Oh... no, I didn't get a before, and after flow, I also didn't get flow with a fresh 3 angle. The flow test I have was after a simple cleanup.

Speaking to the rods.... There may be something... small end .8662(22mm), big end 2.1654(55mm) center to center 6.098". I'm not sure if conventional rods will work - these are diesel, or split-angle rods, and getting them tightened may require a similar rod - do to the length of the block skirt.

I ordered the cometic gaskets last week and projected delivery in 3 weeks. Thanks for making it easy to get these. I checked with Origon cam and have not been able to get Comp or Isky to call back or email back. I have been trying to get info on cam blanks to do a roller cam. The blank for this cam is easy to machine because the dist. gear is keyed on the front end.

warrenwelder said:

I ordered the cometic gaskets last week and projected delivery in 3 weeks. Thanks for making it easy to get these. I checked with Origon cam and have not been able to get Comp or Isky to call back or email back. I have been trying to get info on cam blanks to do a roller cam. The blank for this cam is easy to machine because the dist. gear is keyed on the front end.

https://www.bulletcams.com/

oldeskewltoy said:

I don't expect this engine to be assembled anytime soon, there are over 100 engine builds at the shop currently in front of mine, so I expect mid/late summer.

Took a while... but the engine is back on track... heads now have a fresh 30/45/60 valve job, along with 30 degree back cut intake valves.

More updates to follow..........

In reply to oldeskewltoy :

Is that the two roter cap with 4 wires on top and 4 wires on bottom?

warrenwelder said:

In reply to oldeskewltoy :

Is that the two roter cap with 4 wires on top and 4 wires on bottom?

I believe it is.... each rotor arm fires 4 cylinders. internals appear to be batch type injectors - 4 per "batch" so fires twice...??? I have not yet counted the # of contacts in the lower sender

warrenwelder said:

I ordered the cometic gaskets last week and projected delivery in 3 weeks. Thanks for making it easy to get these. I checked with Origon cam and have not been able to get Comp or Isky to call back or email back. I have been trying to get info on cam blanks to do a roller cam. The blank for this cam is easy to machine because the dist. gear is keyed on the front end.

please check your email.... wondering if you might have access to any "spare" intake rocker arms??????

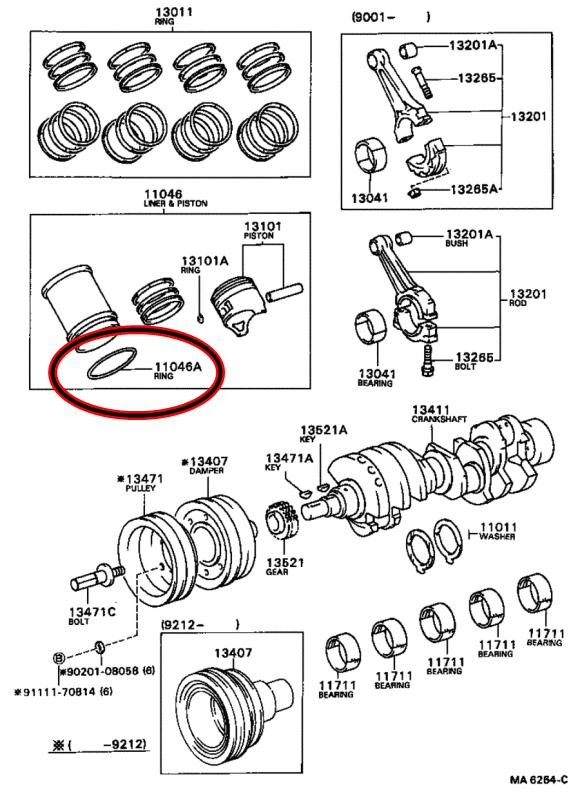

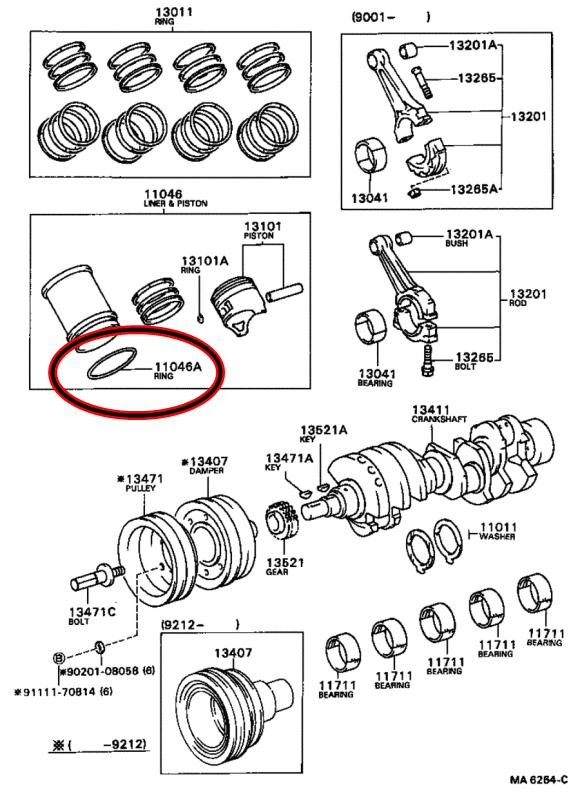

Realized something. The rods had to be angled like that because, due to the wet liners, you can't rotate the engine without the cylinder heads attached to hold the cylinders in place.

Pete. (l33t FS) said:

Realized something. The rods had to be angled like that because, due to the wet liners, you can't rotate the engine without the cylinder heads attached to hold the cylinders in place.

If you use a large washer and spacer tube (on studs) or a short bolt, you can hold the liners down while turning it over.

Common problem for wet liner motors.

mke

Dork

9/3/21 6:36 a.m.

