In reply to oldeskewltoy :

Valve size isn't great. The exhaust seat throat diameters are just over 22mm. Not measured the inlet yet. Im really only aiming for a clean up rather than a revolution in flow. I'll definitely put some effort into the header flange area where things expand a lot and the neck down again. A bigger flow problem for me is the very tame exhaust cam. A supercharger may eventually fix all of these issues.

So quick back story on the Korean beta engine. You’ll notice a lack of EGR. These engines met SULEV standards without using egr by using cam profile and a high overlap. That means that you don’t get much N/A gains with the normal methods(intake exhaust header etc). But they really wake up with forced induction.

But in a small car like you are planning and about 150fwhp/tq it’ll be a hoot!

In reply to bobzilla :

So basically egr internally via overlap. Im aware of the issue and am contemplating a pair of 1.8 inlet cams in both positions. Of course an inlet cam won't readilly fit in the exhaust position, but whatever. This would give me a slight increase in lift and duration on the inlet and a lot on the exhaust. Then i need to make timing adjustable to dial them in and retain the vvt.

Im hoping for 160hp and sub 900kg.

Everyone focused on the hp they could make with these. They always forgot the torque curve. You didn't need to wind them to the moon because they had a great torque curve across the rev range. Always made them feel faster than the hp numbers showed.

Long long ago there were reground cams for them floating around. Not sure what happened to them.

