Well, my weekend went by quick. After tearing out the engine harness and degreasing that side of the bay, the body harness looked at me with puppy eyes and begged to get torn out as well. Far more wiring than I really wanted to do. But the simpleness of deleting the solenoids up near the bumper will be so pleasing to me. It was too cluttered. The major pitfall of doing this is basically that everything on the harness is tied together in some fashion. I think Mazda were trying to even out the weight distribution by adding massive amounts of wire in the front half of the car. I will be "simplifying" it by using 3-way switches flasher cpus and momentariness. Thankfully, this is essentially my autocross car and occasional weekend or work drive car so. Really didn't want to do but, oh well. I guess I'm not really to the point of no return on the body harness yet. I've only cut off the headlight retractor plugs and a couple others that were never plugged in. We'll see how far I'm willing to go with it.

Oh boy...

Well, the quest for more power continues and the saga thickens. My boss gifted me a Borg Warner S300 66mm compressor core. Of which I ordered a .91 ar exhaust housing so, now I'm waiting for a good deal on a compressor housing. Slowly but, surely collecting parts. I picked up a 3 foot piece of O1 tool steel and made my own dowel set. Some people/ companies use A2, which has the same exact hardness rating as O1 however A2 is wear resistant, which is unnecessary for what they are doing, and a little more costly. The 3 foot piece was only 16 dollars where A2 would be 30 for 1 foot. 16mm OD @ 9.0625" long (230~mm) for those who are wondering.

Also in the works, is the ecu panel. It's pretty much at a stopping point now until it's in the car and the engine is in so wires can be routed and landed where the need to be. The more I look at the mess of stock wiring, the more I want to rip all of the old wiring out and start fresh. For now, I am focusing on the engine portion though. Once that is pristine, I will consider more wiring. The wiring layout on the panel is really subject to change as I'm not 100% certain which way I want to go yet. One thing is for certain though, all of the grounds other than the ecu will be grounded to a copper bar instead of the chassis. Still things to play around with and get it exactly how I want it.

