Another hack for transverse bike engines is a belt drive, or maybe even a Harley gearbox (some of them have reverse).

Still leaves the diff issue.

Simplest solution is a small, light, high output FWD motor.

Think Honda D16, with goodies.

Would a Subie or Porche motor fit?

jmc14 wrote:

Thank you for everyone's input, suggestions, and comments. I think that going with Motorcycle power is the way to go. The suggestion to get the entire bike is a great idea. I think that there will be room to fit a Motorcycle engine with out a problem. My goal will be to keep the weight as low as possible.

I have been reading about the different options for a diff and reverse. I came across a diff that has been designed for Motorcycle powered off road vehicles. It has a built in reverse, limited slip, and the option of inboard brakes. The Engine is coupled to the diff with out a chain. The problem is that it is $2500. www.transworks.biz.

2500$ seems like a heck of a deal when you consider the packing has already been worked out and its a known product. 2.5K is a drop in the bucket on a project like this and could save you months of trying to hack something else in.

Love the body that would be a blast to build.

In reply to TeamEvil:

Better than Campys? Bite your tongue sir. Even a replica of an Italian car should be shod in the proper shoes. As for the engine, a vintage Fiat DOHC would be proper.

I vote rotary engine. I have no clue if it would fit or if there is any easy way to bolt a transaxle to one, but the sound of angry triangles revving to 9k would be awesome.

Would a Goldwing engine fit? 2000+ models appear to have 118 hp, 123 ft/lb torque, and reverse. The weight of this car is probably about the same as a fully-laden Goldwing with two "full-size" riders and a trailer.

Ian F

MegaDork

11/27/14 7:59 a.m.

wearymicrobe wrote:

2500$ seems like a heck of a deal when you consider the packing has already been worked out and its a known product. 2.5K is a drop in the bucket on a project like this and could save you months of trying to hack something else in.

Love the body that would be a blast to build.

That's pretty much how I see it as well, although it's actually a bit over $3000 with the inboard brakes. It's a product designed EXACTLY for this sort of project.

Ian F wrote:

wearymicrobe wrote:

2500$ seems like a heck of a deal when you consider the packing has already been worked out and its a known product. 2.5K is a drop in the bucket on a project like this and could save you months of trying to hack something else in.

Love the body that would be a blast to build.

That's pretty much how I see it as well, although it's actually a bit over $3000 with the inboard brakes. It's a product designed EXACTLY for this sort of project.

This is a brilliant piece, and I want one.

I also just noticed that they can make a drive coupler for pretty much anything.  I'm a driveshaft away from the Guzzi/BMW cyclecar of my dreams!

I'm a driveshaft away from the Guzzi/BMW cyclecar of my dreams!

jmc14

Reader

11/27/14 9:30 a.m.

I've been emailing Transworks and an engineer at Radical Race Cars. The Radical SR3 is close to the same size and weight as the Stinger will be. Actually, the stinger, in street trim will be lighter. Transworks tells me that the stock transmission /clutch work with out a problem in the off road world and that there hasn't been any issues with oiling. They told me the common practice now is to rotate the engine so that the valve cover is horizontal. This requires the oil pan to be modified. They are doing this to mitigate the weight of the engine being off of centerline. When rotated the difference in weight is 15lbs. I'm thinking of building my personal car as a single seater with the seat centered. I have a my Cobra tribute that I built and the car in my profile. I almost always drive them alone.

Radical has the engine mounted transversely. They use a differential unit from Quaife. It also has a built in reverse. It's a cool unit but it's more expensive than the Mini Diff.

Ted, an engineer at Radical told me that they have built over 1000 cars with Hyabusa engines. They use the stock transmission and OEM clutch (with stronger springs) and haven't had any problems. He told me that some of their cars have 350 RWHP. For street use the stock oiling system is fine. The are pulling over 2gs in corners and install a dry sump in their race cars.

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/hyabusadifferentialusedinradical_zps1df9b1ea.jpg.html] [/URL]

[/URL]

I'd put a dry sump (or at least a baffled & trap-doored pan) on a 'busa engine anyway, they're well known for blowing up when installed in cars without oiling system mods, even in Radicals.

R1 engines seem to have a better reliability record in BECs, but again you should do something different with the oiling system if you use one. A BEC with a stock oiling system is asking for it IMO. They weren't designed to have to deal with gravity coming from the side at all.

Chet

New Reader

11/28/14 12:21 p.m.