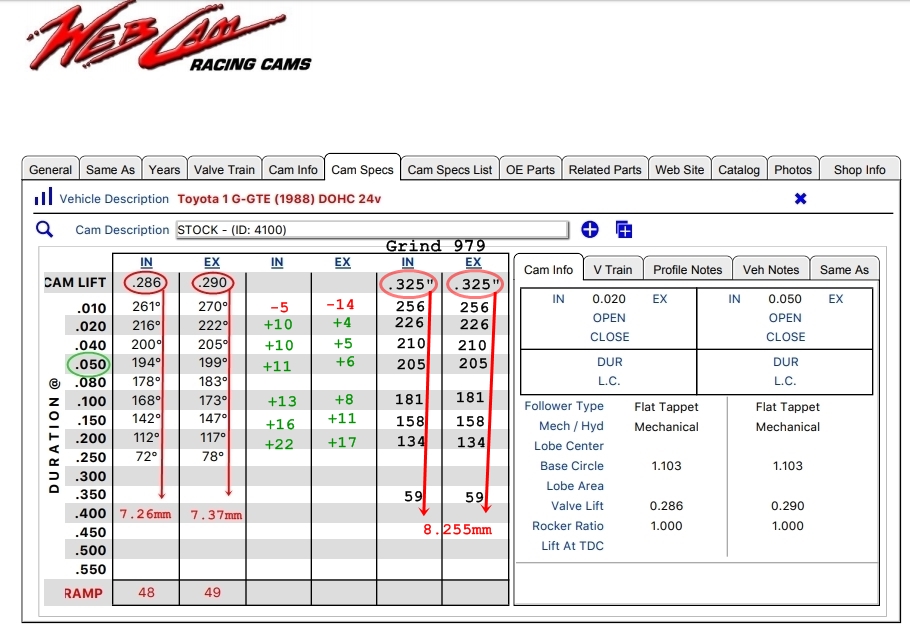

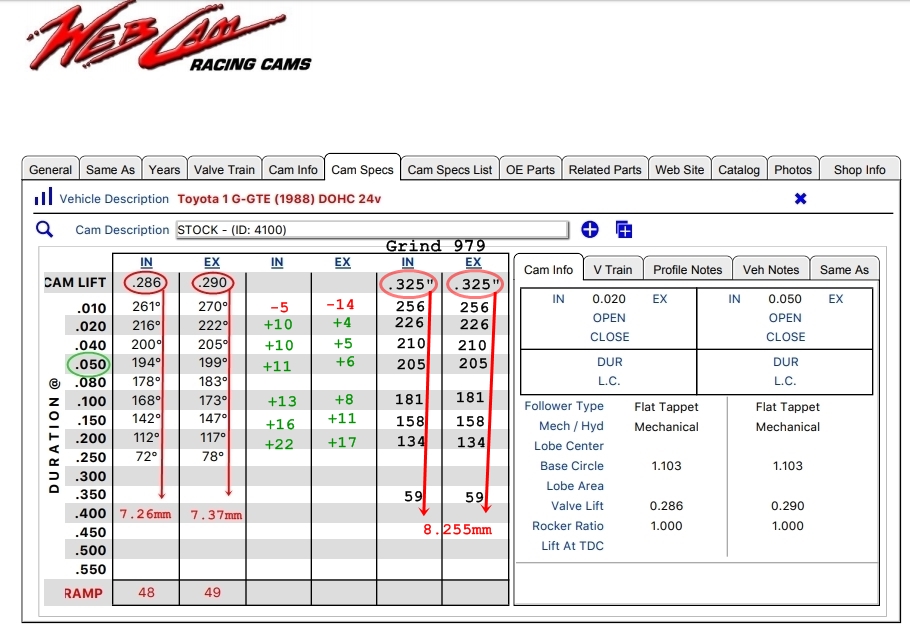

Web camshafts can "build" you a set. They have hard weld technology that allows you original cams to be built up, and reshaped. I had this done to a set of Toyota 1GG cams....

additionally you want the ID of the seats to be about 85%-86% of the valves diameter.

Great job. Subbed to see where this goes

bobzilla said:

Long long ago there were reground cams for them floating around. Not sure what happened to them.

Id love to find a set at the right price but not too hopeful. Any chance you would know the specs for the 1.8 cams? Anecdotally they are bigger lift and duration.

additionally you want the ID of the seats to be about 85%-86% of the valves diameter.

Ill have a measure. Thanks for the info.

So not much progress lately due to life getting in the way, but over the weekend I managed to start work on the exhaust headers.

These were a cheap set I found online and it shows. I'm now spending time bringing them up to where I'd like them. I made some inserts out of 2mm sheet metal and welded them in. This is to prevent the dramatic change in port area as the exhaust enters the header and then necks down into the primary pipe. Then it was pointed out to me that the secondary pipes are fitted and welded inside the collectors and are press bent so they'll be getting redone too.

In other news I have bought the car that this lot is going in to. I'll pick it up this week and get some photos up. It will be doing daily duties for a few weeks while I swap over my other daily.

And here it is. The fun starts in earnest now.

This is a cool project. My mom used to have a blue Elantra similar to your donor car...I don't know if the engine was the same, but it's funny to imagine her car's engine being used in a race car :D

Got a nice sunny day today so made the most of it and scrubbed and painted the wheels. I'd been tossing up between a mid grey kind of colour and white, for the rally car look. Some of the wheels had quite a lot of gutter rash and consequently needed lots of primer. This gave me the opportunity to see what grey would look like, pretty good I'd say.

But the white came up real nice

I was lucky enough to find five of these wheels. I'll hopefully get them fitted up next week when the hub rings, spring compressor and guard roller I ordered turn up so I can lower it at the same time. This will give me clearance for the big brakes to go in, so thats next on the list.

As a side bonus I have already sold the wheels on the car now.

ill_climber said:

bobzilla said:

Long long ago there were reground cams for them floating around. Not sure what happened to them.

Id love to find a set at the right price but not too hopeful. Any chance you would know the specs for the 1.8 cams? Anecdotally they are bigger lift and duration.

Gude Performance still makes cams for the Hyundai Beta engine. See below:

http://www.gude.com/camlist.php#hyundai

A bit of progress over the last week.

All the guards have been rolled with new wheels painted and fitted. Then yesterday the suspension got pulled to bits for full clearance check and lowered springs. It's come down about 35mm and drives and looks much nicer. Suspension will stay like this for a while until coil overs come into play. The car runs out of rego at the end of the month so that's when things will get serious on the engine swap.

