12 days after my initial contact, the seller has agreed to send me a replacement tube. I'll stick it on the shelf as a spare.

12 days after my initial contact, the seller has agreed to send me a replacement tube. I'll stick it on the shelf as a spare.

So yesterday I was doing some bellmouth intake testing that involved cutting holes in cardboard. I was tracing circles and using a utility knife to hack them out, which took a while and left me with a pretty ragged hole. I also tried a compass with a knife blade, but it's designed more for fabric and didn't deal well with the corrugated cardboard. Then I said "I have a laser, duh". The laptop was already hooked up with LightBurn running. So I marked an approximate center point on the cardboard piece, drew a circle in LightBurn of the exact diameter, placed it using the camera and pew pew. Took about 20 seconds and I had the perfect hole.

Overkill? Maybe. The laser making its first appearance as a labor-saving tool? Definitely.

A few things I've learned.

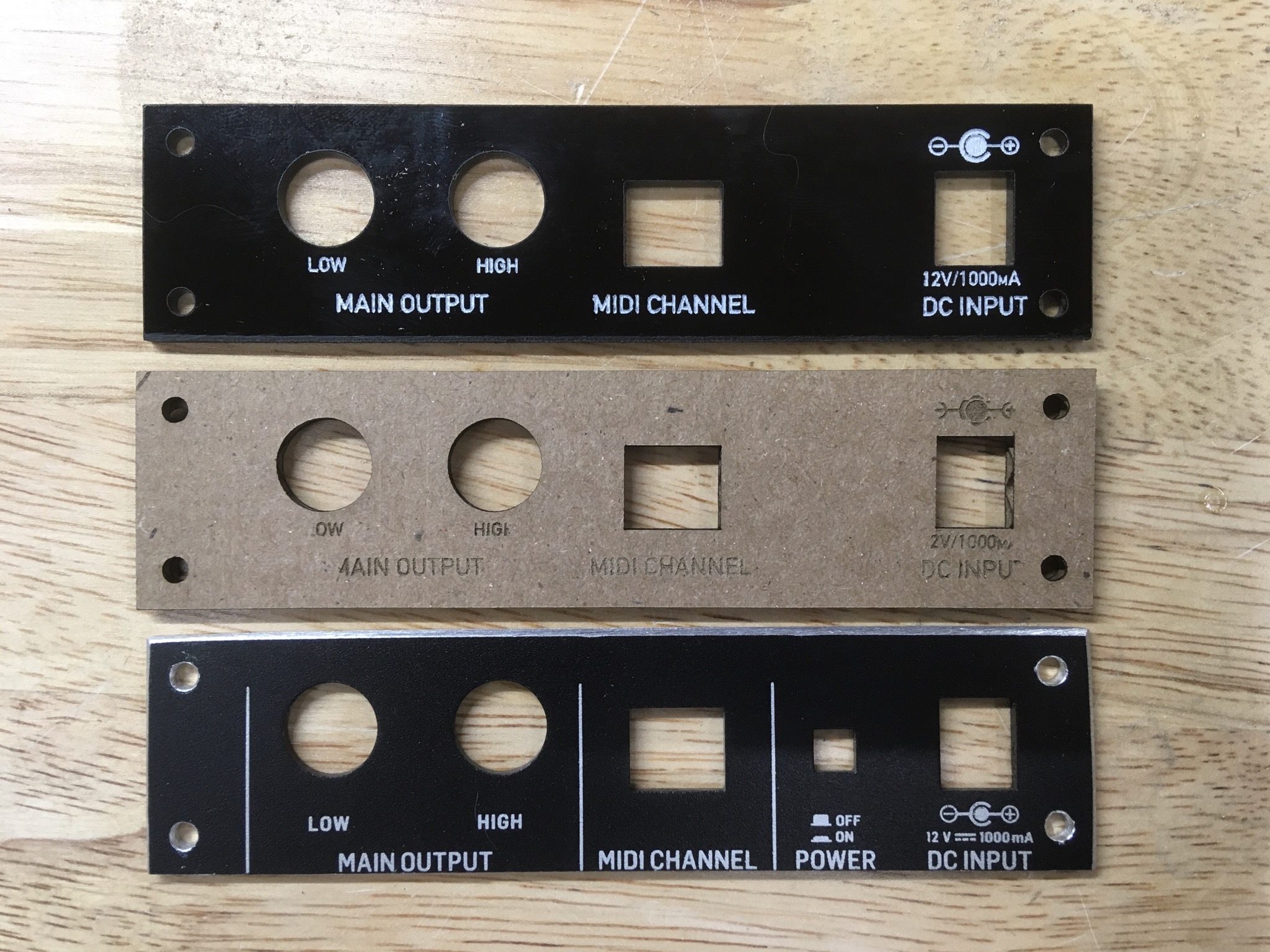

If you engrave acrylic, you can shoot the piece with paint before you peel off the masking to give a highlight. Just mask off the holes so you don't highlight the edges. Unless you want that.

