So, driveline choices. I've been all over the map.

TLDR if you don't enjoy hearing my justification for what is basically an emotional decision:

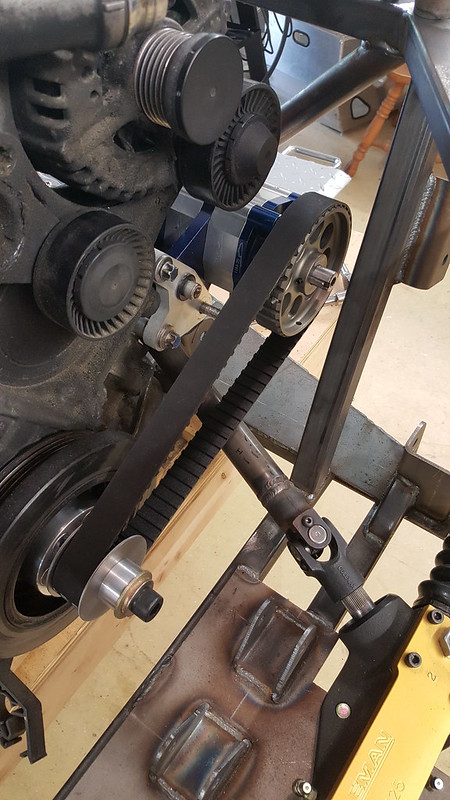

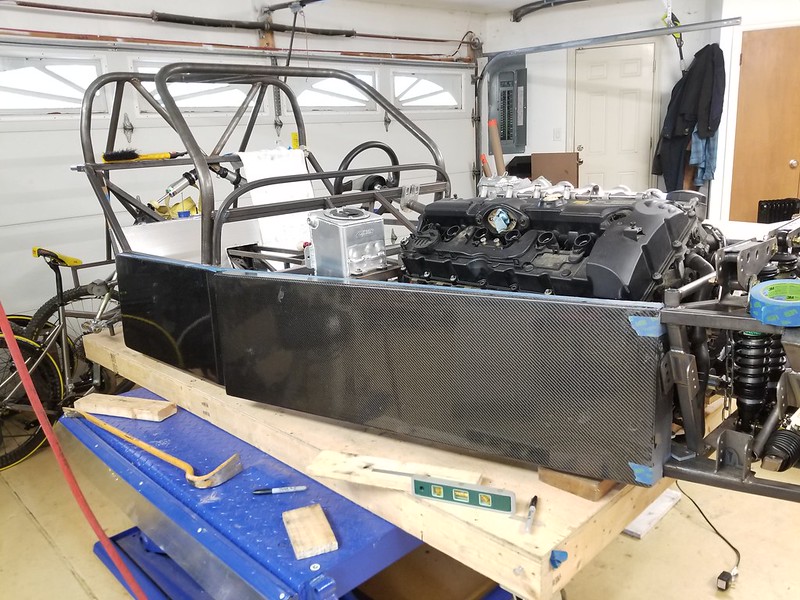

Car is going to be a BMW N52 running megasquirt with a Quaife 60G sequential box.

This car's primary mission in life is making me giggle on the way to work on nice summer mornings. Basically looking for a 4 wheel motorcycle (I have tried really hard to love riding motorcycles but just can't) That means the main metric for the driveline is a roll-on left turn getting just a *bit* sideways. Of course, it needs to do track days well but it's not a race car so there will be nothing to measure outright speed against, just has to be really fun.

I'll just get it out of the way and will accept no arguing about this part. It must have a sequential gearbox. That's about 50% of the reason for building it, I've driven a few sequential cars on the road and they make me laugh so much that it's a must do.

