Following your build closely for obvious reasons.

Please make all the mistakes possible so I know where they are.

Thank you. ![]()

Following your build closely for obvious reasons.

Please make all the mistakes possible so I know where they are.

Thank you. ![]()

A re-ring shouldn't be too expensive. As long as the cylinders aren't scored, throw a set of rings and a hone at it and call it good. I've done that on a couple of outboards. Easy, just don't forget to re-torque the head at the 10 hour mark or it is almost guaranteed to pop a head gasket.

Bearings almost never fail unless they get water on them and rust. Mains and rod are usually roller bearings, rather than sleeve. I've never had a set fail.

914Driver, I've been scouring CL for a suitable replacement. The first one you posted is more than my boat will handle (rated for 80 hp), and I've been staring at the second one for a loooooong time (actually knew which one you were talking about before you posted it). Problem is I can't compression test a stuck motor, and I'd hate to wind up doing this again.

I'm gonna try de-gunking this one, and if I can't get my compression up I'll look into re-ringing it.

Alright. Yesterday I picked up and hauled home a parts boat- a late 70's 18' aluminum bowrider that has been a yard ornament for a friend's dad for the last decade or so. It was a pretty nice boat until a tree fell on it. I'm interested in the 55 hp Johnson outboard, which looks a little less period-correct than the Evinrude and mounts with bolts rather than clamping on, but should push this thing around quite nicely. Also has rack-and-pinion steering so I can get ride of the old clothesline on pulleys setup. The recycler should give me back more than I paid for the whole setup once I scrap the hull.

Unfortunately, it's looking more and more likely that I won't be getting out in this thing before winter. I'm thinking it's just time to go full-bore restoration this winter and debut it next spring. We'll see what happens.

psteav wrote: 914Driver, I've been scouring CL for a suitable replacement. The first one you posted is more than my boat will handle (rated for 80 hp), and I've been staring at the second one for a loooooong time (actually knew which one you were talking about before you posted it). Problem is I can't compression test a stuck motor, and I'd hate to wind up doing this again. I'm gonna try de-gunking this one, and if I can't get my compression up I'll look into re-ringing it.

Apropos of nothing but a funny story. You mention power ratings...

