With nothing left to do to the car, I decided to busy myself with a fresh stereo install. More bass make you go faster, right? Here's a quick recap on what I've got and my thinking for the future.

The car still had its original Harmon Kardon "premium" stereo when I bought it, but a lot of the front speakers were blown out. I kept things alive for as long as I could by installing original speakers I found at junkyards, but after 4 years or so, I eventually decided to rip it all out and install new stuff. I tried to build a decent stereo as cheaply as I could, so I replaced the 3 way front speakers with a 2 way set of JBL GTOs, and 6x9 GTOs in the rear deck. Powering it was a 100w RMS x 4 RF amp. And you know what? I was pretty happy for a few years. It was worlds better than the factory setup. I eventually wanted more bass, so I added a JBL BassPro SL2 underseat sub.

One thing to keep in mind about the limitations for the stereo is that I can't have a traditional sub in a box. When I drive to a race, the car is packed to the brim with 8 wheels/tires, and all of my gear, so there's no room anywhere for something bigger than that wimpy under seat sub. And before you ask, no, I don't want to just remove the sub when I drive to races and reinstall it when I get home. I often have to drive 2 hours to get to a race, and I need that bass all the time  :D

:D

But over the years of listening to my very budget build (seriously, I think the total cost with the sub was less than $500), I was getting pretty fed up with its inadequacies.

First up was the front stage. The E36 has 5.25" speakers in the kick panels, which play directly into your ankles. There was pretty much no bass from the front stage. Then there was the fact that I downgraded from the factory 3 way to a 2 way setup. This forced much of the mids to be played from the 5.25s, which are incredibly off-axis. You can't see the driver's speaker when in the seat, and you can barely see a sliver of the one of the passenger side. So the reproduction of vocals was pretty bad, and I really struggled to hear things when driving.

This forced me to rely on the rear 6x9s to hear mid range frequencies, and well as most of the bass (until I got that under seat sub). So the sound stage was pretty terrible.

Adding the JBL under seat sub helped improve the bass situation, but not by much.

So after 4-5 years, it was time to upgrade again. I wanted to do it right this time, and not really leave any room for future upgrades. First thing I knew I needed was a 3 way front stage to help bring the mids back closer to ear level. My ankles just don't hear as well as they used to! I toyed with off the shelf setups in the $500 range, but it seemed a lot of options in that price range weren't actually much of a quality upgrade over the JBLs I had, they just had an additional speaker. I eventually settled on the Stereo Integrity speakers:

TM65 mkIV

M3 Carbon

M25 mkII

But of course, this meant I would need to make 6.5s fit where the 5.25s currently reside. And I would need to figure out a crossover solution, since SI doesn't offer one, and I wasn't going to run active. I picked up all the SI parts over their winter sale, so the total cost wasn't too far off what a mediocre off the shelf 3 way setup was going to cost.

I decided to piece together a crossover network made up of Dayton Audio parts. They have a pretty wide selection available:

https://www.daytonaudio.com/category/35/assembled-crossovers

I found parts for the right frequencies and impedance, but they only offered them with 12 dB slopes instead of the recommended 24 dB slopes SI recommends. Oh well. I picked them all up on sale from Parts Express at their winter sale for something like $100 total.

Next up was a more powerful 4 channel amp. I settled on a used Alpine PDX-F6 with 150w RMS per channel, partially based upon this review:

https://www.audiosciencereview.com/forum/index.php?threads/alpine-pdx-f6-review-4-channel-car-amplifier.28870/

I can't say I understand any of it, but it sure sounds like a well engineered amp.

Anyways, enough talk. Let's see some pictures!

These are, without a doubt, the nicest components I've ever owner!

Old 5.25 vs new 6.5

Gosh, I really hope these things will fit. I don't have a Plan B.

It took a lot of work, and some very uncomfortable body contortions, but I was eventually able to get the 6.5s in there. Thank god they are so shallow! I did my best to seal up the cavity, but it's not perfect.

After quite a bit of trimming, I was barely able to get the factory covers to go back in place without interference.

Thankfully the mids and tweeters were very simple in comparison. I made a spacer for the mid, which I epoxied to the door card, and then screwed the mid to that. The tweeter just screwed on, super simple.

The SI grilles hadn't been released yet for the M3s, so I cut up the factory piece and glued it in place.

Far from beautiful, but it's functional. This has generally been the theme for the car.

