I'd have a hard time not modifying it to be safe for 55 mph and then daily driving it.

Next step, when you flip the ignition to "mag" does it keep running?

In reply to RossD:

That's more or less impossible, a T is good for maybe 35mph max cruise before the engine is spinning too fast. You need at minimum a model A with some upgrades to drive it outside of strictly low traffic pleasure driving.

In reply to Kenny_McCormic:

The magneto wire on the bellhousing was disconnected by the PO for some reason.

Yesterday I took the truck for a short ride... the truck is getting closer to being Jackson County hillbilly road worthy every day.

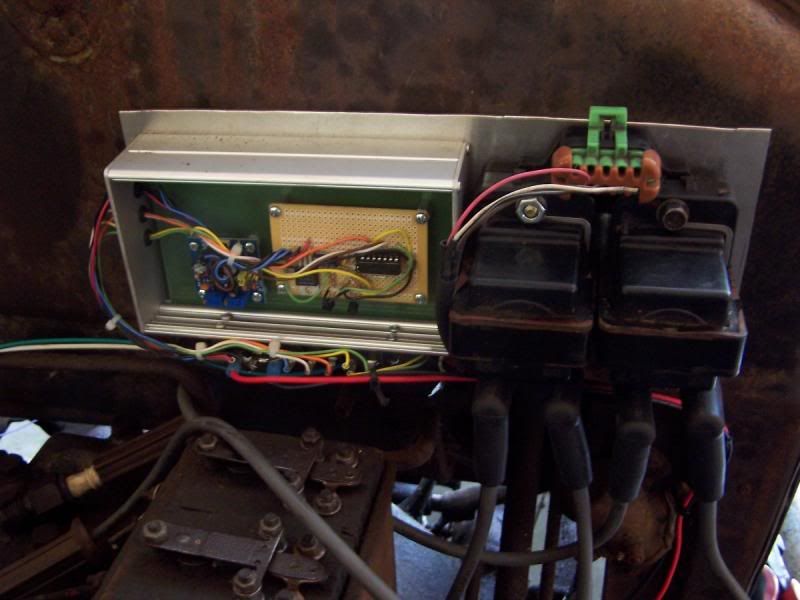

I put together a "solid state" ignition system that functions exactly like the buzz boxes. I know its blasphemously but I need the engine to start and run without any fiddling. I'll test the system latter this week.

AFAIK the only thing you need to do to future proof the stock buzz coils is pop them open, replace the condensers, and seal it back up. Decent shape used ones shouldn't run too much. Also, you shouldn't run modern gear lube in that rear end, contains brass thrust washers, the two aren't known to play well when things get hot.

RossD wrote: I'd have a hard time not modifying it to be safe for 55 mph and then daily driving it.

It's best to think of these things as not for use on paved surfaces.

Was not one of the GRM brethren (offspring?) daily driving one of these for a while? How did that all end up?

Woody wrote:RossD wrote: I'd have a hard time not modifying it to be safe for 55 mph and then daily driving it.It's best to think of these things as not for use on paved surfaces.

That^

Ignoring any laws against it, if you'd you be comfortable driving a golf cart with semi functional brakes there, you can probably drive a T there, beyond that your a moron. The service brake in a model T is a single wet band in the trans, the drums in the back wheels are meant for parking. Speaking of which, probably not a bad idea to reline the bands before driving this one, its a cheap and easy job(trans stays in car).

I live about a mile from the edge of civilization and the T would happy on the rural roads. I think if it were mine I would drive it..... often..... but I wouldn't take it on any real roads.

The new owner isn't planning to drive it on public roads, it will only be driven on a private road. All the truck has to do is start and move under its own power....reliably.

More updates soon!

Quick update + video!

I installed the digital electronic ignition in the T yesterday. It runs better but I'm not happy with it. I think I'll rebuild the buzz boxes. Pictures of the ignition will be forthcoming.

Meanwhile, grab a beverage and enjoy the movie.

http://youtu.be/wtstSj3JtHc

Stay tuned!

Thanks for sharing.

