Turbine said:

In reply to 95maxrider :

Roughly 5 psi or so. My gauge doesn't have any divisions below 10, so that's kind of a rough estimate.

Based on the results of the mechanical gauge and oil analysis, I might just have my tune revised to raise my idle to 750 RPM or so.

That's a good idea. What did you oil analysis show? I'm about to send a sample in myself. Unfortunately for me, me idle is already set to 900. I think that had something to do with the single mass flywheel, but I can't remember at this point. Maybe I'll go back to running the 15w-50 that the previous owner of this engine said he used. The only brand of 15w-50 I could easily find was Mobil 1, what do you use? I wonder if the 10w-60 stuff for E46 M3s would be of any use.....

Josh- I missed your question earlier- no, no bearings have been replaced on this engine that I'm aware of. I considered doing it before installing the engine, but decided against it since I have absolutely no idea what I'm doing.

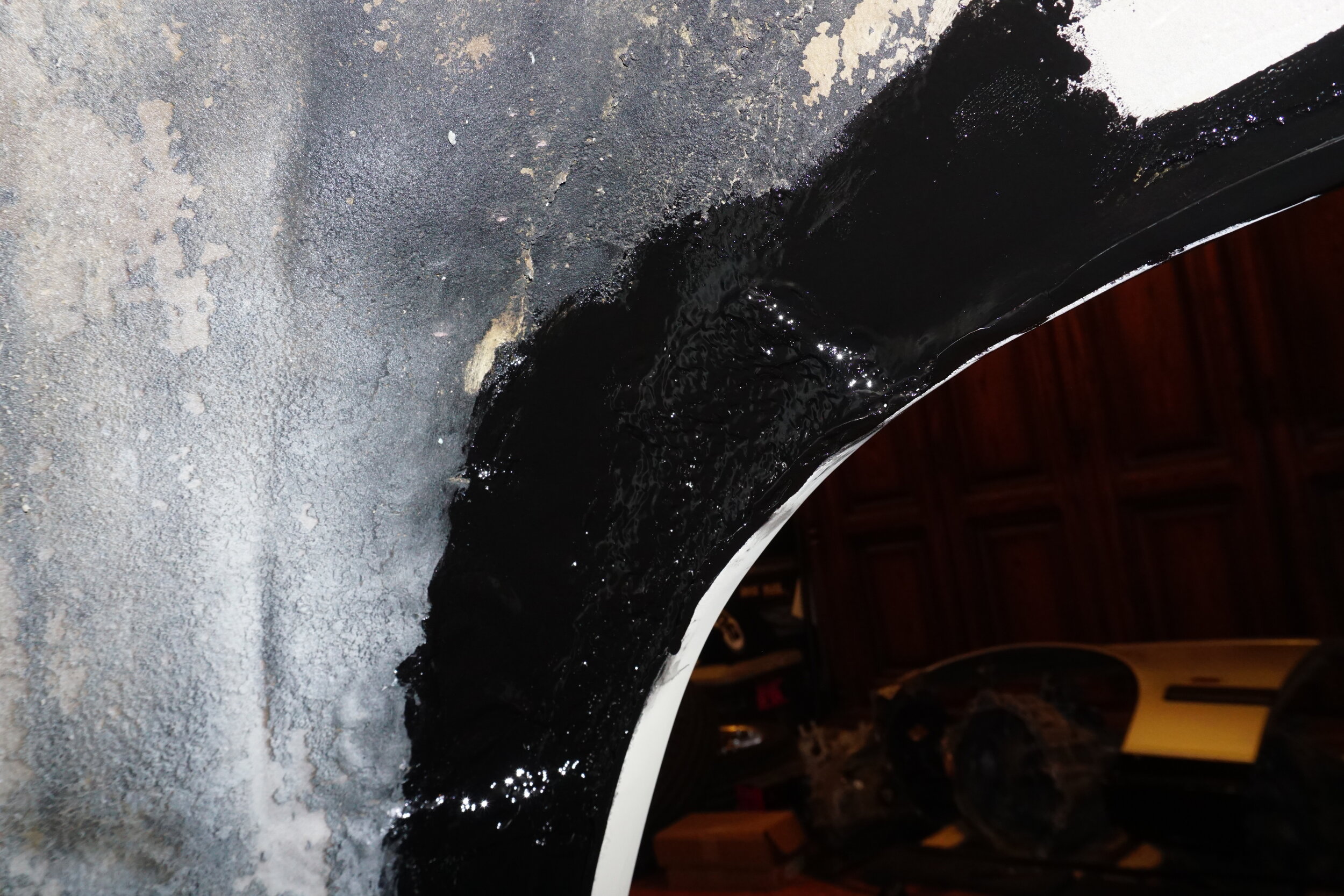

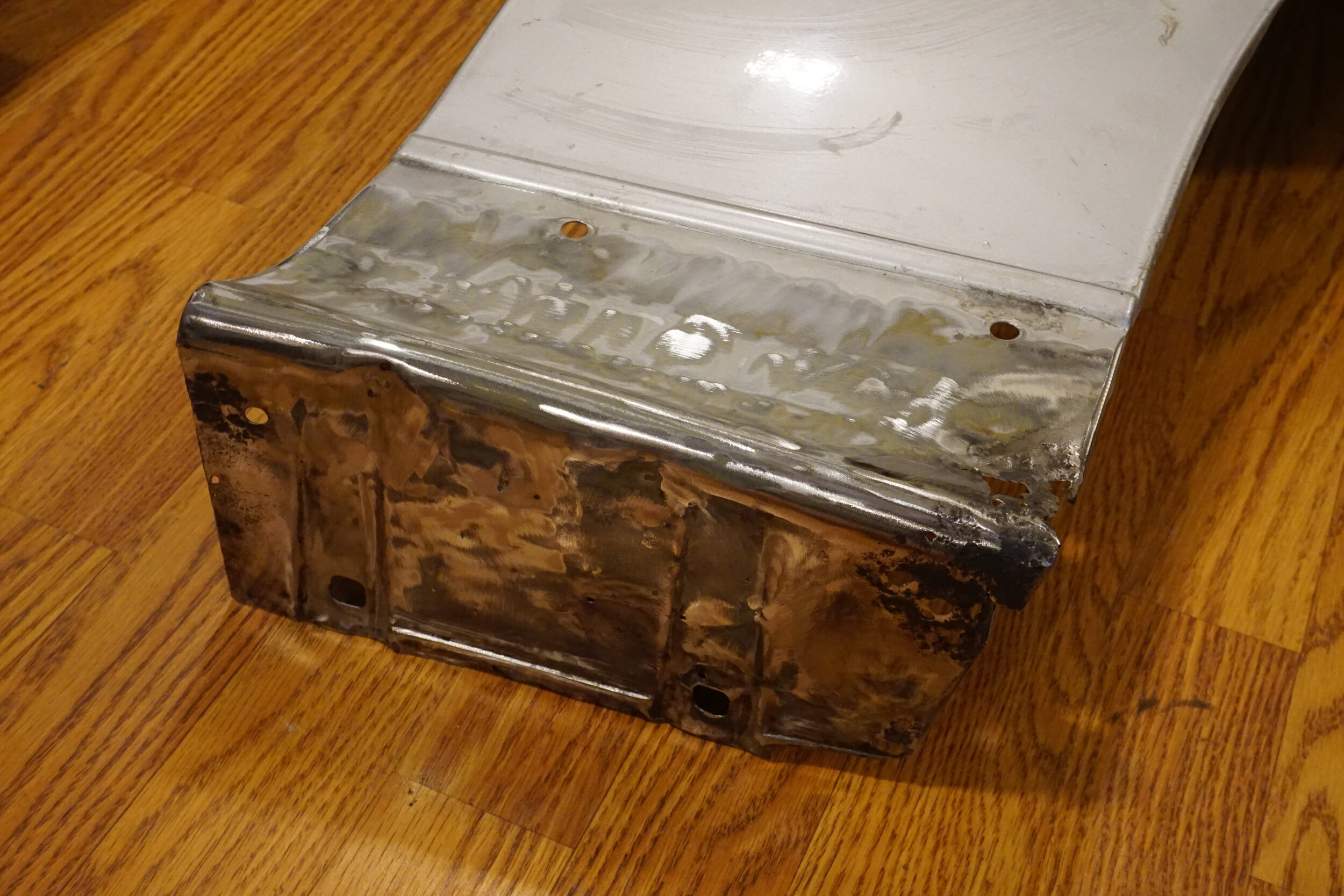

Catching up on things a bit, I put in some fresh fluids. Is it normal that my diff fluid always comes out looking like this even after only like 3,000 miles? I've got an upgraded triple clutch plate LSD.

