rcutclif wrote:

JohnRW1621 wrote:

I have enjoyed watching your thread and I look forward to our battle of the Big Girls.

WOOT WOOT!

Sounds awesome, are you driving down?

The plan...

Drive the Q45 1,000 miles from Ohio to Gainesville.

Compete for two days.

Drive the Q45 1,000 miles from Gainesville to Ohio

Solid plan.

What could go wrong?!

John, awesome plan. Sounds a lot like mine. Ha. I think there might be a Saturn coming from really close to me as well. I will see if I can contact that team through the board to see what their travel plans are when we get closer.

Tonight I still did not grab a no exhaust running video. I had kid duty until bed time because my wife had church council meeting. And since our neighbors are really good to us but about 80 years young, I decided not to fire up the unmuffled v12.

Instead, I decided to put my passenger side strut back together!

So first I put the new bilstein in the strut tube and tightened the fancy new collar nut.

Next I cut my spring. It was about 6.5 coils, and I took as close to two as possible out. So I think that means the spring rate should be increased about 30 percent. My math correct on that?

Anyway, the spring was a little beehive shaped, so when I cut the bottom off, I then had a coil too big to fit in the strut. So, a little heat, a little vice action, and fixed.

Finally, I reassembled everything. Heck, even the top mount bushing still rotates smoothly and the rubber looks good (much better than the metal looks).

I'm quite happy with how the strut looks now, can't wait to see how it drives!

In reply to rcutclif: I really love your approach.. How much are you able to "gut" the car? Do you have to have inner panels? If so can you go crazy with a hole saw and then dimple the holes to regain some strength? Can you remove all glass? What about side impact door beams, bumpers etc?

I should imagine the car weighed around 4000+ pounds when you started and if you can remove a 1000 pounds you should be more competitive. Personally I'd put that power train in a lighter smaller car

frenchyd wrote:

In reply to rcutclif: I really love your approach.. How much are you able to "gut" the car? Do you have to have inner panels? If so can you go crazy with a hole saw and then dimple the holes to regain some strength? Can you remove all glass? What about side impact door beams, bumpers etc?

I should imagine the car weighed around 4000+ pounds when you started and if you can remove a 1000 pounds you should be more competitive. Personally I'd put that power train in a lighter smaller car

Thanks! I hope it works out.

Yes, I agree this motor in a lighter, smaller, car would be the bees nees. however, my schedule will not allow me to do that much work between now and this year's challenge. Maybe next year. As far as reducing weight goes, I think I could easily get 1000 lbs out, but then that would likely murder the car's concours scores. I agree the thing would go like a bat out of hell though.

For now I'm trying to take weight out where it has little effect on overall look of the car, and I'd like to keep the functionality such that I can drive it to the challenge. However, I think weight melts quickly off big cars like this, so I might indeed have a chance to remove quite a bit. So far:

- 'dyna-mat' type adhesive insulation, 10 lbs (this is a lot of effort, probably not worth it, ha!)

- carpet, 65 lbs

- rear seat gutting, 50 lbs (i'd like to try to keep the seats)

- front seat gutting, 25 lbs

- exhaust system, 50 lbs (was 80 total, but something will replace it)

- rear bumper and hardware, 50 lbs (was 65 total, but again I will have to put something back)

That's 250 or so right there (all weighed with a bathroom scale, I hop on, check my 'tare', pick up the part, and hop on again), and there's lots more easy weight in the interior, doors, front bumper, A/C (still haven't checked to see if it even works).

I dunno if I will start skinning stuff, I tried the trunk lid, ended up taking out maybe 10 lbs, but now the trunk lid is really crappy and lost basically all function. I'd hate to do that to the rest of the car because I'm not sure its worth it.

Got both front struts done (the driver now matches the passenger). Here is the new stance. Interestingly, even after rolling the car back and forth to settle the suspension, it still didn't lower as much as I expected.

Still haven't driven it yet for an impression.

New stance.

I also got the exhaust back to I think how I will run it for the challenge, barring any issues. Basically I chopped the final muffler off, and replaced it with 2 straight 2.5 inch pipes.

Welds aren't great, but they will hold and I ran out of wire. I also decided to pull off the small heat shield, which I quickly regretted. More pics of the final install and a couple videos later on.

I've noticed that with the bilsteins they will raise the height on stock springs. Not sure why this is just that it happens. Might need to drive it around a bit and see if it settles any. Like where this is headed.

