In reply to frenchyd :

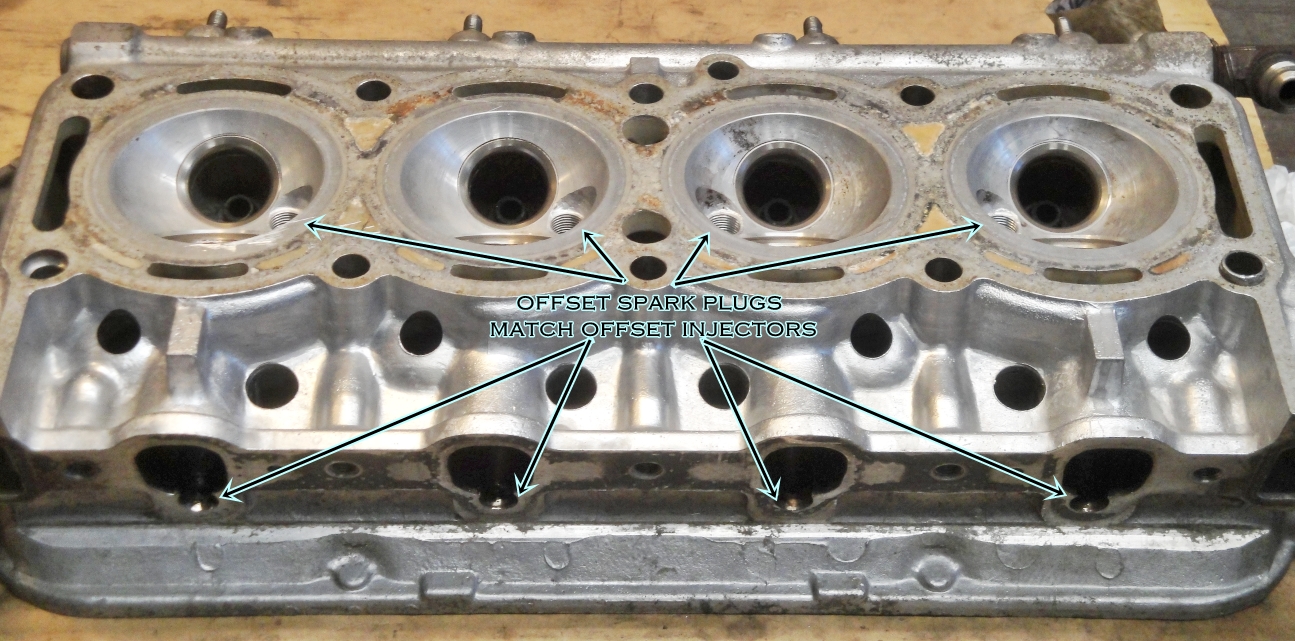

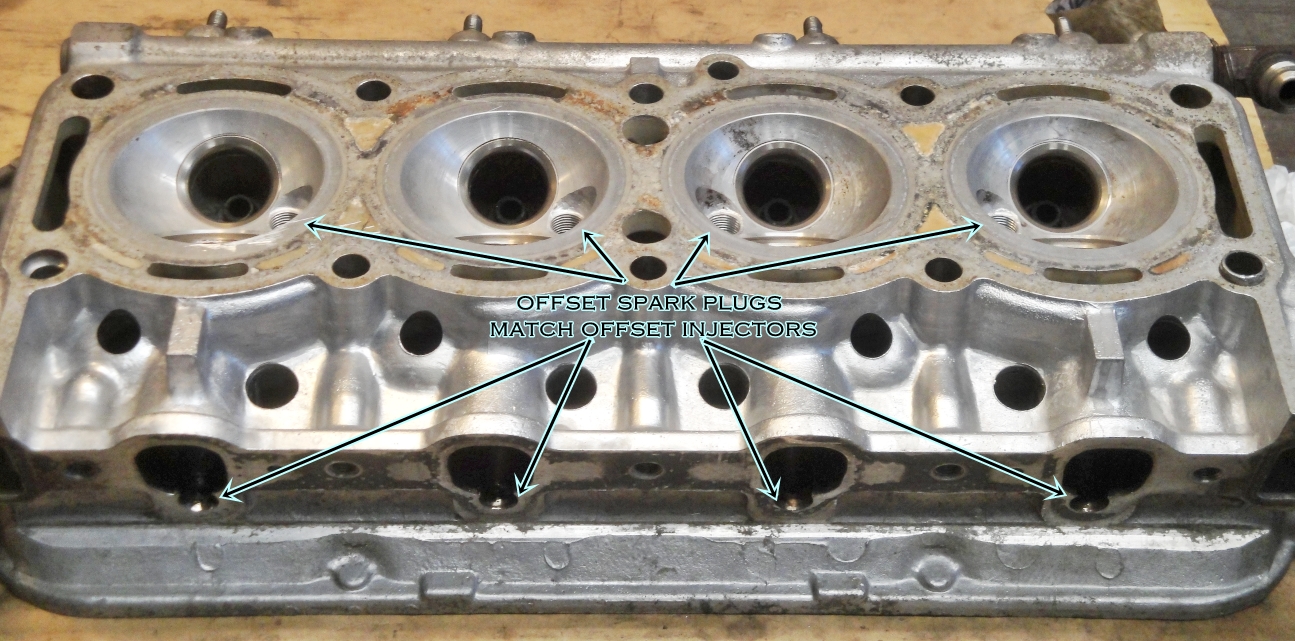

One of the advantages you get with a "hemi" head is the valves necessarily have to be clocked laterally across the deck instead of inline, which makes the ports a lot nicer. The intake port flows more to the center of the chamber and the exhaust port doesn't have a big dogleg.

The 3rd generation Mopar Hemi isn't a hemispherical chamber (which had a lot of purists furious), it's an actual wedge chamber with quench pads. But it still has centrally located (ish) spark plugs and the good port geometry.

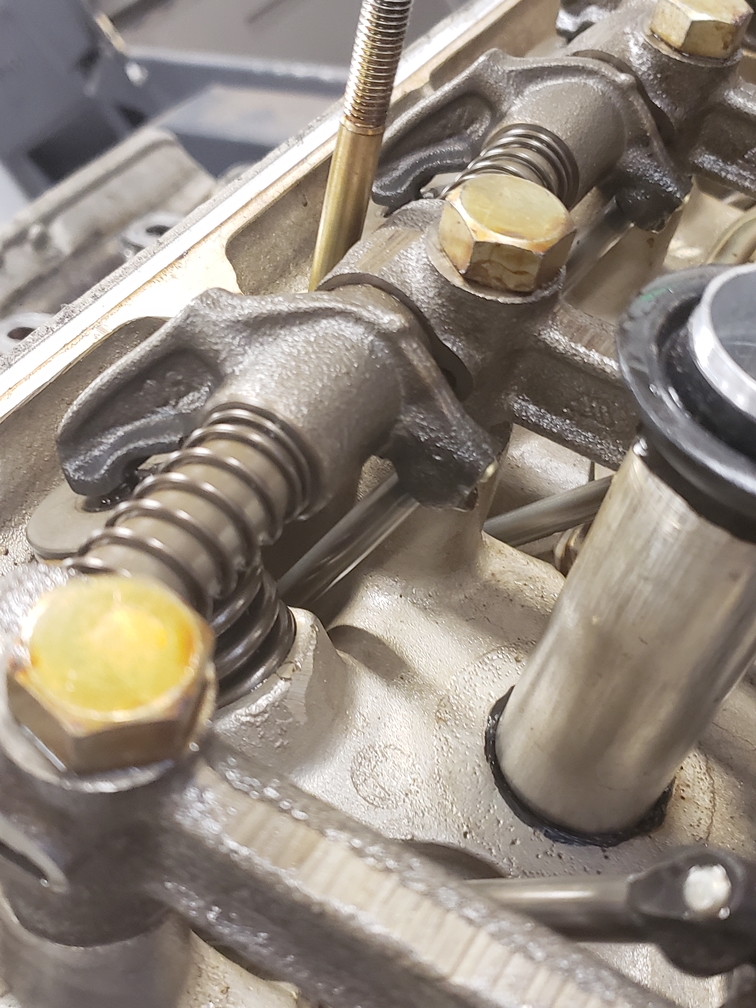

One thing that all three generations of Mopar had issues with was rocker tip lubrication. The exhaust rockers are about two feet long and the intake rockers go "backwards", in both cases not much oil spashes up near there. Engines that idle a lot have a lot of valvetrain issues as a result.

