NOHOME

MegaDork

11/29/23 7:02 p.m.

8 hours in and making good progress on removing the DS sill structure. I am doing the full inner, middle and outer sill for this project.

And don't worry, it really is as bad as it looked in the first pic.

I take a E36 M3load of pics as I go along, so if anyone who might be contemplating this kind of work wants detail pics of anything and I can post and explain. I can also make a point of illustrating when I get to the other side if need be.

The front half of the sill is relatively easy to remove. The back 1/4 after the B pillar is a lot of work

About the only thing holding the floor in one piece is the sound dampening strips.

Nukem

Reader

11/29/23 8:24 p.m.

In reply to NOHOME :

I've got the same job ahead of me (all three sill parts both sides plus floors), hopefully this winter, so these pics are appreciated!

The back sill parts looked pretty daunting to pick apart.

NOHOME

MegaDork

11/29/23 8:51 p.m.

In reply to Nukem :

The back section IS a royal pain. That said, it is mostly just drilling a 5/16 hole through all the spot welds. There are like 75 of them holding the parts together in this rear section.

Let me carpet bomb you with pics

I start at the front. I dont bother to pic the spotwelds on the castle where it wraps up the foot panel. I just cut around the perimeter and make a patch panel later.

I then use a sawzall and run it down the inner edge of the castle rail. Kinda follow the dotted line back to the crossmember. Save yourself the fun of picking all the floor to castle and inner sill spotwelds. Skip over the crossmember and you can cut along the castle until you reach the B post area.

Drill out the spotwelds in the side panel. At this point I also cut out the front of the outer sill. Note that I cut AROUND the flange at the bottom of the A post where the outer sill meets the B post. I come back later and clean that up with a flap wheel from behind because drilling out the spotwelds makes a mess of the flange.

On the inside there are some spotwelds and two stitch welds that need to be dealt with. Once again, just drill straight through the spotwelds with a 5/16" bit. I use a 1/8" to pilot drill the spotwelds. I use an old wood chisel to separate the layers. And an air chisel if you have one.

Then turn the sawzall sideways and cut right through the entire sill assembly just in front of the jacking point. Keep cutting until you reach the lengthwise cut that you made along the castle rail. That will free up this lump:

Some things to note in the pic below. The door is on the car beause I like to check for fit as I reasemble the car. It should have the gaps it started with so I leave the door on.

There is no bracing across the door opening. Never felt the need for it and done a bunch of these

Note the black tube that goes from one side of the car to the other. It is welded to both sides so that the outer panel on the DS does not move when the sill assembly is removed.

You can cut out another big chunk of sill assembly just behind the crossmember up to the rear chassis triangular thingie.

Then you are back on the drill. More pics tomorrow when I finish the job.

NOHOME

MegaDork

11/29/23 9:49 p.m.

In reply to Nukem :

Went out an took a few more pics, so might as well get caught up

Here you can see where I cut out the chunk behind the crossmember. You can also see where the holes need to be drilled to free up the inner corssmember. These are the easy ones. Just drill through with the 5/16" bit. The remains of the inner sill are still in there. I forgot to take pics of the vertical flange spotwelds that hold the inner sidepanels, the inner sill, the middle membrane and the outer sill together, once again, just a 5/16" bit through all the layers. The side panel does get a bit chewed up by the time it is all done.

You need to free up the ends of the castle, inner sill, middle membrane and outer sill drilling from the rear wheel well. I did not do it this time, but on the PS I am just going to cut out the piece of wheelwell tub around the perimeter of all those parts. It is easier to make a patch panel than to drill all the spotwelds and deal with the mess left behind. Besides, these areas are ussually pretty crusty to start witn

Then there are about 25 spotwelds under the car that need to be drilled out. Once again, no big deal, just a 1/8" chassed with a 5/16" bit. But drilling through all the layers under the car with no leverage just plain sucks. Hell, it was bad enough just trying to get a pick of the last foot worth of caslte rail.

The lazy man's answer is the jacko-matic drill press.

Total time to level the car on axle stands with shims ( important) and get this far was 7 hours. Maybe as much as another hour to finish the demolition job.

Total time to level the car on axle stands with shims ( important) and get this far was 7 hours. Maybe as much as another hour to finish the demolition job.

Nukem

Reader

11/30/23 9:14 a.m.

In reply to NOHOME :

I have a MGB restoration book with a bunch of black and white pictures that look like they had been photocopied a million times. This is orders of magnitude more useful than that.

