Can you take more pictures of the inside of the hogshead? I'm having trouble imagining what the other side looks like. The pedal linkage explains the trans brake though.

That crank looks so weird.

Can you take more pictures of the inside of the hogshead? I'm having trouble imagining what the other side looks like. The pedal linkage explains the trans brake though.

That crank looks so weird.

In reply to ssswitch:

you bet!

The crankshaft has no counterbalance weights, however it can be modified for weights. I hate to think how much that would cost.

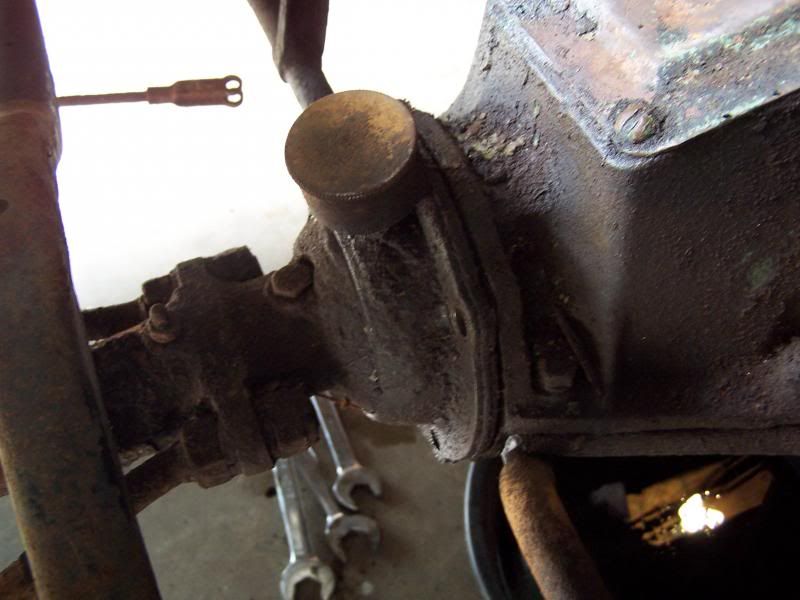

I put the hogs head back on the engine for reference points.

I put the hogs head back on the engine for reference points.

Another shot showing some of the block.

Another shot showing some of the block.

This shots shows the center-line (green). The yellow is the area where the driveshaft flange bolts to the hogs head. The weight of the spinning transmission stuff is supported from above the centerline. I'm used to working on motorcycle transmissions and engines where the case has a horizontal split and all the stuff is supported by the lower case.

This shots shows the center-line (green). The yellow is the area where the driveshaft flange bolts to the hogs head. The weight of the spinning transmission stuff is supported from above the centerline. I'm used to working on motorcycle transmissions and engines where the case has a horizontal split and all the stuff is supported by the lower case.

These are the only two bolts that mate the hogs head to the engine. I speculate that these are critical bolts and if they were loose the crankshaft could potentially snap.

These are the only two bolts that mate the hogs head to the engine. I speculate that these are critical bolts and if they were loose the crankshaft could potentially snap.

A shot of the rear of the hogs head.

A shot of the rear of the hogs head.

This is a shot of the driveshaft flange thingy that I really didn't look at when I dissembled the car. Apparently this is what actually supports the tail of the transmission shaft.

This is a shot of the driveshaft flange thingy that I really didn't look at when I dissembled the car. Apparently this is what actually supports the tail of the transmission shaft.

Stay tuned!

I knew that the standard brakes operated on the driveshaft, but I never realized that it was internal.

I'd like to mess with a Model T sometime. The guy who runs the Model T Club of America lives around the corner from me.

Woody,

Over at the Model T camp, I have hears stories of folks collecting parts off craigslist and building complete cars. Apparently parts are still plenty and relatively cheap.

Miata will always be the answer, but this thing is cool in its own way.

My favorites are the Torpedos of 1912-1914 or so and then anything from '26-'27. Someday, I'm sure I'll put one together.

I'll assume someone has invented a reliable hydraulic brake brake kit for these? Neat project. For something so "simple" its rather complex!

In reply to Gearheadotaku:

They aren't fast enough to bother and the front end isn't built for the twisting forces. Stock "brakes" aren't much of a safety concern, you have redundancy between the main service brake band in the trans, the parking brakes on the rear wheels, and the reverse pedal. Hitting any two pedals at once will stop it and stall the engine.