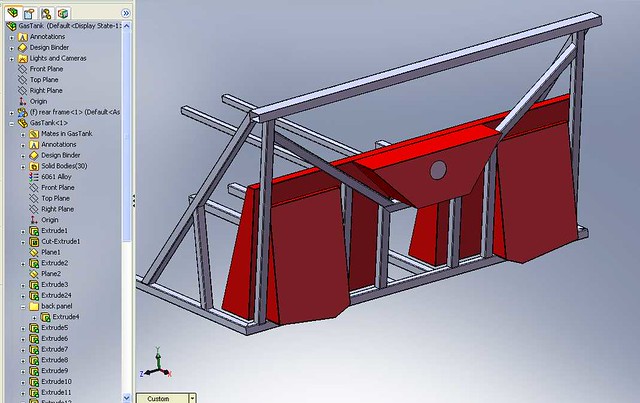

This is not cost-no-object but it's not a budget build either. Each piece needs to be 'right' from an engineering perspective but I can't go off the rails on money. Figure $10-12K for a complete driveline.

My day job puts me in the full spectrum of Corvettes and Camaros on a race track a few times a week so it also has to have some balls to keep me entertained. I am not in the category of people who, as the other 7 specific forums all warn against, will be "terrified by a couple hundred horsepower in a car this light." It needs to keep up with, and hopefully beat, a new Z06 from a HP to weight category. That means my goal is an even 300hp. The weight goal is realistically sub 1400lbs but the stretch goal is 1250.

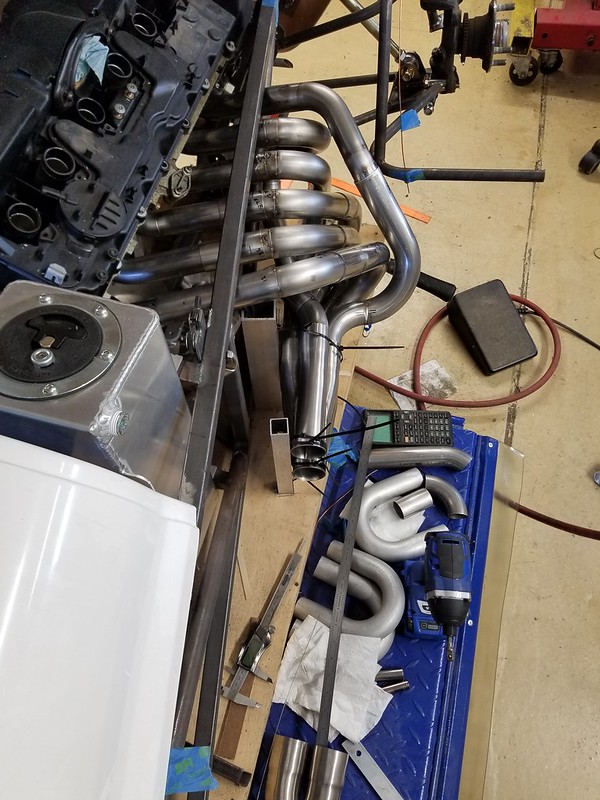

Also has to sound great, no normal 4cyl, sorry. Needs 5 or more cyl or a bike engine to get my motor running.

So, a few options here:

Hayabusa - the gearbox comes with the motor so that shaves huge cost and weight. However, 300hp out of a 'busa reliably is not cheap. Figure $10K driveline cost with turbo or supercharger, trick oil pan or dry sump, gears to make the trans ratios streetable in a car this heavy, etc.