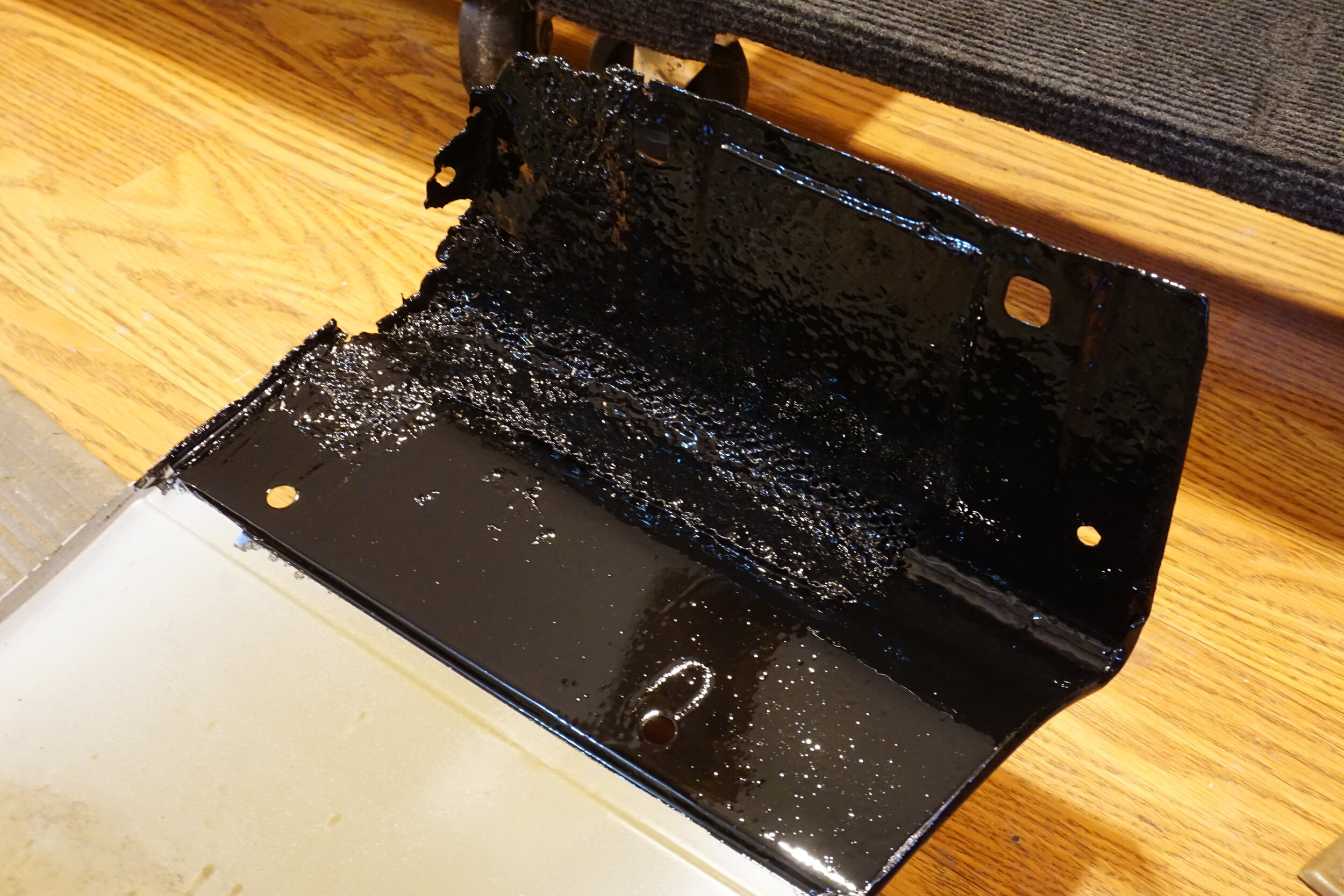

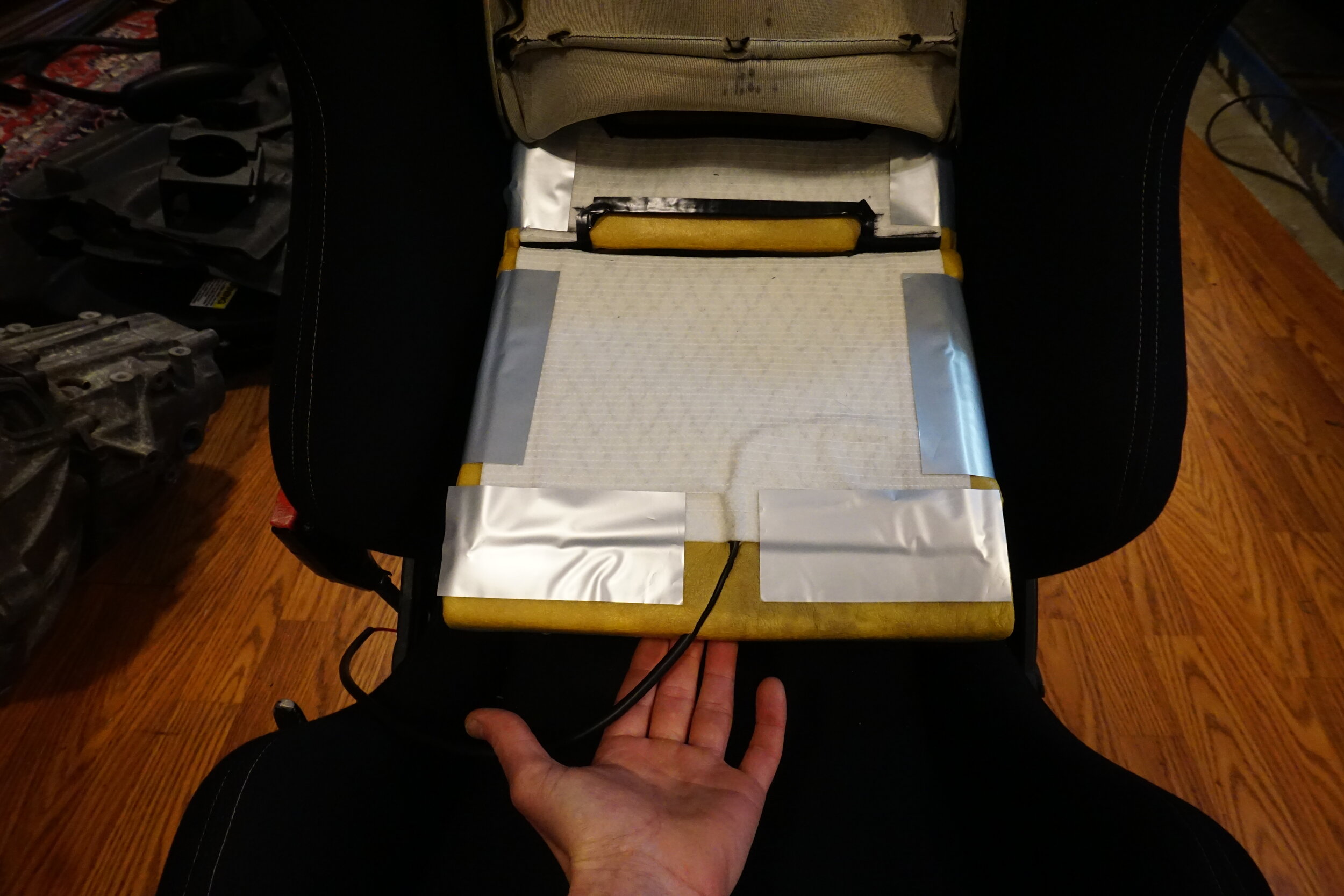

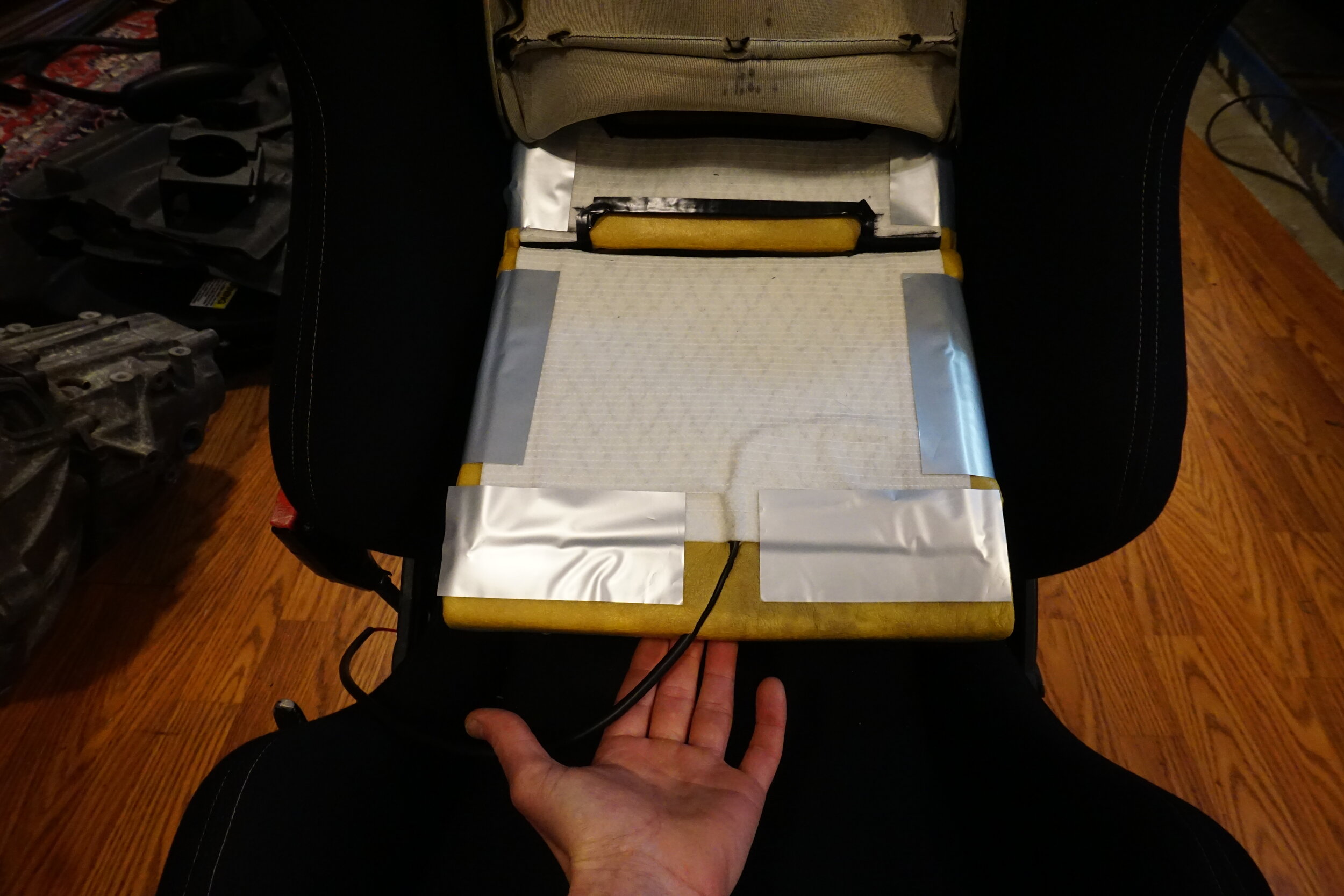

I also finally got around to installing my aftermarket seat heaters that have been sitting in my closet for the last four years. Well, at least the one for the driver's seat. I think I've had someone in the passenger seat like 10 times in the last 5 years, so that one might get ignored for another four years. I really wanted to be able to use the factory heated seats button, but it was cutting out at max heat, running for a few seconds then turning off for a while, then turning back on. On low power they worked fine. Oh well, guess I'll have to use the switches that came with the heaters. I got 12V power from the power seat wiring, and the switched 12V from the factory button. I wanted to make sure that if I left the heated seat on when I turned off the car that it also turned off.

Getting the element on the seat base was easy, but the back was tricky. I had to cut out some holes for the rod that holds the seat cover down to go through.

I wanted a clean but removable install for the switch, so I got a new blank plate for the dash and got to trimming. I was left with about 1 mm of material left on the sides of the blank plate, but it seems to be enough to hold it all together. I had to grind off quite a bit of material from the switch to get it to fit into the hole in the blank plate.

But I think it was worth the effort.

I'm kicking myself for not installing these things earlier, they are so awesome! They heat up fast and get really hot. Ahh, heated Recaros!