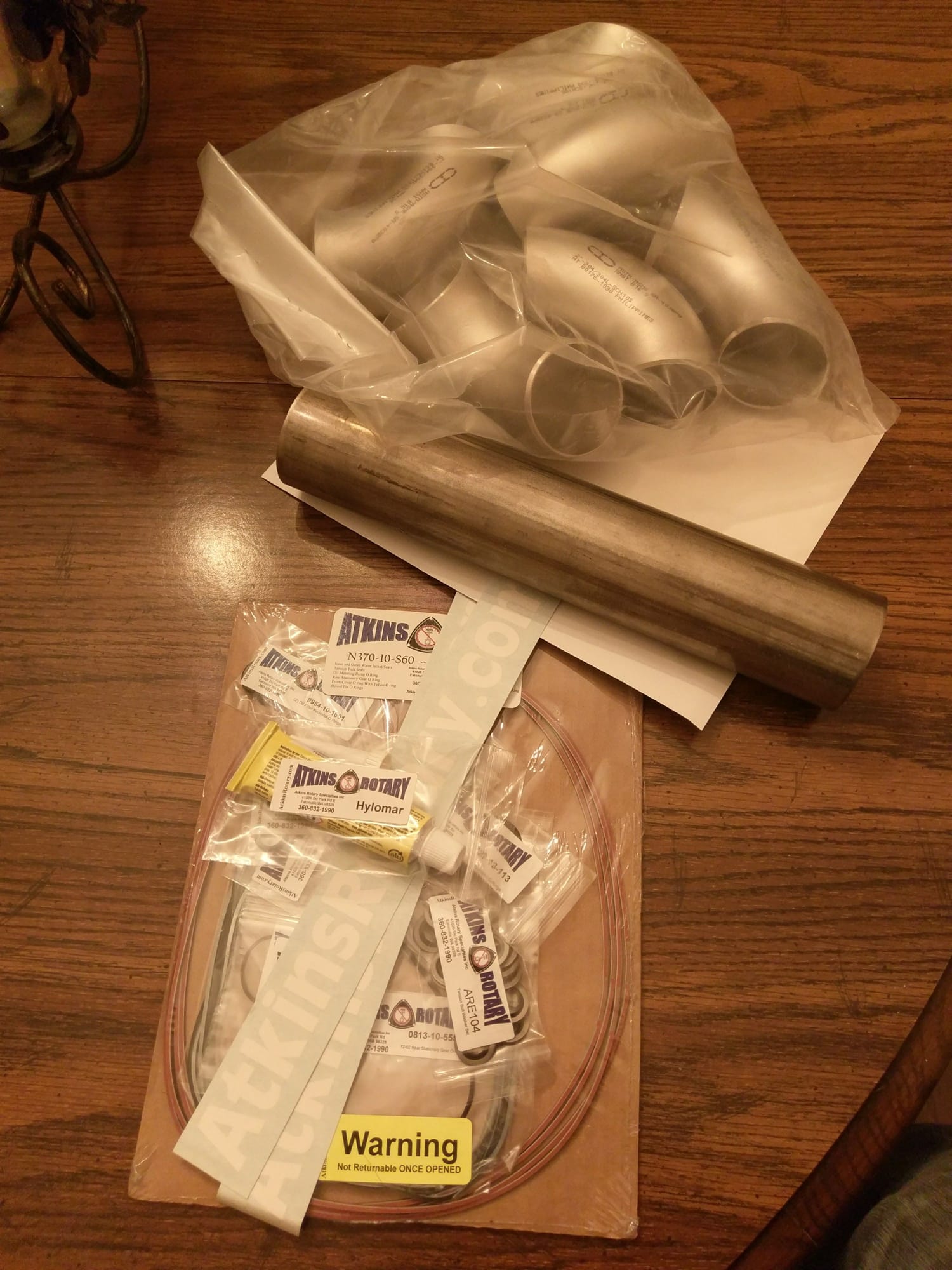

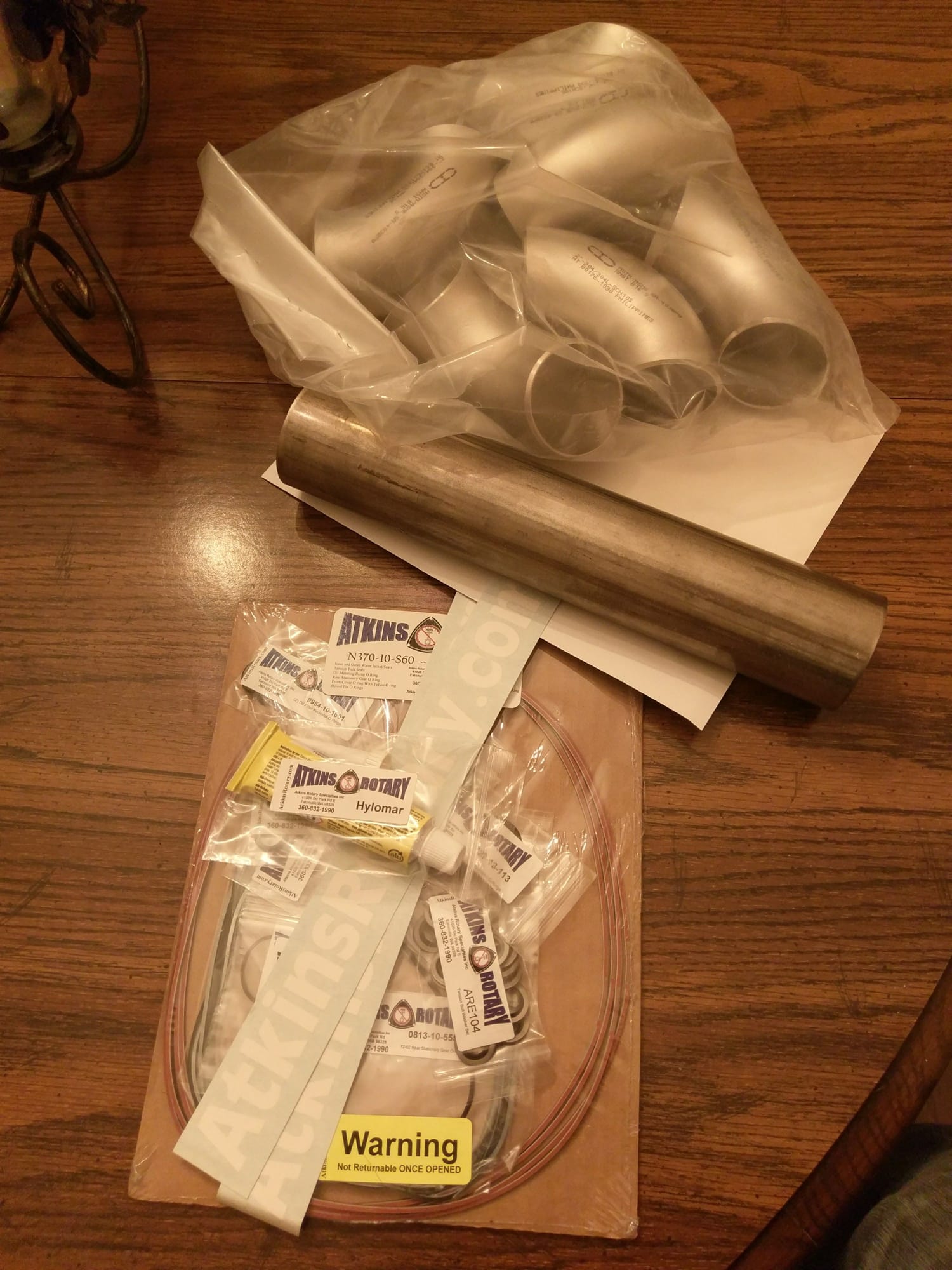

The make your own manifold pipe kit (just an array of 90s and a straight piece and the header flange and turbo flange) is on hold until the engine is assembled and installed. The pipes were a steal from one of my work vendors at $36 total. You'd be well over that using McMaster or other online vendors.