Gammaboy said:

Pete. (l33t FS) said:

Realized something. The rods had to be angled like that because, due to the wet liners, you can't rotate the engine without the cylinder heads attached to hold the cylinders in place.

If you use a large washer and spacer tube (on studs) or a short bolt, you can hold the liners down while turning it over.

Common problem for wet liner motors.

indeed

The angles end rods thing is normally about getting the rod to physically fit through the bore. The smaller the bore/stroke ratio the more likely you'll see the rods angled, its very common in diesels. I have a flat head Lincoln with angled rods but the larger bore fords engine it was based on uses straight end rod and no way the readily and cheaply available ford rod is going through the Lincoln bore :(

Gammaboy said:

Pete. (l33t FS) said:

Realized something. The rods had to be angled like that because, due to the wet liners, you can't rotate the engine without the cylinder heads attached to hold the cylinders in place.

If you use a large washer and spacer tube (on studs) or a short bolt, you can hold the liners down while turning it over.

Common problem for wet liner motors.

True, but on an assembly line, where you can make changes to the parts to make the assembly line go faster, it makes more sense to design the rods so you can tighten the bolts without having to rotate the crank. That costs very little compared to assembly-line time.

In reply to mke :

Subaru have angled rods on the FB engines, and they have nice big 86mm bores. It's for assembly line access reasons there.

Finding this pic in my old Photobucket account is what made the lilhemi connection click.

mind you, I'd love to get my hands on a Ferrari "166" engine with teeny tiny bores, but nobody has offered one up yet

My rocker arm "problem".....

In reply to oldeskewltoy :

I have no spare rockers. I do have 2 sets of head gaskets and a spare starter.

I finished rebuilding my shop after the hurricane and just need to clean up and reorganize the shop before starting the teardown of the 5v-eu engine. I am starting to think that a long runner tunnelram is what I need for the intake rebuild.

I haven't taken off my rockers yet to see what a good one looks like. If there is wear in the pushrod socket It should be no problem to weld it up and remachine the socket to spec and normalize the heat treatment.

I was checking 3t pistons for fit to the 5v and measured the chamber it be much smaller in diameter on the 3t and it has a 1,375 compression hight. They do come in 87 and larger bore. I don't know what the compression hight is on your pistons but I emailed your supplier and asked for that info and the pricing but got no answer yet. Back in the day I could get 3t pistons from wiseco for $35 a hole. I'm sure it can't be more than social security check now.

Warren

oldeskewltoy said:

Alright... the 2S flywheel will "fit" the 5V crankshaft.... YES

The center hole fits the crank snout, and the bolt spacing is correct. What is still unknown is if we will need a step/shoulder type bolt or not, and what the back spacing is - we'll need the crank in the block, and the starter fitted to verify back spacing.

more to come.....

So the Camry flywheel ALMOST fits... the center hole is about .005"-.010" too small, the flywheel can be mallet-ed on about 1/2 the distance, but it doesn't go on any further.... AND the crankshaft bolt holes are about .020" narrower bolt circle then the flywheel. Last the backset appears to be .040" too much. These small modification will be done to the flywheel to make it fit the crank.

The Camry clutch is still available......

I have a call into ACT clutch to see if they can turn a Camry 2SE pressure plate (100 pound/feet of torque), into a 5V-EU pressure plate (300 pound/feet of torque) I'll also need a custom disc (AR5 spline on Camry 9" disc)

For now, the crankshaft will be balanced, as will the pulley, the flex plate, and hopefully the flywheel. Having both the flex plate, and the flywheel balanced allows me to put off the final decision on what transmission I'm going to run.....

Yes, Virginia..... I'm thinking of going with the already engineered A340E.....

The Camry clutch is still available......

I have a call into ACT clutch to see if they can turn a Camry 2SE pressure plate (100 pound/feet of torque), into a 5V-EU pressure plate (300 pound/feet of torque) I'll also need a custom disc (AR5 spline on Camry 9" disc)

ACT couldn't help... but it appears Clutch Masters has a pressure plate strong enough.........

oldeskewltoy said:

The Camry clutch is still available......

I have a call into ACT clutch to see if they can turn a Camry 2SE pressure plate (100 pound/feet of torque), into a 5V-EU pressure plate (300 pound/feet of torque) I'll also need a custom disc (AR5 spline on Camry 9" disc)

ACT couldn't help... but it appears Clutch Masters has a pressure plate strong enough.........

The clutch kit is $500.00..........

For now both the flywheel, and the flexplate will be balanced.

Per our in-person conversation the other day re: automatic transmission control, here are a couple links. I know there are folks on here versed in these transmissions, so perhaps one of them will pop in and add something better than my quick Googling:

Good A340 overview and HGM Compushift info

11 pages of info on MegaSquirt/Microsquirt A340 control

ae86andkp61 (Forum Supporter) said:

11 pages of info on MegaSquirt/Microsquirt A340 control

Bookmarking that for the hypothetical eventual AW4 swap into my J20.

One more piece to the puzzle found... or so it seems...

4M valve seals are also "top hat" type seals, and appear to fit the 5V-EU...

more to come......

another piece........ the O-rings at the bottom of the cylinders - these are crucial, as the separate the oil side from the water side... so these are a can't fail item.

found, and locally (I'll try to find out where exactly...)

And the rockers (all 16) are on the way back from being reconditioned. Besides fixing the 5 with bad push rod sockets, all 16 got the valve end (lower left in photo) reconditioned as well. Essentially giving me 16 "new" rocker arms.

more to come........

ShawnG

UltimaDork

12/25/21 5:08 p.m.

Ahh yes... The "Can't fail" o-rings.

That abomination PRV V6 engine has those. Except it's French instead of Japanese so they're "might not fail" o-rings.

I hate wet-liner engines because of those.