Since I'm still an amateur, I took quite a while to put on the hoses since I tightened the clamp on the hose a little too much.

I also struggled putting the airflow tube for the alternator since everything is a tight fit with everything in there. I'll probably put the fuel rail cover back on tomorrow or Sunday, but it can stay off for now. Is it normal for the injectors to not snap or slide in place? They didn't slide down in place like they did before.

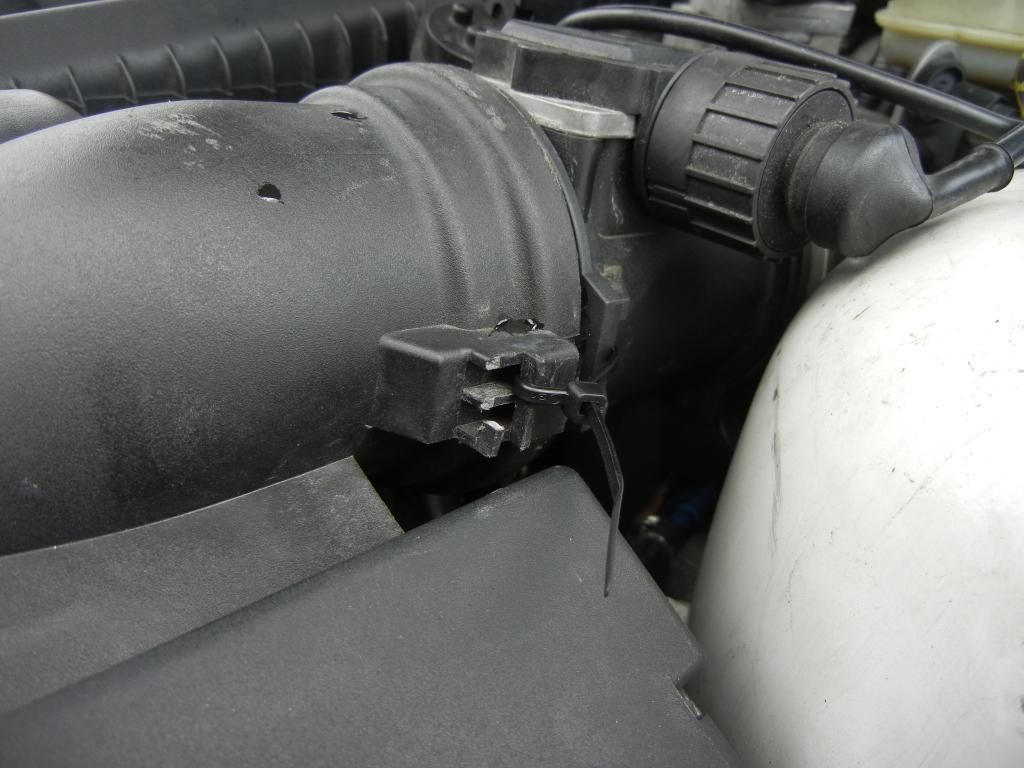

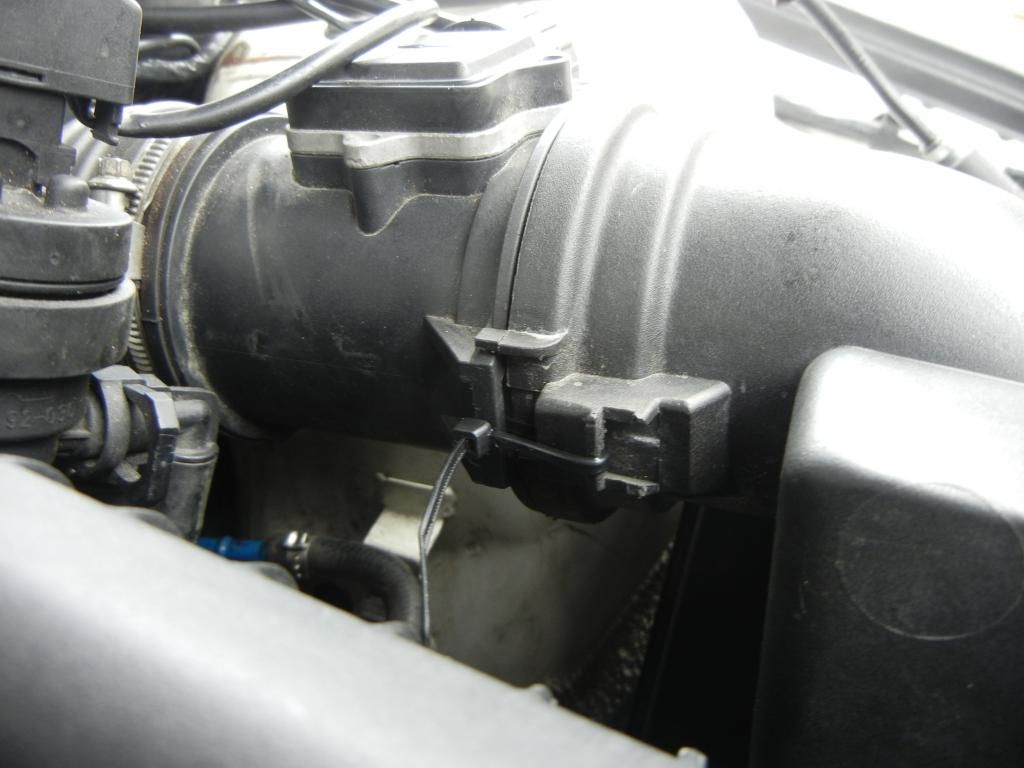

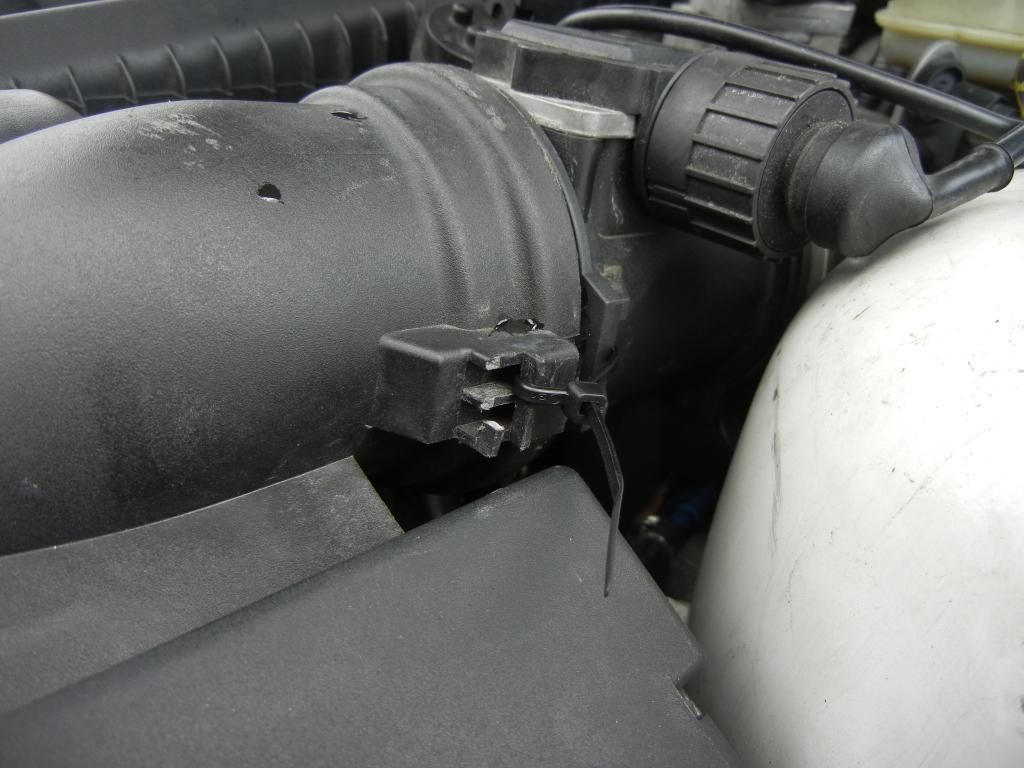

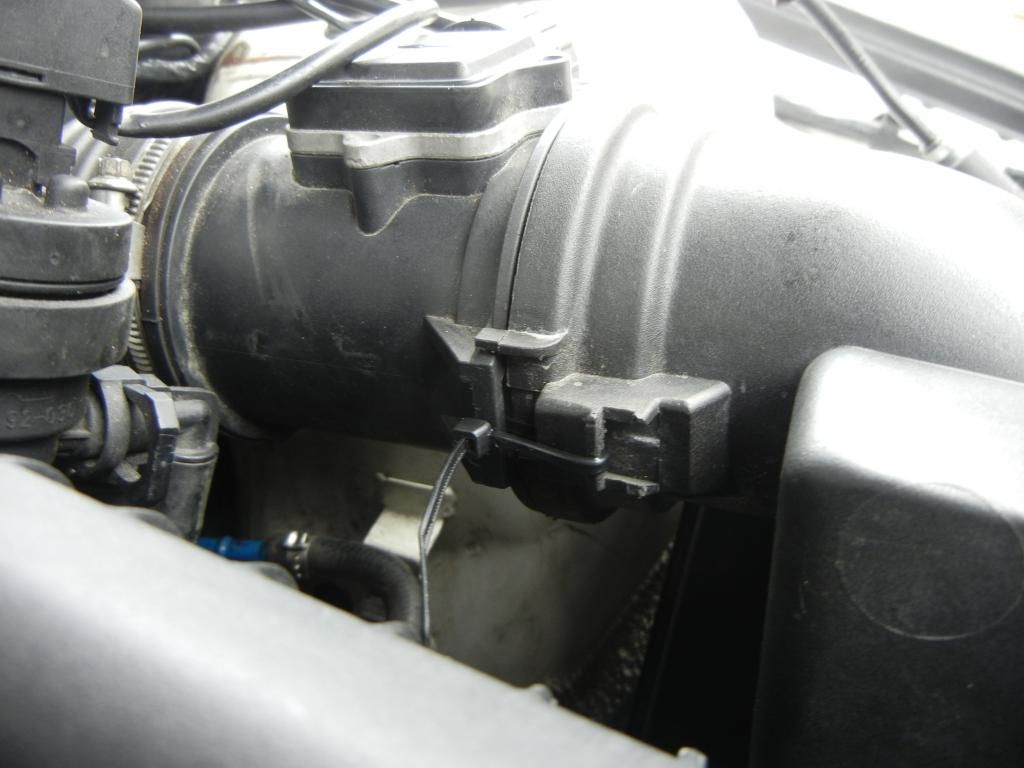

Also, the plastic broke on the factory airbox.

I know, I know, it won't seal the airflow like the clamps did. If this doesn't work, the junkyard may have one.

Way to go on the work so far! It's hard when something is so new, and my hat's off to you for doing the work in a driveway. Keep going, you're getting close.

Thanks. Small update now. I checked the weather yesterday and it said I'm going to have scattered thunderstorms for 4 days straight so progress will be limited. I'm glad I got this far with the weather. I also checked my local junkyards and the closest two didn't get another 328i in so I'm most likely going to need to get a welding shop fabricate me a transmission support bracket.

Two things....

1) Which tranny mount do you need?

2) Did you try car-parts.com, rockauto.com or fcpeuro.com?