Its a very steep slippery slope modifying a car like this one to cope with the modern world, pretty soon you find yourself with just another hot rod.

Well it been almost a year since the last update s'pose now is a good time if ever..

A limited autopsy was conducted and the findings were not good. The crankshaft has .059 end float (.004-.007 service limit). A common trick is to pull the rear main cap then ladle in some babbit and machined the cap. Some folks think this is OK and others think it's a shoddy repair. I honestly don't know what camp I belong to. Cheap repair sounds awesome, but this ain't how I would repair a modern engine that went .052 beyond the service limit.... but I also don't know E36 M3 about Model T's.

"oh E36 M3" .. this is not looking good.

"oh E36 M3" .. this is not looking good.

While I pondered the dilemma of the rear main, I took a better look at other areas of concern. The connecting rod nuts were finger tight and the only thing keeping them from falling off were the cotter pins..... Ok, I'm done.

While I pondered the dilemma of the rear main, I took a better look at other areas of concern. The connecting rod nuts were finger tight and the only thing keeping them from falling off were the cotter pins..... Ok, I'm done.

Back in the day this car could be fixed with chewing gum and roller skate key... or something like that. Unfortunately I'm afraid this rusty hulk has seen better days. With the exception of the tires, everything needs to be rebuilt or replaced. However, as a rule, in Michigan..... if it's got wheels..... its drivable.

Back in the day this car could be fixed with chewing gum and roller skate key... or something like that. Unfortunately I'm afraid this rusty hulk has seen better days. With the exception of the tires, everything needs to be rebuilt or replaced. However, as a rule, in Michigan..... if it's got wheels..... its drivable.

While plenty of enthusiast and even novices can overhaul a model T engine, it isn't a cheap endeavor. This car not only needs a full engine overhaul, it also has bad gears in the transmission. Realistically we are looking at $3000 + on a tight budget.... in the end the T would be running again, but it would still have maintenance procedures above and beyond what the owner is willing to do.

So the only real answer was to put a Honda engine in it.....

To be continued..

The engine bay seems empty, A flat head V8 would be awesome, but the owner rejected that idea.

The engine bay seems empty, A flat head V8 would be awesome, but the owner rejected that idea.![]()

The oil pan on the Model T is a stout chunk of iron. The front suspension wishbone and the rear torque tube tie into the pan, this makes the oil pan an integral part of the car.

The oil pan on the Model T is a stout chunk of iron. The front suspension wishbone and the rear torque tube tie into the pan, this makes the oil pan an integral part of the car.

The front suspension wishbone pivot point. Note.. the oil pan service panel was removed for this picture.

The front suspension wishbone pivot point. Note.. the oil pan service panel was removed for this picture.

Here we can see sort of how the driveshaft/ torque tube ties into the oil pan.

Here we can see sort of how the driveshaft/ torque tube ties into the oil pan.

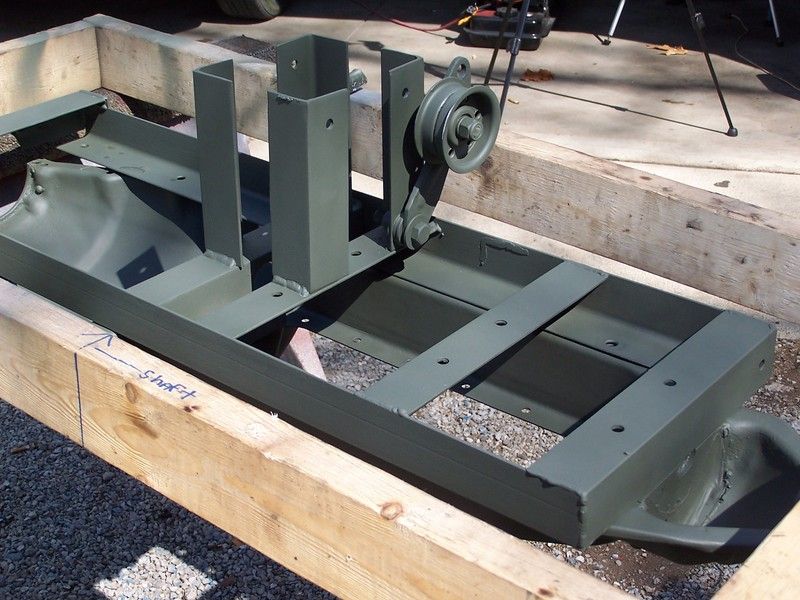

A 2x4 buck was fabricated in the exact dimensions of the Model T frame.