I wonder how the Toyotas fared.

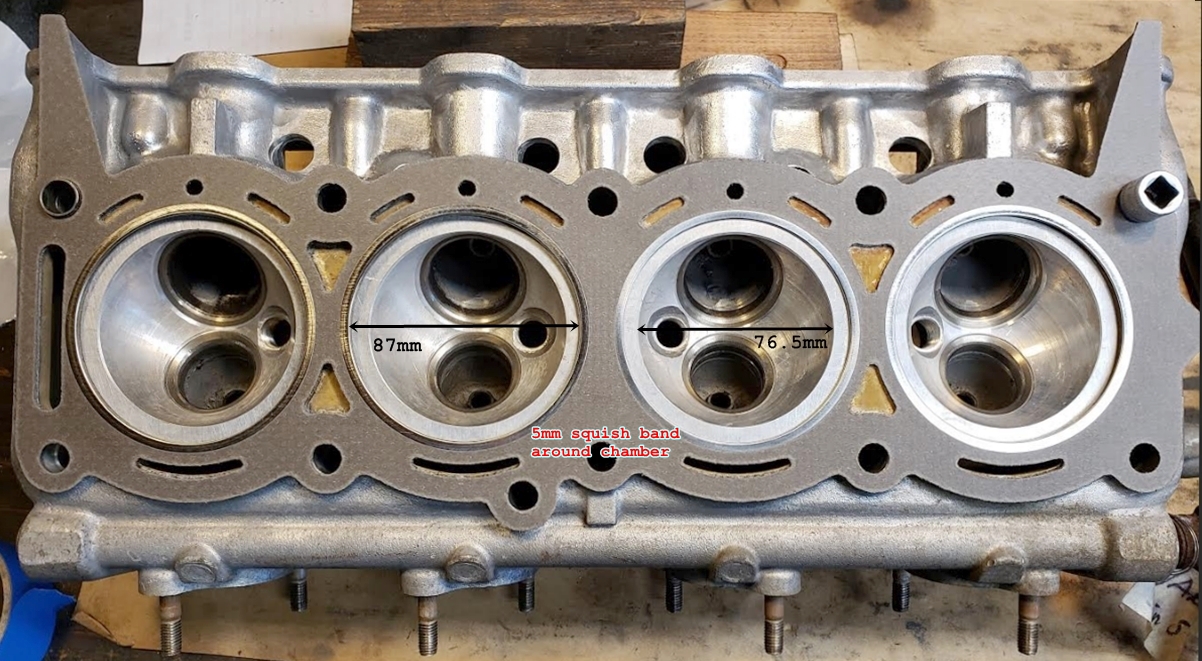

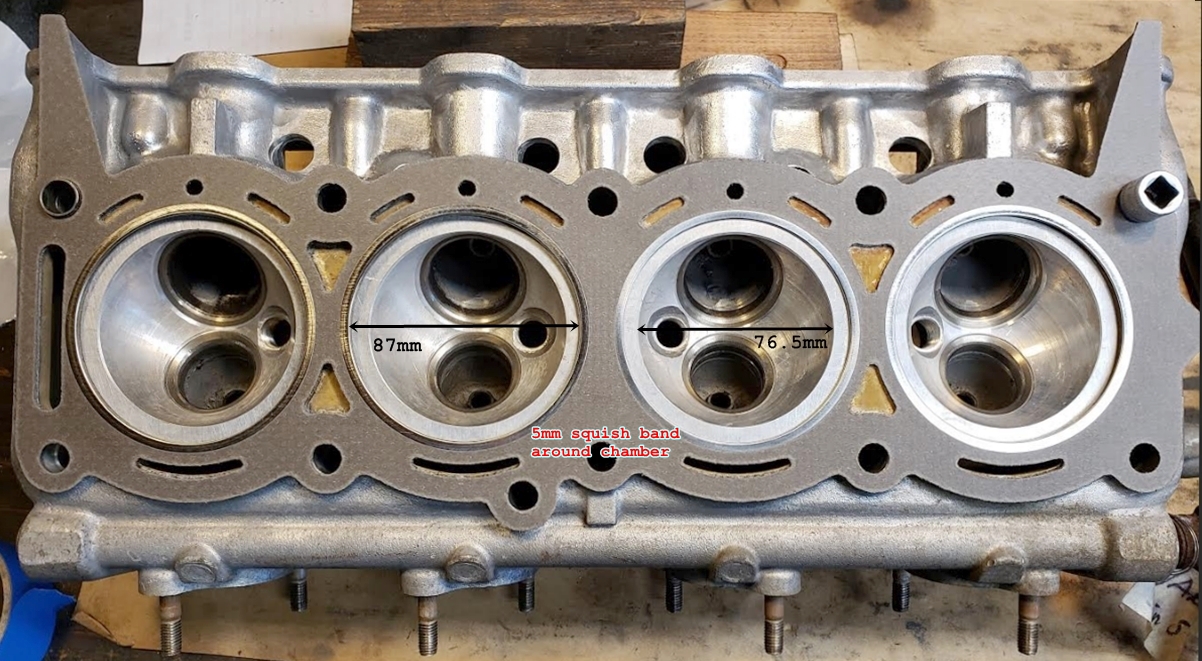

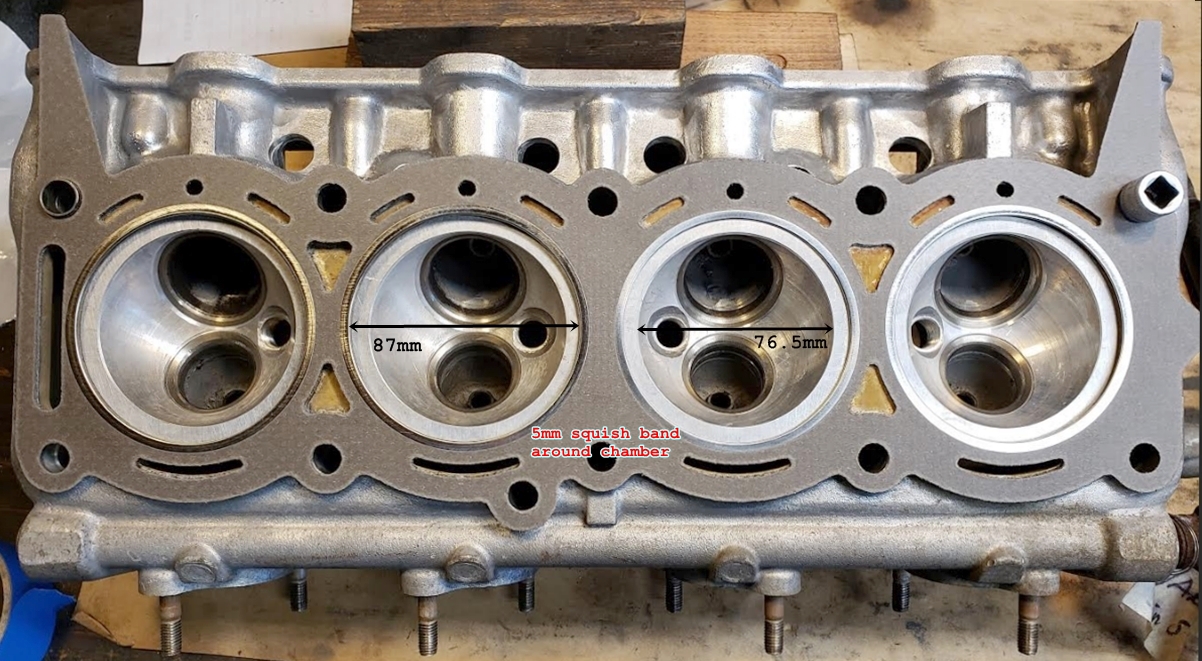

If I wanted too... I could have the chambers welded closed to gain compression and give me squish/quench pads.... but the math isn't in yet as to how much dome I'd need to bump compression. Stroke in this is 84mm (3.307"), stock bore is 87mm(3.425), so the engine is slightly oversquare, and if I decide to overbore 1mm (.040"), the engine size will effectively be 250cid. Additionally it will be easier to gain compression with an overbore.