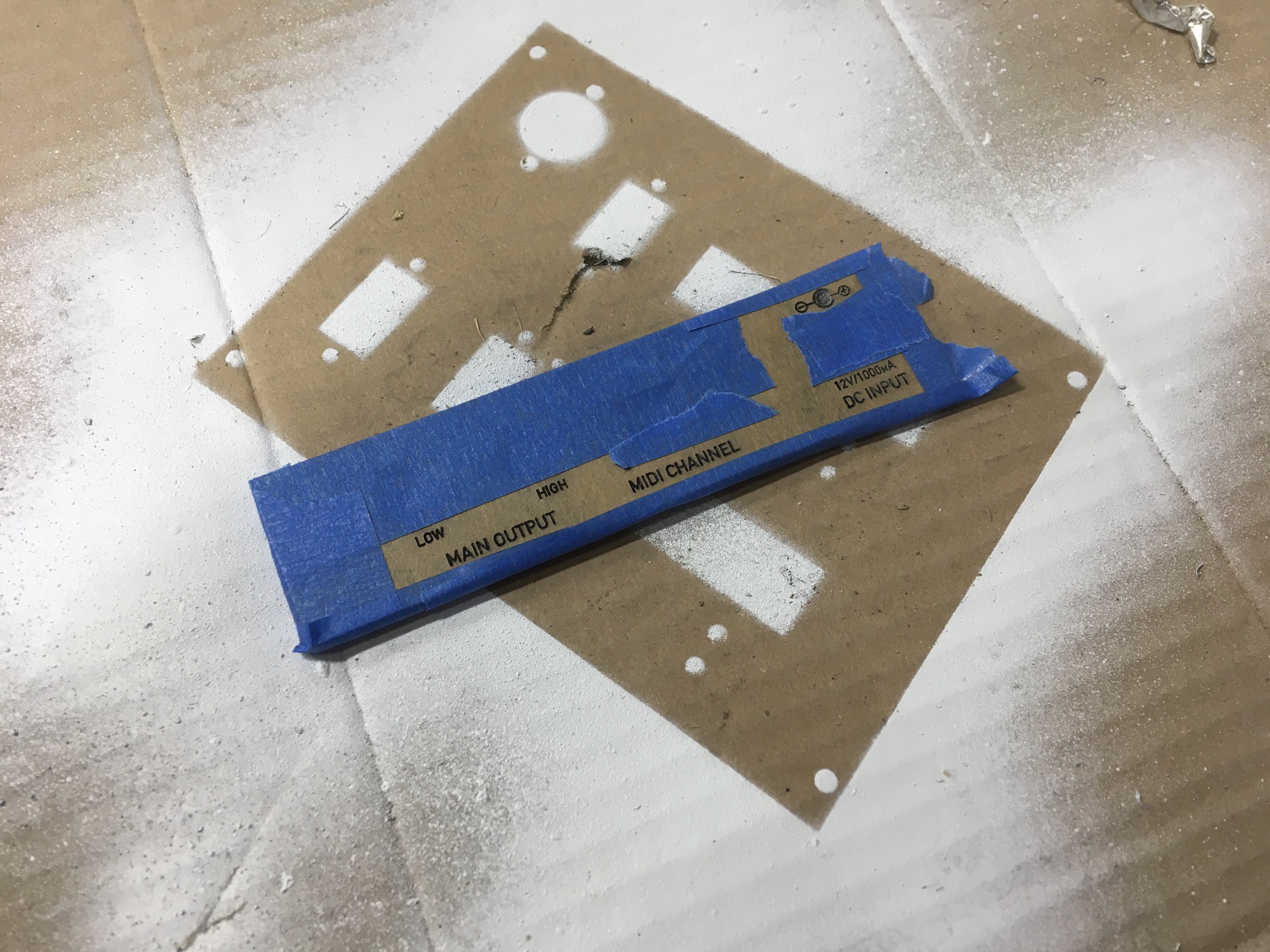

That's the result up top. The smallest text is 7 pt. And of course, the quick and cheap prototype made from cardboard.