Can you briefly describe the leveling / shimming process?

I have a similar project starting this winter on my TR250. Rockers shot, floors are surprisingly good, so a combination of factory replacement inner and outer rockers and a bunch of patch panels for the areas like the inner fenders that need some patches. Nice to see your technique and process. MGB's being unit body are much more complex, but the process is similar. Have to admit, first time I have seen a reverse drill press, but verse laying on your back and eating metal filings, I admire your creativity!

NOHOME

MegaDork

11/30/23 10:08 a.m.

In reply to Nukem :

I like to have the car sitting flat because it avoids any twisting forces from being introduced to the tub while it is partially pulled apart.

The floor in my shop is not perfectly level

Leveling the car is simply a matter of using a few levels along the inner sills and across the rear fenders, then add shims under the axle stands or on top . I have a bunch of aluminum strips that fit in the saddle of the axle stand. I then mark the position of the axle stands on the floor and what shims were used at that corner should I want to move and relevel the car at a later point.

Once the floors and sills are done, I think this one will go on a spinner just so as to keep my old body off the floor! You cant do structural work on the spinner because of the aforementioned twist forces.

At one point I had a frame that I could level and then put the car on top of. This had the added benefit of telling me if there was any twist in the frame before I started. If you want to use a laser to make sure that the tops of all your stands are level, you could do that and it would tell you if the chassis is bent or straight.

NOHOME

MegaDork

11/30/23 8:32 p.m.

Continuind.

Here is the last bit of the castle rail after the reverse drill press action. Just 5/16" holes About 20 of them and three from the wheel tub side.

What it looks like once freed from the flange at the back by drilling out 3 more spotwelds and making even more swiss chease of the wheel tub

Next is the remains of the inner sill that is wedged into the rear frame rail receiver. This sucker is in tight and so will the new one be once you finally get it in there.

Next is the remains of the inner sill that is wedged into the rear frame rail receiver. This sucker is in tight and so will the new one be once you finally get it in there.

Here is a view of the flange at the rear of the inner sill that attaches to the wheeltub. Pretty chewed up after all the drilling.

And here, after much cussing and fettling is the new inner sill in place. Now, if you are really smart, you would anticipate where the paint should be removed for welding before you install the part. This is because it does not want to come out once it is in place. But it has to. Sucks to be me.

Got all the parts trial fitted and nothing alarming to report. One thing that does bear knowing about MGBs is that the DS outer sill has a flaw from the factory. It is too short. With the front lined up, the flange should mate tight to the hole drilled in the wheeltub. But for some reason they do not. The answer is to shove the sill rearward until it does mate to the wheeltube, but that then leaves you with extending the front of the sill and dealing with a large gap between the bottom of the fender and the swage line that should have lined up with the bottom of the door.

Almost looks like a solid car again, minus a hundred or so spotwelds and a bunch of fine tuning. You can really see the gap due to the outer sill being too short at the back where it is meant to meet the wheeltub. Will address that in the future.

Nukem

Reader

12/1/23 2:22 p.m.

In reply to NOHOME :

Your fast pace is making me feel bad. I've had all these replacement panels on a shelf for like 3 years now...

JK this is really invigorating.

Do you have any tips on doing the leaf spring perches? Looks like yours are in ok shape but I've got one that definitely needs doing.

NOHOME

MegaDork

12/1/23 6:10 p.m.

In reply to Nukem :

Keep watching...All four pickup points for the leaf springs are a mess. They are the scariest part of the sandblast that was not known of beforehand. At this point there is no going back.

Today was just adjusting the fit on the sill components and drilling/punching a bunch of holes to weld the parts together. Might get to burning stuff together tomorrow.

NOHOME

MegaDork

12/4/23 9:08 p.m.

So 10 hours of work later and while I might not have a lot to show for it picture-wise, a lot has been accomplished.