I have thought about doing the same with a early model A8 since my 01 S8 is pretty fun but is getting up in mileage and is still to nice to take apart.

BradLTL wrote:

Still no sound clip

For some stupid reason my phone won't upload to YouTube but it will to photobucket.

No exhaust

With exhaust

They are really crappy videos and really don't get the sound across well. But there they are.

At billy bc, thanks! I need to make good progress now because I have stuff scheduled every weekend in October, so I want to try and be as prepared as possible.

At brad 131, thanks, and do it! I'm sure an a8 would qualify to compete directly with the 7 and john's q in the 'aristocrat' class.

rcutclif wrote:

They are really crappy videos and really don't get the sound across well. But there they are.

That thing sounds awesome!

At bradltl, thanks! I certainly like it. Still think it has a bit of a miss going on right now. I think with some fresh gas that should clear right up. I can also ohm out the plug wires and stuff to check.

Made a lot more progress today.

Remember I grabbed a 3.64 diff from a junkyard a while back? Well I cracked it open today to have a look inside.

Yep. Not an lsd. Bummer. I thought all 750ils came with it but I guess they didn't. Oh well. So I took it apart to get the ring gear off.

The axles pop out easily with a pry bar, then you can unbolt the bearing faces.

Spin and pry to grab the bearing faces out of the diff.

Then the diff and ring gear come out, you can pop off the speedo wheel with a pry bar.

My electric impact blasted the bolts off no problem.

Put in gingerly in a vice, and then I used this cold chisel backward taping around and around the ring gear to get it to pop off.

Next, to remove the existing diff from the car!

Pulling the diff out of the car was pretty straightforward. Unbolt the CV joints at the diff, unbolt the driveshaft, and then unbolt the three mounting bolts. I didnt even have to move anything out of the way. Easy peasy. Except these guys (diff to driveshaft bolts). I had to run to the store for a new 17mm wrench because of the angle needed and mine are flat. Ended up not working anyway so I had to vice grip them. Oh well. Offenders.

Diff out.

Now that's what I wanted to see, a real clutch pack lsd unit. Too bad the ratio is 3.15. Maybe I can make one diff out of these two?

Apart, same procedure as the other one.

Apparently I didn't take pics of reassembly, but, i made sure to use the case that has the pinion gear that matches the 3.64 ring gear. I used some loctite on the ring gear to diff bolts just to be safe. I made sure to use the bearing faces that came from the matching case as well, and took care to even keep them on the same sides.

Even tapped the axles back in, but I left it there for the night. I will get some chalk to check the pattern tomorrow, but for now it feels good. I didn't check lash, but there is just enough lash that you can feel it, but I was hard pressed so see it (turning the input by hand slowly and trying to see the output not turn).

been working slowly over the week, had lots of time with the kid this week which makes progress slower (but is a great trade!)

Anyway, I got to the parts store and got some patterning grease, as well as some lube to refill the diff. Checked the pattern and it looks great. Apparently I didn't turn the input at a constant speed through the grease, but the 'ridge' near the base of the ring gears shows me that the pinion is making good contact with the ring gear all the way from inside to out. So I am happy. Will hopefully drive the car a bit tonight to see!

Also, I didn't buy a new gasket, I just used some RTV.

Popped the cover back on, and let it set overnight.

Last night I filled the diff back up with almost 2 quarts of 75-90 synthetic diff oil for limited slip applications. Finally I hoisted this beast back up into the car and connected the three mounting bolts. I didn't connect the CVs or driveshaft yet, I hope to do that tonight.

Don't have any pictures, but to get this thing up into the car I used a process I like to call the 'belly press'. Basically you slide the diff under the car, roll under next to it, spoon it, and then roll onto your back so it is now up on your belly. Then by taking a deep breath, you can use your belly to lift it up into position and you usually have at least one hand free to tighten the bolts. Probably not the recommended way to reinstall a diff...

bgkast

UberDork

8/13/15 12:39 p.m.

It helps if you nibble on the diff's ear while you spoon it.

bgkast wrote:

It helps if you nibble on the diff's ear while you spoon it.

I'll try that next time. ha.