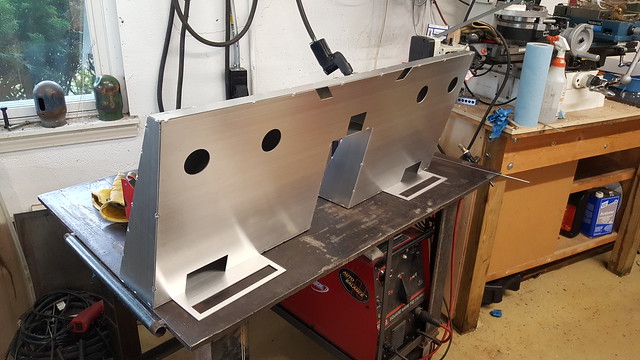

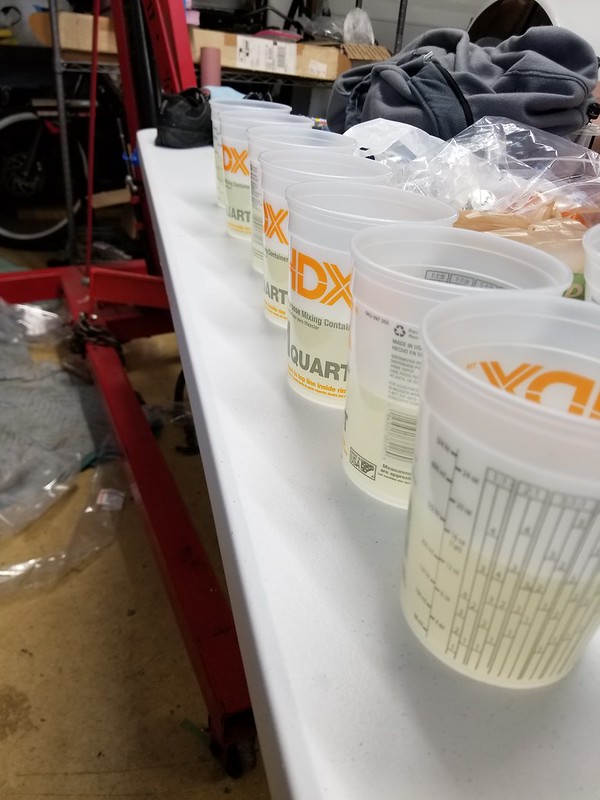

All car engines - nearly $8K cost of entry for the sequential gearbox. No way around it, I've chased every lead I can find for 6 or more years, you just have to pay to play. That means I need to keep the engine pretty cheap to make this option comparable to the 'busa on cost alone. The resale on the box is crazy good if I totally F this up and decide to bail at some point, even after it's complete.

My target, again, based on LT4 powered Corvettes and Camaros is ~0.9G in 1st for that squirmy back end feel we all love and 0.6G in 2nd for that smooth left turn roll-on oversteer without being unmanageable.

Here's what brakes the 'busa option: It only exceeds 0.4G above 50mph in 1st gear. It easily makes the 0.9G target eventually but you're doing 60 by then. I just don't see this being a fun car to squirt away from a stoplight. Of course, you can clutch it and launch like a bat out of hell but that's not what I'm going to do leaving my neighborhood at 7:30 in the morning. I'm saying I want torques. I'm also really skeptical this can be a reliable package.

LS is out. Love the motor. Best power to package size and weight going. I just don't need that much power. If someone made a 3.5 liter LS7 that was half the weight and power I'd be all over it. A full size LS would ruin this car. Someday I will build a car for a really nasty LS, it's just not this car. Also, the engine plus the sequential is way over budget.