A 2x4 buck was fabricated in the exact dimensions of the Model T frame.

The Oil pan was mounted to the buck. This arrangement allows the Honda engine to be fitted within the limited space Henry Ford allocated.

The Oil pan was mounted to the buck. This arrangement allows the Honda engine to be fitted within the limited space Henry Ford allocated.

An engine cradle was fabricated with scrap steel.

An engine cradle was fabricated with scrap steel.

Close up shot of the rear of the cradle.

Close up shot of the rear of the cradle.

Another shot of the cradle

Another shot of the cradle

Engine cradle fitted to the oil pan.

Engine cradle fitted to the oil pan.

The fabricated engine cradle is connected to the oil pan via four 5/16 fasteners.

The fabricated engine cradle is connected to the oil pan via four 5/16 fasteners.

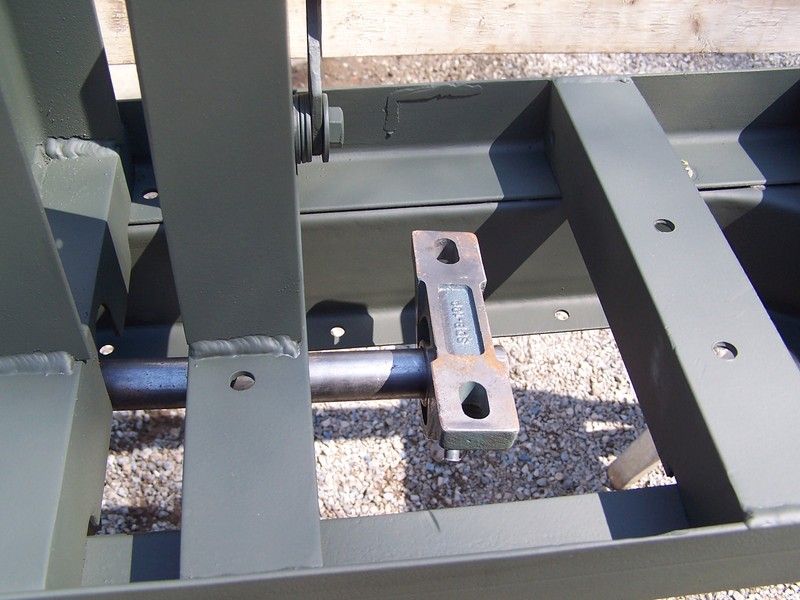

Rear of the cradle as it is mounted to the oil pan. The Model T driveshaft/torque tube will eventually mate to this.

Rear of the cradle as it is mounted to the oil pan. The Model T driveshaft/torque tube will eventually mate to this.

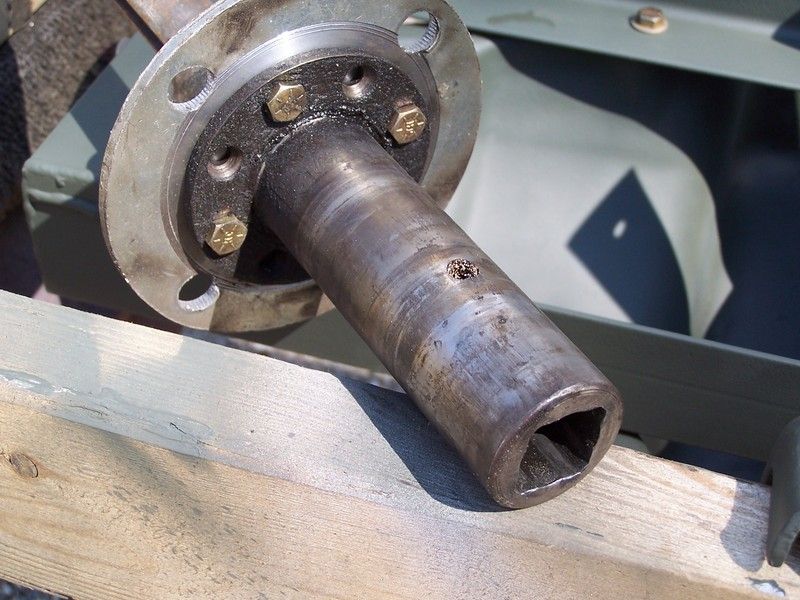

This is the receiving flange for the Model T torque tube.