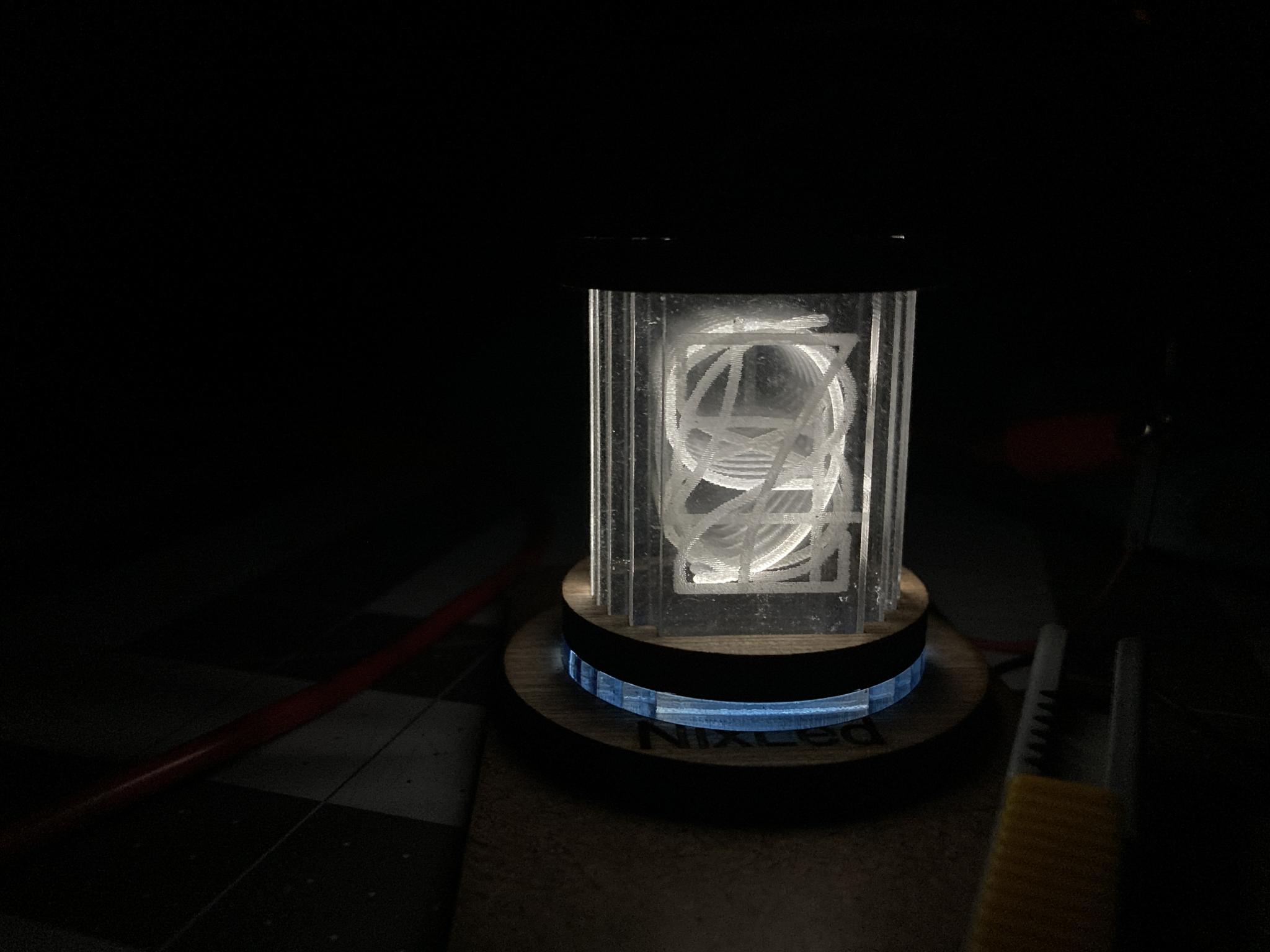

I've always liked fluorescent acrylic for the way it lights up on the edge. And if you engrave the bottom, it glows when it's on the table.

With the new tube, it's working well. I've found that gel ice packs work well for dropping coolant temperature. I keep a couple in the freezer in the little garage fridge and drop them into the bucket before I turn the pump on and it knocks about 4-5 C off the temp.

Update! Things are working, this is proving to just be a useful tool. I do need to recalibrate the camera, I think it may have shifted on the mount. I did a quick alignment adjustment in LightBurn but I want it more accurate than that.

I've collected quite a few variants of acrylic so I can experiment and to have it on hand. But the material I find I'm using quite a bit is 1/8" hardboard. $8.38 for a 4x8 sheet, which I cut into 9"x12" squares to use as raw material. That gives about 42 pieces at a massive cost of 20 cents each. It cuts and engraves cleanly and is fairly strong. The only downside is that it only has one good side. I have some 1/8" plywood as well but it's very prone to warping so it's hard to get a flat piece.

Here are a few projects.

