java230 wrote:

In reply to 2K4Kcsq:

Stop it. If you get it to WA I'd think about it...

I've been wanting to take a drive up that way.

Painters grinding called me back. They really are a bargain I think. $220 shipped back to me isn't bad at all. Sure I have paid less for an 8v head but that didn't include the extra machining or a trip thru the bead blaster. Plus any machine shop I personally have dealt with are usually a longer turn around than 4 working days.

Once the heads are back I will have everything needed for this fire breathing 1384cc 40+ horse Kristi krate engine. Maybe I'm speaking to soon but if the Porsche engine option in the KT3 was the fastest Kristi ever built, that means mine with its displacement bump and performance cam ought to smash every Kristi speed record on the books  we are hoping for 29mph! hahaha

we are hoping for 29mph! hahaha

Rally though think about it, 29mph in a fiberglass tube on tracks is flying!

My wife thinks I'm nuts. She says snowcat is far down the "I need" list.....

I imagine almost 30mph in snow is more than enough for most cases in something like that

Who am I kidding, when does the turbo go on? Haha

In reply to chiodos:

Fast enough on big heavy tracks! But snowmobiles are fun with turbos

I wonder if it's power or gearing limited?

In reply to Keith Tanner:

I totally assume gear, but like my grandmomma always said, more power never hurt anyone.

I agree. Gearing/rpm will determine speed limit. Can't afford a scat crank or any of the high rpm vw parts so 20-25 will have to do.

Keith Tanner wrote:

chiodos wrote:

In reply to Keith Tanner:

I totally assume gear, but like my grandmomma always said, more power never hurt anyone.

I like your grandmomma.

She's got two cars, both are 327" one as a new ls based all aluminum in a envoy Denali, the other is in a 1954 corvette backed with a Muncie close ratio 4 speed. She has also driven a few laps in a nascar on track, I'll let her know what the king of Miatas thinks of her :))

2 small updates. I will be going to fastenal for some button head cap screws for the cam/gear which will give me a chance to ask them if they will work some sort of trade with me for longer bolts on the cleats. Yes I'm going to end up adding the wood like everyone says I should do.

Second, I'm basically ready to assemble this engine but I need a press jig thin enough to get behind the timing gear on the crank. I have a press, just nothing strong and thin enough to hold behind the gear.

Because I prefer things like old audi's and kristi's I feel like I'm 2 weeks from everything

Can KCW help with the press?

In reply to Keith Tanner: I decided 15yrs press rigging is long enough and bought every size of bearing separator at harbor freight. Now when people randomly show up at my house to press bearings I might have the proper tool for the job!

Also the fastenal rep was super cool about the bolt situation. We ended up shipping all the short ones back, they gave me store credit and I ordered 2" long bolts, Also on closeout. Should work out better than I'd hoped.

RossD

UltimaDork

2/26/16 7:36 a.m.

What luck! Don't forget that guy when you're buying beer or donuts...

Yeah he was really understanding and cool about it. I walked in there expecting a "don't let the door hit you-" kind of response and left pleasantly surprised. Didn't even have my receipt but he was able to do it with the shipping label and my email address. That one situation will keep me a returning customer for sure!

