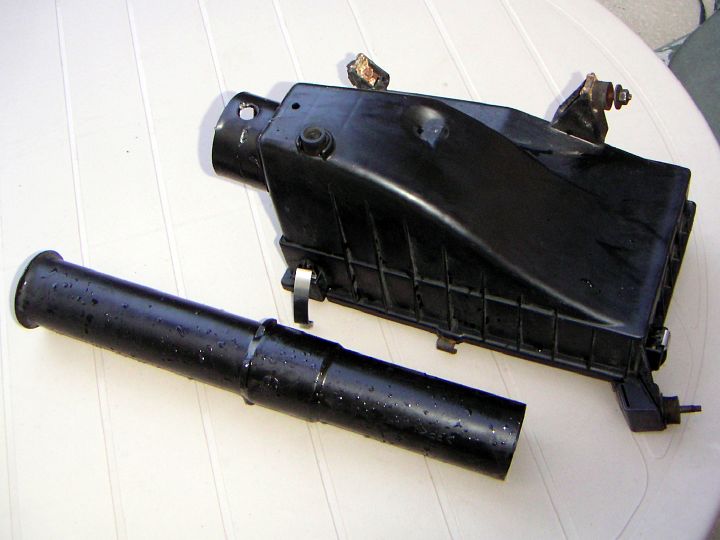

Get some thin walled 3 in PVC pipe. Then pull the air box out of the car. Once you have the AB out take out the stock snorkel and toss in the trash. The next step is to cut a bigger circle in the airbox for the PVC to fit in. I did not have a big enough hole saw so I used my dremel to make the hole. I then split a lenght of fuel line length wise and put it around the inside edge of the hole so there would be a good seal when the PVC was put in. Next put in the PVC and cut for length. I then belled the outside end of the PVC with a heat gun, painted it black and put everything back together.

The car was my wife's DD at the time and the day after I did this she called me in a panic. She said that the car was making "whooshing" noises and wondered if something was broken.

On a side note, on a few long interstate trips I saw indicated MPGs in the low 40's once or twice.

In reply to Rusted_Busted_Spit:

Thanks. Something like this then:

http://photo.platonoff.com/Auto/20050527.Saab_NG900_Airbox_Inlet_Pipe/?all

to

I will have to pick up a spare airbox and try it,

The kids haven't been letting me have much time in the garage. It's like wack-a-mole at bed time. Put one to bed and two others pop up and start running around, deal with them and the first is back up...then one of the babies wakes up. I got out into the garage at 9:00 last night. ![]()

The used axles are re-greased and booted. I got the car up on jackstands and the wheels off and found that I don't have a 32mm socket to get the axle bolts off, so I did some investigation instead. The passenger axle seems better than I thought, and the driver's seems worse. Not only does the driver's side inner joint have a bunch of torsional play in it, but it has lateral play where it enters the transmission, like this (not my video):

https://youtu.be/w2YaaTdenF8?t=30s

I guess this is somewhat common. Mine has about that much play, which apparently is almost in spec and maybe not an issue if the seal isn't leaking. I don't really want to do this job twice so I have ordered a new bushing and seal 2nd day air. Removal of the old one involves using a hack saw to cut the old bushing in half while hoping not to get any metal filings into the transmission. I can't wait. ![]()

I got everything apart but the passenger side intermediate shaft last night. It's loose but wouldn't pop out at 11 pm so I gave up. I braved Portland traffic this evening and picked up a new carrier bearing for the intermediate shaft. $17.50 at a bearing house vs over $60 for an oem part. ![]()

One more thing re the airbox. I have read that you will get better flow if you make the end more like a trumpet, curved back somewhat. I do not know how true it is but I did mine that way.

In reply to tuna55:

The random object that I found to drive the old one out and the new one in was just a bit too small of a diameter and put pressure on the side seals and bearing cage when I was trying to pound the new one into place. I really need a press and bearing driver set...

No need for an expensive large diameter driver set, when pressing bearings, take apart the old one for the outer race, and depending on the application grind the OD slightly(basically just enough to mark it and take off a few thou), clean it up and you have a custom bearing driver that you can then push on with whatever questionable junk you have laying around. I do it almost every time I have to press a wheel bearing

You'll need to log in to post.