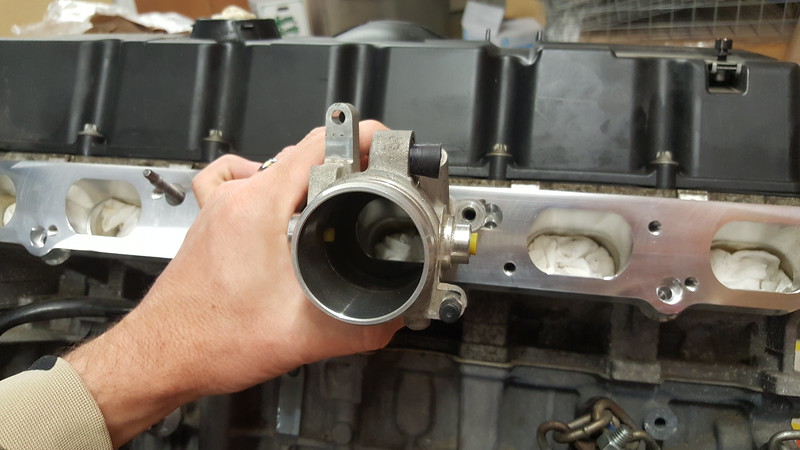

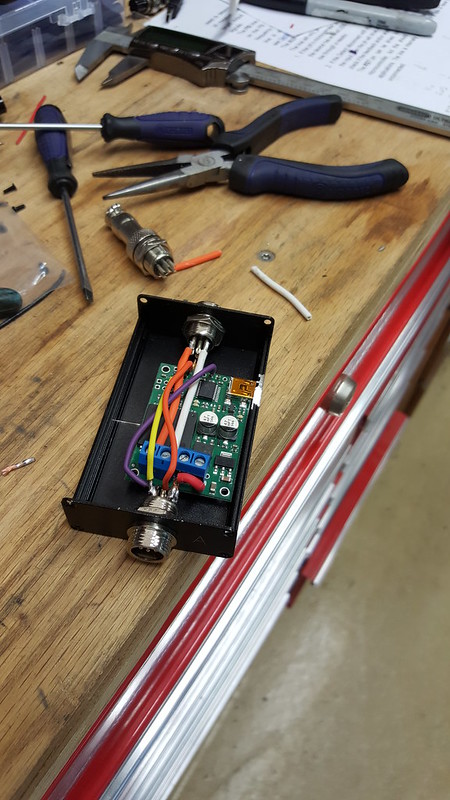

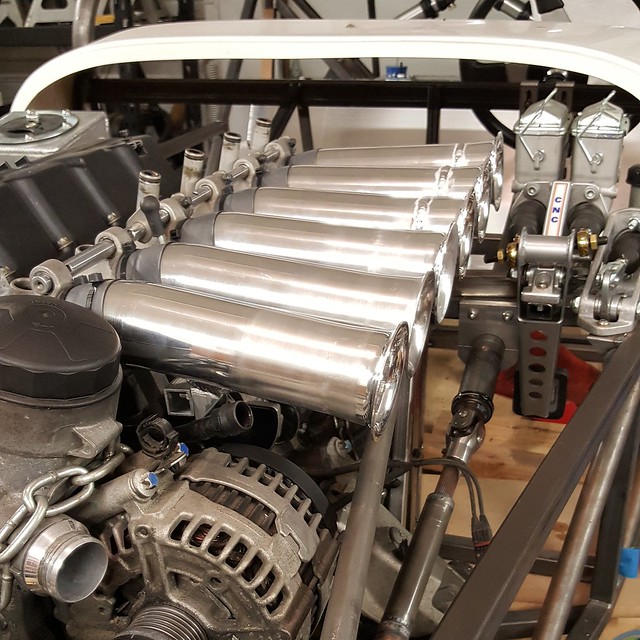

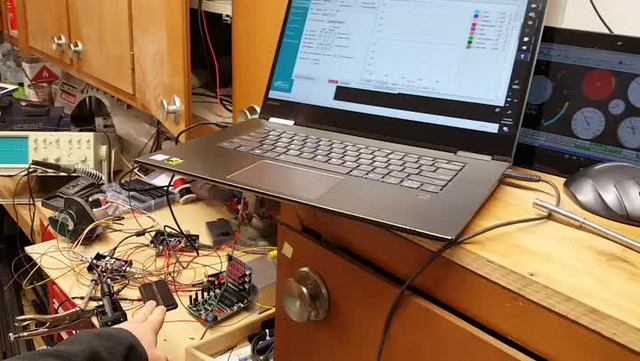

I've settled on a BMW N52. It's their ~2006-11 straight 6 naturally aspirated. Co-cast magnesium and aluminum block and reasonable strength parts make it sub 300 lb for a 3.0L six. That's a pretty awesome deal, basically nearly the weight of a typical aluminum 4cyl. They're also cheap since everyone wants the N54 with boost. I am very comfortable with megasquirt so I don't need to worry about BMW engine management. MS can run dual vanos, electric water pump, variable oil pump, etc. Locking open the valvetronic is pretty well documented already. Also, I love the sound, probably more than any other option here.

I'm anti 4 cylinder turbo just because I already did a big turbo 4cyl for my Volvo. Doesn't seem like the motor I want in this car and there's nothing new to learn there that I'm not already learning in the Volvo.

I was actually in England when they 'Brexited' so I called up a Quaife dealer that Wednesday when the pound was at it's lowest and ordered the 60G gearbox with helical sequential gears and the BMW input shaft/bellhousing. Scrap yard N52's are between $1500-1750. Done and Done.

Alex

![]()