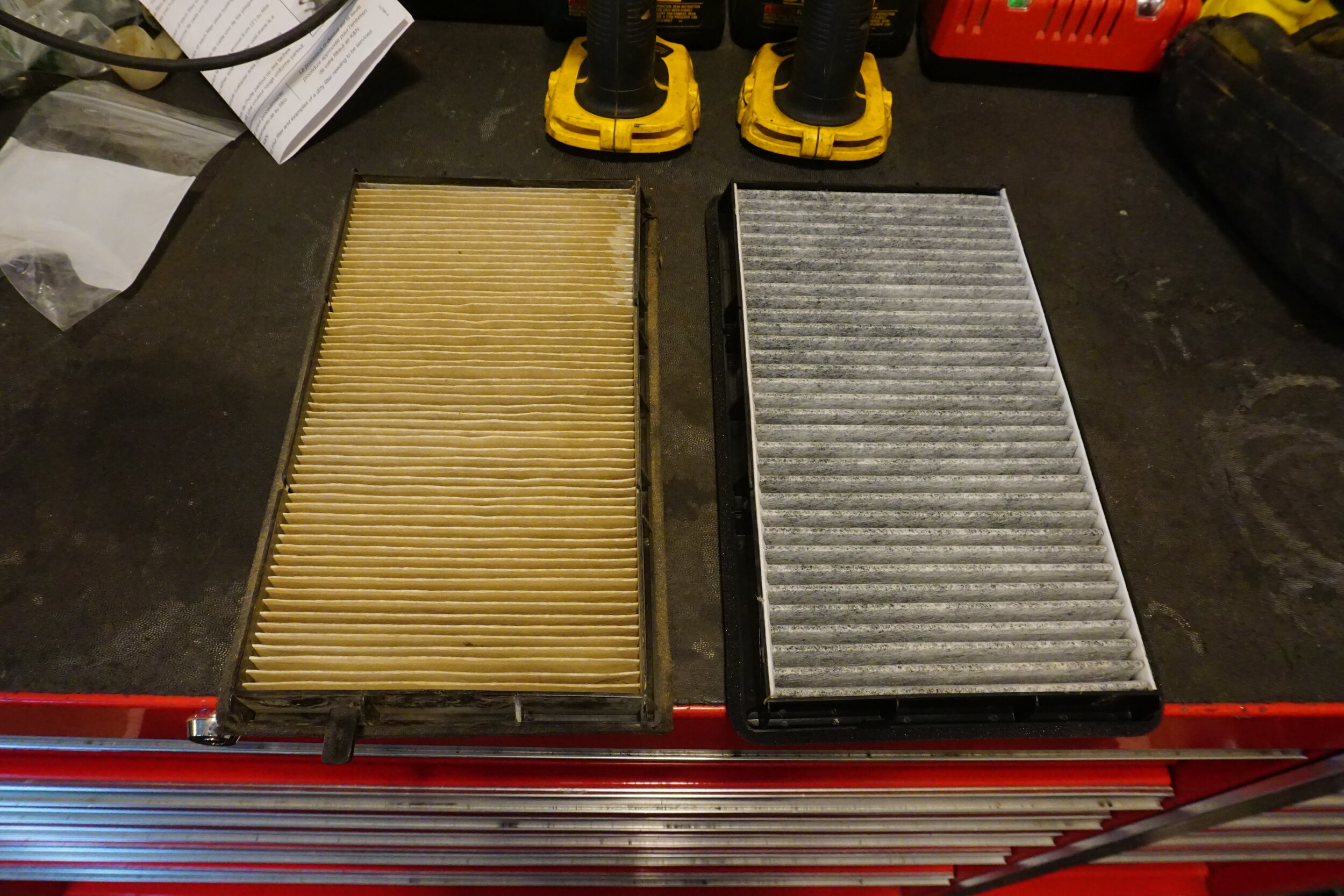

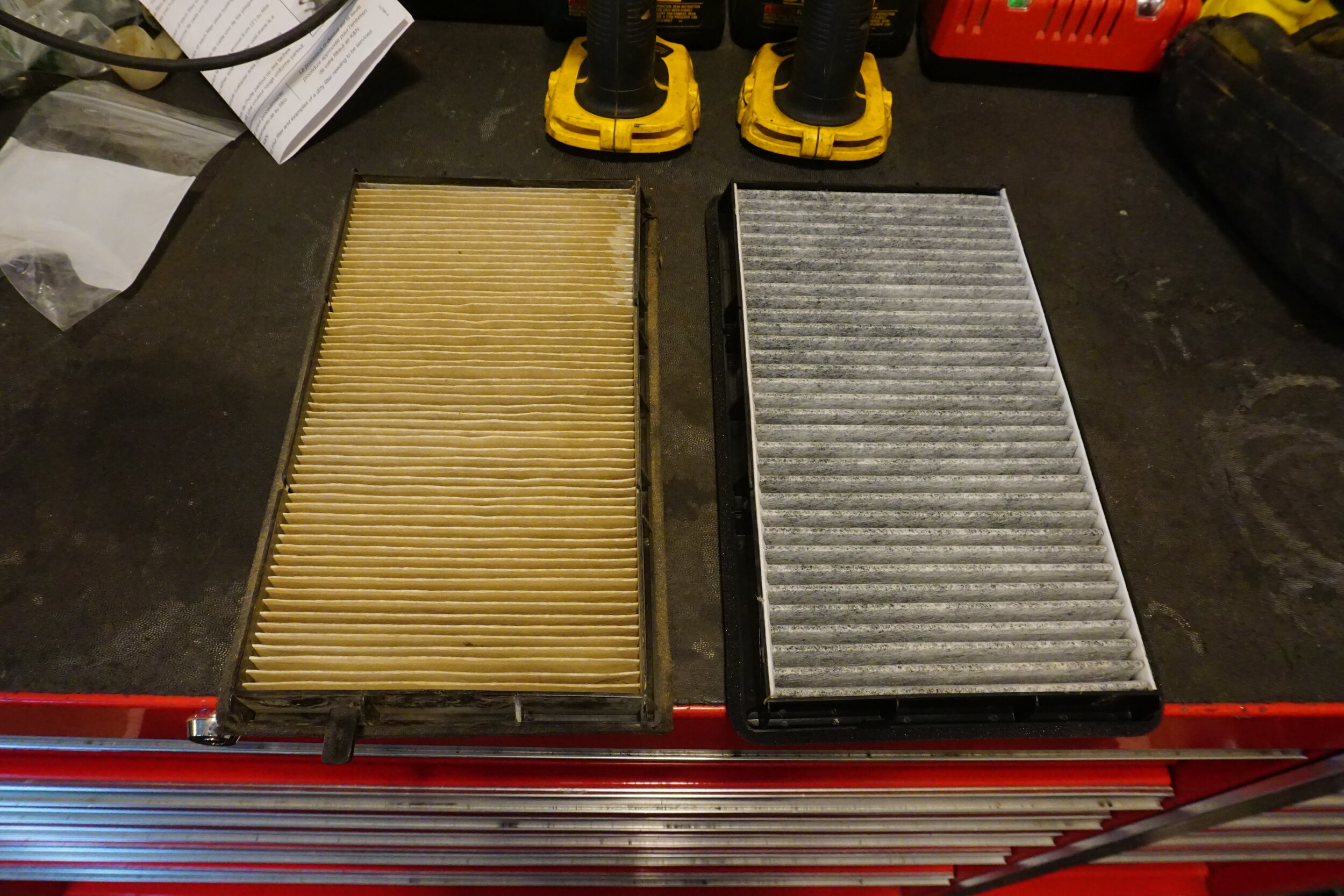

It had been a few years since I replaced the cabin air filter, and I was reminded how much I hate doing that job. The filter never wants to come out, and getting it back in isn't easy either. But at least it's done, and this time I got me a fancy "carbon activated" filter.

And while I was in there I got rid of this 10 pound paper weight. It's not like it was active anyways. Woo hoo, weight reduction!

Oh, and since nobody ever sits in the passenger seat, I decided to block off the air vent for their feet, so now it should all come to me!

Or maybe it will all get pushed to the vent under the passenger seat, who knows....