This could be a very fun project!

Chet

Since the uprights will be more than likely 4 X 100 bolt pattern I've been looking around through the multitude of cheap Miata/Civic/MR2 wheels to find something that has a similar look to the original Campagnolos. So far I've found these Traklite "Drum" wheels:

They only come in 15 X 8 so they don't work for and original staggered type setup, but they are pretty cheap. Not sure about the quality of the wheels, but Good-Win-Racing sells the "Burn" wheel from the same manufacturer for track day use.

Chet

New Reader

11/28/14 12:44 p.m.

oldtin wrote:

Subscribed. Starting to plot for one. Needs a better sound track than a Japanese sport bike. Big triumph triple? Ducati?

Apparently you've never heard a Hayabusa powered car.

Watch the opening scenes of the movie Gran Prix and you'll get some appreciation of the possibilities.

Chet

nhyrum

New Reader

11/28/14 8:36 p.m.

singleslammer wrote:

OoOOh My eyes! The holy light!! It Burns!!

OH!!!!! OOOOOOOOOOOOOOOH GOOOOOOOOOOOD!!!!!

well... i gotta go change my pants.... that was so sexxy... my wife wont be getting any tonight! I think im going to take one of those eventually...

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

mblommel wrote:

"Drum" wheels:

Since the uprights will be more than likely 4 X 100 bolt pattern I've been looking around through the multitude of cheap Miata/Civic/MR2 wheels to find something that has a similar look to the original Campagnolos. So far I've found these Traklite

They only come in 15 X 8 so they don't work for and original staggered type setup, but they are pretty cheap. Not sure about the quality of the wheels, but Good-Win-Racing sells the "Burn" wheel from the same manufacturer for track day use.

They only come in 15 X 8 so they don't work for and original staggered type setup, but they are pretty cheap. Not sure about the quality of the wheels, but Good-Win-Racing sells the "Burn" wheel from the same manufacturer for track day use.

bpimm

New Reader

11/29/14 9:57 a.m.

I have one of these transaxles in my shop, I was going to incorporate it into my Busa powered Amod, but I have been thinking I want a 2 seater to play with instead, this car looks like a great candidate.

I think the Miata uprights are a great way to go, I realize it's early in the process so you may not have answers yet but I'm just wondering what other ideas you are planning on incorporating into the chassis?

I noticed you mentioned "the Stinger in street trim", Have you found a source for windshields? I have noticed in some pictures they have wipers which would suggest a glass windshield.

Does the door open or is it fixed?

How tall of a Driver will be able to fit under the roll hoop? I'm 6' and have to recline a bit and stuff my knees up into the dash to clear the roll bar in our Miata which is not a comfortable driving position.

Can't wait to see how this comes together.

Brian

P.S. I have a small CNC mill, I may be able to build a jig to re-drill the miata hubs so they will be able to accept 4 on 98 and 4 on 100 bolt patterns if you are interested.

jmc14 wrote:

I've been emailing Transworks and an engineer at Radical Race Cars. The Radical SR3 is close to the same size and weight as the Stinger will be. Actually, the stinger, in street trim will be lighter. Transworks tells me that the stock transmission /clutch work with out a problem in the off road world and that there hasn't been any issues with oiling. They told me the common practice now is to rotate the engine so that the valve cover is horizontal. This requires the oil pan to be modified. They are doing this to mitigate the weight of the engine being off of centerline. When rotated the difference in weight is 15lbs. I'm thinking of building my personal car as a single seater with the seat centered. I have a my Cobra tribute that I built and the car in my profile. I almost always drive them alone.

Radical has the engine mounted transversely. They use a differential unit from Quaife. It also has a built in reverse. It's a cool unit but it's more expensive than the Mini Diff.

Ted, an engineer at Radical told me that they have built over 1000 cars with Hyabusa engines. They use the stock transmission and OEM clutch (with stronger springs) and haven't had any problems. He told me that some of their cars have 350 RWHP. For street use the stock oiling system is fine. The are pulling over 2gs in corners and install a dry sump in their race cars.

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/hyabusadifferentialusedinradical_zps1df9b1ea.jpg.html] [/URL]

[/URL]

bpimm wrote:

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

Here's a photo of the backside of the Miata hubs:

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

Miata hubs and uprights are not that light. Unless there is a specific reason to use them I am not sure they are the best bet. With the light weight care are there other options from smaller chassis racing classes that might work?

bpimm

New Reader

11/29/14 9:18 p.m.