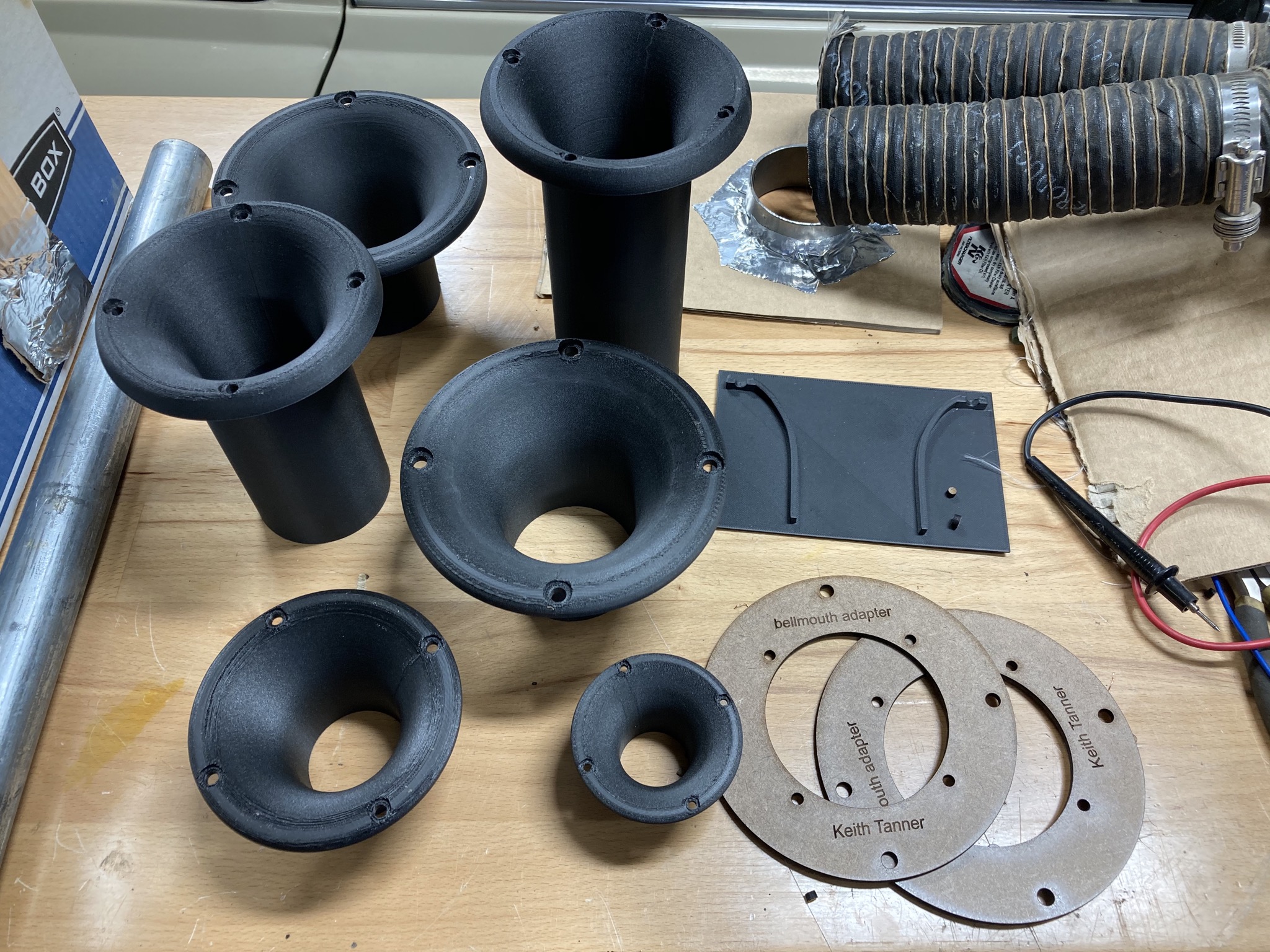

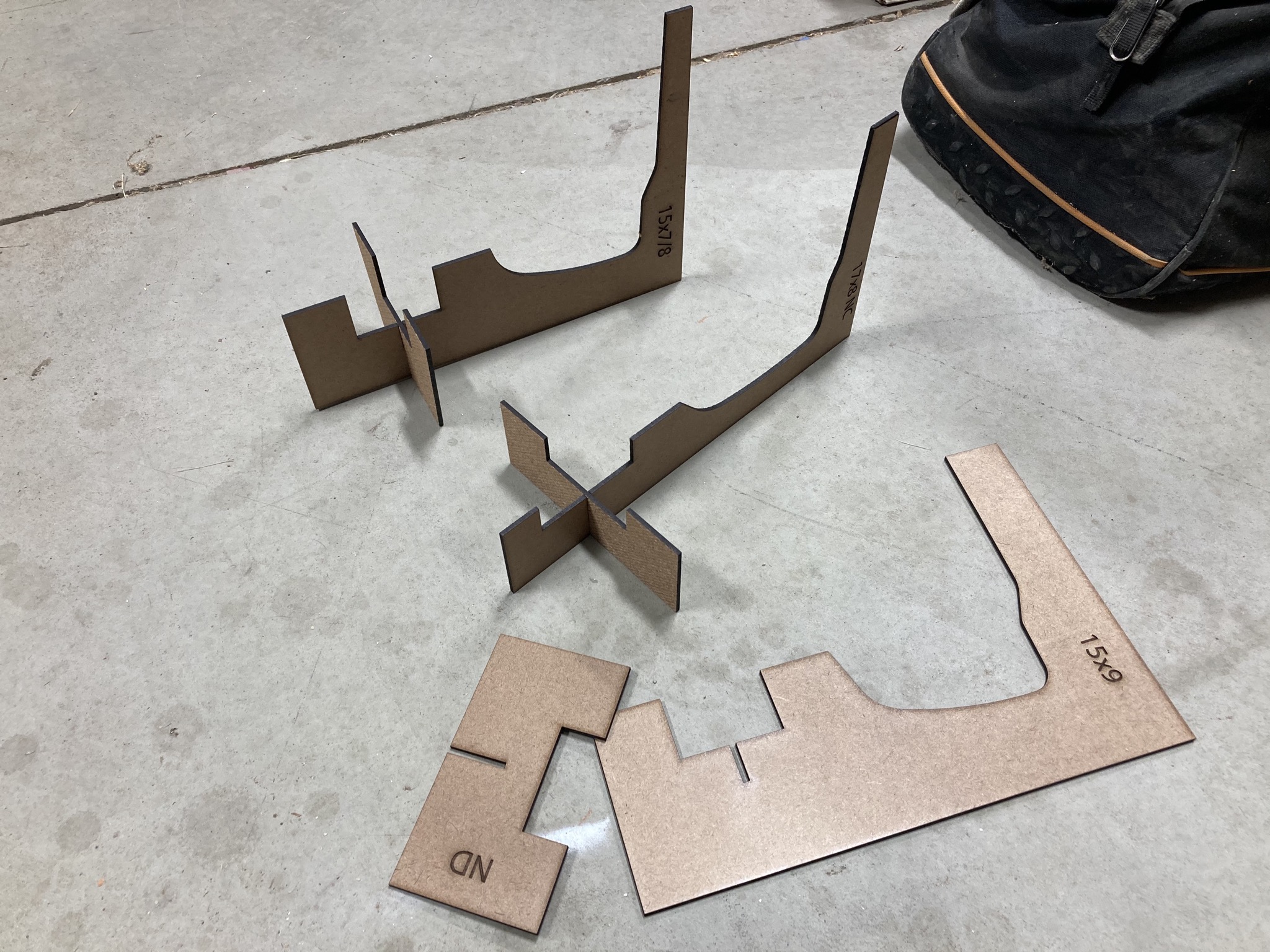

For the 3D printed bellmouths I've been playing with, I needed a flange to allow the smaller variants to use the same mounting hole. Quick and easy cut out of hardboard.

