Yup aluminum ribs and aluminum skin will be a much better starting point. Did I mention that I bought a welder? A Millermatic 211 and a Spoolmate 150 with a 20 foot lead. I've always planned on making provisions for walking on the roof and sitting up there in camp chairs to watch the sunset, concert, race, etc. I was initially thinking roof rack but I think I've got a much better idea now. I'm going to use my spool gun to weld aluminum angle or tubing to the existing Z channel. I'll double up all the existing ribs and maybe put some stringers in too. Might as well frame out the MaxxFan too. Then I'll glue and screw furring strips to that just like I plan on for the walls. Then spray foam, then paneling.

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Before you have the floor in how about some sort of plastic or metal fender liners for the rear wheels? Keep stull from being thrown up on the underside of the floor and everywhere else on the underside of the truck.

noddaz said:

Before you have the floor in how about some sort of plastic or metal fender liners for the rear wheels? Keep stull from being thrown up on the underside of the floor and everywhere else on the underside of the truck.

Bedliner is going in the wheel wells.

Ok, serious question here. My van has semi truck sized mudflaps. I was talking with Kathleen and said that since it has semi truck sized mud flaps, the only reasonable solution is to get the ones with the hot naked lady in chrome on black rubber. Right? She gave me an odd look. I said well I guess you could also run the "Back Off" mud flaps with Yosemite Sam on them. That would be reasonable.

Current mud flaps removed for the frame painting. They're 24" wide by 26" tall.

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Replacement flaps are 24" wide by 30" tall. 4" taller. Should be fine as is and even better after a lift and bigger tires.

$123 shipped is the best price I've found for the fiberglass reinforced rubber that stays flexible in the cold. What do you think? Are there cooler mud flaps out there? Is it a waste of money as long as the white ones aren't cracked?

The chrome naked lady outline ones have been my favorite since I was about 13. Still are.

You need the Naked Trucker mudflaps.

I took some daytime photos of the finished product this morning.

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Wait,

the spacer from the frame to the box truck is a 4x4? no way. wow.

That's still a pretty standard way to space things out on medium duty trucks. If it works for Morgan..........

So remember, when buying box trucks in the south, rust is less of a concern, but be sure to check for TERMITES.

Ian F

MegaDork

12/20/17 7:26 a.m.

In reply to ultraclyde :

Insect damage, perhaps, but termites nest in the ground. A truck would need to be stationary for quite some time to be at risk for termites.

RossD

MegaDork

12/20/17 7:58 a.m.

In reply to Ian F :

"Stationary for quite some time" is the preferred prerequisite of buying cars on GRM, in case you hadn't notice.

Petrolburner: great truck! great work!

Ian F said:

In reply to ultraclyde :

A truck would need to be stationary for quite some time to be at risk for termites.

Haven't spent much time in Georgia, have you?

Ian F

MegaDork

12/20/17 8:55 a.m.

In reply to ultraclyde :

I was born and grew up in Georgia.

Yeah it's wood. Squeak free and maybe a slight compression when the frame twists. Or tries to twist, I don't think the box frame allows the real frame to twist. But maybe that's why my van to box sealant cracked.

In the back you can see where a plate was welded to semi permanently join the box and the frame. Maybe I should have welded a bunch more on before painting? There's half a dozen big U bolts spaced out along each frame rail. I straightened out the wood blocks where necessary and then tightened all the U bolts before painting.

Any suggestions on fasteners for the base plywood to the frame? 5/16" by 1 1/2" long self tapping trailer decking screws? 100 will let me get all the edges and roughly one foot spacing on all the I beams.