I ran all new 16 AWG OFC cable to each speaker, which was not much fun.

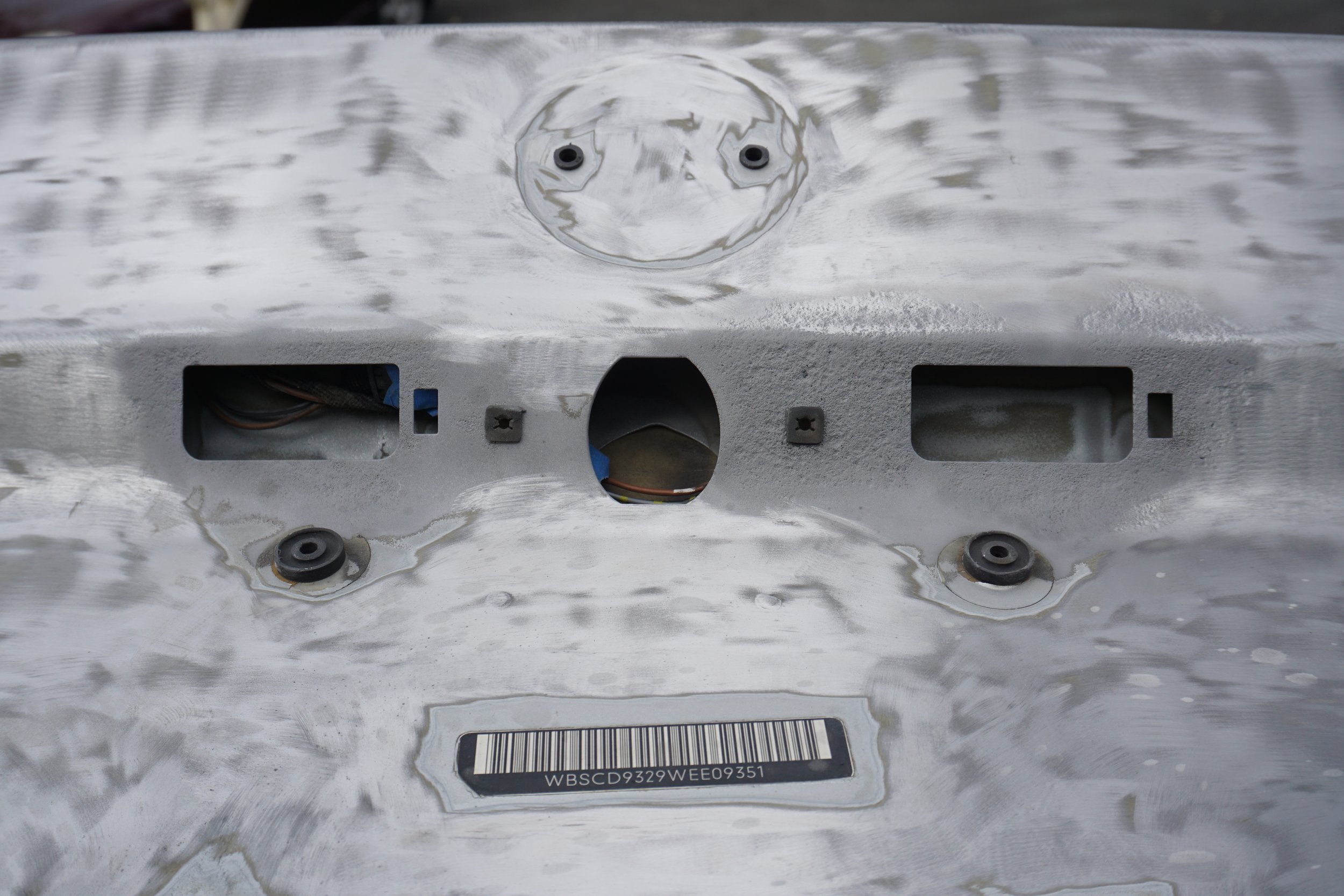

Time to head to the trunk. Here's how the old RF amp was mounted. Ignore the wires, this was mid-disassembly.

The new crossovers were....slightly larger than what the JBLs came with. Quite a bit heavier too.

Which meant they couldn't be tucked up in the dash and had to be in the trunk.