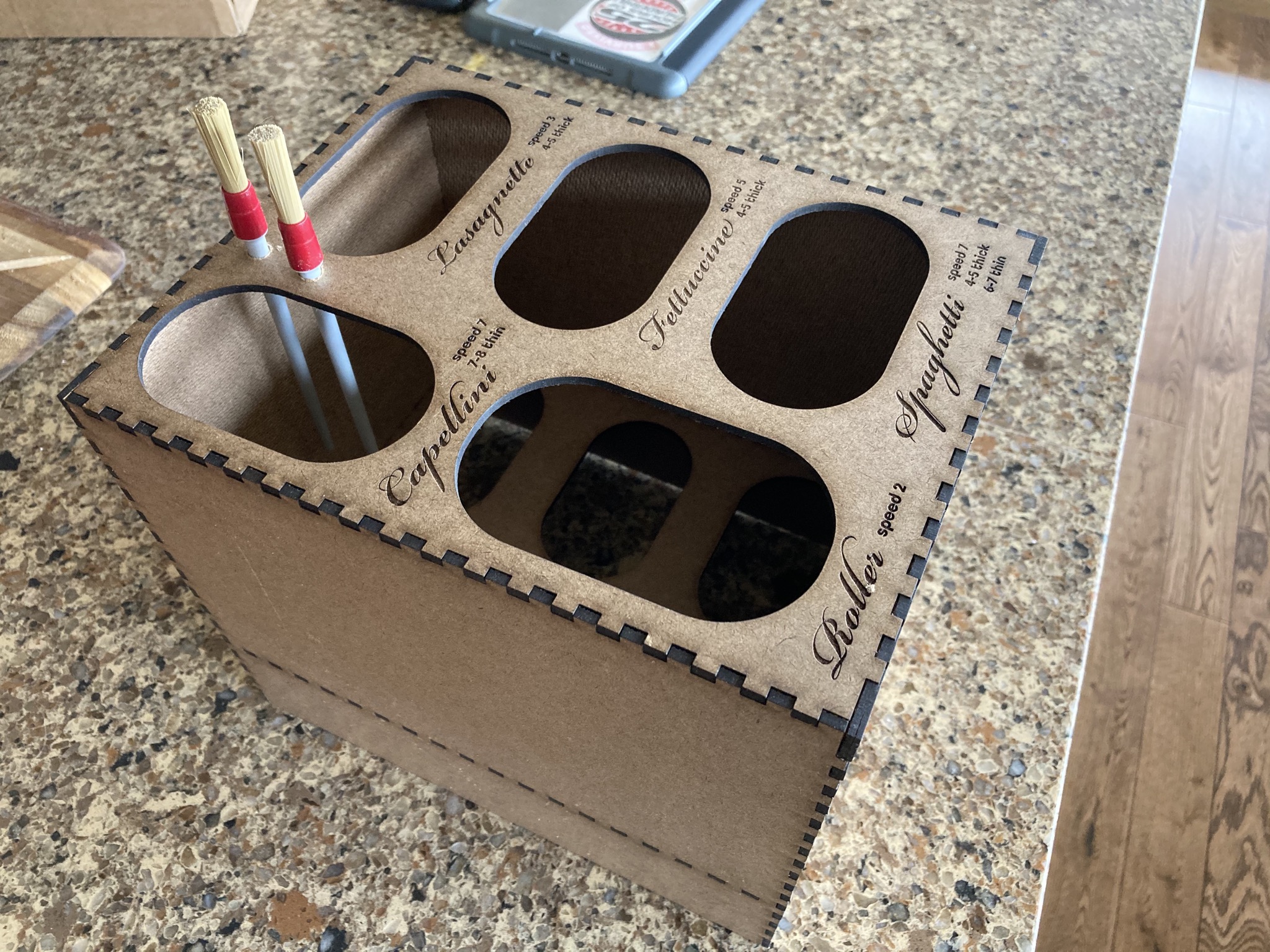

We have a Kitchenaid mixer that has a PTO on it, and some pasta attachments that plug in there. They're a bit unruly in the drawer and I'm always having to refer to what the appropriate settings for each variant are, so I decided to organize. Downloaded a box design from one of the online box generators and modified it to suit including moving the bottom level up. I did this in Illustrator because I have a high level of familiarity with the tool, but LightBurn would have been capable. I was a little parsimonious with my tolerances and I needed a hammer to put this together :) This one took a while, that top panel was about 16 minutes of laser time due to the engraved lettering. The end result worked exactly as I'd hoped.

Note, if you want to justify your weird tool acquisitions, make something for SWMBO with it.

I needed a way to check wheel clearance over various brake setups and I had a dimensioned drawing of the wheel. Pew pew, nice stiff templates that lock in over the hub.

And a goofy fun one. I've been playing around with an idea for a tiered table, and I realized I could make a quick and dirty version with the laser. First picture is a 3D model.

And my roughly 12.5:1 (2mm = 1 inch) model.

I did start working on anodized aluminum this evening, but haven't done anything other than a quick burn test to get a general feel for power/speed levels.

OjaiM5 said:I am really interested in this cutter Keith. Thanks for all of the information! Lightburn is the program that you run? I would be transferring files from illustrator

Hi .....if you want to play with one of these K40 lasers I just picked a used one up today ,

you can come down and borrow it and see if its what you want....

I am by LAX

or anyone else close-by , its just going to sit around and I need to get my desktop CNC going,,,,,,

Thanks for the offer! I bought a Ortur 15w and have been having a blast with it. But like Keith I want a K40 now. I have been doing skate decks for the kids at the local park.

Man, this is making me interested in getting my own laser if it has this many crazy uses.

Slightly off topic for you Kieth, but I saw those 3D printed ITB trumpets; how well do they work versus metal ones? I heard somewhere they were pretty brittle and too easily broken for most, but I might have made that up.

