Keep posting updates, love reading this build thread!

continued from Pg 3:

I had caught up to P9 in class and was working on how to get around him when he got pretty loose in T3 and I was able to sneak to the inside of the corner and get past him.

After that, was basically looking for P8 and working through some lapped traffic while keeping my nose clean as the front runners and those pesky SRF's were lapping me...

Ended up P7 in class - "I WAS SEVENTH!!!!!" and had a great last race of the season.

As I was briefly digesting the data after the race, the SOLO showed a best theoretical lap of a 1.24.8 or so when my best actual lap is still ~1.27.5. Definitely more time in the car.

I did notice that in several corners- T3/carosel and others, there is some strange feedback in the steering wheel that i need to dig into in the off season. Probably need to upgrade some bushings to bearings before spring and thinking of the Kingpin Machine front Compliance Bearing as the place to start.

So the winter updates have begun...first order of business is to add some ballast so I designed up a plate that I had cut and bent to bolt into the passenger seat mount. I will then bolt weight plates to it based on ballast needed...

Looks surprisingly like the driver's seat mount but heavier..

Cut some brackets for the rear attachment points and now need to clean the clear zinc coating off the rear brackets so I can weld them on and paint.

Then on to getting the weight plates cut out. Will have some that mount below the plate and more that will bolt on top based on the weight I need to add.

Was working on more updates for the 2016 season and installed a pair of Kingpin Machine complaince bearings into the front suspension...

I was happy with how the front suspension came apart- really love working on rust free cars.

Was also surprised at how the OEM bushings looked in really decent condition for the age and mileage on them...

Ordered the ballast plates that will get bolted below the plate in the passenger seat mount and after cleaning them up a little, hit them with the spray paint...

Then started cleaning up the front floor boards from when the sound deadening was removed and noticed the ECU mount was a little loose so made an adapter plate to better mount the ECU to.

Took a piece of aluminum angle and after bolting this to the original ECU mount, added some new studs to rotate the ECU a little to get three bolts on it. Much more sturdy.

So, a little update here...

Ended up only running two races this past season and while I am still sort of mid-pack, my lap times are continuing to drop so I have that going for me, which is good... I think I got down to a 1.26 at Blackhawk Farms. Was hoping to run Road America this past season also but could not make that event with family stuff happening.

Did mount some 'new to me' Hoosier R7s for the season and these seem similar or perhaps a little stickier than the R6s but are a little wider also which I noticed after the last race are causing a little rub on the rear fenders...time to find a fender roller before the 2017 season starts.

devina wrote: ...time to find a fender roller before the 2017 season starts.

My experience on racers over the years -- I wouldn't bother trying to find a "roller". Many times ineffective on actually rolling the fender. And given that you're beating the car up on a regular basis (and I mean that in a GOOD way!), I'd take a cut-off wheel to the offending area, make some 'pizza slices' along the inner lip, and just grab the piece with channel locks or vice grips and bend them out of the way.

Could definitely cut the lip and bend it but trying to avoid having to repaint when done.

Did pick up a spare cylinder head a few months back so have been working on that...

Head is disassembled and cleaned and then cleaned up the valves. Hope to just relap them, shave the head a little for a small compression increase and reassemble things for a little power increase. Will get pics posted soon for this...

In reply to devina: No repaint necessary with the approach I suggested - all the cutting/bending is just on the fender lip - once it's bent up UNDER the fender opening no one sees it. I spray a bit of rattle can black just to keep the cut edges from rusting - but no one can see it under the fender.....

Maybe I missed it, but did you end up installing the short ram? Did it make an appreciable difference? When I added one to a (decidedly less sporty) mostly stock Corolla, it did help with throttle response, though the butt dyno hardly registered a blip in HP at the wheels.

Also, while the head is off, I know you mentioned shaving it down. What about a thinner gasket? Im not familiar with your class rules, but I would think it could be another nice little bump.

Any plans for a limited slip diff?

OK, im done spending your $ for you. This is a really entertaining thread. I like that its been happening mostly in your garage, and really paying off in fun behind the wheel. Further proof that you dont need a massive operation to have fun on track in a real racecar...and it doesnt have to be a rust bucket.![]()

....be sure to check quench dimension before going with thinner head gasket....pistons hitting the head at high rpm usually makes a mess....