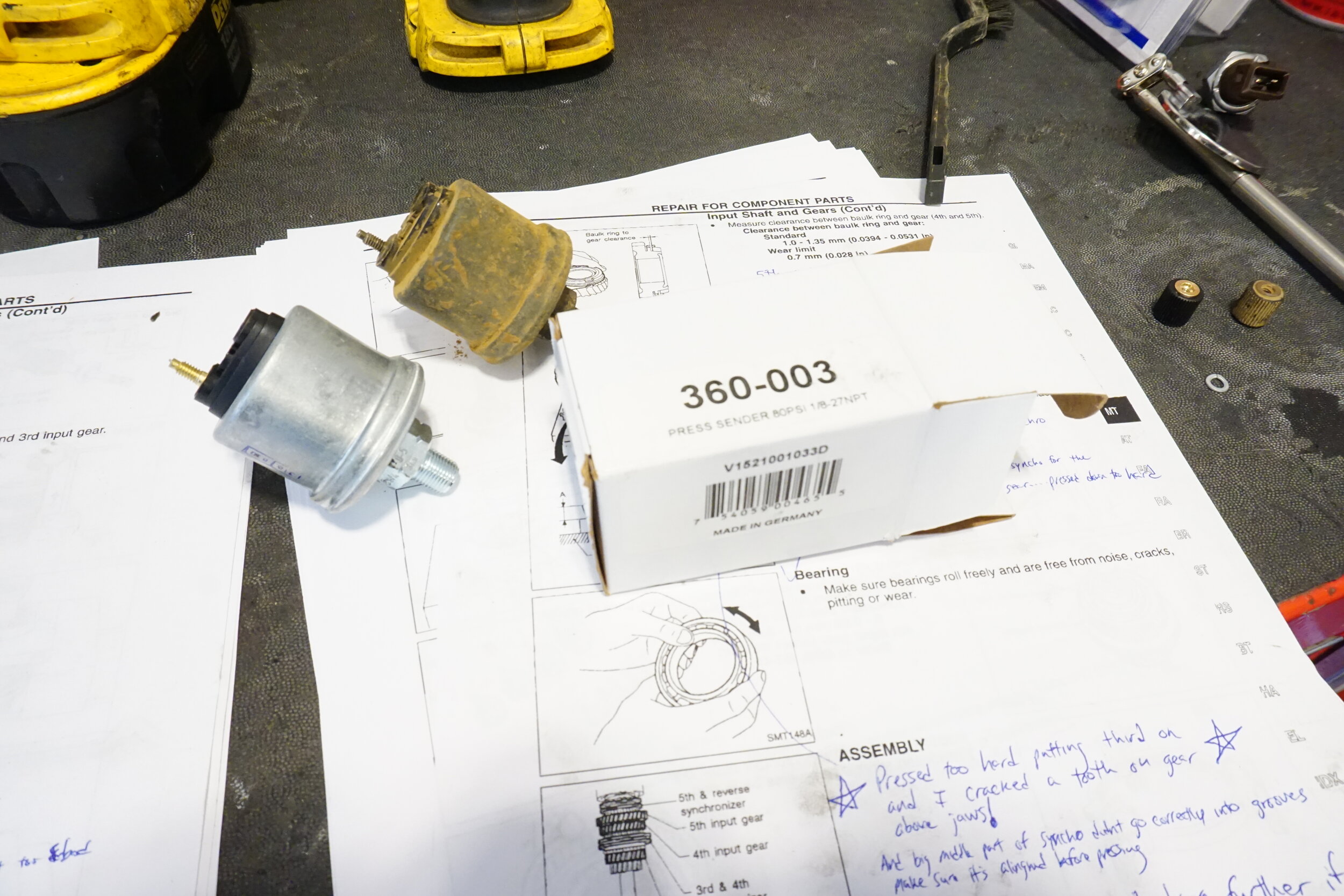

Anyways, back to my oil pressure. I bought a new OEM sender, and decided to replace my VDO stuff as well. My current VDO oil pressure gauge goes from 0-150 PSI, and considering I've never seen pressure go above 80, I wanted to see if I could get a gauge to better match my pressure range. Lo and behold, VDO makes a 0-80 PSI gauge, so I got one and the matching sender unit (0-5 bar instead of 0-10 bar). This should make it easier to see which side of 10 PSI my pressure is when I'm idling.

Taking a look into the area where this all lived, I realized access was going to be a bit of an issue. It also looks like a number of these things had been leaking some oil.