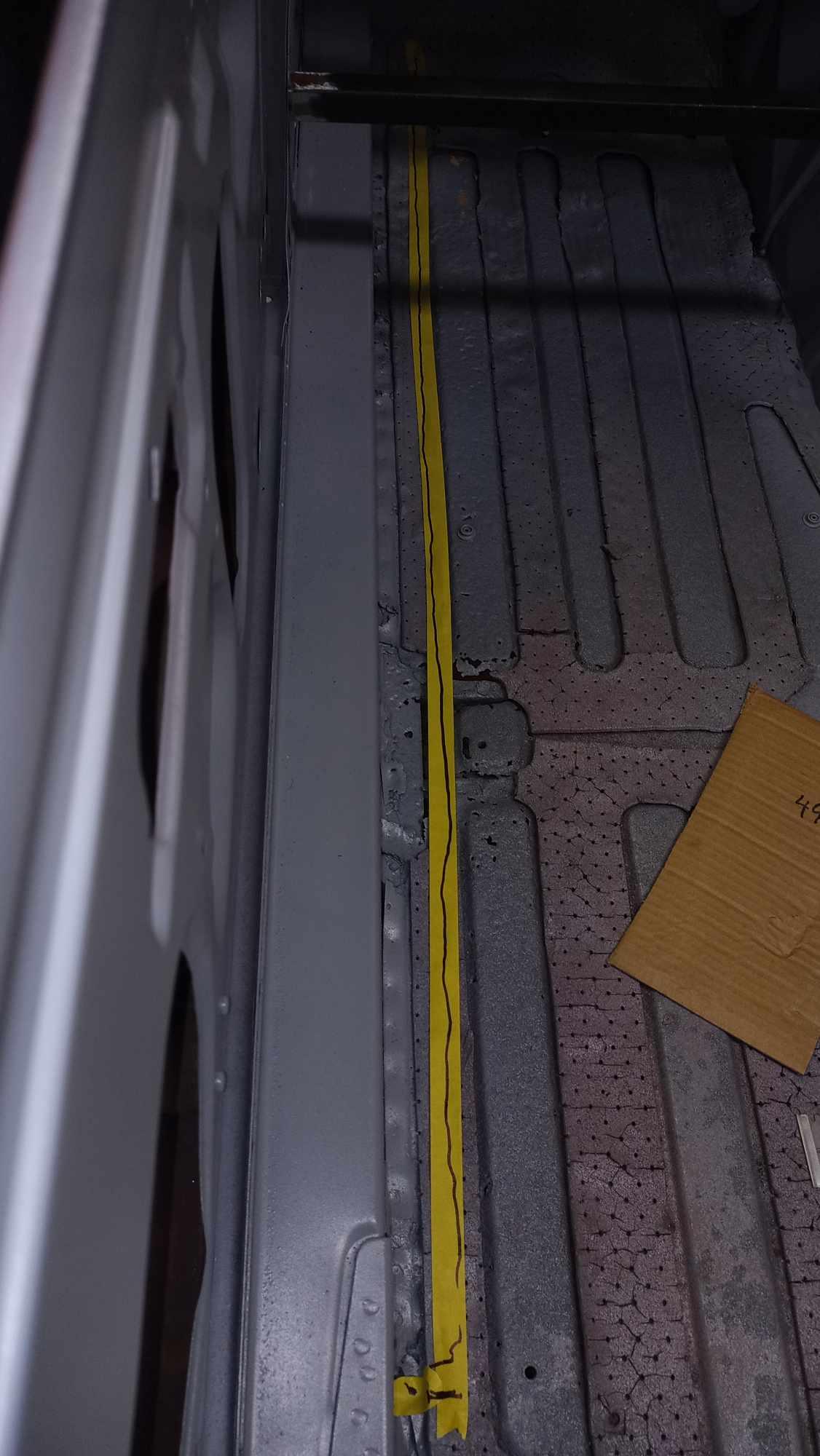

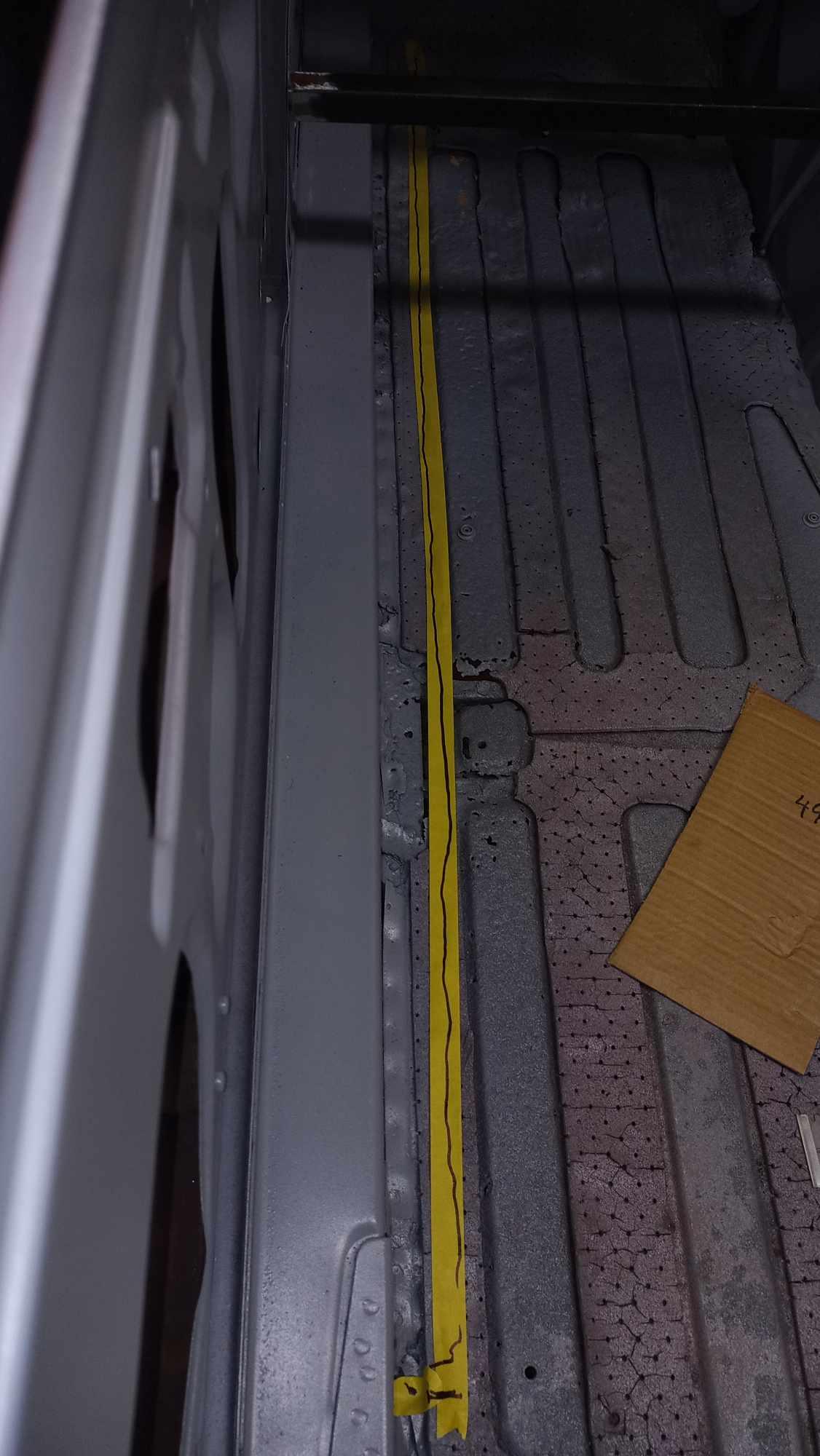

This is the rear wheel tub looking forward. Between the rust and the 20 or so spotwelds that had to be drilled out to free the sill parts, there was not much left of the tin. So out comes the masking tape to make a random-shape-i- don't wanna-measure template. The black line is where the inner and outer wheel-tub sections meet and overlap. So I have to make this out of two pieces or else it will look wrong as a single flat piece of metal.

And some time of more magnitude than I want to admit, it turned into solid metal again.I have pre-drilled the holes needed to attach the sill assemblies that butt-up to the other side of this panel.

Similar effort at the front. At first it looks like a simple rectangular patch, but it wraps around and forms part of the toe-panel. So yeah, once again, way more time than it seems to deserve.But it is done.

At this point I could locate the front of the inner sill with the two self-tappers. This means that the inner sill is committed location wise and I could then spend a few hours making the rest of the parts play nice.

One of the problems of giving your tin-guy aftermarket parts is that he is going to burn hours of your time making them play nice with each-other. So if you think that spending years collecting parts at swap meets is a money saver, your time better be free.

The middle sill is laying over the outer sill panel. You should not be able to see any yellow if the parts nested as required. Either the middle sill membrane is too short or the outer sill curve is wrong and the resulting panel is too tall. Gotta fix that somehow.

If all goes well tomorrow I will burn a lot of wire. From here on, once I stick the two panels above on to the car, there is no going back and there are well over 100 spotwelds to be administered,

Nice work as always, Pete! You're more patient than me with drilling spotwelds. I usually weaken them with a grinder, then pop them loose with an air chisel. Can't do that with all of them, but with the parts you're scrapping it's a real time saver.