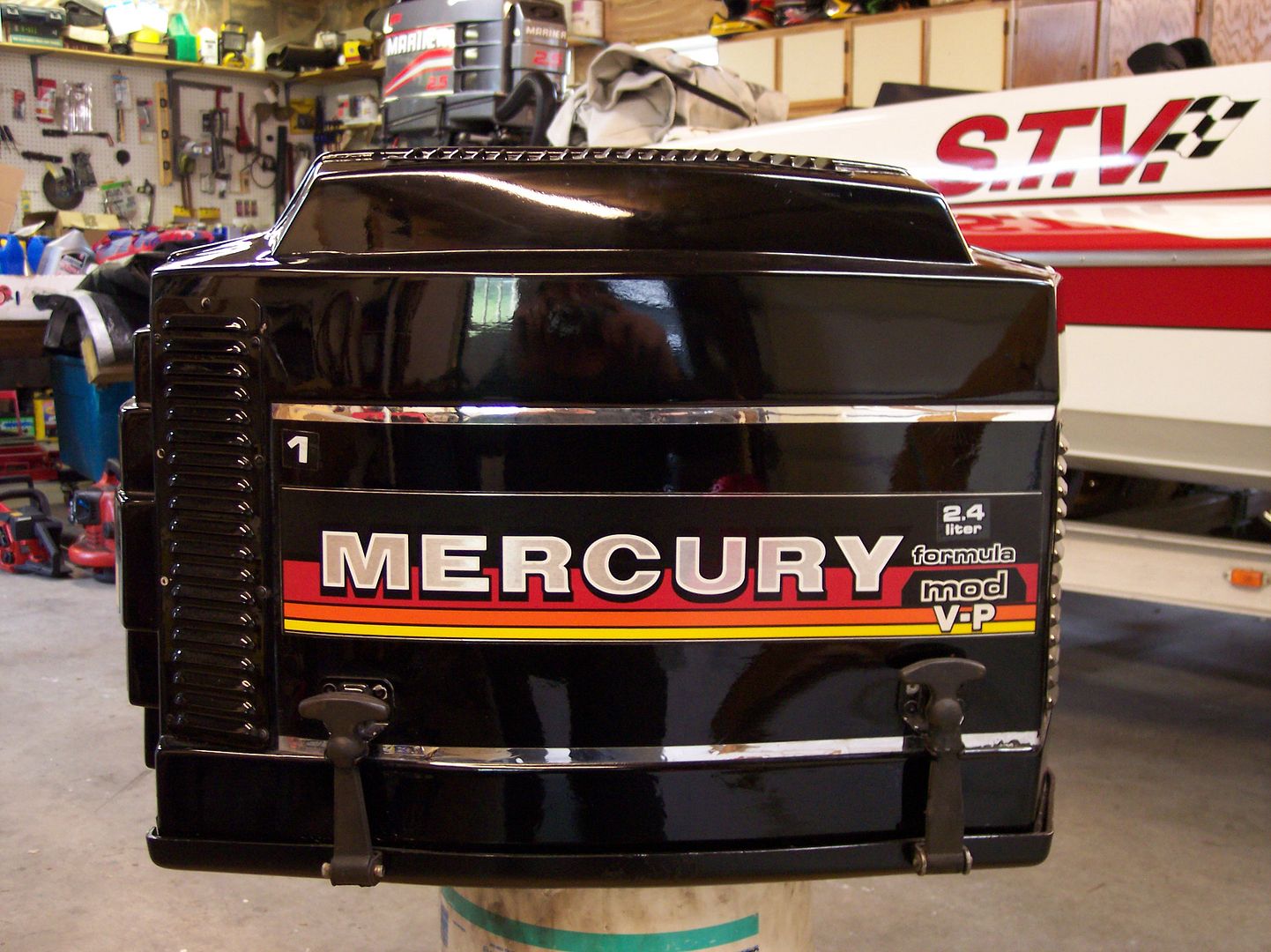

Many years ago I earned money by putting silly horsepower boats on the water. One serious nut-bar walked in and asked that we install a Mercury Mod VP on the back of a boat about the same size as your project. I did a very nice job of it,including a transom that could be raised as the speed went ballistic so you could run on just the single blade in the water. To this day I wonder where the body is buried. That was a 250 hp engine on pump gas.

Back from the dead!

No pictures this time; slight change in focus. I've started prepping the boat for paint. I'm still waffling on whether I'm going to strip off all the paint (time consuming) or just sand off the surprisingly few loose spots, scuff the good stuff, prime it and call it a day. Apparently both strategies have their proponents...be interested in hearing from the hive mind here.

As for motor, I've found a guy in KC who has a BUNCH of period-correct 30-50 hp outboards, including some short-shaft ones. This thing has a 16" transom, which means most outboards are going to be too tall for it, and I don't want to put a jack plate on it if I can help it. Short-shaft motors are hard to come by, though...both of the motors I have are long-shaft. Also, the one I got with the boat doesn't have electric start, which would be very nice to have.

I think I'm going to go for a period-correct cleanup/resto on it, so I'm going to keep the cable and pulley steering. My gf has planned upholstery for it, which will be the next (hell, only) big step after getting it painted.

I'd also be interested in hearing from anyone who's put flooring down in a boat like this. I wouldn't mind putting some sort of decking in in front of the seats, but I don't know that it's worth the trouble and extra weight, and I'm not entirely sure how I'd attach it short of screwing into the top of the aluminum ribs.

Pics to follow.

I never quite figured out that whole long shaft/short shaft thing, but a lot of boats back the 1950s used them; my dad had a '56 Herters runabout with a 30hp Johnson short shaft. I would suspect that if you're looking for a period correct motor that short shafts are more common, into the 1960s and 1970s there were a lot less of them.

The old cable steering works well enough as long as it's in good condition. You may have to replace the cable if it's kinked up and maybe some of the pulleys as well.

Floor decking wasn't very common in boats like that, usually aluminum boats just had an open floor. It's not as nice looking but you don't have to worry about gunk collecting under the floor and rotting it out.

Stuart, from what I've seen the short-shaft motors were definitely a lot more common in the 50's and 60's than later on. Some of the motors can be converted back and forth between the two-assuming you can find all the parts.

I'm going to replace the cable for the steering, but the pulleys/turnbuckles/etc. look to be in decent shape if a little crusty. Turning the wheel still moves the cable just fine though.

I'd say you could definitely let the floors be an "after it's functional" project. One thought that came to mind for how to mount them is "Rivet Nuts." http://www.mcmaster.com/#standard-rivet-nuts/=uwbqon (or search mcmaster.com for rivet nuts and you'll see them)

They've also got your solid aluminum rivets that you'll need to patch up the few holes in the hull: http://www.mcmaster.com/#standard-rivets/=uwbrgs

I'll see if I can find where to get the bucking tools to form them (I've got an air hammer somewhere).

On the engine. You know what would be cool? If you could find one that is close enough to the one(s) you have now that you could use it for spares.

Clem

You'll need to log in to post.