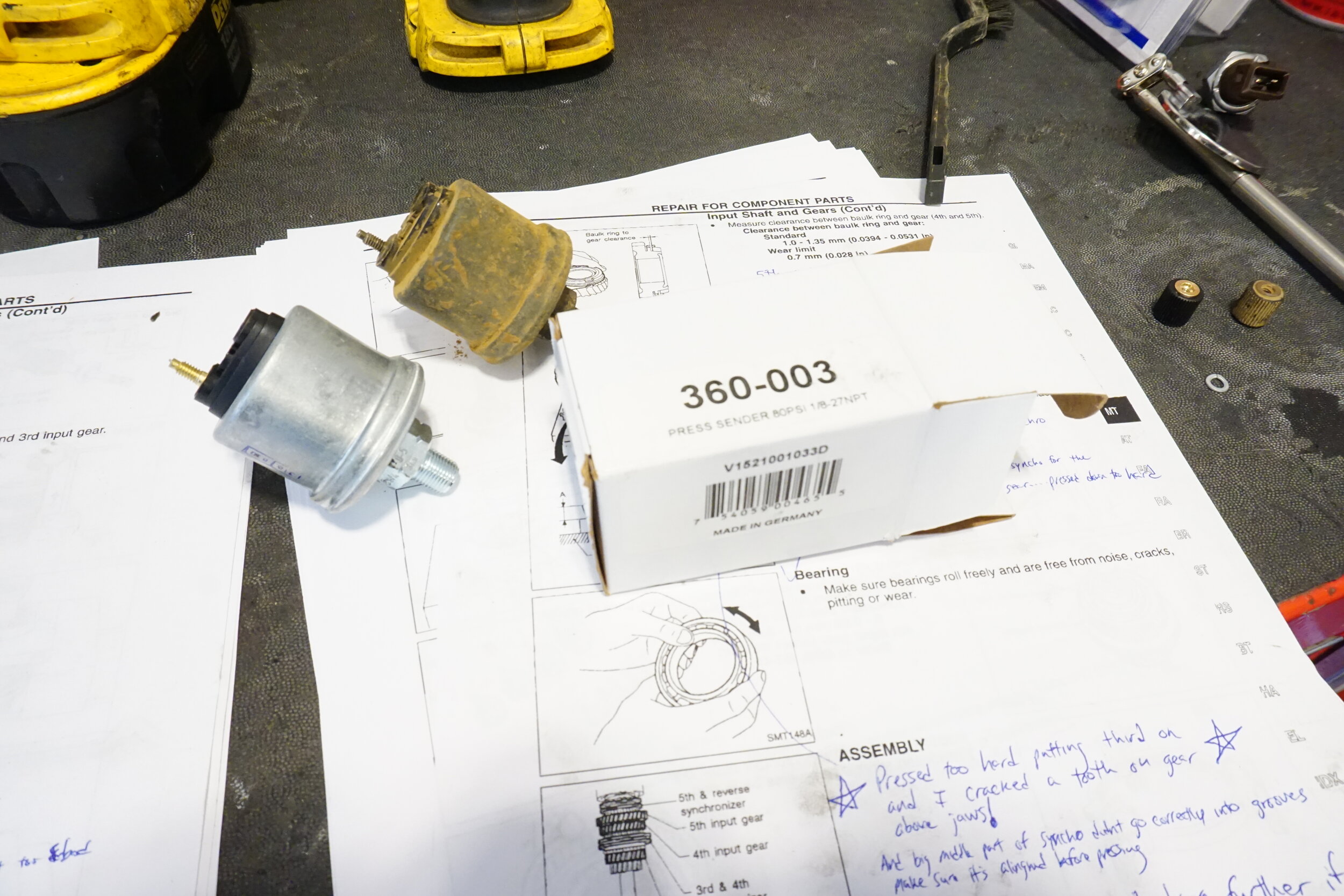

New VDO sender (360-003, 1/8-27NPT for BW distribution block). A stubby 17mm saved the day here.

As for the factory sender, well, that was far trickier. It's on the bottom of the distro block, and there no real access from the bottom. My larger 140a alternator wasn't helping matters either, my old 80a was much smaller. I considered taking the alternator off to make things easier, but eventually found I was able to unscrew the old one with a crowfoot wrench.

It had seen better days and had been leaking a bit. In fact, when I got the crowfoot wrench on it, it came off with almost no force. If it had loosened up a bit more it could have been very bad. I could read the date code on the sensor, and it was the original one from 1998. But then I was faced with another problem, how do I screw it back in? Access was so tight that I couldn't get it back in there. I tried everything, but no dice. Maybe the alternator was going to have to come off after all. In a last ditch effort I got my wife to come out and help. She held the sensor roughly in place from above, while I got under the car and squirmed my hand up there and was somehow able to get it screwed in. Awesome! The same problem reappeared when I went to reconnect the electrical connector, and again, and second pair of hands saved the day. I made sure to tighten this one in pretty tight, so hopefully it won't leak anymore.

When it was all said and done, I was left with this:

So I installed the new gauge. It's not perfect, but it should be a lot easier to tell if I'm at 8 or 12 PSI.

As a refresher, at cold start I would usually see around 65-70 PSI. I read that in these engines pressure is regulated to 58 PSI, but I haven't been able to verify that, so I don't know if my old gauge was accurate or not. So I turned on the car, and my pressure was only 50, quite low compared to what I'm used to. So now I don't know if the new gauge is accurate, or if the old one was. Or neither? I haven't had a chance to drive it yet, so I don't know if the new OEM sensor fixed my warning light or not.