Those are brake inlets, actually. And it all comes down to the printer and the material. The carbon-fiber reinforced nylon we use would not be a problem.

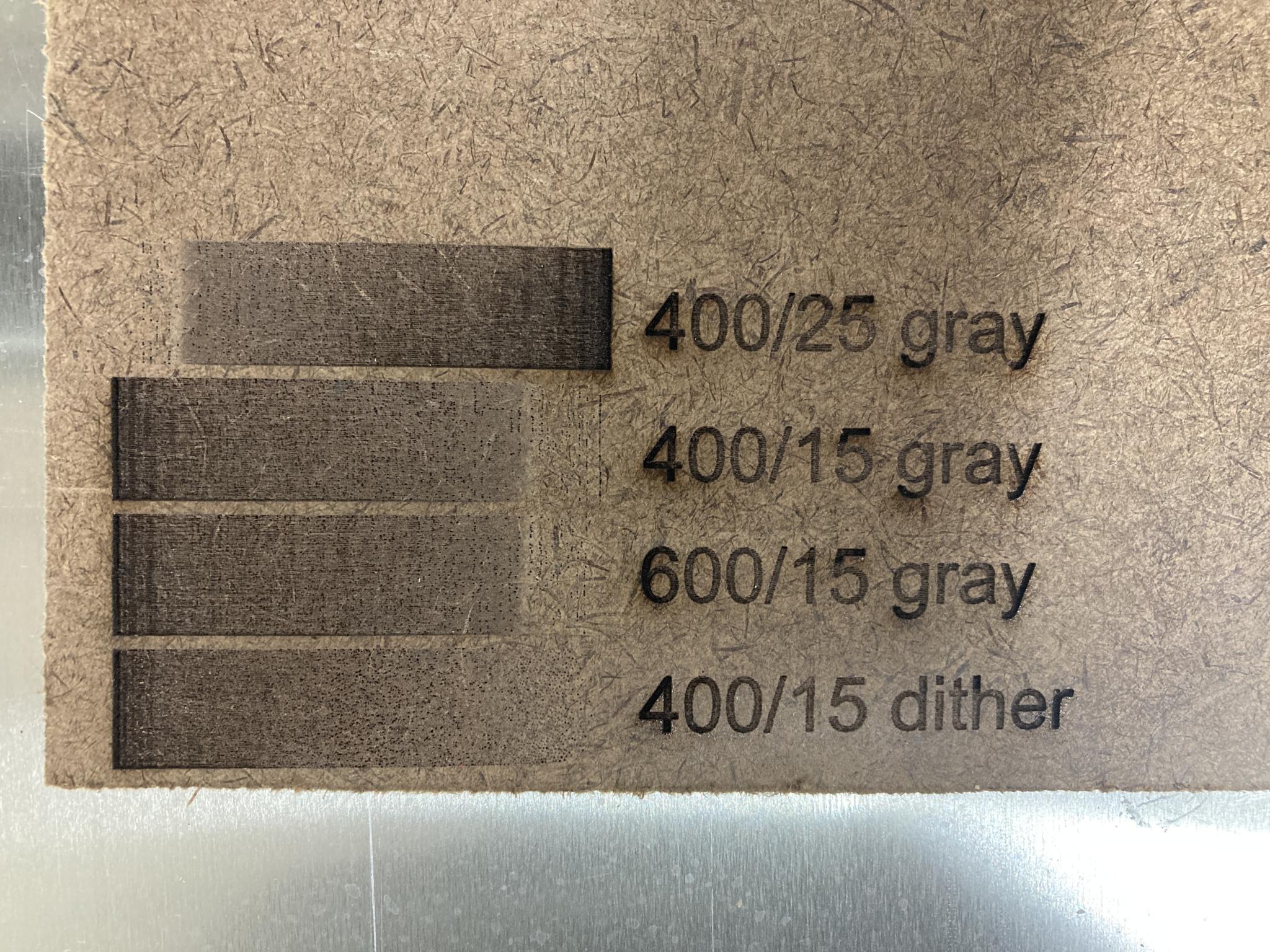

I realized this morning that the upgraded controller on my K40 can do grayscale and I haven't played with that. I have an idea...

Since Tom has started a 3018 CNC thread, I figured I'd do a quick update on the K40. It's just been working.

I've ordered a stack of acrylic in various colors and thicknesses, pre-cut into 9x12 squares. So I've got raw material to do things. Here are a few of the things I've made.