As of now this is all speculation...

Knurled - The exhaust rockers aren't long at all...

the intake rockers are interesting to say the least

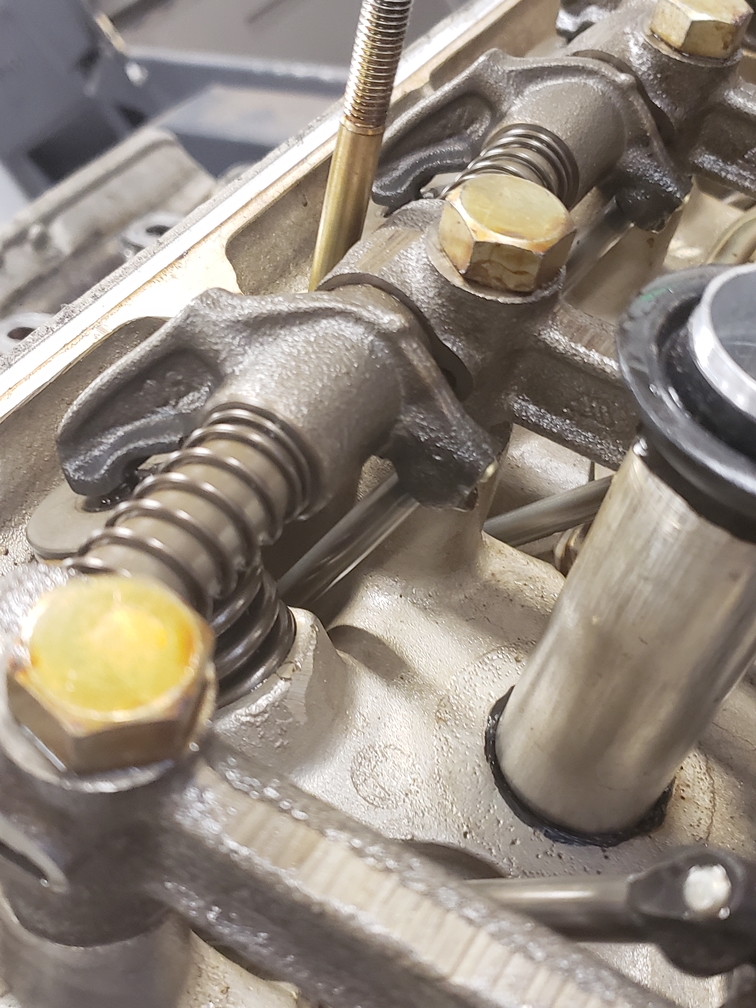

BUT there was 2 lifters that appear to have not been oiling well, the ends of the rockers will need a bit of machine work. That is one decision already made, it looks like I'll be running an adjustable push rods to compensate for machine work, and the cam re-grind.

No flanges on those head bolts?? Not even a washer?

In reply to oldeskewltoy :

Mopars have cantilevered intake rockers just like that.

oldeskewltoy said:

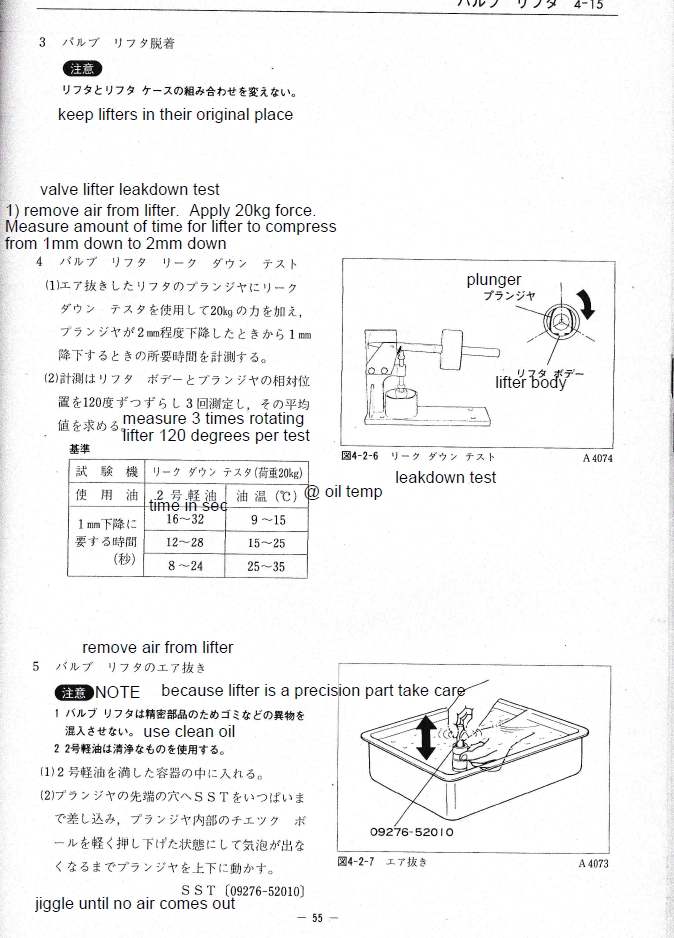

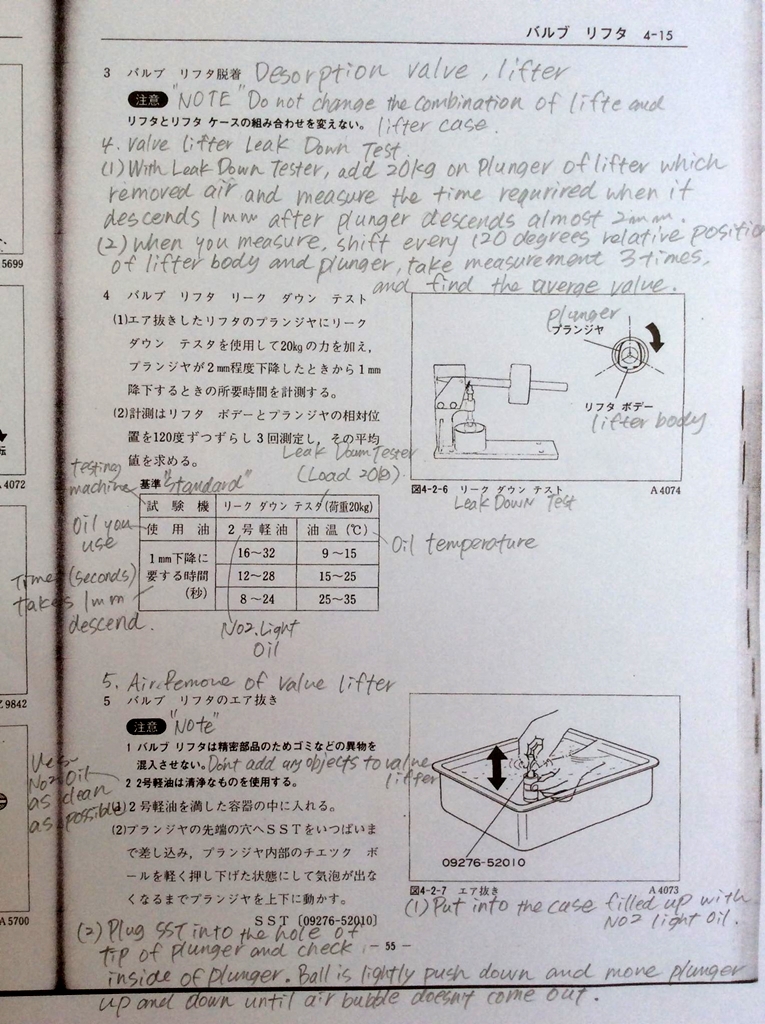

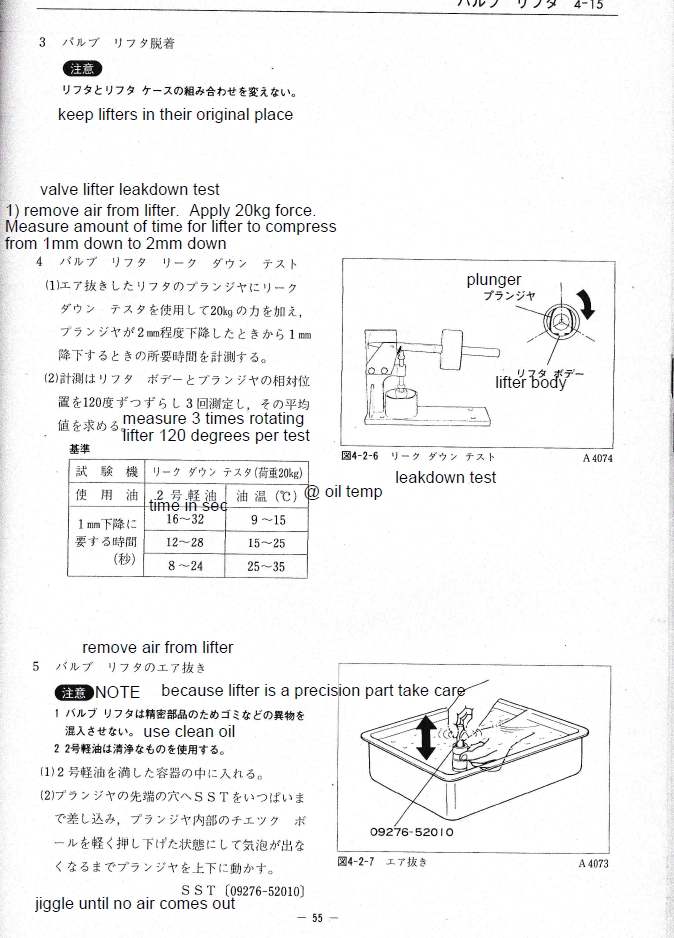

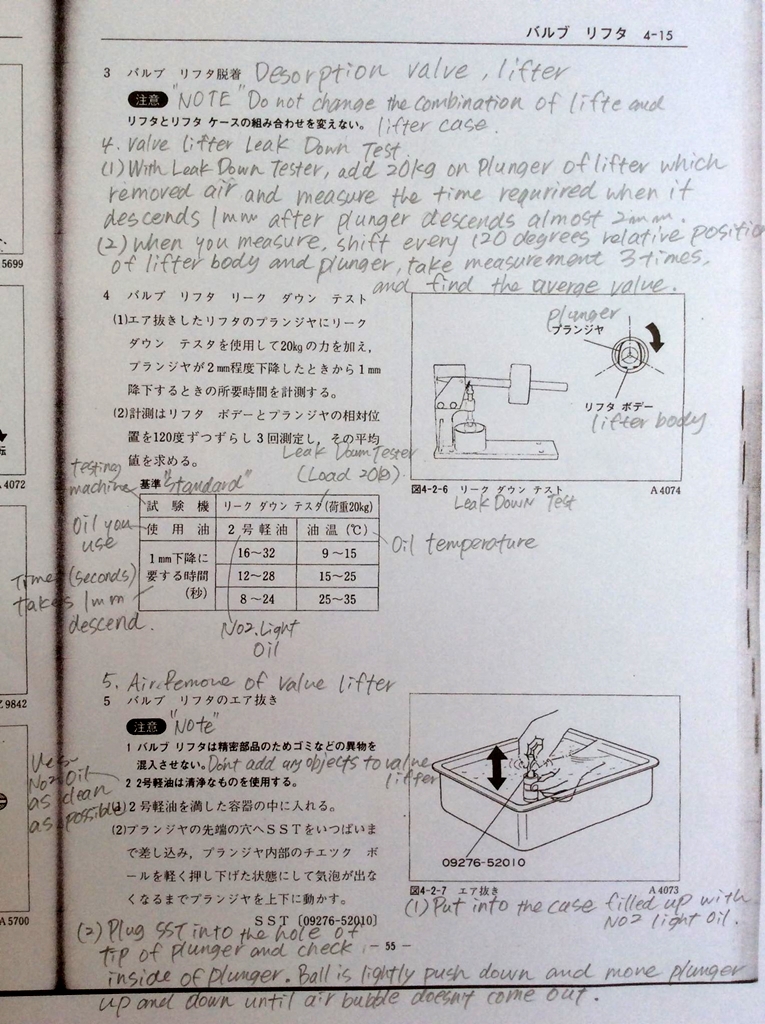

While I'm pretty confident of my translations so far...

I'm feeling uncertain about this one... anyone read (interpret) Japanese??

It was good that I was suspicious....

without this, I'd likely condemn all the lifters based on my original translation....

more to come...

Knurled. said:

In reply to frenchyd :

One of the advantages you get with a "hemi" head is the valves necessarily have to be clocked laterally across the deck instead of inline, which makes the ports a lot nicer. The intake port flows more to the center of the chamber and the exhaust port doesn't have a big dogleg.

The 3rd generation Mopar Hemi isn't a hemispherical chamber (which had a lot of purists furious), it's an actual wedge chamber with quench pads. But it still has centrally located (ish) spark plugs and the good port geometry.

One thing that all three generations of Mopar had issues with was rocker tip lubrication. The exhaust rockers are about two feet long and the intake rockers go "backwards", in both cases not much oil spashes up near there. Engines that idle a lot have a lot of valvetrain issues as a result.

I wonder how the Toyotas fared.

That’s the advantage of overhead cams. Without the need to allow for pushrods You don’t need to go to elaborate lengths to get good ports. Plus without pushrods and rocket arms the need for stiff springs is eliminated. Yes you do wind up with a slightly taller engine. But slightly less than the height of the camshaft.

As for the 3rd generation Hemi I’m sure that was done to meet smog requirements. Jaguar faced a similar issue with their “reverse Hemi” V12 in order to conform to California’s 1980’s smog requirement Jaguar had to eliminate their free breathing V12 head and adapt a version of Chevy’s old fireball head.

The result instead of making well over 750 horsepower on French pump gas the new HE version tops out at about 450 horsepower.