So a couple updates...

Started working on rebuilding a cylinder head that I picked up last fall but then this fell into my lap...a 94 Teg parts car. Was a GSR but had an LS engine in it, Koni shocks, chipped ECU, CF hood and some other interesting parts.

turned into this

pretty quickly...

Needed to get this torn down and get rid of the shell and parts I don't need so that took most of the winter. Had some good parts to keep and some good stuff to sell.

It came apart pretty easily for a Wisconsin car but the wiring was pretty hacked and there were lots of interesting mods. It had Miata wheels on it as pictured with extended wheel studs but the "wheel spacers" were some large flat washers and nuts between the brake rotors and wheels. Definitely pretty sketchy...

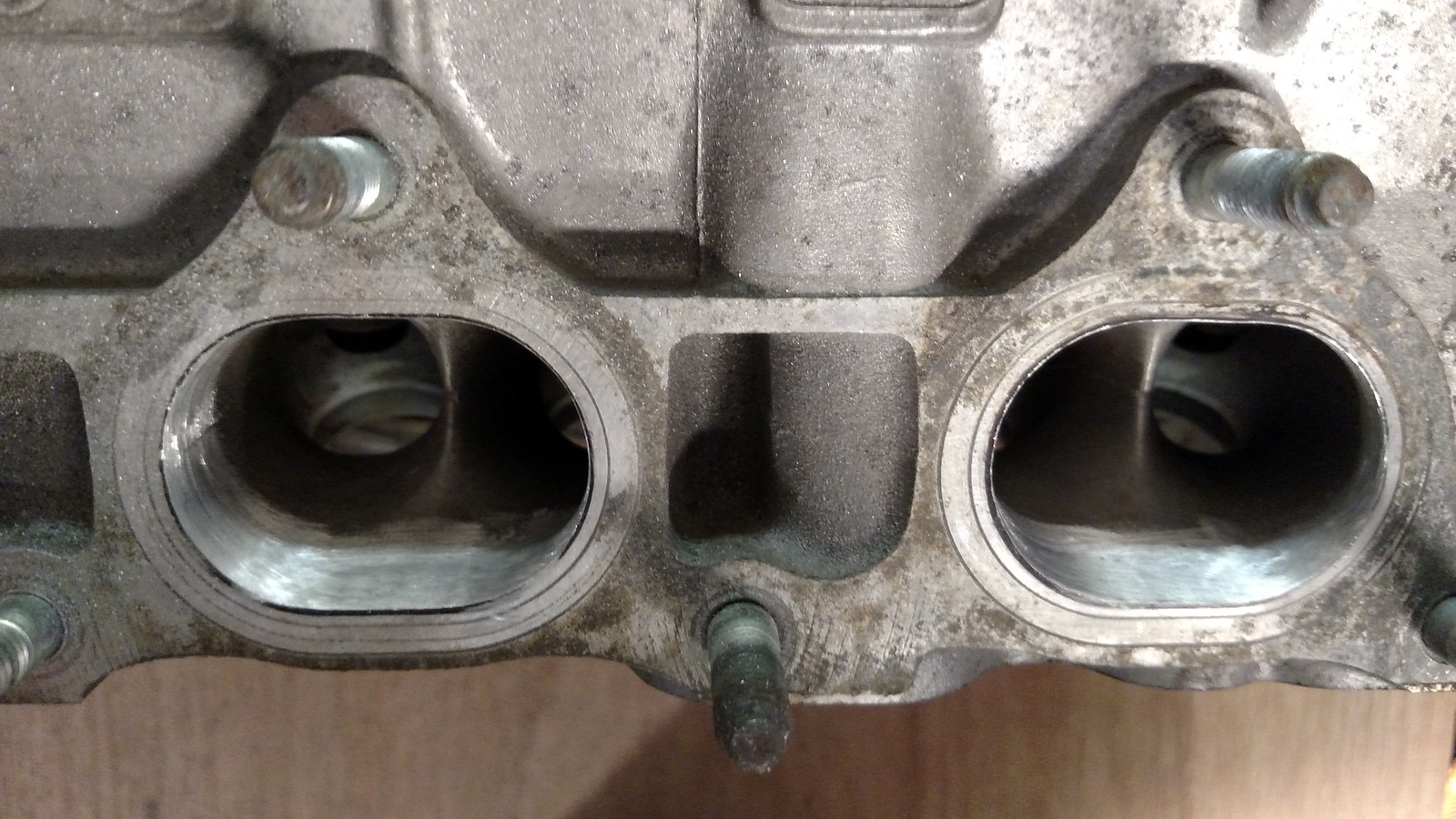

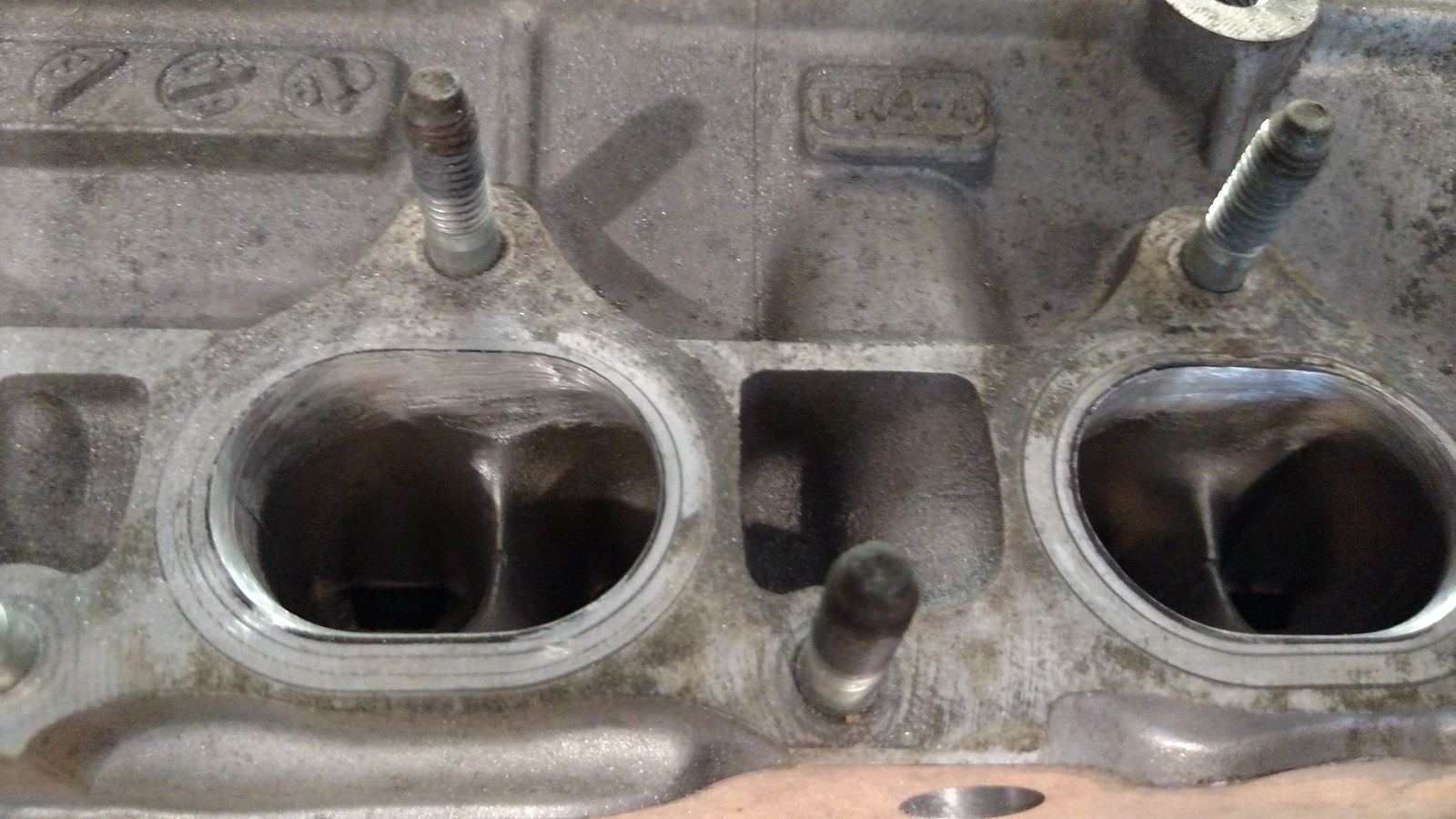

Before the parts car came along, was able to get the spare cylinder head stripped down and cleaned

Before pic

after cleaning

read a little online and ended up chucking the valves up into the drill press to spin them and then used mostly a brass wire wheel on a second drill to clean these up

I picked up the porting kit from Eastwood so I can gasket match the intake and exhaust manifold gaskets to the head but need to get an intake manifold gasket..