Rolling

Rear full bump clearance check

Front clearance without bumpstops

A few measurements along the way

The result

84FSP

SuperDork

7/14/19 6:22 p.m.

That looks really sharp! Interested to see what gains you get from your efforts on the head.

Hey there. I just found this page thanks to google.

I'm actually doing the same swap at the moment.

My plan is to keep the motor stock and just do normal maintenence stuff.

I'm just about finished making one loom out of two and I have the engine mounting done.

I am using the Getz gearbox bolted to the 2l Beta so drive safts all fit fine.

I chose not to notch the right hand chassis rail so the engine fits but its tight. If it turn out I do need to notch it i will.

Kenzza said:

Hey there. I just found this page thanks to google.

I'm actually doing the same swap at the moment.

My plan is to keep the motor stock and just do normal maintenence stuff.

I'm just about finished making one loom out of two and I have the engine mounting done.

I am using the Getz gearbox bolted to the 2l Beta so drive safts all fit fine.

I chose not to notch the right hand chassis rail so the engine fits but its tight. If it turn out I do need to notch it i will.

I'd be interested to see what you have done, maybe you could start a build thread here too. What ecm are you using? By my measurements you will need a 10mm notch in the chassis rail unless you ditch the AC

Kenzza

New Reader

7/18/19 8:09 a.m.

Well I'm sticking with the Beta ECU. I know it works. The motor does fit with about 5-10mm clearance. Changing the belts would be a small issue but I have a plan for that. I'm not sure how much the motor moves around in normal driving conditions but I will try it as is and if it needs notching I'll do that at a later date. I'm not one for doing a build thread but I am recording it so eventually I might put it on YouTube.

In reply to Kenzza :

Excellent. Does your ecm have an immobiliser? If so do you have a plan for that?

The immobiliser issue is what led me toward using aftermarket ecm (microsquirt most likely) which also gives me good tuning scope and can add forced induction later. No air flow meter is another bonus.

Kenzza

New Reader

7/20/19 1:42 a.m.

In reply to ill_climber :

Yeah both cars have the factory immobiliser with the transponder chip in the key. I have the keys for the elantra so it makes it easier. I'm going to take the chip reader off the key barrel of the Elantra and wire it up under the dash of the Getz. Then just duct tape one of the Elantra keys too it. That does mean effectivly there is no immobiliser so I will add another form of immobiliser.

I've just about finished the wiring loom. I'm using the Elantra engine loom and just adding anything out of the Getz loom thats needed. I'm cutting off the 4 plugs off each loom and swapping them over so it just plugs straight into the fuse boxes.

I'm hopping to try and start it this next week, if I don't get lazy :)

This is awesome ill be watching with interest. What happens with the 4th engine mount on the beta engine? The front one.. is it just not used?

In reply to Cwds :

I haven't got there yet but that was the basic plan. Use the layout from the Getz with new brackets and beefed up mounts as required.

The Getz is now in position in the workshop for the major work to begin.

I was like a kid in a candy shop so randomly did a bit of everything except work on the new engine like I should have been.

Jacked up on 4 stands, wheels off, a few covers off, pulled all the stereo and some other weight reduction. Then I randomly switched to the brake upgrade.

This has been the boon of the project so far. Got the Accord calipers on with only minor work to the backing plate and bracket. Hose bolts right up. Measured up for rotors. 275mm will fit, up from 241mm stock, leaning towards Renault Megane at this stage for rotors unless I find something better.

Hey mate, just wanted to know if you could post an update on where you are with the car and whether you had to trim the chassis? Looking at doing something similar to my Getz. Also what would be a rough estimate that this conversion costed you?

The build thread is current to where I'm up to. Engine is still in bit and hasn't been offered up to the Getz yet.

Looking at kenzza above, cutting isn't required but it's tight. I may take a slightly different path to use the Elantra box and shafts.

Cost is modest so far. All depends on how far you go with extras and what you pick up the components for.