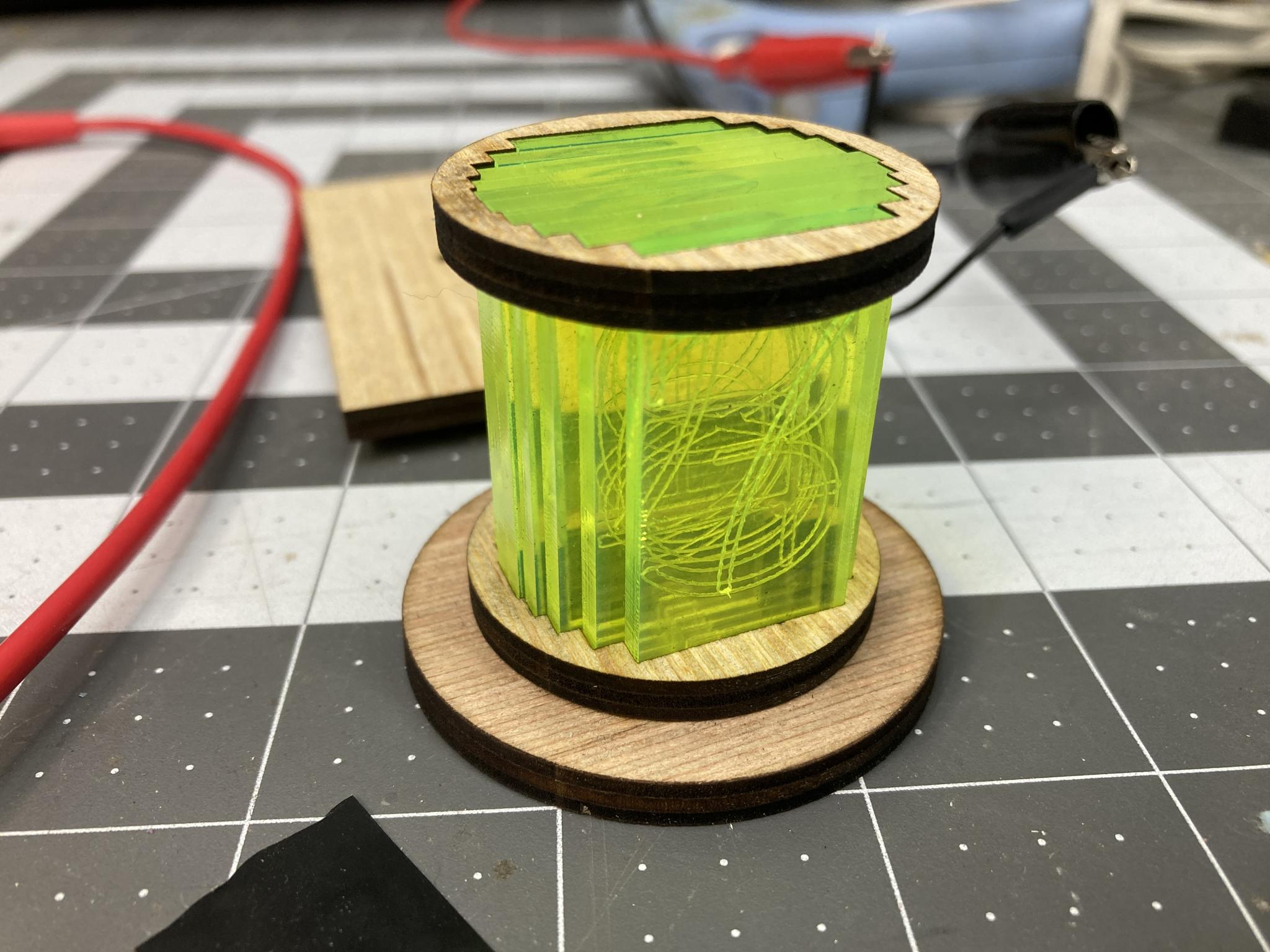

I decided to see if I could create nixie tube knockoffs using the laser and some electronics. Turns out this has been done but I didn't know, but hey. I've been having fun perfecting the design without looking at anyone else's work. The tolerances are tight enough that this is all a friction fit, no adhesives.

(yes, this one is a different "tube" out of clear)

I also built a slot light aperture for testing although the final version will use an LED array. The goal is to build this completely with the laser and no 3D printing. This is still underway.

I was reading about Tesla valves - think of a fluid diode - and decided to make one to play with. Here's the first run, I'm going to keep tweaking the design because this is just fun. That's 3 layers of acrylic sandwiched together. This one's too big to work without some pressure behind it.

I also built a dinosaur skeleton that I oddly don't have pictures of at the moment, so consider this a placeholder. (Edit: now with more dinosaur)

Janel has been doing machine embroidery and applique work, which often involves some fairly precise cutting. Some of these patterns come with SVC vector files, so I just load them up and zap my way through it. Super-fast and very appreciated.

And a few other switch plates (including a doorbell surround made of some nice wood), quilt rulers, phone stands, quick templates and the like. I've started playing with the greyscale a couple of times but haven't started a project that needs it. Here's a test run with speeds (mm/s) and power %. Those are all full black to full white gradients with an even transition. The top one I accidentally inverted.

Keith Tanner said:

Hey, my Dad made something like that back in 1973! He gave me a tour of his lab, something like this was on his bench. The interior was under vacuum but had valves in it, I asked how he cycled the valve without violating the vacuum. He just smiled and whipped out a pencil magnet, each valve had a small magnet glued to it. I later learned it was a laser for an aircraft wing. He was a glass blower at Knolls Atomic Power Lab. He said it was a nice mix of technical and artistry. When he retired he was the youngest one, they're not making any more.

Below is a picture of what I got when I retired, also laser cut, only posted it in case you ran out of ideas.....

It's been a while and this popped up in another thread, so here are a few things the laser has been doing.