Also picked up the Eastwood fender roller this spring and used that to flatten the rear fender lips. The paint is starting to peel on the lip so not sure what I was worried about with the paint flaking off... Before bolted up the roller

IMG_20170516_161452911 by Devin Anderson, on Flickr

IMG_20170516_161452911 by Devin Anderson, on Flickr

IMG_20170516_161444125_HDR by Devin Anderson, on Flickr

IMG_20170516_161444125_HDR by Devin Anderson, on Flickr

the finished product

IMG_20170524_170442933 by Devin Anderson, on Flickr

IMG_20170524_170442933 by Devin Anderson, on Flickr

Worked pretty well but will need to touch up the paint just to keep the fenders from rusting. Did use a little heat to try to keep the paint flexible.

After this, did a little more prerace prep and checked things over. Brake pads are wearing great!! The main preseason update is to install the rear swaybar and brace that came on the parts car so went from the GSR rear swaybar which was like a 14.7mm diameter to what I think is a Type R rear bar at 22mm diameter. Nice improvement in rear roll stiffness.

IMG_20170527_130508856_HDR by Devin Anderson, on Flickr

IMG_20170527_130508856_HDR by Devin Anderson, on Flickr

Attended the Memorial Day weekend Midwestern Council of Sports Car Clubs race at Blackhawk farms and while the early weather predictions called for a bit of rain in the morning, it was supposed to stop mid-morning and clear up. Heading down the morning of the race, it was raining pretty hard at times and the predictions seemed to have changed overnight- go figure.

Got to the track and unloaded and ran through Tech and the rain has slowed but was still coming down fairly well. With being group 2, did not have enough time to swap the rain/intermediate tires onto the car for practice so just bailed on that session. At the driver's meeting, they made a pretty solid point that with all the rain, if anyone went off track and got stuck, you might be there until the end of the session with how sloppy the runoff areas are...

The rain did stop around 9 and the track started to dry for qualifying but was still fairly damp in spots. With the larger rear swaybar, was feeling the car out and trying to keep it on the black stuff so only qualified with a 1.30 and change. This put me 9th in class of 11. If I had run similar times to last fall, I would have qualified 3rd in class...

Race started fairly uneventfully and I started to move up and was actually outbraking some Miatas, which was nice. Still feeling the car out a bit so not pushing too much but was able to get down to a 1.28 in the race. Between passing a couple cars and some DNFs, ended up finishing 5th in class.

In reply to 4cylndrfury: I did try to install the short ram air intake but this did not work with the front strut bar since the short ram was for a GSR/VTEC Integra and I have an LS (non-VTEC) engine. The parts car did come with a full cold air intake but that is not legal to run in my class since I have to pull air from the OEM location. I may try to modify this into a short ram at some point.

I want to stick with an OEM head gasket when the time comes but will only need to shave a small amount off the head in order to bump the compression the little bit allowed in IT.

There will be a limited slip diff in the future but not sure when. I don't feel a lot of wheel spin at this point but perhaps when I find all those missing ponies, this will become more of an issue. Am leaning toward an MFactory clutch diff unless I can find something cheaper...will see.

The parts car has a spare trans but I need to figure out if it was a GSR trans or LS. I need to retain the OEM trans per the rules but can change final drive ratio and add the LSD.

Car is a lot of fun and I do enjoy working on this and developing it.

Now- off to prepare for Grattan at the end of the month...need to add a fuel test port and the master electrical disconnect.

So in preparation for running the first SCCA event with this car, I need to add a couple things to be SCCA legal- need a fuel test port and a master electrical disconnect switch. I ordered the fuel test port fittings a couple months back in preparation for this. Also, the parts car had a fuel pressure gage mounted in the fuel filter banjo bolt so kept those parts for just this occasion...

