Ordered the 2.8 style mounts shortly after the last post, and got the chassis mounts from Rock Auto. I need to check the numbers, but I think that they'll actually save me some money in the budget. Parts arrived on Friday, and I started in on the truck on Friday afternoon. Weather was bad, so I couldn't open up the garage and get more work space.

Since I had problems trying to do a hybrid of the JTR instructions and forum build, I'm trying to stick closer to the book build now. First thing I did was a little extra bashing in of the firewall near where the passenger exhaust manifold will go:

That should allow the exhaust to fit fine.

Saturday was a bit more productive. First things first, one of the local junkyards had a 50% off sale, and I still have some parts I'm looking for, in addition to maybe needing a few things I may have broken. Met up with Ashyukun, and we set off in search of parts for our respective challenge cars. I lucked into an old pre-refresh square body S10 there, that had the grill/bezels/lower grill trim mostly intact, so I snagged them, since I like them better then the later grill. May or may not show up at the challenge, but it's nice to have them in my stash. I also found a 350 TBI air cleaner lid, which will allow for a larger air filter, and grabbed a distributor off the same truck, in case mine was broken in the earlier engine removal. Ashyukun found some decent wheels, and some really ugly ones, too, thankfully he didn't buy those.

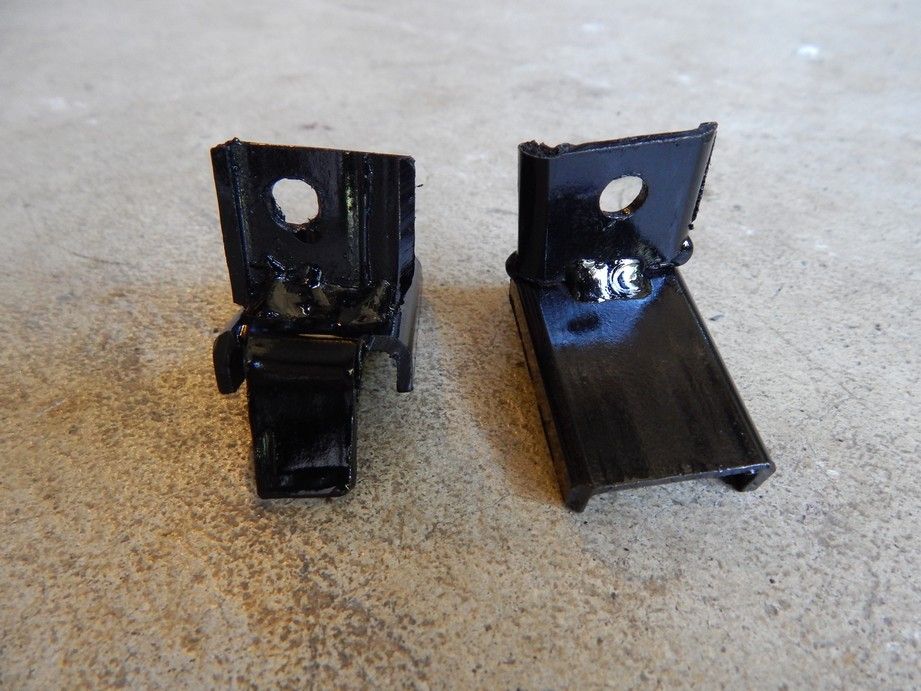

The mounts were unpainted, so I cleaned them up and rattle canned them in the backyard:

I also started modifying the transmission cross member, first removing the lip at the front of it:

Enlarged the hole the trans mount goes into, to allow for the drivetrain to be shifted backwards and/or towards the passenger side (and quickly spray painted it):

While the paint was drying, I attacked the original V8 mounting plates. To install the passenger mount, I had removed the front right suspension. This time, I passed, and took a 1.5" hole saw to the crossmember. It worked excellently at allowing access to the hardware holding the mount in.

Sunday was time to get the engine in, come hell or high water. Still had a few little things to wrap up before it could go in. The firewall needed a new hole for the engine harness:

Later, I'll use some metal from the fireturd's hood to close up the original hole.

I debated moving the steering column a bit, and decided to leave it in the stock location for now (more on that later)

The 2.8 mounts went on fairly easily, especially with the newly drilled hole in the crossmember. The holes for them were in the exact same place as the 4.3 frame mounts were:

The adapter mounts simply bolted up to the 2.8 frame mounts. They are at least .75" shorter than the V8 mounts were, with the 45 degree angle they should drop the engine at least half an inch from where it was, and probably more:

I don't think they are as strong as the V8 style mounts, but the added adjustability is worth it. Strength should not be an issue on an engine as low powered as mine.

To prep the engine, I pulled the knock sensor, inspection cover, and starter, in order to get a little more maneuvering room, then got to work. Here's an engine's eye view:

It took some help from my wife, but we managed to get the engine installed:

In order to make adjusting the whole assembly easier, I reinstalled the transmission mount and crossmember (though the driver's side bolts need to be tightened, I'll consider this a reminder). We adjusted it so everything should fit, but the oil pan is very close on the passenger's side, and the steering column is closer than I'd like it to be. From reading, I can probably still adjust it over at least 1/4"-3/8" just notching the bolts that hold it to the firewall, and will probably do that. Also, some people shim the front bolt of the power steering pump in order to get a little more space. If I do either of those, I might slide the engine over a bit more too, to help the oil pan clearance.

Next steps will be to do a rough toe alignment, so I can drop the front end off the cheap harbor freight wheel dollies. They do fine moving the front of the truck around when it's just a roller, but the added weight of the engine makes them a lot less useful.

After that, weather permitting, I'll pull almost everything out of the bed, start cleaning and organizing the garage, and get everything to where it can be worked on as needed. Tons more to go, but it's nice to finally feel like I've made some progress.

![]()