I love when you can disassemble, clean and reassemble parts to get them working. It is so much more satisfying than bolting on a new part.

Thanks for the comments, it was a fun video to make. The T is right at home on gravel roads and narrow lanes. The car is a throwback to simpler times and putting along at 15 MPH feels natural.

The starter Bendix took a huge E36 M3 on Friday and I haven't had a chance to see what the trouble is. Anyway, the hand crank is supposed to be an alternative way of starting the engine so I figured I would give it a shot.

But first I needed to fix the ignition.

Sometimes my idea of fixing E36 M3 is OVERKILL. The new ignition functions exactly like the old buzz box system and is theoretically bullet proof... however it may be too powerful. I need to look into this.

With the new ignition in place the engine fired right up with the hand crank. Simply amazing. I think overall I hand started the engine about ten times yesterday. Once you get a feel for it, its pretty easy.

Take a look.

This is the modern version of the Ford buzz box ignition. This thing will knock you off your ass if you accidentally touch something. The cover is off for adjustment and the unit is more or less weather proof.

Bzzzzzzzzz! Plenty of spark to start an antique engine. I need to check the plugs after running the engine for a few hours yesterday. I suspect the plugs might have eroded a bit.

Bzzzzzzzzz! Plenty of spark to start an antique engine. I need to check the plugs after running the engine for a few hours yesterday. I suspect the plugs might have eroded a bit.

Stay tuned!

The last outing took a toll on the T and the starter/flywheel were damaged beyond repair. An argument can be made that the 12 volt battery was too much power for the antique car, however the flywheel was damaged since the car arrived. The last time I had the starter out, I found several teeth from the ring gear laying in the bendix cover. It was only a matter of time before the flywheel was going to give up.

The single most popular car in the history of the world, and not much info on how to remove the engine on the internet. A little sleuthing gave some clues but I more or less guessed on how to take the engine out. It isn't rocket science, but it is a bit tricky.

Step one, remove everything that get in the way...

Step two, remove engine.

Actually, pictures tell a better story.......

the t engine lacks any sort of lifting points. A clever gizmo is available to convert the sparkplugs holes into lifting points. I purchased two of these thingy's because two is always better.

Screw one into the #3 plug hole and the other in the #2 plug hole.

Remove the front motor mount clamp.

Remove the rear motor mount bolts. (One one each side).

Remove the four bolts that hold the driveshaft whatchamacallit to the transmission.

Lift engine from the #3 plug eyelet and and wiggle the engine forward until the driveshaft disengages. Then lower engine and switch to the #2 eyelet.

lift engine and wiggle it forward and rotate to clear the pedals and steering column.

radically rotate engine until it is almost sideways in the chassis to gain enough clearance. At this point the engine comes right out.

Next up is taking this monster apart...

Stay tuned!

What an awesome car. The videos work really well for it too. Curious what the guts of the engine look like, I've never thought to take a look at one before - flatheads are about as old as I've ever looked at.

I can't help but think if I had one of these I'd be doing a bunch of modern stuff like the solid-state ignition just to watch purists freak out about it. Maybe heated Recaros too.

In reply to ssswitch:

I'm half tempted to megasquirt this buggy. Air conditioning would be nice too.

The Model T engine lacks any sort of conventional lugs to mount the motor to a modern stand. An adapter was located and purchased so the disassembly could begin. Although the engine is only 87 years old, the engineering is well over a century old and is not exactly intuitive. I managed to remove the "Hogs head" and oil pan with a little help from my friend the internet, but I then hit a brick wall. Some books were ordered because the Model T folks are not internet savvy and I don't know how to disassemble the transmission without a BFH.

Let's look at some pictures.

This lump of iron is 177 cubic inches or 2.9L.

This lump of iron is 177 cubic inches or 2.9L.

A chunk of the starter Bendix was found in the transmission.....

A chunk of the starter Bendix was found in the transmission.....