NICE!!!! but a few things...

Cleverfrog said:

So, I guess my thread will become another one of those "Hey, I'm looking for 300-350 Hp to the wheels" threads. I will try to be more mythological and methodical than some. My plan here is to have my s5 turbo front and rear irons lapped with the s5 NA iron (as the NA and TII irons are identical according to my limited research). I will be reusing the eccentric shaft from my NA engine, purchasing either FD or FC rotors (they are also the same), doing a custom exhaust and turbo manifold, I will be doing a bumper delete sort of and a center exit exhaust, 750 secondary and 550 primary RC engineering high impedance injectors with a walboro 255 pump, custom fuel rails and lines, TII intake manifold, try my luck with deleting the BAC (I know it's nice for idle if you don't know how to tune for it), BorgWarner S360 turbo, not sure yet if I want to do a v-mount or a front, all ready have been working on the megasquirt ms3x, raspberry pi digital dash, I would also like to get everything rebalanced (perhaps to go above 9k rpm for future endeavors), probably more stuff I can't remember at the moment however, that's most of it. There's still a lot of researching and purchasing to be done. I also am working on my own custom engineered dual element rear wing. I've put a lot of time into flow analysis and have a great profile ready to be shaped with carbon fiber. This is purely a fun weekend/autocross car. The goal is to have a relatively quick turbo response time so I'm not blowing the tires off when boost hits. All of my research is showing that the s360 should be the perfect size and cost for my goals, same with the injectors. Is there a better way to achieve what I want? Probably. It's all about the knowledge and learning experience for me though. I am a very DIY oriented person. Loads and loads of work and updates are coming.

If you're getting everything balanced, consider going to an rx8 e-shaft swaps right in and is about .6lbs lighter with better oiling properties. plus it comes loaded with the pilot bearing which is a bitch to change, even with the right tool. They are sub 200 NEW from mazda and its billet piece - pretty incredible. If you want to spin it past 9 I would be clearancing the rotors too but your intake manifold is gonna limit your power peak RPM it may not matter, above 8500 you want carbon apex seals the steel ones are too heavy and if you're gonna go that right go full bridgeport lol but that's a slippery slope.

You have turbo irons but NA housings? you need to ditch those exhaust diffuser inserts and go with the turbo ones.

I HATE atkins rotary their custom service is terrible and their in house products are garbage their solid corner seals wouldn't fit an OEM new apex seal without filing it. I refuse to buy anything from them, however you are just buying OEM parts so not so big of a deal I would recommend pineapple racing for things like this, those guys are great.

Can you make me a dowel set in the future? I'm tempted to do this for the next build and run the oil externally from F to R iron.

RX8 e-shaft is more susceptible to flexing because of the method of weight loss mazda used. I looked into that a bit. I don't think i will balance everything simply because I am keeping the NA rotors. High compression = better response... yet it really needs tuned correctly to not explode. The housings I was just using as mock up to check fit. I have turbo housings. I've not had any issues with Atkins at this point. In the future I would switch to Goopy apex seals. I've only read good things about them. I'm still laying out plans for things so, everything is still subject to change.

I could make a dowel set. Or you could order the bar stock from mcmaster for cheap and cut it with an angle grinder and an abrasive wheel. Just have to go slow.

Still playing around with mounting and angles but, the coolers are in the rough location that I want them in. I found an RX7 FD manual gearbox for so cheap I couldn't pass it up even though the FC T2 boxes are said to be better. They want too much for those. So, I need to get an FD clutch (possibly a lightweight assembly with counterweights etc) and some other parts plus an odd ball driveshaft. Also thinking that for the rear end a ford 8.8 LSD will be the best option for the power. Fuel injectors have been sourced from detschwerks and are 1200 primaries and 1800 secondaries. With a walboro 450 pump I should be able to hit 5-600hp in theory. First priority though is finishing up the cooler mountings so the engine bay can be primed and painted before moving on to assembling the bay. Just wish I had a bigger garage. Good news is that the megasquirt was bench tested and works through the raspberry pi just perfectly and I finally got my gps code to function so speed can be shown now. I'd rather use the ford 8.8 speed sensor over gps but at least I have a back up now. I have too many things I'm thinking about right now and just need to start knocking them off one by one.

Long overdue unwarranted update.