Oops my bad, I looked at the wrong hub. No those don't lend themselves to re-drilling.

mblommel wrote:

bpimm wrote:

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

Here's a photo of the backside of the Miata hubs:

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

jmc14

Reader

11/30/14 11:03 a.m.

One of the biggest questions when building a specialty constructed vehicle is how does it get registered and is a DOT windshield required. The fact is that each state has it's own requirements and you need to check with your DMV as to what is required. If you follow your states requirements to the T it is possible to register a car like this in almost all instances. One of the biggest things is to keep detailed records of EVERY purchase. I will be issuing a Manufacturers State of Origin for the body and frame. If you purchase parts from a vehicle make sure that you have a copy of the title along with a receipt and vin/part numbers. I built a high dollar car once and purchased a complete engine from a well known company. They purchased salvage blocks and when decked the VIN number was removed. Even though I had a receipt for a $10,000 engine the state of NH would not register the car because I couldn't prove the block wasn't stolen. Yes, it can be that crazy.

Some states allow Polycarbonate windshields. Some states will allow you to run a Polycarbonate windscreen. But, if it's tall enough to be considered a windshield will not allow it. If a windscreen, prepare to wear googles!

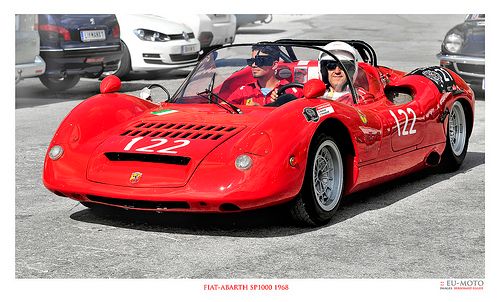

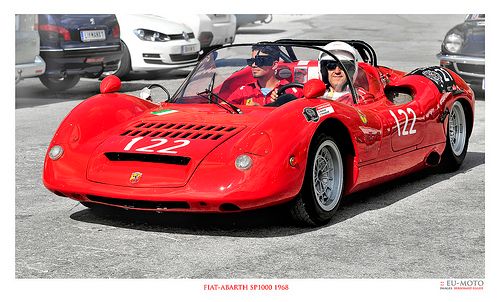

I've searched the Web for pictures of the SP 1000. There are pictures showing a full windshield and many showing different styles and heights of plastic windshield and screens. I have plans to build one of these with a removable top. In that case a windshield will be required. I will have a mold made for the factory styled windshield and will have DOT legal windshields made. The idea will be to make the windshield removable so that I can change looks and functionality based on what I want to do with it.

The builder will have the option of making the doors fixed or functional. The doors do have inner skins. The frame will have hinge mounts.

I'm 6'2" and have a 34 inch inseam. Obviously I've never tried sitting in this car. But, I have a friend that owns a 1964 Crusader which is a mid engine car of virtually the same size. He is tall and fits great in the Crusader. He tells me that I would fit in the Crusader with out a problem. One of the keys for this is that the frame wraps around you. You sit in it and not on top of it. This allows a very low seating position. I have built a number of cars with a perimeter frame. The height to the top of my roll bar on those cars was 39 inches. My head was comfortably below that. I believe the same thing will happen with the Stinger.

I've had a great conversation with a gentleman that I met years ago at a car show. He's been building Hyabusa powered mid engine cars for over 10 years. He graciously has given me a ton of information on using the Hyabusa. His cars weigh 1000lbs and with stock power run 0-60 in the low 3 second range. I can get excited about that.

Here are few pics of cars with different windscreens/windshields.

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarth2634frontgreatpic_zps8c4f262b.jpg.html] [/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarathsp1000122fromrightfront_zpsa34ca4bf.jpg.html]

[/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarathsp1000122fromrightfront_zpsa34ca4bf.jpg.html] [/URL]

[/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/abarth21fronthigh_zpsa0d2dabf.jpg.html] [/URL]

[/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarathsp1000front_zpsb8029997.jpg.html] [/URL]

[/URL]

bpimm

New Reader

11/30/14 12:22 p.m.

jmc14 wrote:

I have plans to build one of these with a removable top. In that case a windshield will be required. I will have a mold made for the factory styled windshield and will have DOT legal windshields made. The idea will be to make the windshield removable so that I can change looks and functionality based on what I want to do with it.