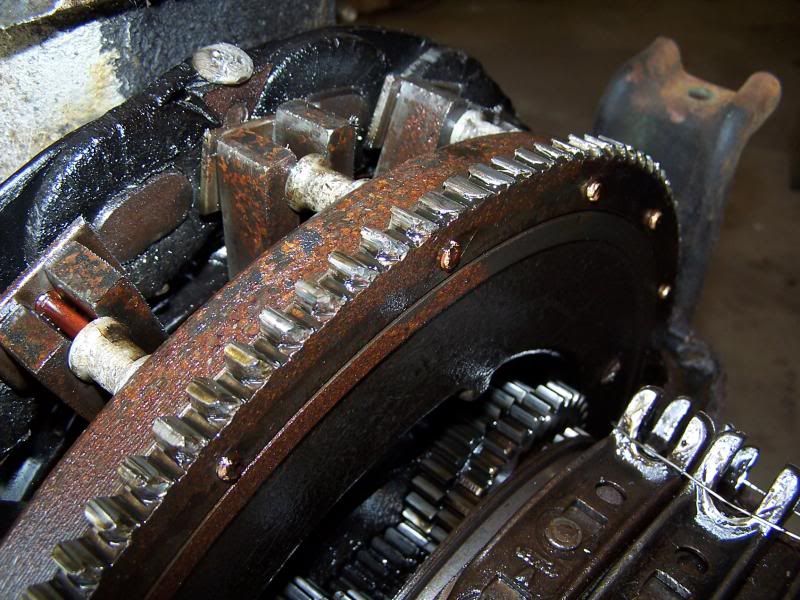

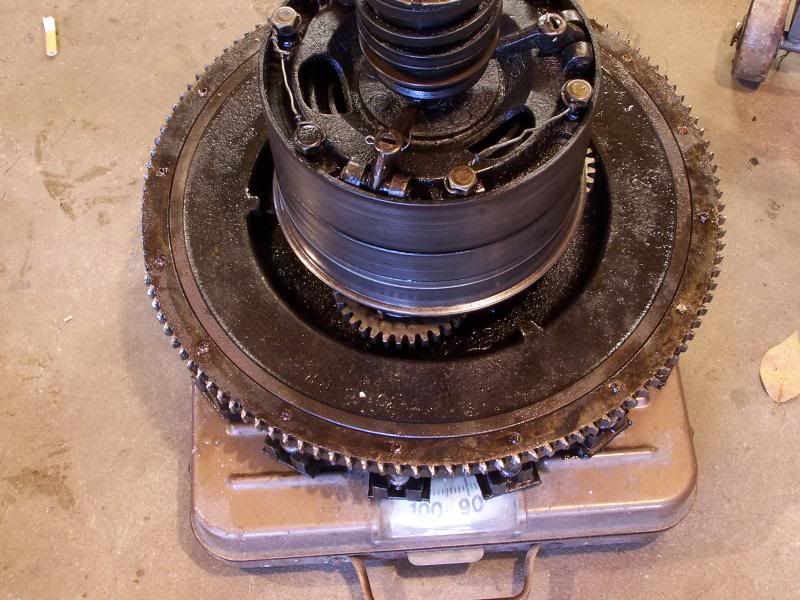

Flywheel ring gear is well past its time.

Flywheel ring gear is well past its time.