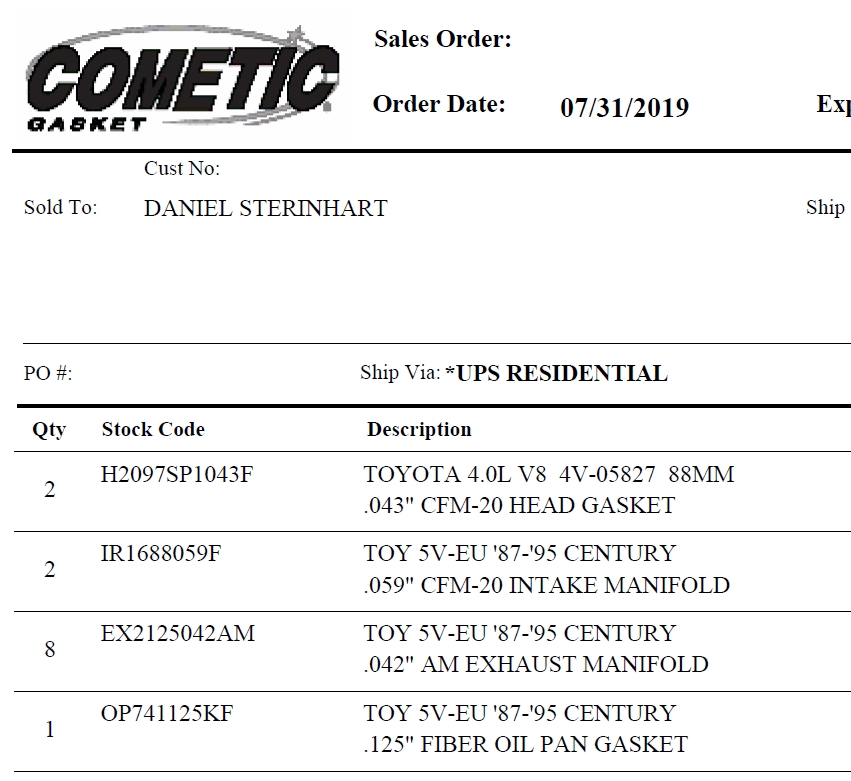

They should be here within 10 days, to 2 weeks.....

They should be here within 10 days, to 2 weeks.....

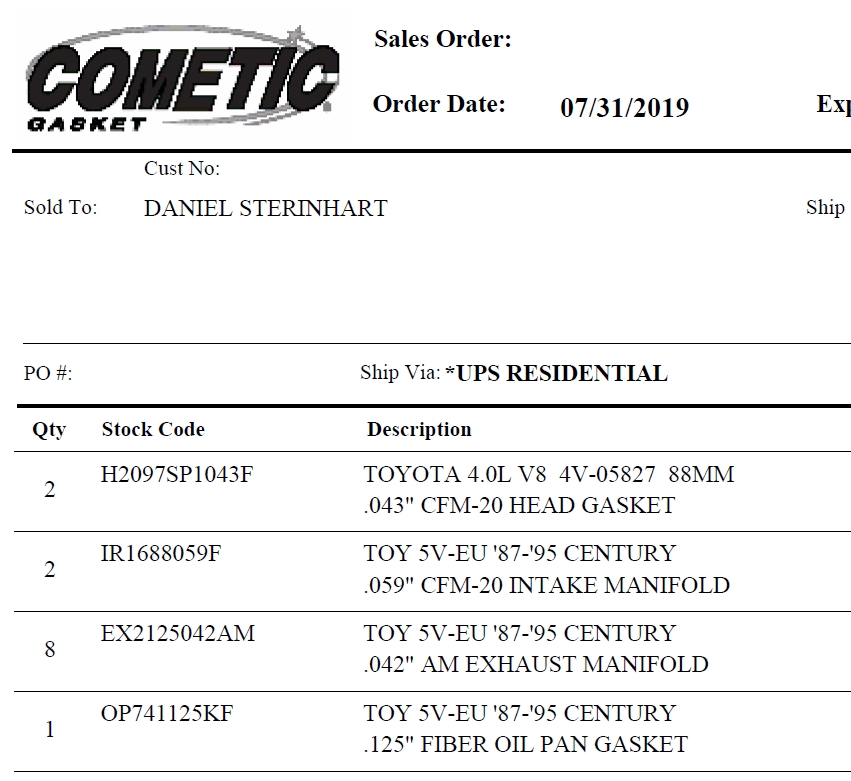

EDDIT - Just a heads up for anyone... the head gaskets listed below are NOT correct - correct gaskets are later in this thread.

Not saying there are a lot of you planning on building one, but if you stumble over one... you now have gaskets

The squish will be tighter as the new head gaskets are about .005" thinner. At 88mm, there is also room for an overbore if I choose too.

More to come......

The gaskets have arrived, I'll be laying them up on the block and intake manifold in the next day or 2 to make sure it all lines up. Still don't have timing cover, or water pump gaskets - I'll be concerned about that later if I need too.

In the mean time I've been thinking about the ignition system since the shipping company busted the distributor, which may be(is likely) a blessing in disguise.

So my plan for the ignition is a crank sensor, and cam sensor.

For the crank sensor, I'll take an existing crank sensor and mount it to the crank pulley, making sure to get it re-balanced.

For the cam sensor.....

The plan is to use the existing pick up @ the very base of the distributor - remove all but one of the spokes, and then use that spoke as the cam sensor. The remaining cast housing will be machined away at the base/mounting flange, and a small cap placed over the pick up and single spoke to keep dirt, and debris out of the way.

This should allow me to run the ignition, and if I want sequential injection. As of now, I'm thinking of running GM type wasted spark coils so I can retain the hemi look with individual wires going to each plug.

Anyone(particularly the ignition, and management people) see any issue with this set-up?

More to come.....

Now this is a development.....

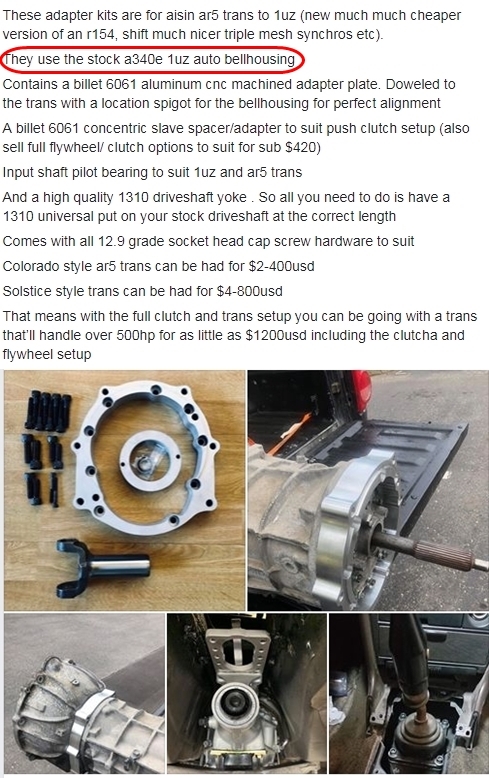

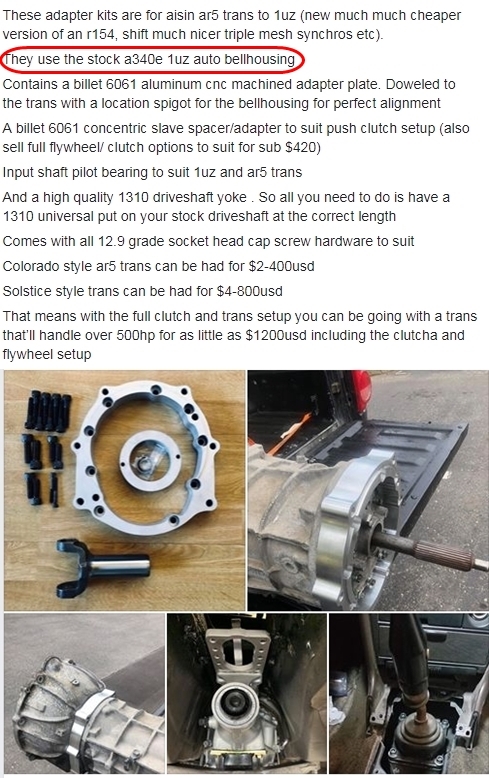

About the time the engine arrived, I was still working on a transmission solution. The easy answer appeared again on Yahoo Japan auction

It is an A340E for an early 90s Century, it comes with the bell housing, unique to Century, and torque converter, also unique to Century. So I bought it.