This is the receiving flange for the Model T torque tube.

Flange temporally mounted.

Flange temporally mounted.

Inside shot of the flange.

Inside shot of the flange.

This is the output shaft. It was harvested from the ruined Model T transmission. It was one of the few good parts in the transmission.

This is the output shaft. It was harvested from the ruined Model T transmission. It was one of the few good parts in the transmission. ![]()

A go kart axle seems out of place, but I assure you this is the correct photo.

A go kart axle seems out of place, but I assure you this is the correct photo.

At this point, have you figured it out?...

At this point, have you figured it out?...

Hanger bearing for the go kart axle.

Hanger bearing for the go kart axle.

Bearing slips on the the shaft.

Bearing slips on the the shaft.

bearing gets bolted to cradle

bearing gets bolted to cradle

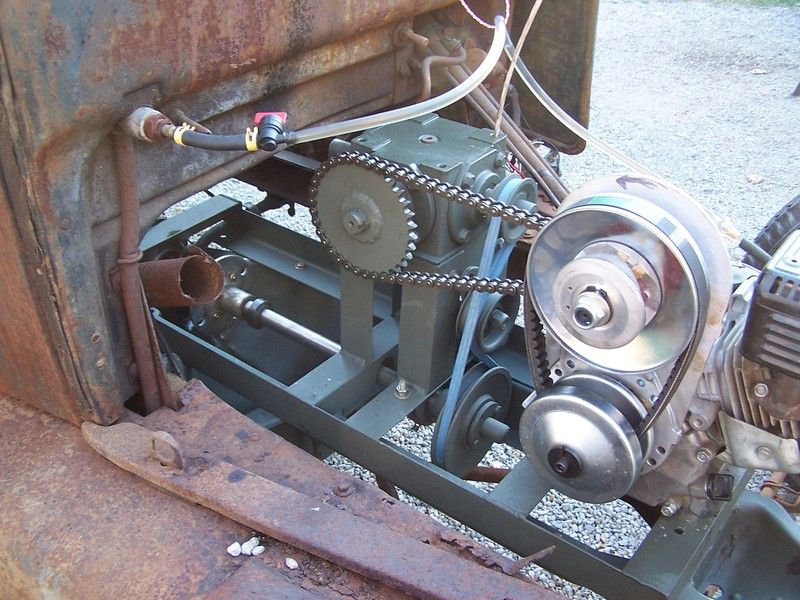

Heavy duty right angle gearbox is fitted.

Heavy duty right angle gearbox is fitted.

Sprockets!

Sprockets!

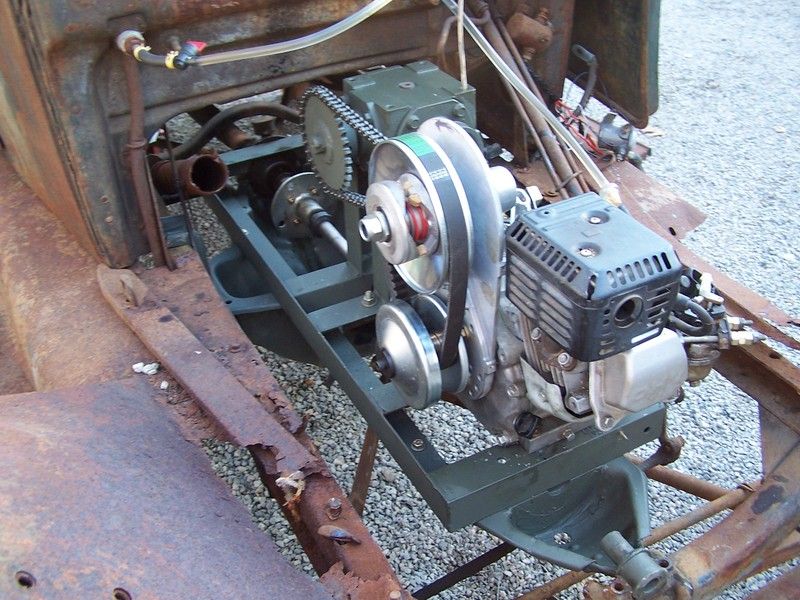

The engine cradle/oil pan gets transferred to the Model T. Notice that the car has not been modified and this engine swap is completely reversible.