Swung by the local farm store on Friday night after work and picked up some wiring supplies- a long main battery cable with the battery connector on it and some lugs to add depending on the length I would need.

Also ordered a new fuel filter and banjo bolt gaskets from HPD recently as good PM since I was going to be in there anyway.

Spent some time after dinner tonight installing the new fuel filter and then the fuel test port. Ended up having some fuel tolerant sealing goop for the NPT fittings left over from a previous project so that worked out well..

Then removed the battery and the stock main power wire and laid out the wiring I would need to get from the battery to the master switch and back. I am thinking I will install the switch in the passenger side airbag cover as this will protect the switch while giving reasonable access to the switch.

Spent some time later tonight downloading and reviewing the data from the last race. While my best race laptime was ok, the data showed that I have some good lap segment times...while my best lap was a 1.28.1xx, if you add up my best segment times from the day, I could have run a 1.24.5 lap..need to review this more to understand where the variation is coming from. Some is going to be traffic, etc but should be room to improve here. Still great to see the potential is there for some decent lap times in this car!!

So got the fuel test port and master switch installed and loaded up for Grattan. Was a fairly miserable drive around Chicago on a Friday afternoon due to traffic and the GPS taking me on some interesting routes...took a scenic tour past the Indiana dunes area and Michigan City but made it to the track in time to get registered and teched Friday night.

Saturday practice and qualifying went pretty well- remembered the line fairly well from my last visit there in the ITC CRX and started clicking off faster laps. During the Saturday race I got down into the 1.35s which I thought was fairly reasonable. The car felt great and the new rear sway bar (22mm) seemed to add just a hint of oversteer under the right conditions. The jump was not as scary as I remembered and I was braking a lot less after this one for the next turn. Really getting the hang of the offcamber T3.

The GoPro battery died for the Saturday race so no footage of that.

Sunday was more of the same- getting pretty comfortable with the track and car and ended up with a 1.34.5 fastest lap. Not quite enough to catch P4 in class but did not lose sight of him during the race.

A little you tube in car footage..

The data shows a best theoretical lap of a ~1.32 so definitely some time to be gained with more consistency but pretty happy with the event.

Guess I forgot to update this last summer...did run one of race days at the Midwestern Council event at Road America in August. Had not run there since like '06 so it was definitely time.

Took it a little easy getting used to the track again and since it was the first time there with the Integra. Was feeling pretty good about it so was going to pick up the pace in the qualifying session but a car blew its engine in the qualifying session before mine and dropped oil from before T14 and all the way into T1. The track folks did a great job cleaning that up but it took a fair bit of time to clean that up. When we went out, there was oil dry (or whatever material they use) remnants from T14 through T1 and all the way up the front straight which made it tough to see even and the surface was pretty loose for most of the session.. I think I qualified with a low 3.01 or something. Not quite where I was hoping to be but not bad with the conditions.

The race start was pretty decent and I picked a couple spots before T1 but could only hold onto one of those as a competitor just motored by heading into T5. Ended up finishing about where I started and was able to break into the 2.59s. Car was running and handling pretty well but getting a little loose in the slight bend before T12 (Canada corner). Will have to check the rear trailing bushings in the off season..

That brings us to the 2018 season prep- did get the valves lapped into the head and gasket matched the head on the intake and exhaust side of the head. IT rules do not allow any cylinder head porting so can only remove material to match the gasket openings to the casting openings and cannot modify any surfaces more than 1" in from the gasket. Was a little surprised about how decent the castings are to the gasket openings- only removed maybe a 1/16" in some areas.

IMG_20170827_162832987 by Devin Anderson, on Flickr

IMG_20170827_162832987 by Devin Anderson, on Flickr

IMG_20170827_162838911 by Devin Anderson, on Flickr

IMG_20170827_162838911 by Devin Anderson, on Flickr

and the intake side

IMG_20170827_162754126 by Devin Anderson, on Flickr

IMG_20170827_162754126 by Devin Anderson, on Flickr

Then took the head over to King Motorsports for a cleaning and shave. IT rules also only allow a max compression increase of 0.5 point over stock so had that done...

Need to order the valve guide seals to finish reassembling the head!!