While it does provide me a transmission solution, at the time I wasn't aware of THIS:

I've spoken with the adapter's manufacturer, and he believes the 5V-EU bell housing can also be adapted!!! Since the bellhousing doesn't get modified, I'm left now with a "2 in 1" option. I can use the manual trans set up while I'm still able, and if need be, I can swap the auto back in at a future point in time IF I can no longer drive a shift, or I'd want to for some other reason...???

DEFINITELY more to come.......

coolest JDM project ever! Question could you find another distributor housing and combine the existing distributor shaft from your engine with that housing? Might have to machine some surfaces. that way you could get a GM HEI or some readily available aftermarket distributor mounted in the place of the broken stocker. The engine won't know the difference.

How are you shipping it ?

californiamilleghia said:

How are you shipping it ?

I assume you mean the transmission.... I bought it through the same company I did the engine. The problem last time was the US shipping leg(or so I was told....). I'm not entirely sure yet what to do, if I can "do" anything, to insure a better result. I was giving some thought to asking the importer, once it arrives, to remove, and.drain the torque converter, and bell housing and ship them separately.... I'm not sure he'll even do that.

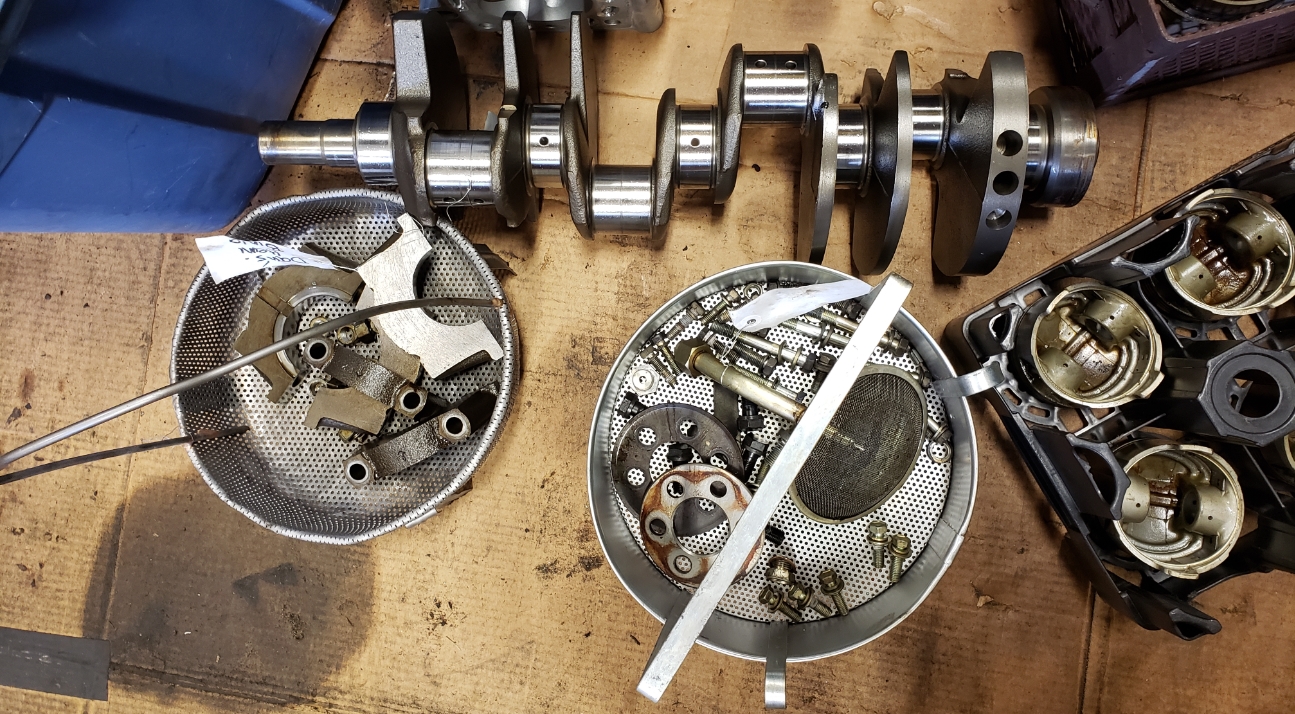

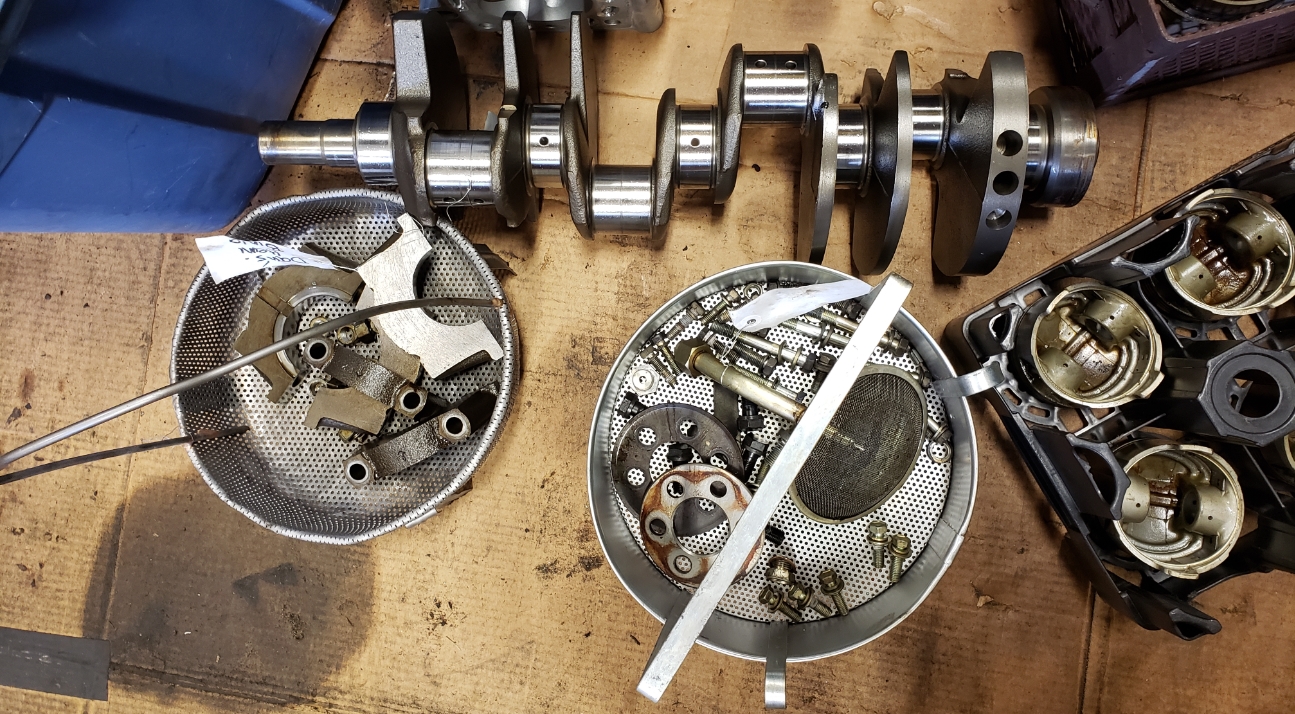

I has been a while....... the engine has finally been torn down to the last nut and bolt. The good news is all the bearings show little or no sign of wear (YEAH!), the oil pump, and housing also show no sign of wear(YEAH!), and the final bit of good news is the timing chain, and tensioners show only minimal wear (YEAH!)