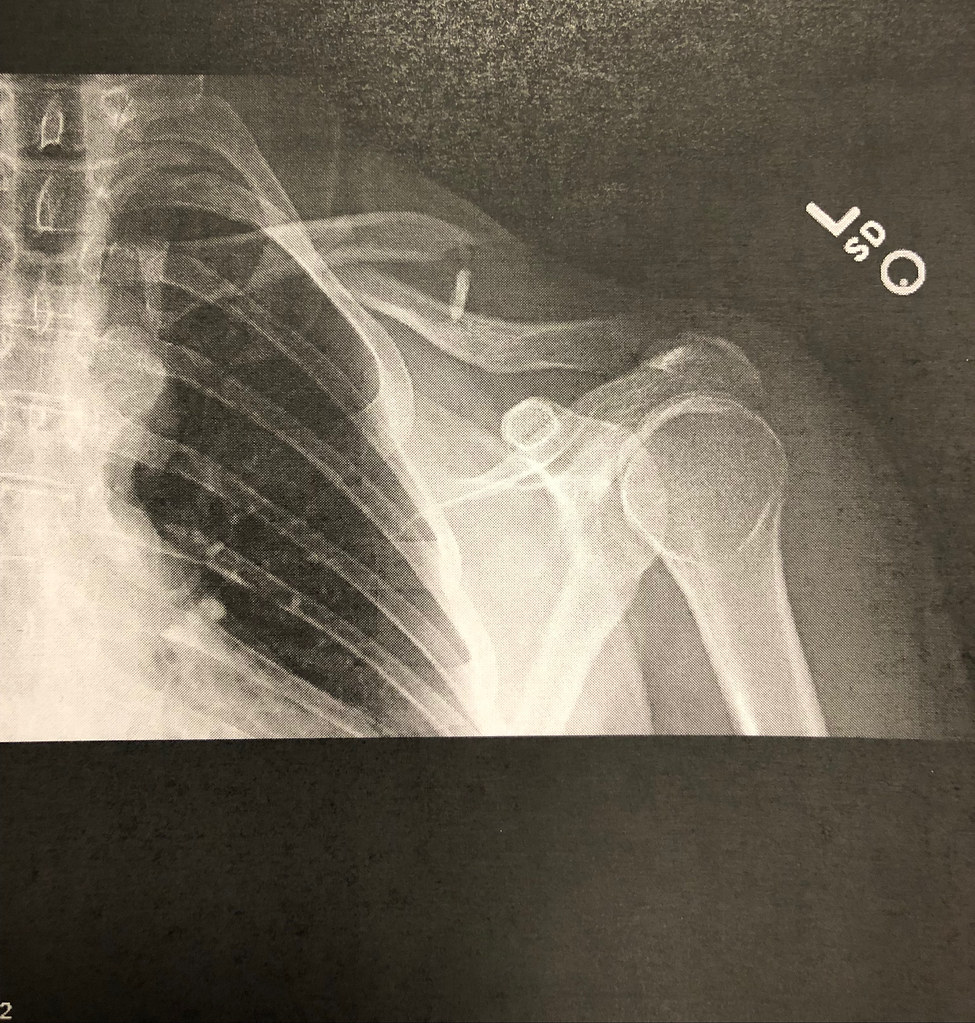

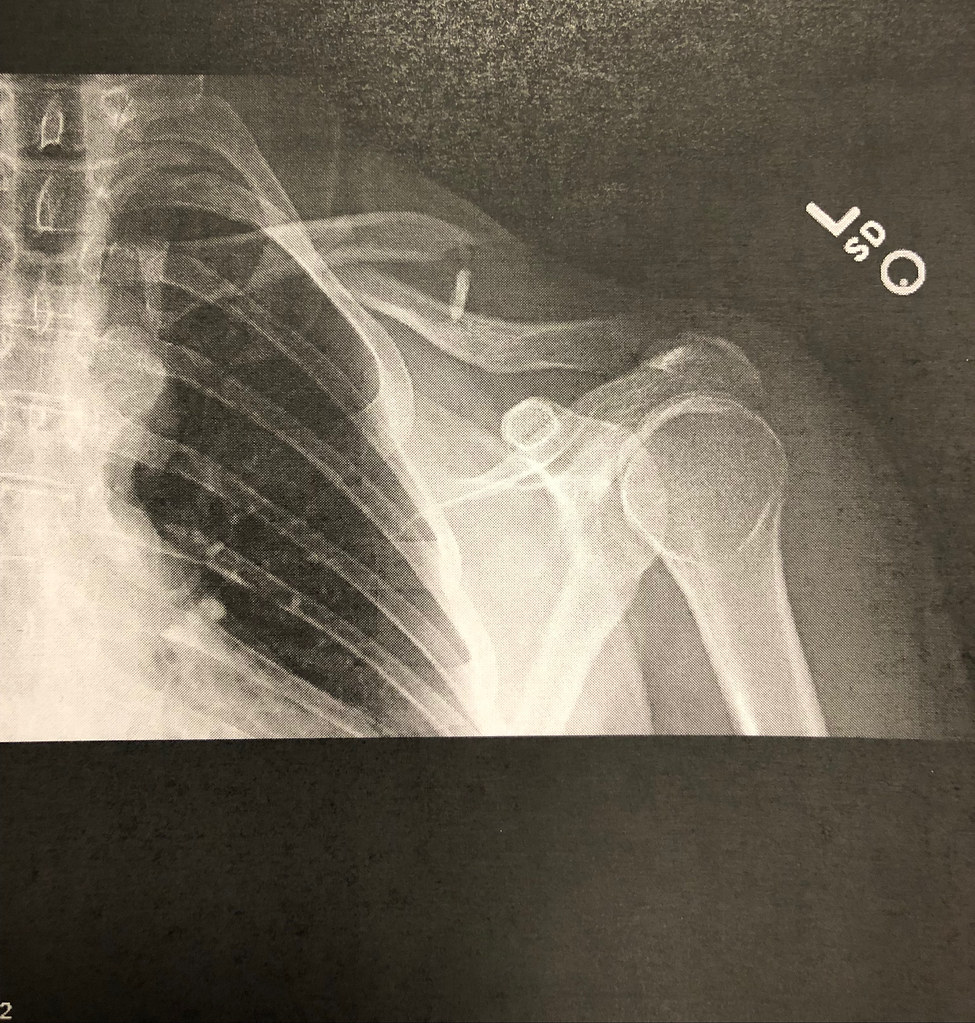

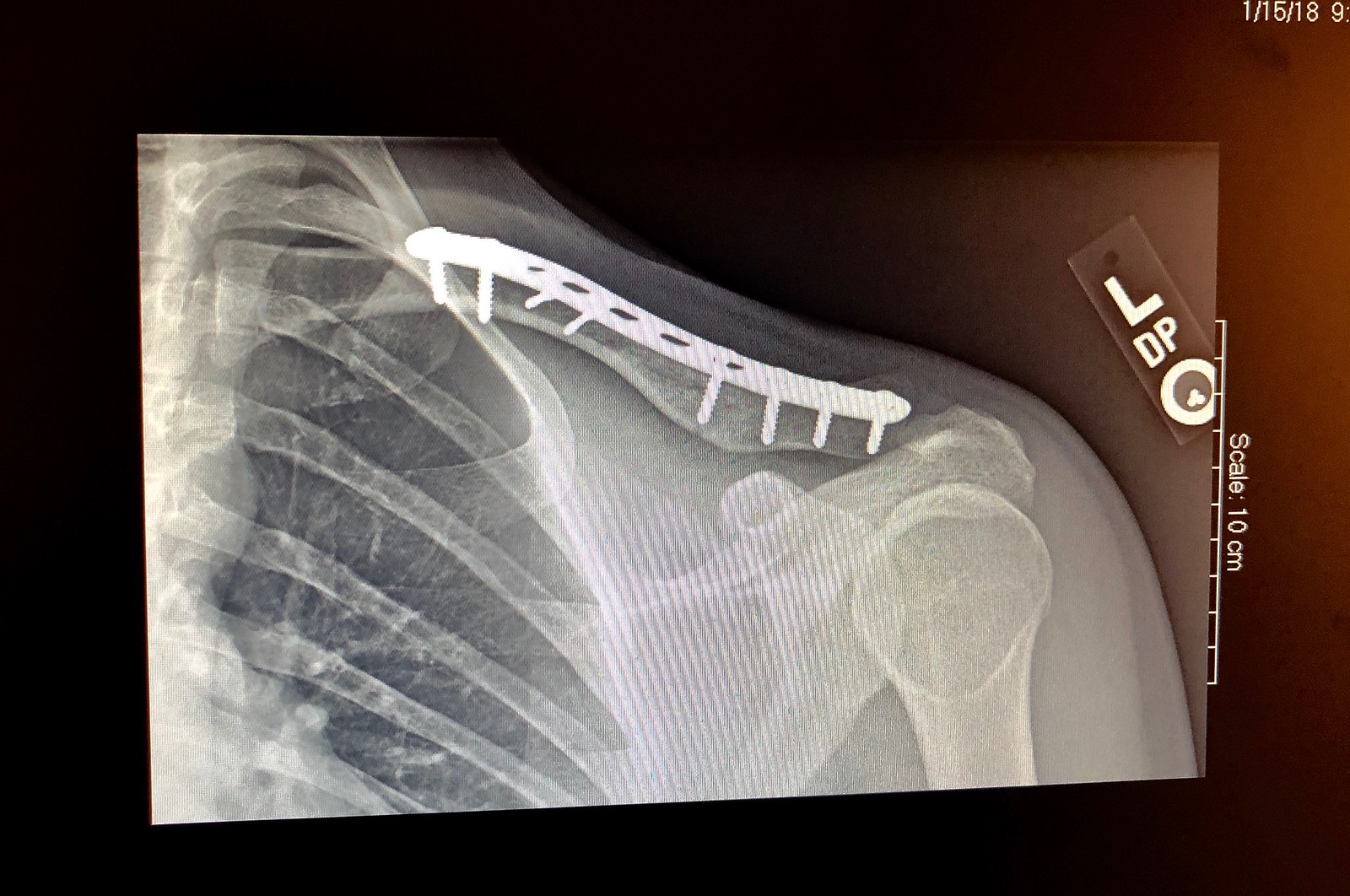

The build is going to be slowed down for awhile. I'm in a sling for 6 weeks.

Fractured clavicle by Petrolburner, on Flickr

Fractured clavicle by Petrolburner, on Flickr

Yikes, that sucks! Have they screwed you back together yet?

That one looks like it's going to need reinforcement. Ouch.

i'm no doctor, but i'm seeing the "something" bone that is not connected to the other half of the "something" bone... hope healing goes smoothly

Sucks. Just doing a sling? It's amazing what kind of malalignment clavicle fractures can tolerate with good outcomes.

Oof! Got all excited for Grumman update, sorry to see the damage. Hoping for a quick recovery!

Originally Posted by Raul

Originally Posted by Raul

Ouch. Sorry to hear that. Are you taking yourself to a dealer? If not you may want to do a DIY of the repair and post it on RecoveryPortal.com