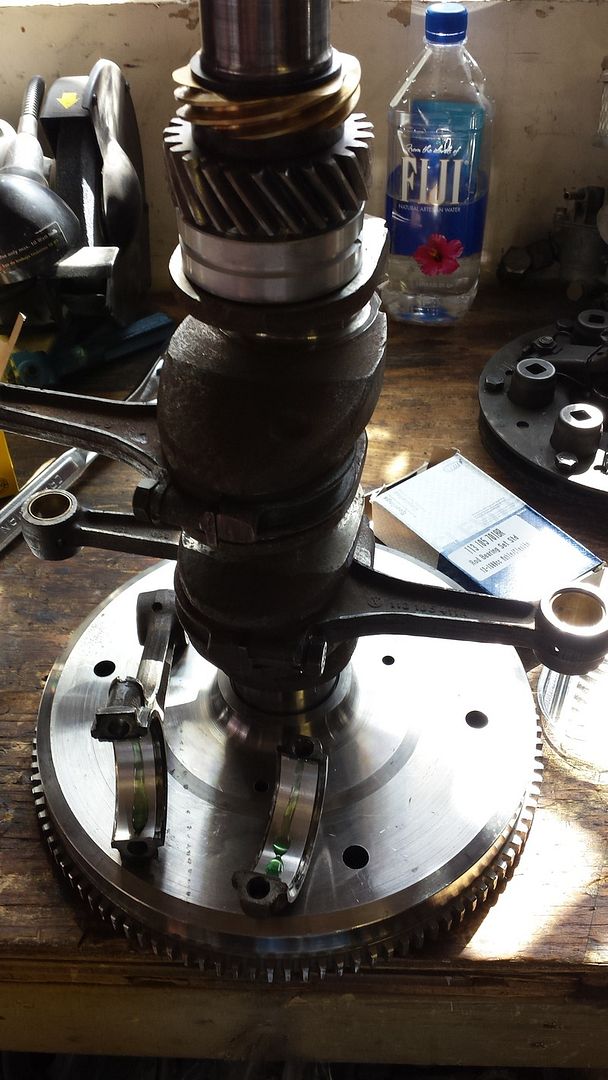

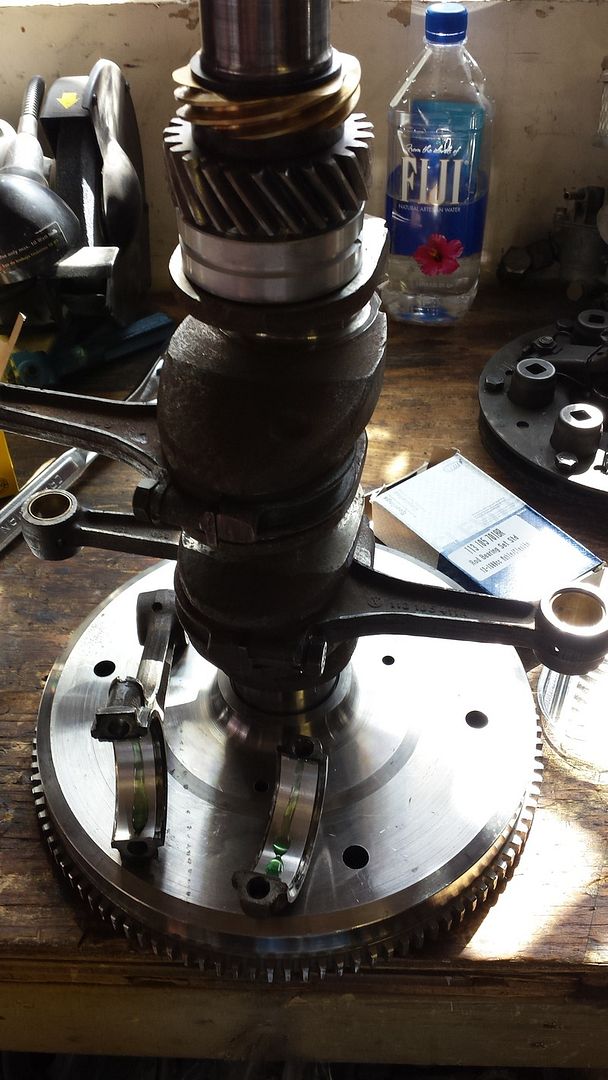

Yesterday I began engine assembly. First thing was to polish up the crank. It mic'd out within 2 tenths across the board so it didn't really need grinding. The corrosion on main #2 was worse than I'd like but it polished out decent.

I cut some 1500 grit paper into strips and went after it. Took a while, just always remember to keep moving. Even when working on a rough spot or corrosion you can't stay in one place for more than a few strokes or it will start to become out of round.

After the crank was clean I spent time on the flywheel. The starter must not mesh well with the teeth and they had some burrs and things. Cleaned all that up with a cutting disc and a flat file. Then began crank assembly.

Everything about this build is so different than any piston engine I have rebuilt. Glad I have a good book to keep me in check.

For me personally, the hardest part was dropping the crank into the case half while trying to keep timing set and lining up the one piece main bearings with the dowel pins. I must have spent 20 minutes on that one step. But it's in, cam is in, rods and case are all torqued, got the flywheel on and everything spins easy. Today I will tackle pistons, cylinders and top end.

Also, I am still looking for an affordable set of 36-40hp pushrods. They are shorter than all the late model dual port stuff. I only need 2 so if anyone has some lying around I'd be happy to purchase them.

Sweet! Progress!

Think it will be on the snow this year?

In reply to java230:

Still pushing for this season. Late March might be a little to late with the warm temps we are having.

Rebuild engine, install & break in. Drill wooden cleats, Assemble tracks. Load onto trailer.

Seems doable

Ah, we'll get snow in April. Always do.

Definitely, Id love to lend a hand if I were closer! But im stoked to see it running.

Surprised there was no crocus cloth used on the crank as a final step. The motor looks beautiful though and it's a VW so it'll run fine no matter what. Did you use Hylomar on the case halves or is there something newer that works better?

True. Once all the fruit trees start to bloom we'll get an April fools storm.