The "bad news".... the rubber "O" ring that seals each cylinder into the block will need some kind of replacement, and the bigger bad news is there is wear in the pushrod end of the rocker arms(most of them) a solution is now undecided..... and still to be determined... the lifters also show some cupping (wear). The cam and lifters are going out to Oregon Cam to get "read", so that we learn the duration, lift, and since it is a single cam - lobe separation angle....

The block has some nifty features... the main caps are all doweled, and all the mains use studs. Additionally the oil galley plug acts as a timing chain squirter/oiler.

the crank, and main caps

more to come...... :D

You should be able to make your own cylinder O-rings from cord stock. That is what I do to assemble Mazda rotaries without spending $40 per O-ring or whatever Mazda charges. Assuming the grooves are rectangular, you just find the cross section area of the groove and choose a round cord of that same cross section, and then you just cut the cord to the right length and use cyanoacrylate to glue the ends together.

McMaster-Carr sells neoprene, Viton, anything you want. I use Viton for the O-ring that potentially sees combustion gases and neoprene for the oen that doesn't, and I buy enough for 2-3 engines and spend less than $20. Never had an issue.

It looks like that distributor already had a multi-tooth wheel and single tooth wheel, but it's difficult to see from the be photos if they're in decent shape.

If they are, the multi-tooth wheel will serve as your crank trigger and the single tooth will work as your cam trigger. This means you won't need to adapt a trigger to your crank pulley.

It also occurs to me that they also sell large O rings. Just spitballing a number, I looked at 90mm OD units and they go as small as 2mm thickness.

The ones I use for my engines are, IIRC, 2.2mm for the inner and 2.0mm for the outer, but if you need smaller then you can buy in bulk down to 1mm. There is also apparently a custom O ring service, which I assume is them gluing the ends of cord stock together for you.

The more pictures you post, the more impressed I am with the design and construction. Given the number of superficial similarities (all aluminum block with separate camshaft carrier, wet liners) I almost wonder if Cadillac was looking at it when they were developing the 4.1l. Which makes me wonder if these engines had a similar bad reputation, or if the reason parts for the engine don't exist is because they were exclusively for Toyota's top model and the people who bought those didn't repair them, they'd just buy a new car.

Knurled. said:

The more pictures you post, the more impressed I am with the design and construction. Given the number of superficial similarities (all aluminum block with separate camshaft carrier, wet liners) I almost wonder if Cadillac was looking at it when they were developing the 4.1l. Which makes me wonder if these engines had a similar bad reputation, or if the reason parts for the engine don't exist is because they were exclusively for Toyota's top model and the people who bought those didn't repair them, they'd just buy a new car.

Speaking to the o-rings, the McMaster-Carr look like they may fit the bill....

Wasn't the 4.1 fitted with iron heads???

As to exclusivity all the parts are listed in Toyo DIY (factory parts scans) so I believe at one time you could get parts......

In reply to oldeskewltoy :

Yes, the 4,1 (and the 4.5 and 4.9 descendants) had iron heads. And the valve cover spanned the head and intake manifold, like an FE Ford.

There were many compromises made in the interest of low hoodline. The ports would make you wince. I mean, they're bad. Terribad.

I can't be sure.... but there are not many hemi owners who can carry both heads at the same time....

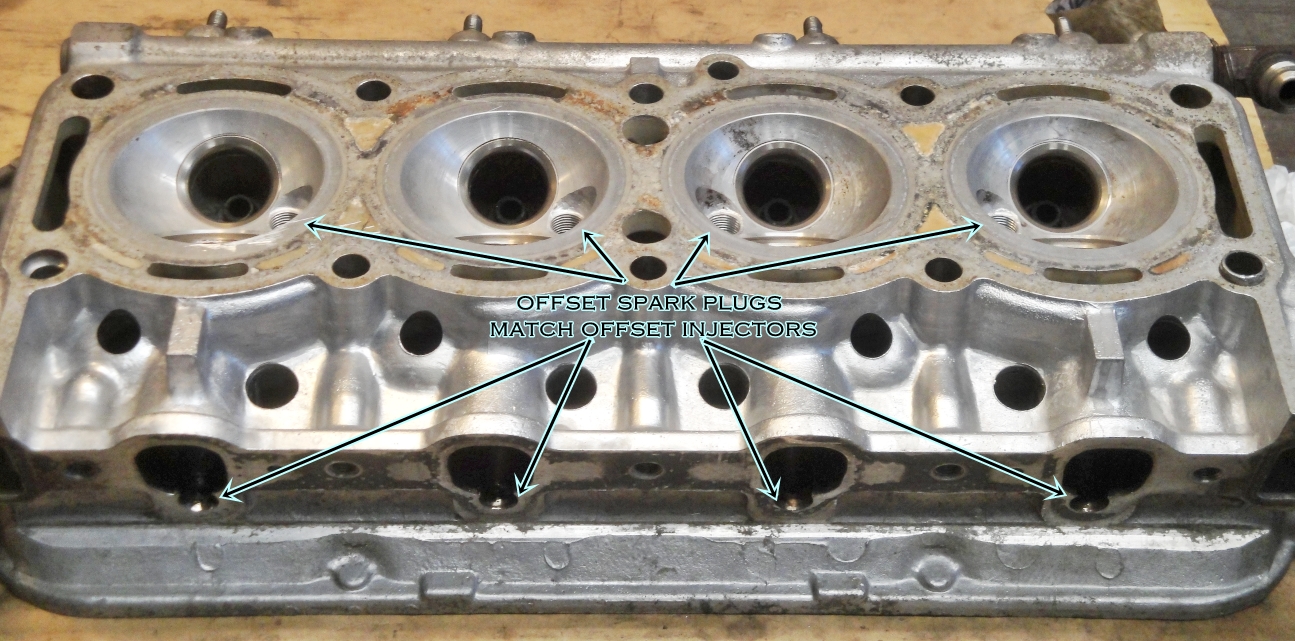

A bit of discovery....

and a bit more discovery

btw, that is one of the new Cometic head gaskets.

More to come.....

oldeskewltoy said:

A bit of discovery....

and a bit more discovery

and a bit more discovery...... I did a bit of casting.......

Exhaust....

Intake....

Both....

more to come.....

What did you use to make those castings? That looks awesome and much easier to visualize.