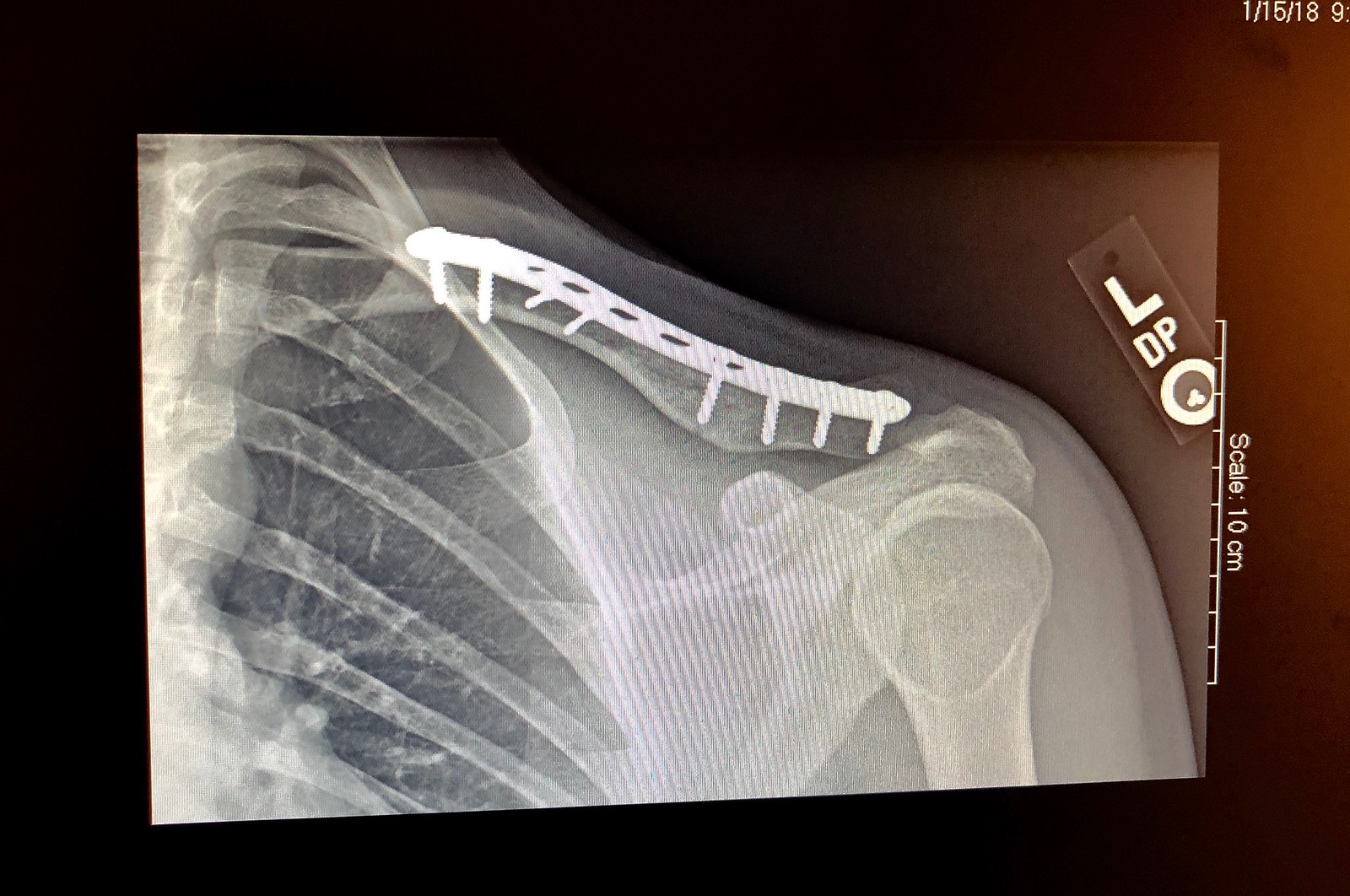

I've enlisted the help of professionals. They chose the size and amount of titanium hardware to install. The installation was done on Tuesday afternoon. The goal is to move as little as possible for the next two weeks so the bones can get tacky and expedite the fusing process.

Dead_Sled said:

Oof! Got all excited for Grumman update, sorry to see the damage. Hoping for a quick recovery!