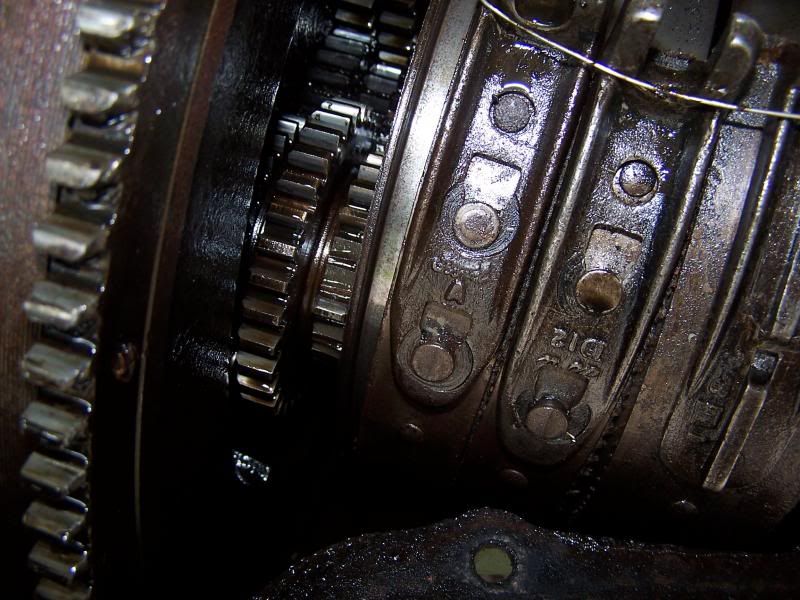

Oh E36 M3!.... the triple gears are berkeleyed. The good news is this stuff is dirt cheap.

Oh E36 M3!.... the triple gears are berkeleyed. The good news is this stuff is dirt cheap.

Stay tuned

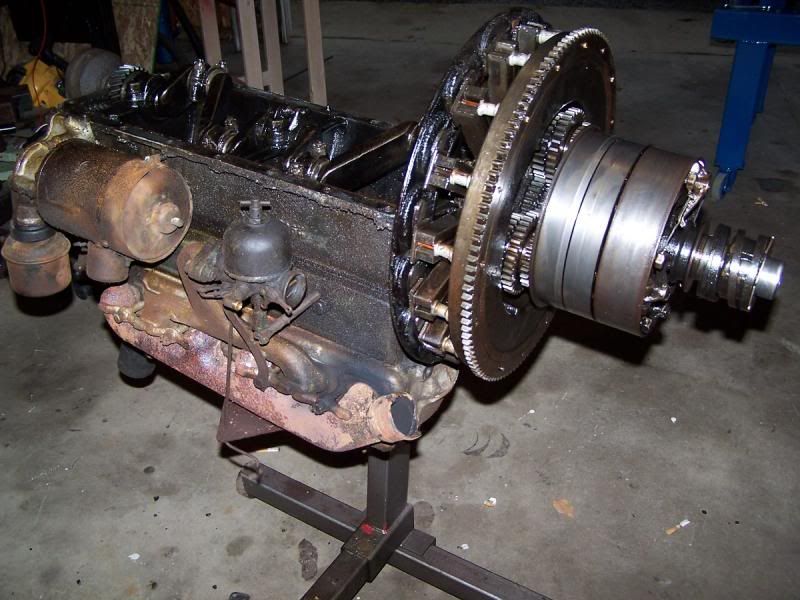

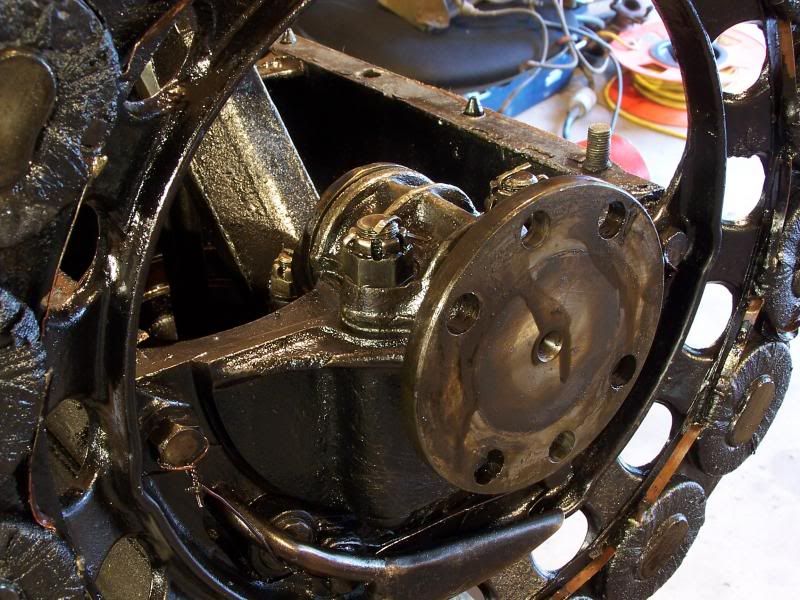

I poked around and discovered the transmission is attached to the engine by four large bolts..... but wait this isn't a normal transmission. The model T transmission is a collection of gears and drums that actually hang precariously on the crankshaft flange by four bolts. This massive 95 lb assembly of wickedly crude parts just flails around inside the case and somehow makes the car move. I understand the principal of operation, but wow this thing is heavy and it just hangs on the end of the crankshaft.