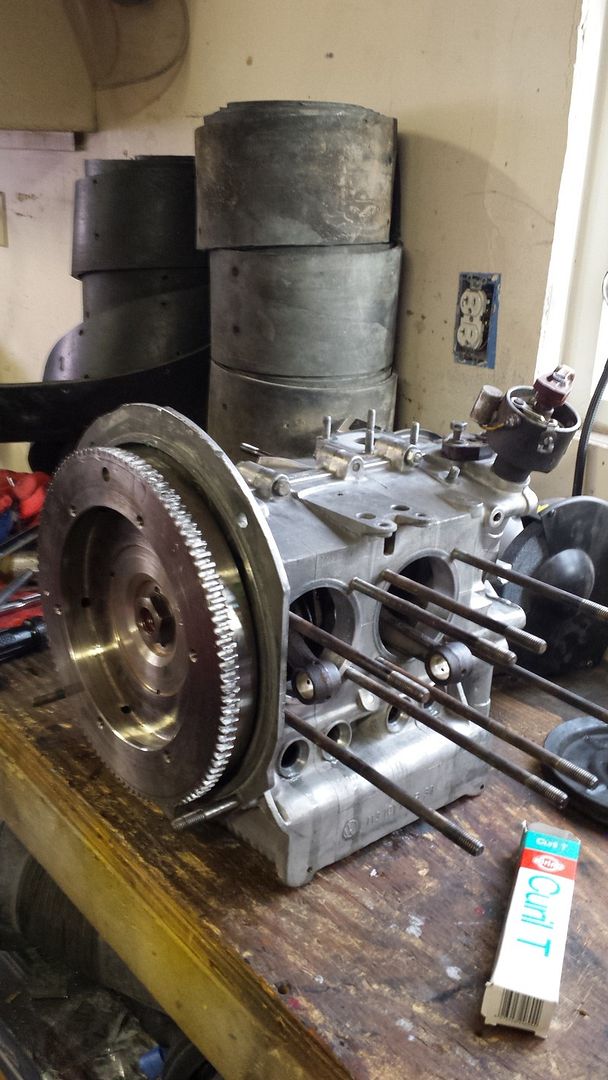

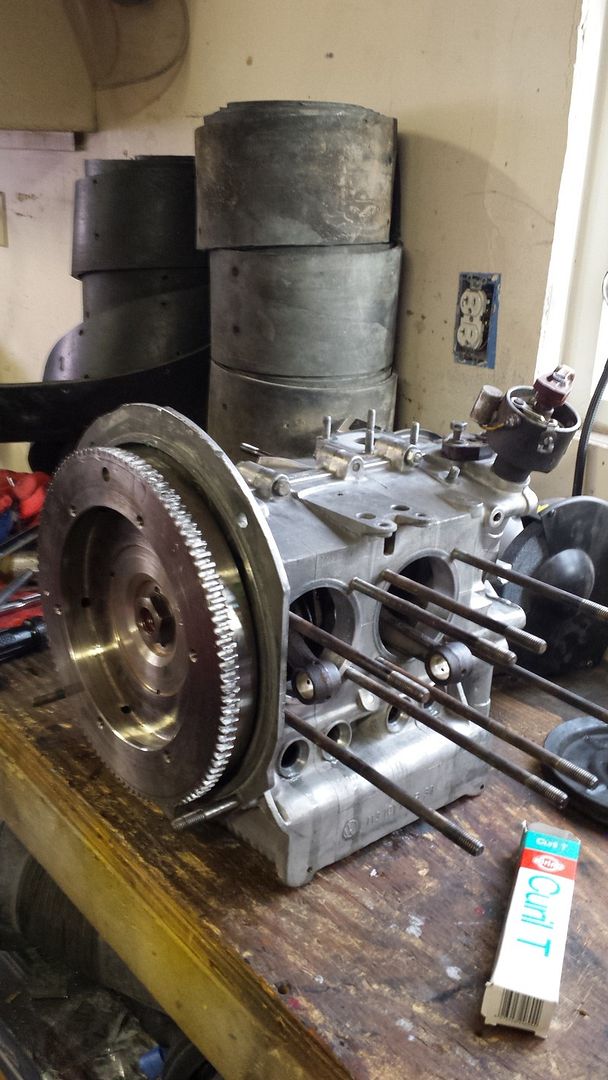

Today I managed to get the strainer and plate in, oil pump in, torqued the flywheel, checked deck height then went ahead installing pistons and cylinders. Slapped the heads on temporarily to keep it all clean and tight till I'm ready for install.

Work bench looks worse then it is, honest

Jerry From LA wrote:

Surprised there was no crocus cloth used on the crank as a final step. The motor looks beautiful though and it's a VW so it'll run fine no matter what. Did you use Hylomar on the case halves or is there something newer that works better?

the product I used is called Curil T (pictured above) by elring. it was recommended to me by a friend as the replacement for curil blue which was designed for air cooled vw's. at least that's the way I remember it.

Just thought I would post this, supposedly the most common mistake made when building one of these.

As soon as the cylinders are on, clip in those lower cylinder tins!

Once I have the clutch alignment tool I will be at a holding point. I can't torque heads or assemble anything else till I slip the engine in and put the #1-#2 head back on.

I've got a Yeti cooler full of beer to trade for rides...

![]()

![]() we are hoping for 29mph! hahaha

we are hoping for 29mph! hahaha