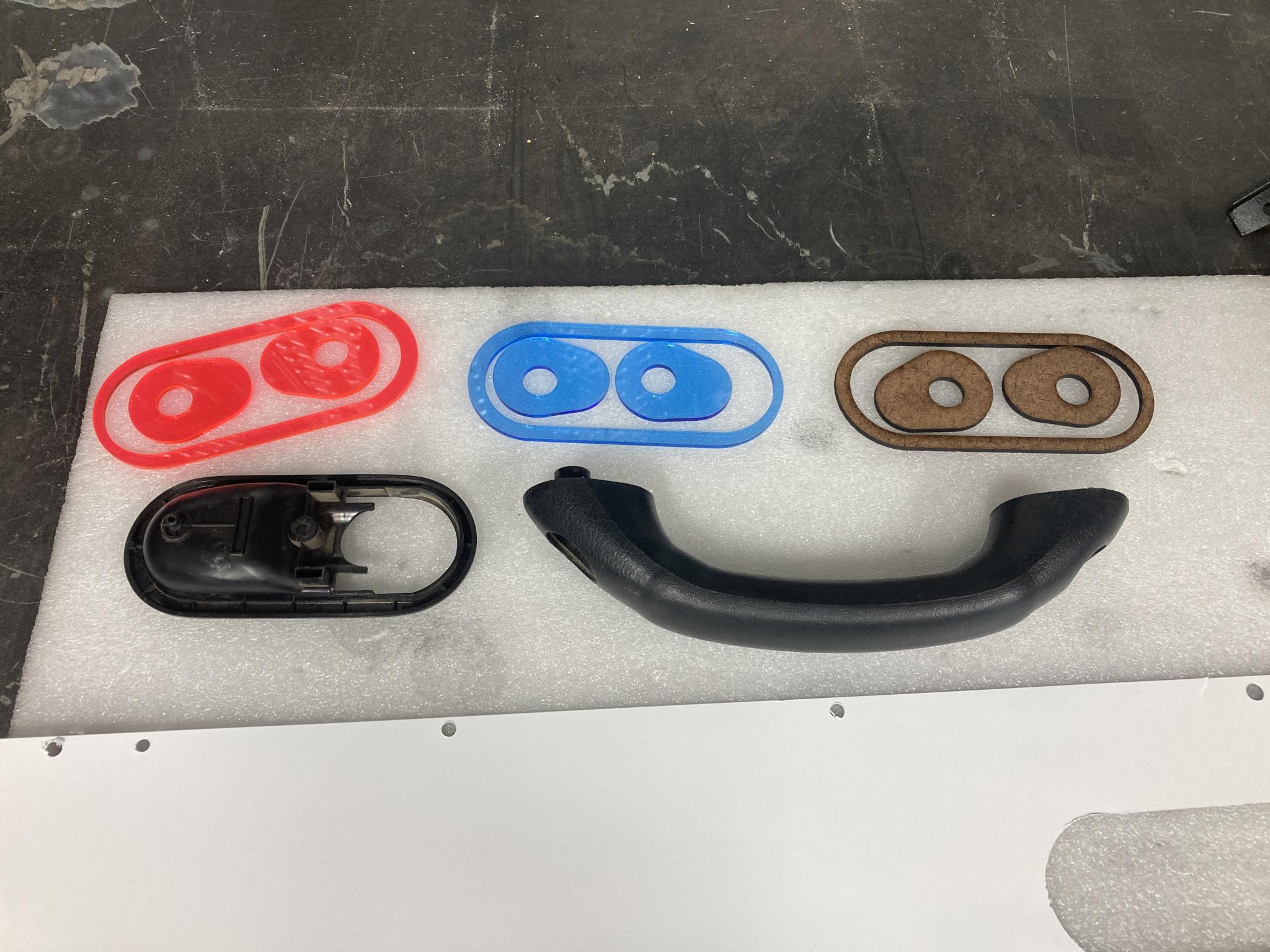

Gauge faces out of LED transparent plastic including a wooden template.

Bracket for a switch on a steering wheel.

Spacers for door furniture.

Shifter surround.

Goofy keychains (being used to test settings here)

A valentine's present for my crazy cat lady wife.

Cool stuff Keith , please keep posting as it will get me a kick to get mine going ,

I would love to make some neat gauges someday !

Meanwhile, what I want is a CNC plasma cutter :)

I did play around with bitmaps a bit, and learned it's important to do a bit of overscan so the laser isn't changing direction at the edge of an image while still emitting. Gets you a deeper/darker halo around the edge. That's just a setting.

I've also been playing with outlining rastered images, such as that black keychain. The arc above "Habudyne" tends to show some aliasing if you just do raster, but the vector outline has to be offset slightly or you lose tiny gaps due to the width of the beam. The offset is in micrometers.

Focus is important as well, I have a very old-school way of doing that. I'll post some pics later.

Keith Tanner said:Meanwhile, what I want is a CNC plasma cutter :)

I have 2 laser cutters and just sold a plasma cutter after own it for 5 years. I use the lasers way more. Unless I was making something structural, I found myself using the lasers. The plasma is good for brackets but not wall art, in my opinion. Happy to talk shop with anyone though.

singleslammer said:Keith Tanner said:Meanwhile, what I want is a CNC plasma cutter :)

I have 2 laser cutters and just sold a plasma cutter after own it for 5 years. I use the lasers way more. Unless I was making something structural, I found myself using the lasers. The plasma is good for brackets but not wall art, in my opinion. Happy to talk shop with anyone though.

Yeah, what you REALLY want is a water jet! That way you can output brackets and such without the surface hardening/scaling of the cut edge.

..I mean, if you're going to encourage the man to make bad decisions, encourage him to go all in!

Ha! I don't tend to use the laser so much for wall art as useful stuff, and it sure would be nice to poop out nice brackets or steel parts I could slot together. But there's absolutely no "business case" for it. It's just a cool thing. I might just have to start using send cut send.

Water jet would also do the job, but I have the disadvantage of not having water at the shop. Not an unsurmountable problem, but it definitely has me looking at plasmas first.

californiamilleghia said:Maybe a wire EDM machine .?

I know its too slow but it a real clean cut !

There's an untapped market, hobby-grade wire edm machines!

You'll need to log in to post.