In reply to Knurled. :

Prosil 1025 2.2# kit(quart size). runs about $60 with freight, or $51 if there is a Fiberlay store near you.... Warning... the activator is age sensitive... when it gets about a year old, its effectiveness wanes.... that is why I don't buy the larger size

mke

HalfDork

10/15/19 7:38 a.m.

oldeskewltoy said:

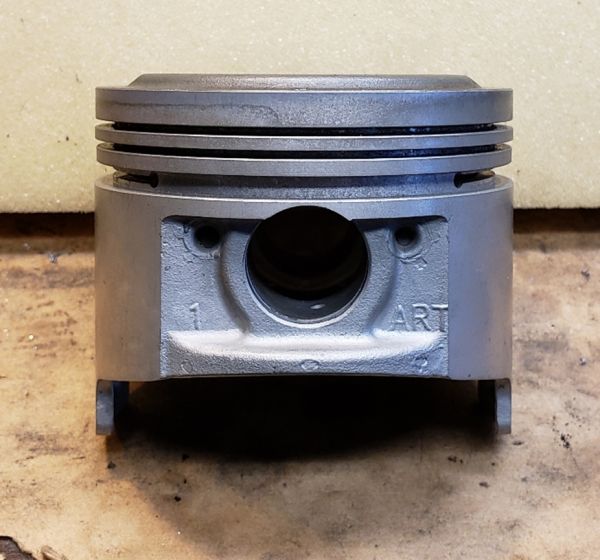

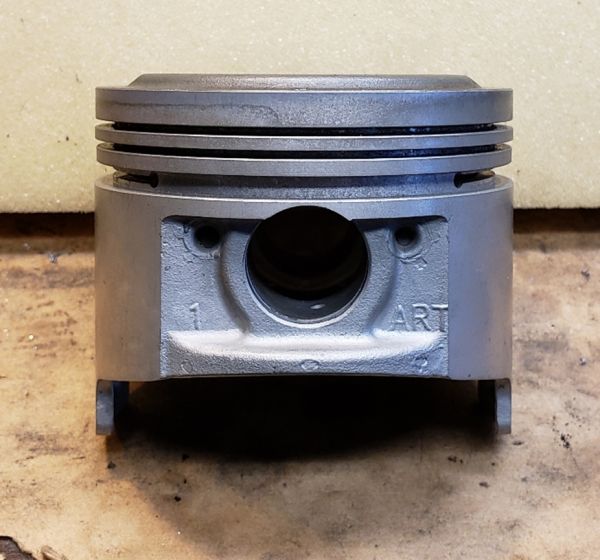

I've also been doing some piston searches.... (preliminary as I don't yet have a chamber volume, or a piston dome volume) I've been looking @ Toyota "T" piston types as they are similar...

As flat as my current domes are, I doubt I'll need anything radical... no where near this

more to come.....

Looks just like an older H-D sportster piston. To echo a little bit what others have said, pay attention to where the spark plug is located relative to dome height. On the H-D engine when you get to about 10:1 the the dome start to go above the plug and blocks the flame path to the far side of the chamber. As that happen going to dual plugs starts to show significant power gains. That could happen with 911 heads too and even the factory started dual plugging them for a while at the end of the air cooled era.

The answer with the H-D stuff was a "bathtub" chamber where you'd weld in the sides a bit and cut about a 60deg included angle squish zone ( I did a 911 set like that that worked quite well too)....again probably more work than you're after though....so limiting compression to a dome that stays under the spark plug is probably the easiest.

mke said:

oldeskewltoy said:

I've also been doing some piston searches.... (preliminary as I don't yet have a chamber volume, or a piston dome volume) I've been looking @ Toyota "T" piston types as they are similar...

As flat as my current domes are, I doubt I'll need anything radical... no where near this

more to come.....

Looks just like an older H-D sportster piston. To echo a little bit what others have said, pay attention to where the spark plug is located relative to dome height. On the H-D engine when you get to about 10:1 the the dome start to go above the plug and blocks the flame path to the far side of the chamber. As that happen going to dual plugs starts to show significant power gains. That could happen with 911 heads too and even the factory started dual plugging them for a while at the end of the air cooled era.

The answer with the H-D stuff was a "bathtub" chamber where you'd weld in the sides a bit and cut about a 60deg included angle squish zone ( I did a 911 set like that that worked quite well too)....again probably more work than you're after though....so limiting compression to a dome that stays under the spark plug is probably the easiest.

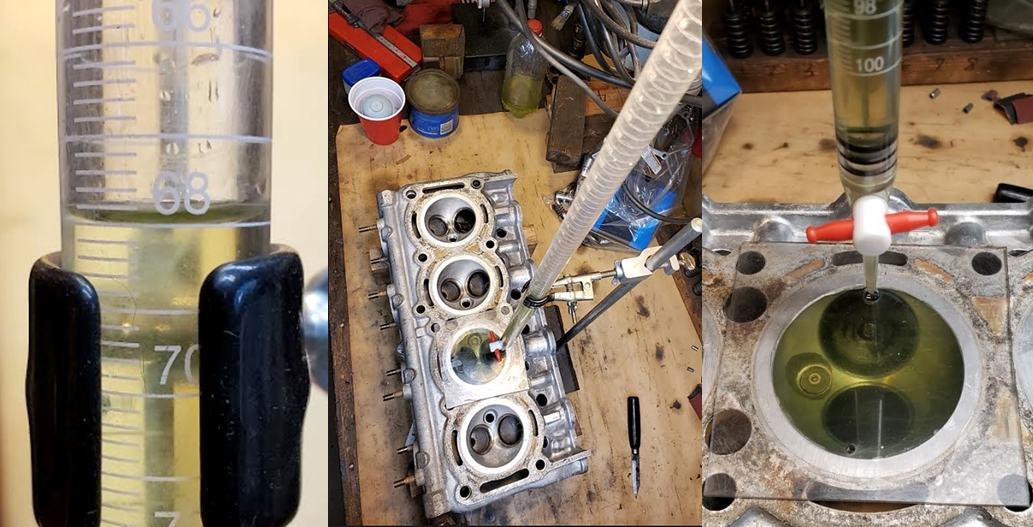

Been working on this.....

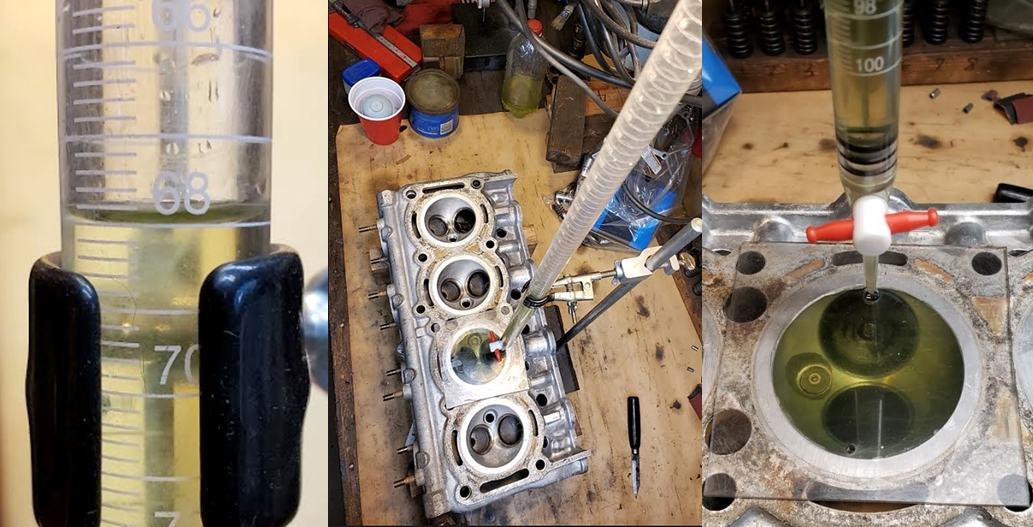

Chamber volume is 68cc (before surfacing).

Original gasket = 88.5 x 1.5mm

Current piston dome volume is approximately 13cc (76mm diameter, by .120"(3mm) tall)

Bore = 87mm

Stroke = 84mm

Gasket bore = 88.5mm

Gasket thickness .043" (1.1mm)

Deck = 0..4mm

Chamber volume after machining - 67cc (estimated)

Dome estimate - 23cc

I've been TOLD... the 2TC piston on the right is 22cc

mke

HalfDork

10/15/19 11:03 a.m.

In reply to oldeskewltoy :

That seems very manageable. Are pistons available or will you have them made?