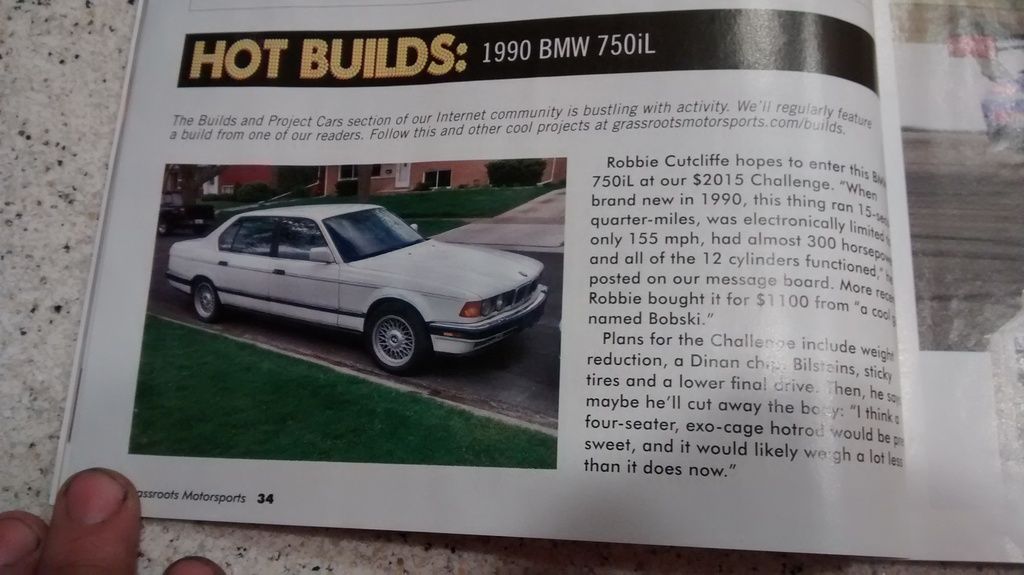

Not many photos but lots of work has been done. I did open the new GRM to see this though! Awesome!

I've been chipping away a little stuff. Lots of weight reduction work (gutting bumpers, dash stuff, wiring that I don't need), basically a ton of time to make little difference in the look of stuff and even less difference in the actual weight of the vehicle. I have no idea if any of this work will even help that much. I did take about 10 lbs! of speaker wiring out of the vehicle.

I also sent off for my title and registration and plates. I hope to drive this down to florida when the time comes!

Finally, I'm doing a bit of project management on it today. Essentially there are 8 weekends left between now and the challenge. EEEK! and, worse yet, I have family events planned on 5 of them. I do get labor day to myself, but that means I have basically 3.5 weekends left to get this thing going. And my todo list is big for 3.5 weekends.

Hopefully though, the only thing I have yet to buy is tires, so that is great news.

got the battery tied down appropriately last night.

While the car came with a battery, and the battery actually holds a charge, that is about where the good battery news ends. This battery is the wrong size (too wide and too tall but not too long), and the terminals are on the wrong sides. Conveniently, the car is also missing its original hold down hardware.

Since the battery is too tall and the terminals are on the wrong side, the terminals were dangerously close to hitting the under seat brace. So first thing I cut that out of the way a bit. Now there are plural inches between the posts and any other metal. Better.

Next I took a piece of the metal I just cut out to make a new hold down device. A little cutting, a little drilling, and a bolt from the pile of bolts I have already removed from the car netted me a nice piece. note the notch I cut, this will actually serve to help prevent the battery from sliding side to side as well as bouncing up and down.

Finally it is all bolted down and into position. Passes the grunt-test so far, but I may add a strap over the top to provide additional side to side support as well as a fail safe. Bouncing battery = bad.

Well, I got out to the Tire Rack saturday and picked up my tires and had them mounted. Had a little test fit yesterday with my spacers up front. I will need to grind my wheel bolt heads down just a tad to really get the spacers to fit, but it was close enough for a photoshoot.

245/45 16 hoosiers - ooh baby!

Also, while hooning it last weekend I tore up the driveshaft center support bearing. Oops. Guess its better to happen now. So I have the driveshaft out waiting for a new part.

And finally, the rear self-leveling suspension finally broke a second (and much larger) leak than the first. Now with the system leaking in two places, I decided to pull it out and find something to replace it with. I scored a pair of bilsteins with Dinan springs on them on ebay used off a 5 series. I ordered them up for $100. They come in tomorrow so let's hope they fit! (they should, but we will always wait until we know for sure).

I'm starting to get a little worried that you are going to beat me.

All of these Hoosiers, I am getting a little worried myself.

Looking forward to the final product.

Tires are free folks, time to sell your bubblegum cards.

Not that it makes a difference, but I am happy that you left the body on the car.

This is so awesome!

Thanks for all the support guys. I hope it turns out to be awesome, there are still a lot of variables in play.