I just re-read the entire post. Ive checked the local lkq and they have 3-525s but I'm not sure if they use the same support bracket. I can prob check to see if they are actually still on the cars sometime this week if you need me to. Let me know.

EDIT>>> Found it on ebay and a few places, but the price is about the same as this dealer....

http://parts.bmwofsouthatlanta.com/products/Cross-member/1285223/24701136499.html?partner=googlebase_adwords&kwd=&origin=pla

I'm going to assume that the 5 series cars don't have the same transmission bracket since the chassis is different (bigger) than the 3 series car. Also, the 2.5 liter engines use the other manual trans I believe, the 328i and the M3 use the ZF transmission. I checked a 325i at a junkyard and that trans bracket is different, but it was also an automatic, which didn't help at all. I wouldn't expect most vendors to have one since they don't get broken very much. Thanks for the suggestion, though. I completely forgot about ebay, which isn't good. And to clarify, the part I broke isn't called the mount, the rubber that insulates the trans from the bracket is called the mount.

In reply to Mr_Clutch42:

Understood. It was a long shot, but it doesnt hurt to ask. The link that I sent had the actual aluminum bracket for sale. It was around $40 if I remember correctly.

Another small update;I went to a local welding shop and drew them a picture of the bracket just in case they needed one. I also left the broken bracket there so they can get accurate measurements to make a steel version of it.

There's one on ebay now so I may buy that one if I need it.

I need some help now. I was trying to start my car yesterday and I forgot to put the clutch slave cylinder on the trans. So I put the spring and cover back in the cylinder, then mounted it on the trans and the clutch goes straight to the floor. Today, I get a one man bleeder system and open the bleed screw so I can bleed it. The pedal just keeps going to the floor. Then, I take it off, and the inside cover came out instead of pushing against the clutch fork. What do I need to do so it's pushing the clutch fork?

In reply to Mr_Clutch42:

OK, so... you pressed the clutch with the slave hanging under the car? That pushed the piston out and possibly blew the seal. Lucky you didn't do it while it was sitting in the hole or you would be removing the trans to retrieve the piston!

In any case... if you didn't tear the rubber to shreds, take the slave off and re-assemble it. If you did - buy a new one. Push the piston back in, depress it ALL THE WAY and stick the line into brake fluid then release it. That will suck it full so you only have to bleed a little.

Re-attach the line, tip it so the bleed screw is up, rap it a few times to jog the bubbles loose then insert it and make sure the piston is in the divot on the fork before you tighten it or attempt to depress the clutch.