Before and after lapping valve seats

IMG_20180119_164834110 by Devin Anderson, on Flickr

IMG_20180119_164834110 by Devin Anderson, on Flickr

Next up was the oiling situation...the internets seem to suggest the B series engine is pretty decent about keeping the oil around the pickup with DOT racing tires but a little extra precaution should not hurt either so picked up the Password JDM oil pan baffle kit and put that in. Pretty basic kit that seems to replicate what the Mugen pan does for the baffles.

Pulled the pan and was pleasantly surprised how clean the pan was, for the most part. Not a lot of sludge in there and could not see any metallic flakes so was pretty happy with that. Test fit the parts and sanded the paint off of the pan surfaces for welding and welded it in. Was a little worried about burning through the thin gage material of the pan but this went pretty well. Did end up burning a couple corners off the side baffle gussets but I don't think this will hurt anything.

Reinstalled the pan and buttoned the exhaust back up and filled it with oil.

Next update was brakes...went through my notes and have about 13 races on the front pads and rotors and the rotors are still in decent shape- some smaller stress cracks in them but still pretty flat. The pads have around 1/2 life left but replaced both anyway. Stayed with the high carbon Centric rotors and the Hawk DTC-60 pads as these seem to be working pretty well. The old pads will be spares for now. Did not get quite this amount of life on the pads and rotors on the old CRX but was running the Hawk Blues.

Santa brought me the rear trailing arm bushing replacement tool so tried that out on Monday...worked really well and again pleasantly surprised how well the passenger side of the car came apart. Old bushing came out pretty easily and once I was comfortable that the new Mugen bushing was straight, that pushed in pretty easily also. Took a couple tries to get the new bushing started straight..

The old bushings were probably original to the car and the upper rubber bridge to the shell was completely torn through on the pass side bushing. The lower bridge was pretty well torn also so hopefully that helps the rear end stay a little more planted..

IMG_20180423_133947475 by Devin Anderson, on Flickr

IMG_20180423_133947475 by Devin Anderson, on Flickr

old nasty stockness

IMG_20180423_133931010 by Devin Anderson, on Flickr

IMG_20180423_133931010 by Devin Anderson, on Flickr

new Mugen goodness

IMG_20180423_133936088 by Devin Anderson, on Flickr

IMG_20180423_133936088 by Devin Anderson, on Flickr

After doing the new rear trailing arm bushings, checked the rear toe and this seems to measure at 0" toe. This is a little more than I would like but did not have time to adjust before the race so let it ride.

Ran the Sunday sprint race at Blackhawk Farms Raceway with Midwestern Council of Sports Car Clubs over the Memorial Day weekend. This one was a shortened schedule due to the Enduro later Sunday afternoon. Got here early Sunday morning and after unloading and hitting tech, hit the qualifying session. Started out a little slow to get some heat in the tires and bed in the new pads and rotors but after a couple laps, the car and brakes were feeling good so started increasing the pace. Ended up qualifying 6th of 10 registered and got down to a 1.27.2 for qualifying. My best lap time in this car is a 1.26.9 to date so was pretty happy with that. It was forecast to be in the 90's for this weekend so did not have high hopes of any fast times but the car and driver were both feeling pretty good.

Started the race a little after 11 and while it was getting warmer out, not into the 90s yet. Started cleaning and warming the tires on the pace lap and the car was feeling all out of sorts- sort of like there were marbles under all four tires. Was hoping it was only a ton of pickup on the tires from the paddock area and after half a lap of scrubbing the tires, the car was feeling pretty normal again.

Had a good start and fairly quickly got up to pace- two cars ahead of me came together on the start and rubbed fenders a little but kept going....the offender was black flagged a couple laps later and the other car retired with other issues. Then was able to keep the gap to the car in class behind me and a Miata that ended up starting in last place was working his way up through the field. I was able to hold him off for several laps until he out broke me into T1. Kept on his tail and outbroke him a couple laps later....was able to stay ahead of him for most of the rest of the race until I locked my brakes up going into T7 which allowed him to get back past me...then could not catch him again..

Was pretty happy with the race and the good battle with the Miata. I finished in 4th for the race and set a new best lap time for me in the Integra with a 1.26.0 laptime!! Will get the video uploaded soon..

https://www.youtube.com/watch?v=qL_8z9fqJXY&feature=youtu.be

You'll need to log in to post.