NOHOME

MegaDork

12/4/23 9:40 p.m.

In reply to Carl Heideman :

You ever restore any that really should not be saved? This might be one of those, but it will work out in the end.

NOHOME said:

In reply to Carl Heideman :

You ever restore any that really should not be saved? This might be one of those, but it will work out in the end.

I'd say 3/4 (maybe 7/8) of the cars we've done shouldn't have been saved, but the customers wanted them saved and we know how. Sounds like you're in the same boat, and honestly, it's a good boat. If we did things because they made sense, life would be pretty boring. You clearly have the right attitude: It's about the journey and the challenge, and that's why we enjoy your projects so much.

This one is the worst one we ever did. I think we had like 500-600 hours of metalwork/welding in it. We replaced almost everything from the tunnel out, after we replaced the bottom 1-2" of the tunnel!

It's funny that it was so bad, but the picture keeps showing up on the internet. In October, it showed up again in Moss' Instagram post because I wrote a magazine story or two about it 15 years ago. (mg_josh worked at Eclectic back then and did most of the work on this one.)

Anyway, keep up the great work. You're inspiring a lot of people right now (no pressure)!

NOHOME

MegaDork

12/5/23 12:20 a.m.

In reply to ish_da :

You gotta be careful sending 1800s to my shop! Strange things happen to them...

I did this job on my 72 BGT in the mid 1990s while it was semi-retired in my brother-in-law's barn in Ithaca. Two harbor freight engine stands and some scraps morphed into a ghetto rotissiere. Entire driveline removed. Beer was involved. Full outer, membrane, bottom (castle section) and 2/3 of the inner if memory serves. Bottom of front fenders, rear quarter patches outer front of floors on passenger side, floor stiffeners, etc... I ended up with a couple of extra jacking point reinforcements so I added them midway. Zinc rich epoxy primer held up well. It ended up with a fuel injected 3.4 liter Camaro V6 and T5. But I kinda did miss the sidedraft Weber and the flick of the wrist overdrive - Laycock on 3rd and 4th gave it bearable highway cruising.

I think I've got a Practical Classics publication which is a compilation of a series of full color magazine articles on an extensive rebuild including sills and extensive rust repair. Not sure if it is kosher to scan a few pages to share, but happy to do it.

Great work, thanks for sharing.

NOHOME

MegaDork

12/5/23 6:56 a.m.

In reply to BrianC72gt (Forum Supporter) :

Brian:

Thanks for the offer. This is like MGB sill job #10 so proof that I never learn anything anyhow!

I will put this car on a spinner, but not until it is solid. Rare that an MG chassis will sag, but it can twist if you don't do this work on a level surface or if you do it on a spinner. As a bare shell, it is pretty stable to do this kind of repair.

NOHOME

MegaDork

12/6/23 8:41 p.m.

Making progress! Doing shell restorations is like building a house where you have to tear the whole thing down to the foundation hole when you get to the roof and the peak is not perfect. More than once! Nothing fits but it has to.

The good news is that:

The end panels on either end of the sill are repaired

The inner sill is in place and finished welded

The Castle Rail is in place and finish welded

The middle membrane is in place and welded

The B post is repaired where it meets the sill

The outer sill is ALMOST welded in place. But for this little flaw buildt into MGB driver's side sills.

The sill is too short. Has been for as long as I have been doing this. So you need to move it to the front or the rear and deal with the other end.

If you shove the sill to the rear it meets the B post where it should and it meets the rear wheel-tub where it needs to be welded.

But then you have to deal with this:

No big deal. Fix with hammer. Nobody going to see.

But then this:

The swage line on the sill needs to line up with the leading edge of the door. First time I dealt with this I split the sill in the middle and welded in a bit of tin. That sucked.

What I do now is cut a strip of 1/4" flatbar and put a curve in to match the sill.

I promise to line it up a bit better at the top before I hit it with the melty wire gun tomorrow and make it a permanent part of the sill. Then a bit of flap wheel to blend it all in.

If all goes well I will wrap up the DS sill tomorrow and get started on the PS. The good news there is that the inner sill does not need to be replaced. Also for some odd reason, the outer sill is not made too short for the car. Gofigure.

NOHOME

MegaDork

12/8/23 8:48 p.m.