Bleed clutch. When you do this - press the pedal down slooowly. Draw it back up from the floor... slooowly. when the screw is tight... pump, pump, pump.... then do it again. It should take about 5-10 cycles to be sure. The pressure bleeder won't work as well as a buddy in this case.

When I check to see if the piston is in the divot, is the divot supposed to almost touch the hole? It's about 2.5 inches away.

The measurement is from the middle of the divot.

Here is the piston.

Here it is back in the slave cylinder.

I never did bleed a clutch slave cylinder before.

Mr_Clutch42 wrote:

When I check to see if the piston is in the divot, is the divot supposed to almost touch the hole? It's about 2.5 inches away.

The measurement is from the middle of the divot.

The measurement is from the middle of the divot.

That is about right. To make sure it's in - just make sure the piston is straight (it can sag a little and miss) and you go straight onto the threads. When it's right, you should have to compress it a bit to push the slave all the way in place - it won't just slop all the way to the bottom of the thread depth.

Mr_Clutch42 wrote:

Here is the piston.

Here it is back in the slave cylinder.

Here it is back in the slave cylinder.

I never did bleed a clutch slave cylinder before.

I never did bleed a clutch slave cylinder before.

There is supposed to be a rubber cap/bellows in there. I think it will work fine for a while without it but - I'd buy a new slave soon if you can't locate/re-attach it because clutch dust is fine and semi-metallic and it will be getting in at the walls. Who knows though... might work forever. It's easy enough to change on jack stands - so try it. Worst case you have to drop $35-50 when the pedal won't hold a bleed anymore.

I have the cap for the bleed screw. I proceeded to bleed the slave cylinder like this.

I pressed on the cylinder with a wrench since I had already tried to use the clutch pedal with bad results twice. It was ok, then I put more brake fluid in the cylinder, and probably another 12oz bottle of brake fluid spilled out before I put it back on the car.

berkeley!! I need to bleed it again!

When I went from the dual mass flywheel to a solid one and changed the clutch configuration like you have, I had to use an M3 slave cylinder. I don't know if you're in the same situation but it may be worth looking into. Mine was on a 318ti with a UUC flywheel and a combination of M5 and M3 clutch pieces sold as a kit by Understeer.com.

It wasn't the cap I was saying was missing - look here in this pic.

There is a rubber membrane that protects the internal piston from clutch dust. There is also the ram with the plastic tip (which I assume you have... but is not shown in the pics - and when you pressed the clutch pedal you blew it across the room). The rubber also helps to support the ram from falling out while you position it on the fork. I think you could use the slave w/o the membrane but:

- dirt will score the walls over time and cause it to leak (maybe not?)

- you will struggle not to drop the ram into the bellhousing during the install

Huge thanks for showing me this. I am missing the rod with the rubber membrane on it and that explains why it wouldn't reach the clutch fork. For some reason, that rod was missing when I took the slave cylinder off the trans. I forgot to look at pictures of new slave cylinders.

In reply to Entropyman:

I just bought a standard kit that converts the clutch and dual-mass flywheel to a standard flywheel and factory spec clutch. I didn't have the moneys for a pricey lightweight flywheel and high performance clutch. Plus, those mods would technically put me in D Street Prepared instead of G Stock.

I just placed an order for an OEM Clutch Slave cylinder. Due to the holiday tomorrow, it will take another day to get here.

Another small update;the welding shop didn't start on my bracket yet. Damn! He said that it would be ready later today or on Monday. There is also a hurricane that is going to hit here sometime in the early evening.

oldtin

UltraDork

7/3/14 10:28 a.m.

if i didn't come out with the slave, the rod is probably laying inside the bell housing - if there's any access, tape a little magnet on a piece of welding wire and fish it out.

Mr_Clutch42 wrote:

Another small update;the welding shop didn't start on my bracket yet. Damn! He said that it would be ready later today or on Monday. There is also a hurricane that is going to hit here sometime in the early evening.

Take care of yourself. I hope that this one stays out to sea and we only get alittle rain. I'm from Greenville and still have alot of family there. We didnt get any major damage during the last one at any of our houses, but I got stuck down there for a few days w/o power. Not fun w/ kids.

I was actually wondering where the rod was, since I didn't remember seeing it when I first took it off the trans. When I was putting stuff up for the hurricane, I found it under the car. I'm not so sure it will work, so I'll still use the new one when it comes in.

In reply to mrwillie:

My boss wanted to hassle me some for calling out, which I hate. I live close to the coast, and I work much closer to the beach. My neighborhood has some elevation to it, so we very rarely have flooding, and we have light property damage and debris.

In reply to Mr_Clutch42:

Good. "High" ground is a good thing. I know people whose property is so low they have to move their cars during a heavy rain.

![]()