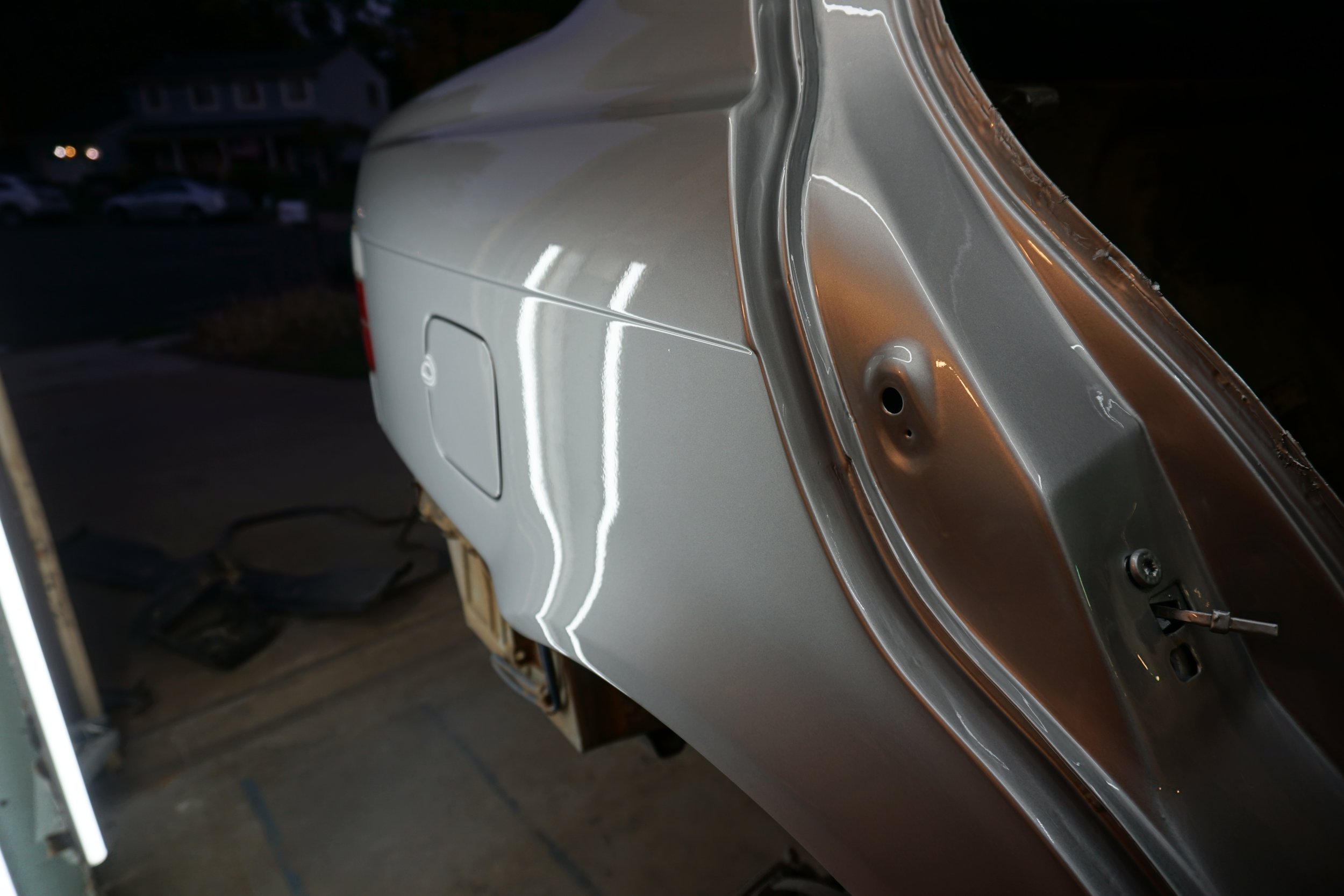

So I made a new mounting board for everything and bolted it up.

And eventually wound up with this:

Another problem I wanted to address was road and exhaust noise in the vehicle. Last year I installed a quieter cat-back on the car, and while it helped, it was still a little too loud on my long trips. It doesn't help that the car runs at like 4,000 rpm at 80 mph. As you can see in the picture above, I did my best to line the entire trunk with 1 lb/ft MLV. The lower portion is easily removable when I get to my race, while the upper portion will stay in place.