Picture time...

This is the Hogs head... in modern terms it is the top cover of the transmission.

This is the Hogs head... in modern terms it is the top cover of the transmission.

This is the transmission assembly. It just hangs on to the end of the crankshaft bu four bolts.

This is the transmission assembly. It just hangs on to the end of the crankshaft bu four bolts.

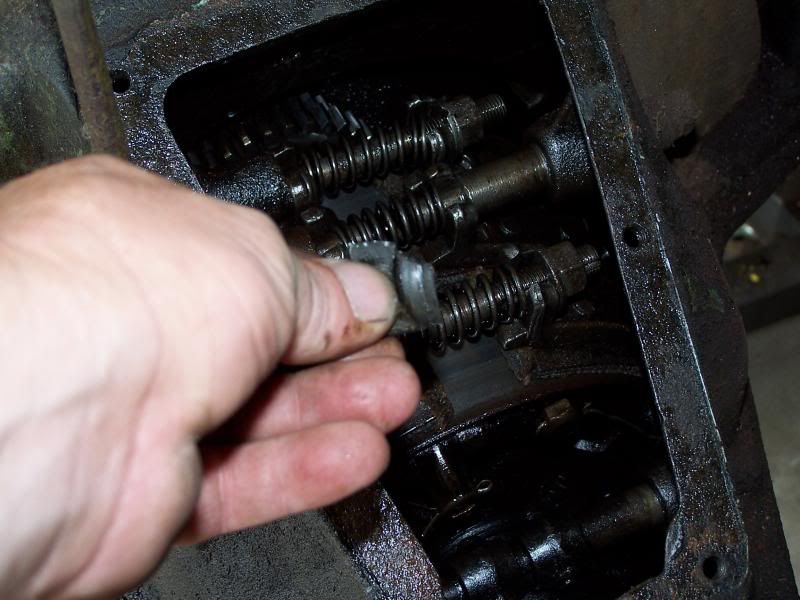

A inside shot showing the last remaining bolt before the transmission can be removed.

A inside shot showing the last remaining bolt before the transmission can be removed.

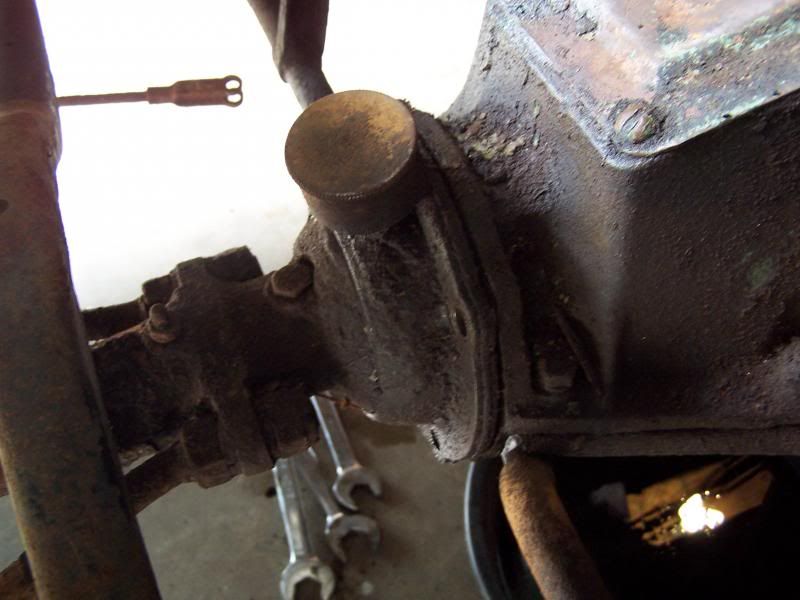

Meanwhile, this goofy unknown device applies a very light force to the crankshaft. Possible thrust bearing of some sort. I'll know more when the books arrive.