The DS sill assembly is done.

I am trying something new. Since I do not want the bare metal bits to rust, I need to coat them. The tub is currently coated in epoxy. So I tried a spray can of epoxy that only activates after you spray it and it meets air.

Moving on to the PS got about half of the demolition done. Still have the dreaded lower post-b-post bits to free up. Thats four layers of spotweld to separate and no room to do so.

This side will go a bit quicker because I am not going to replace the entire inner sill. The only perforation is at the front where the passenger's toes would be. I will cut it back about 1' from the front and splice in a repair section. The rest will get buzzed with the wire wheel and POR coated. Probably only last another 40 years before somebody has to do more repairs.

Sadly, the sandblast treatment found a bit more lace in the central cross-member. The original plan was to do some repairs on the outboard ends, but that ain't gonna cut it this time. Replacing the entire cross-member will be a first for me.

Nukem

Reader

12/8/23 10:05 p.m.

In reply to NOHOME :

Did you make that cross member repair section?

My cross member is solid except for the outward most part of the passenger side.

NOHOME

MegaDork

12/8/23 10:23 p.m.

In reply to Nukem :

No I did not make them. They are like $17 USd or so from MOSS Motors. The full cross-member on the other hand is like $250 plus shipping and 13% Canadian tax; so like $500 Canukbucks.

If you are so disposed, they would be pretty easy to make. Just some 16 gauge tin folded a few times.

NOHOME

MegaDork

12/21/23 9:09 p.m.

Guess I have been remiss at keeping this thread up to date. Sadly, I lied and the sill job on the PS will be the full-monte.

Did not take a lot of pics because it is the mirror image of the DS. This is where I left off today. You would not think so, but that is 5 hours of welding and almost the same number of get- up and get-down on the floor moves. Turns out it takes a lot longer to replace a spot-weld than it does to cut one out.

I let out a sigh of relief at this point because the car is solid once again and the doors have the same fit as when I started. The outer sill still needs to be installed, but it is more cosmetic than structural at this point. Unfortunately there is that bit of crust at the base of the B-post that needs to be cleared up. It is a bit finicky due to location and how it interacts with the surrounding bits.

Outer sill should be on tomorrow if all goes to plan.

Nicely done! I enjoy seeing your cutaway shots and the way that you deal with it in sections. Hope you have a happy holiday full of welding, if that's how you're going to spend it. :-)

NOHOME

MegaDork

12/22/23 1:30 p.m.

In reply to Kendall Frederick :

Been having a happy holiday full of Covid, Not bad enough that I feel like a bag of poop, but it does get me out in the shop because being sick is boring as all get out! On that note, out I go again!

For those following, this car could be the source material a book on how to fix any and all rust problems with an MGB shell. I have done about 10 MGB shell rehabs before now, but this one has ALL of the potential rust disasters that befall these cars, Could have built a new shell with new parts for the same effort most likely,

NOHOME

MegaDork

12/22/23 8:19 p.m.

And we are back,

Simple task today. Just gotta clean up that spot of rust in the circle. Then I can finally weld in the outer sill on this side.

How hard can that be?

Problem is that the rust has crept over the corner into the quarter panel that meets the B-post. See blue arrow. Not bueno.

So now there are two panels to make. Both require a reverse curve. And its a finicky area that has to meet the sill.

To make life easier, cut the one panel slightly longer than the other so that you can weld, clean up with the grinder and place the cover piece over the top. If I had just done a straight cut, the repair would be harder to blend in later.

The side piece after removal and some reconstruction.

Tape patterns rule in this game.

Why we never toss the little sheet metal scraps

Bit of folding on the brake. The easy bit. But now we have to make the piece curve using the shrinker/stretcher tools.

After I lost count number of tweaks

Then repeat for the cover piece that forms the bottom of the B-post.

And it still needs to be welded and ground smooth.

Anyone want to guess how long that took?

Total time to level the car on axle stands with shims ( important) and get this far was 7 hours. Maybe as much as another hour to finish the demolition job.

Total time to level the car on axle stands with shims ( important) and get this far was 7 hours. Maybe as much as another hour to finish the demolition job.

Next is the remains of the inner sill that is wedged into the rear frame rail receiver. This sucker is in tight and so will the new one be once you finally get it in there.

Next is the remains of the inner sill that is wedged into the rear frame rail receiver. This sucker is in tight and so will the new one be once you finally get it in there.