The engine cradle/oil pan gets transferred to the Model T. Notice that the car has not been modified and this engine swap is completely reversible.

Another shot of the new drive system.

Another shot of the new drive system.

The Model T has three engine mounts. Two in the rear and one in the front. All the engine mounts are located on the oil pan.

The Model T has three engine mounts. Two in the rear and one in the front. All the engine mounts are located on the oil pan.

Here is a shot of the torque tube mated to the new engine cradle. I will need to weld in another hanger bearing to take the load off the flange, but for now this will work.

Here is a shot of the torque tube mated to the new engine cradle. I will need to weld in another hanger bearing to take the load off the flange, but for now this will work.

Whelp, that's no vtec, but it is a Honda engine. I poached this little nugget off a power washer. It has low hrs and is Honda reliable.

Whelp, that's no vtec, but it is a Honda engine. I poached this little nugget off a power washer. It has low hrs and is Honda reliable.

Front shot.

Front shot.

The little engine has a Comet tav-2 torque converter for quick acceleration.

The little engine has a Comet tav-2 torque converter for quick acceleration.

Sprockets, pulleys and belts.

Sprockets, pulleys and belts.![]()

Radiator is dead weight but necessary to keep the car looking "normal".

Radiator is dead weight but necessary to keep the car looking "normal".

The car runs and moved a few feet under its own power. I have some tweaking to do but it looks like this will work out just fine.

The car runs and moved a few feet under its own power. I have some tweaking to do but it looks like this will work out just fine.

Stay tuned!

Hold on...you wrote Honda engine? Am I to understand that this will be of the industrial/lawn care line of Honda engines?

Edit: It is!!! Guessed it before the update!

That's a great idea!

Why did you add the transfer box? Couldn't the engine fit sideways and you could have send the power straight to the Kart axle from the TAV? Or is there another reason?

In reply to fanfoy:

The transfer box was advertised as having counter rotating shafts, however it does not. It isn't a mater of false advertising, it was my misunderstanding on how this sort of industrial box is described.

Anyway, the original plan was to use this box for forward and reverse. This was going to be done with engaging and disengaging the shaft pulleys. Well, now I have to go to plan B.

The drive system could have been simpler if I didn't use the box, but I went forward with the build mostly to just get 'er done.

Epilogue,

Engine Swap math is generally easy, for instance a Daihatsu truck only needs a direct drive small block Chevy to get out of its own way. More power= less math.. it just works. On the other hand, less power = more math... because it doesn't work .

The curb weight of a Ford Model T is around 1200 pounds.

Generally a Model T drivetrain on a skid will weigh in at 550lbs. So that puts our project vehicle in the 700 lb neighborhood without an engine/trans.

The new drive train weighs in at about 100 lbs... so basically the goal is to move a 800 pound vehicle up to a top speed of 15 MPH.

3.63 rear axle with 30 inch wheels needs an additional 5:1 reduction ratio to go 15 MPH at 3000 rpm. The Comet torque converter TAV-2 also adds an additional 2.7:1 ratio in low range 1:1 in intermediate and a slight overdrive at top speed.

There is a brick wall, barb wire fence and a acid filled moat that separates the Hot Rod camp from the purest camp. Being a double non-conformist is the way I roll and I won't pretend otherwise. This built thread has certainly taken an unexpected turn.... and neither camp will have me. This engine platform will get the T moving again and will not destroy the car. Oh its unconventional to say the least, but if you have read any of my build threads this is normal....welcome to my world.

While the engine is comically small, it should be fine. This truck is an eye catcher and is used for advertising. The little Honda engine makes the truck into a self-propelled sign of sorts.

The engine and transmission are to be crated and put in storage. At some point the truck and it's ?original? engine will be reunited.

Before the truck is released back to its owner, I'll gather some performance data and whatnot. Should be fun..

You'll need to log in to post.