Meanwhile, this goofy unknown device applies a very light force to the crankshaft. Possible thrust bearing of some sort. I'll know more when the books arrive.

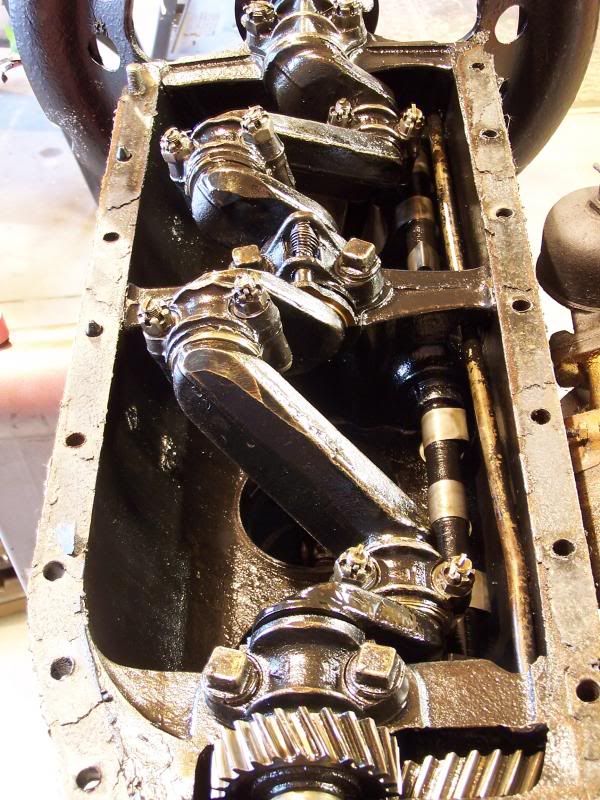

The massive 2.9L 20hp engine is held together by three main bearings. Most of the important bolts need to be safety wired or have cotter pins because the balancing is questionable and everything will eventually shake loose. The engine wheezes like Darth Vader when you turn the crankshaft.

The massive 2.9L 20hp engine is held together by three main bearings. Most of the important bolts need to be safety wired or have cotter pins because the balancing is questionable and everything will eventually shake loose. The engine wheezes like Darth Vader when you turn the crankshaft.

The 95 lbs collection of gears and hubs is off the engine and awaits an autopsy. This thing has some large springs and is potentially dangerous to disassemble without a guide.

The 95 lbs collection of gears and hubs is off the engine and awaits an autopsy. This thing has some large springs and is potentially dangerous to disassemble without a guide.

This is the crankshaft flange that holds the transmission. Hopefully this isn't the only thing that supports the transmission.

This is the crankshaft flange that holds the transmission. Hopefully this isn't the only thing that supports the transmission.

Stay tuned!

Such a fun project! I love seeing the way the engineering challenges of making a car were solved a hundred years ago.

IIRC the trans is also supported by the bearing on the tail end, fitting said bearing involves some talent too as I recall. As you imply, if it isn't set up right and tight, the crank will be overstressed and might break.

This truly is a fun project. It’s actually pure candy for an INTJ personality type.

Kenny is correct, the transmission assembly is supported by the driveshaft flange. It’s hard to wrap my mind around this construction because the loads are carried above the centerline of the transmission instead of below. The heavy duty cast iron hogs head is what keeps everything together and keeps the crankshaft from rupturing. Without the hogs head, the flimsy oil pan would not have the strength to hold it all together. The driveshaft flange hangs from the hogs head by two bolts. Some sort of witchcraft is required to get things to line up and I'll cross that bridge in the near future.

I have to remind myself that this is a well proven and successful design.

You'll need to log in to post.