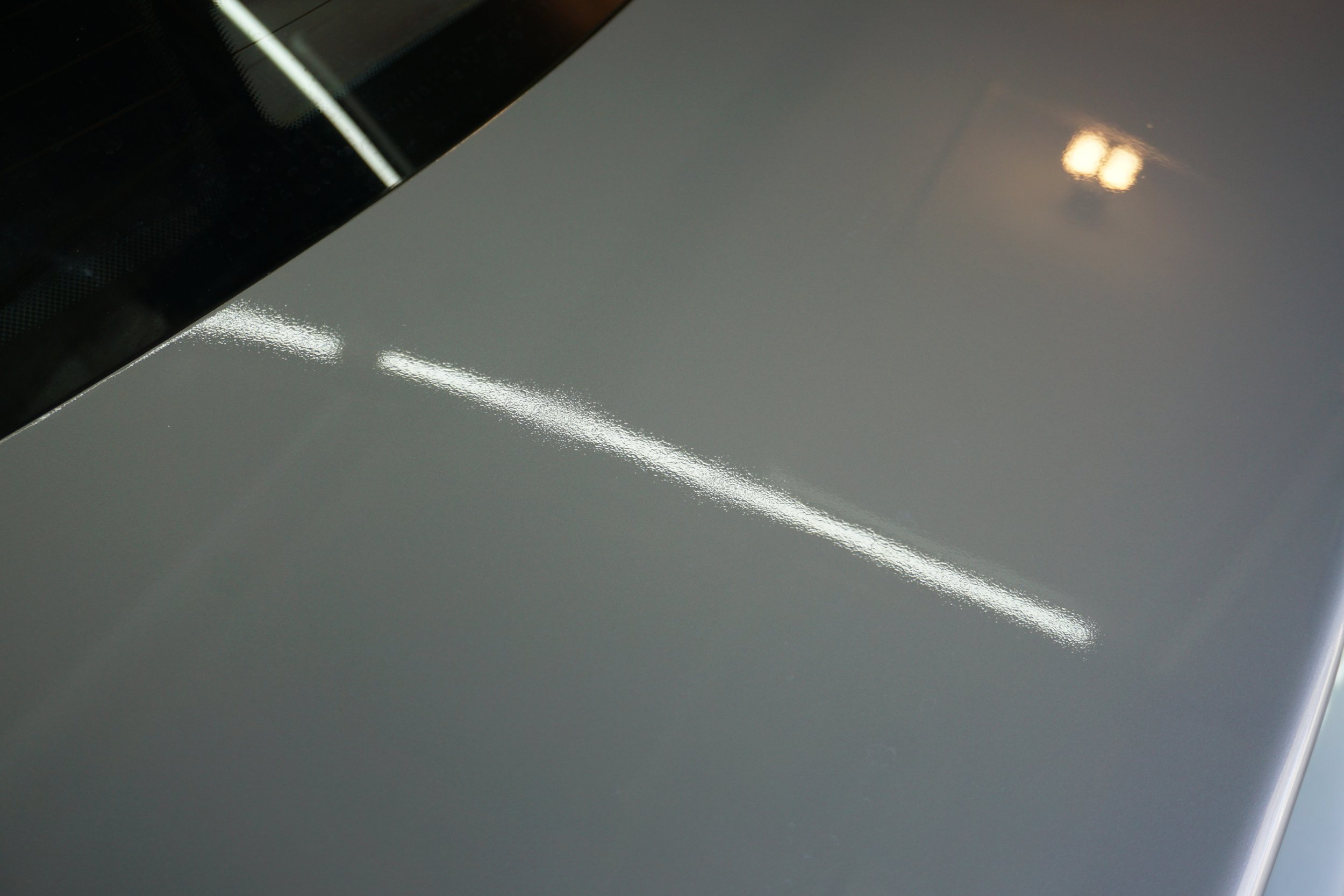

I also wanted to test out another affordable and light weight option for the doors. Thankfully they didn't need any CLD since the 6.5s are in the kick panels, but I did want to keep out road noise. So I bought a box of 1" Owens Corning 703 fiberglass insulation for about $130, which is more than enough material to do all of my cars. So I got to measuring the cutting.

I then wrapped each piece in thin painters plastic and installed them in all the doors.

The rear doors were tough since the openings are so small, but I was able to get them done too.

The car just keeps chugging along, so there haven't been any updates. Until now..........

The car just keeps chugging along, so there haven't been any updates. Until now..........