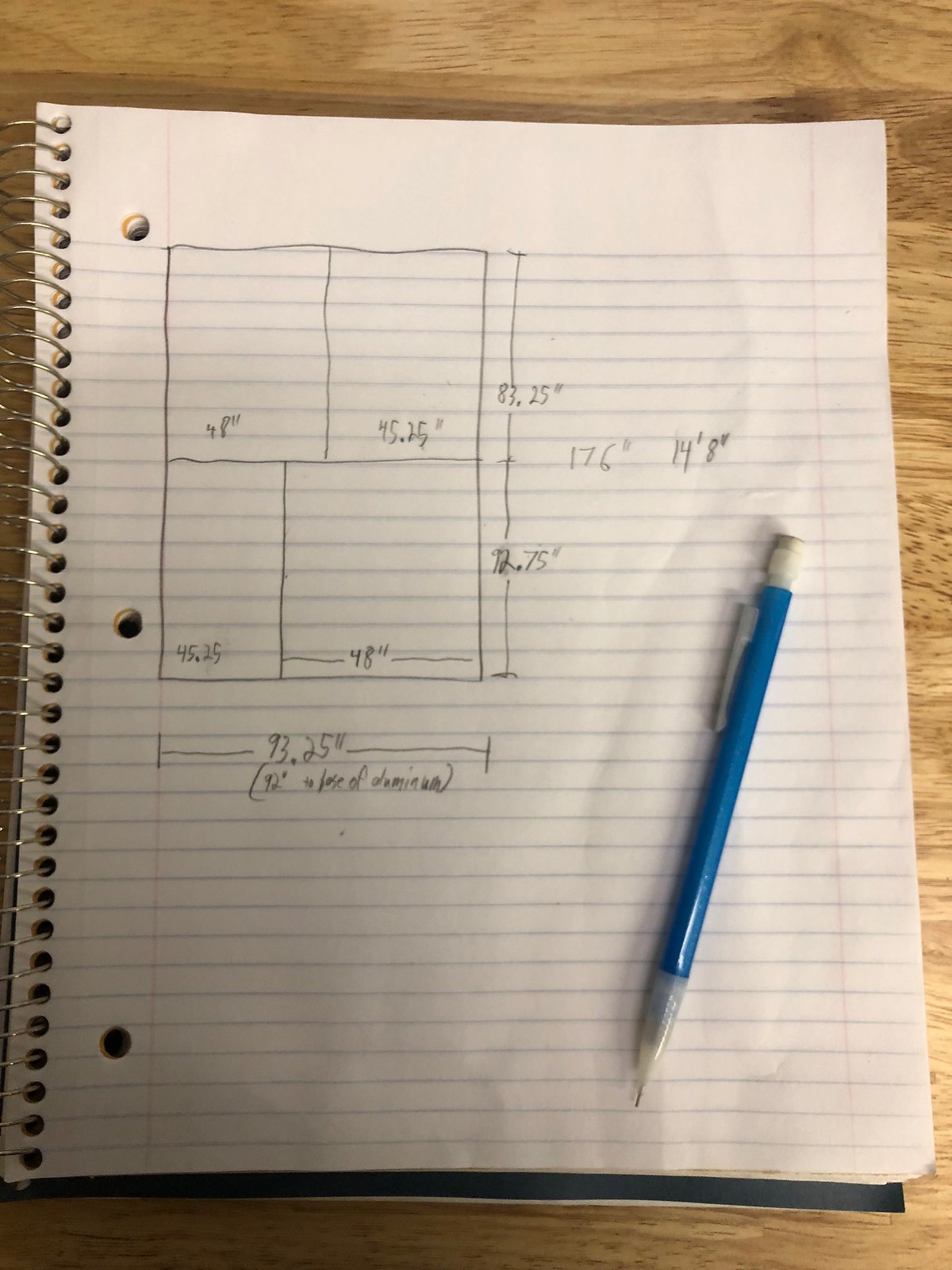

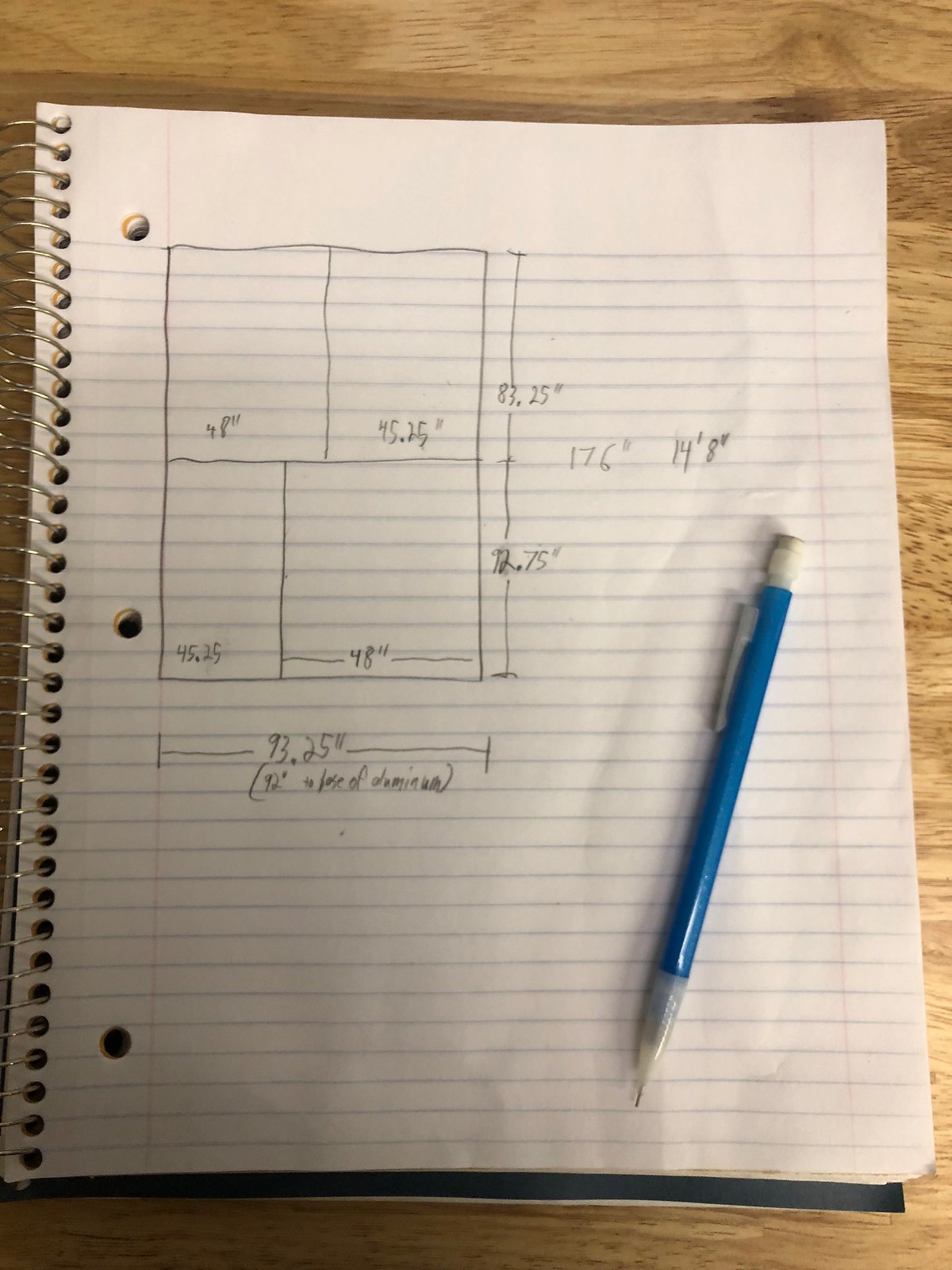

First layer plan. I wanted to avoid having the 4 corners lining up and making a weak spot.

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

Note the cat that I've trained to stay on the stack of moto tires. If she jumps down to wander around, she gets booted outside. As long as she stays right there I allow her to be inside.

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

First layer of flooring by Petrolburner, on Flickr

I missed some steel beams in the front corners while measuring. Therefore the plywood doesn't fit. I cut them a little too tight as well. I cant move the wood around now obviously. I also bought a router off craigslist. I think I can use it on the edges to create some overlap. I don't know the terminology or philosophy.

This next hardware installation is indirectly related to the progress on the BoxVan, or lack thereof. The good news is that the fit up was great and everything was tight at the 2 week post-op inspection yesterday. There is evidence of recalcification along the fracture already and that's a great sign. I get to start using my left hand again in another month.

Titanium hardware by Petrolburner, on Flickr

Titanium hardware by Petrolburner, on Flickr

Cut by Petrolburner, on Flickr

Cut by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr

Untitled by Petrolburner, on Flickr