That sounds good, I was thinking a removable hard top would be a good option. Living in the PNW Rain is always a threat. I would be in for a factory styled windshield as well.

jmc14 wrote:

I've had a great conversation with a gentleman that I met years ago at a car show. He's been building Hyabusa powered mid engine cars for over 10 years. He graciously has given me a ton of information on using the Hyabusa. His cars weigh 1000lbs and with stock power run 0-60 in the low 3 second range. I can get excited about that.

Mine weighs in at 900 Lbs with me in it, the 0-60 times are rather exciting and 0-100 doesn't take much longer.

bpimm wrote:

Oops my bad, I looked at the wrong hub. No those don't lend themselves to re-drilling.

Bummer. I'm was hoping for a magic bullet there. If the Miata hubs are too heavy then is there another, readily available option that is lighter? Is there a weight difference between the 1.6 and 1.8 Miata parts other than the smaller brake rotors?

John, that's great news regarding the DOT windshield. Florida is one state that requires some sort of windshield, although plenty of sand rail guys seem to find a way around the requirement.

bpimm

New Reader

11/30/14 5:24 p.m.

If you could find a stud with the knurled section size 2 mm larger the hole could be offset 1 mm and enlarged by 2 mm and make it work. A quick look turned up studs for a Dodge neon but they were shorter than the miata studs, might not be long enough.

bpimm wrote:

Oops my bad, I looked at the wrong hub. No those don't lend themselves to re-drilling.

mblommel wrote:

bpimm wrote:

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

Here's a photo of the backside of the Miata hubs:

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

bpimm wrote:

If you could find a stud with the knurled section size 2 mm larger the hole could be offset 1 mm and enlarged by 2 mm and make it work. A quick look turned up studs for a Dodge neon but they were shorter than the miata studs, might not be long enough.

bpimm wrote:

Oops my bad, I looked at the wrong hub. No those don't lend themselves to re-drilling.

mblommel wrote:

bpimm wrote:

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

Here's a photo of the backside of the Miata hubs:

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

If you have hub centric wheels, there is not any strict requirement that holes for studs be perfectly round.

The point of an interference fit hole with knurled studs is to keep them in place while the wheel is off.

Once the lugs are tightened, there are tons of compressive force holding everything together, friction between the wheel face and the hub face holds the wheels in place.

The studs will not move around.

It also means that a thinner 'bridge' on the outer edge is not a strength compromise.

That should make it easier to find a replacement stud.

bpimm

New Reader

12/2/14 9:11 a.m.

erohslc wrote:

bpimm wrote:

If you could find a stud with the knurled section size 2 mm larger the hole could be offset 1 mm and enlarged by 2 mm and make it work. A quick look turned up studs for a Dodge neon but they were shorter than the miata studs, might not be long enough.

bpimm wrote:

Oops my bad, I looked at the wrong hub. No those don't lend themselves to re-drilling.

mblommel wrote:

bpimm wrote:

The Miata hub has plenty of meat on it to also bore it for 4 on 98, that way any of the wheels could fit. My X 1/9 is dual bolt pattern 4 on 98 and 4 on 100.

Brian

Here's a photo of the backside of the Miata hubs:

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

Is it really a good idea to put studs through thinner section? Or are you saying offset drill the existing holes for a larger stud?

If you have hub centric wheels, there is not any strict requirement that holes for studs be perfectly round.

The point of an interference fit hole with knurled studs is to keep them in place while the wheel is off.

Once the lugs are tightened, there are tons of compressive force holding everything together, friction between the wheel face and the hub face holds the wheels in place.

The studs will not move around.

It also means that a thinner 'bridge' on the outer edge is not a strength compromise.

That should make it easier to find a replacement stud.

If you stayed with the 90-93 hubs the pattern could be re-drilled to 4 on 98 by using studs for the Mitsubishi Evo. Not quite big enough for a complete re drill but the overlap is only .010" and the Evo stud is 1/4" longer. The later Miata rear hubs use a stud that has a larger knurl size that would make finding a stud much harder, any year of front should work according to ARP stud dimensions.

jmc14

Reader

12/4/14 6:41 p.m.

Found this on the internet. A little tease.

www.youtube.com/watch?v=_sBrM8sgWOw

[/URL]

[/URL]

[/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarathsp1000122fromrightfront_zpsa34ca4bf.jpg.html]

[/URL]

[URL=http://s1143.photobucket.com/user/jmcbigbelly/media/fiatabarathsp1000122fromrightfront_zpsa34ca4bf.jpg.html] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]