In reply to Stefan (Forum Supporter) :

I appreciate the info! I am pretty committed to making the 4-speed work, at least initially, but we'll see where this goes. I make lists in my phone for junkyard parts or for future Rockauto orders, so I might do a bit more research to see what all I need to fit a T350 in there.

The Nippondenso starter worked with some modifications. I needed to blend one area that was contacting the pressure sensor boss on the block. I think I went a little overboard here, because the starter wasn't fitting all the way into the trans due to a burr or something on the snout that was keeping it from fully seating. Didn't realize this until I had taken all that material off, but whatever. I blended down the plug to sit slightly below the surface and installed that for good, then sprayed some more paint to cover up all the marks I made.

The old starter had all straight holes on the flange and bolts were threaded into the trans, but this one has threads in the starter on two of the mounting points. I drilled through holes in the trans and had to lightly blend a spot in the corner for a bolt to sit flat.

I couldn't get the stock lower heat shields to fit back on the exhaust manifold, so I will probably look for a blanket to insulate the starter, and maybe put just the top heat shield on.

Today I cleaned up the dust shield and put that on with the trans and starter. I pulled the speedo cable out and was pleasantly surprised to find the PT speed sensor fits perfectly with the original gear.

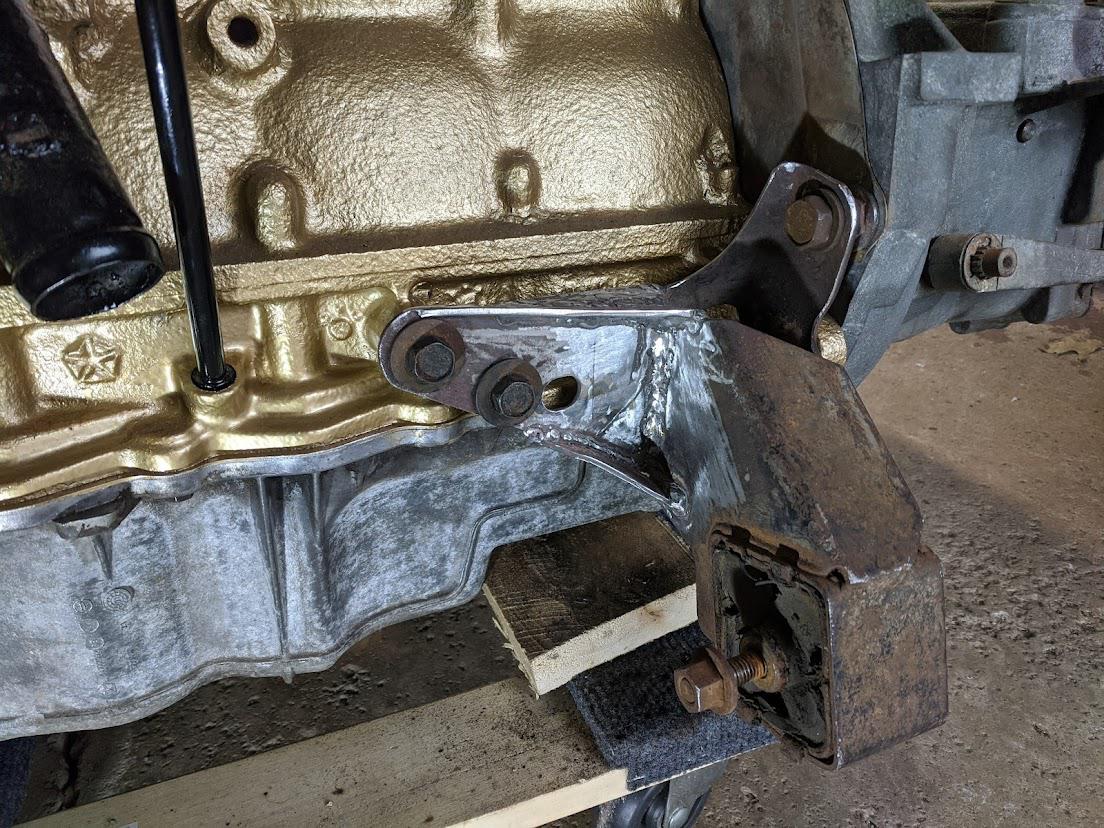

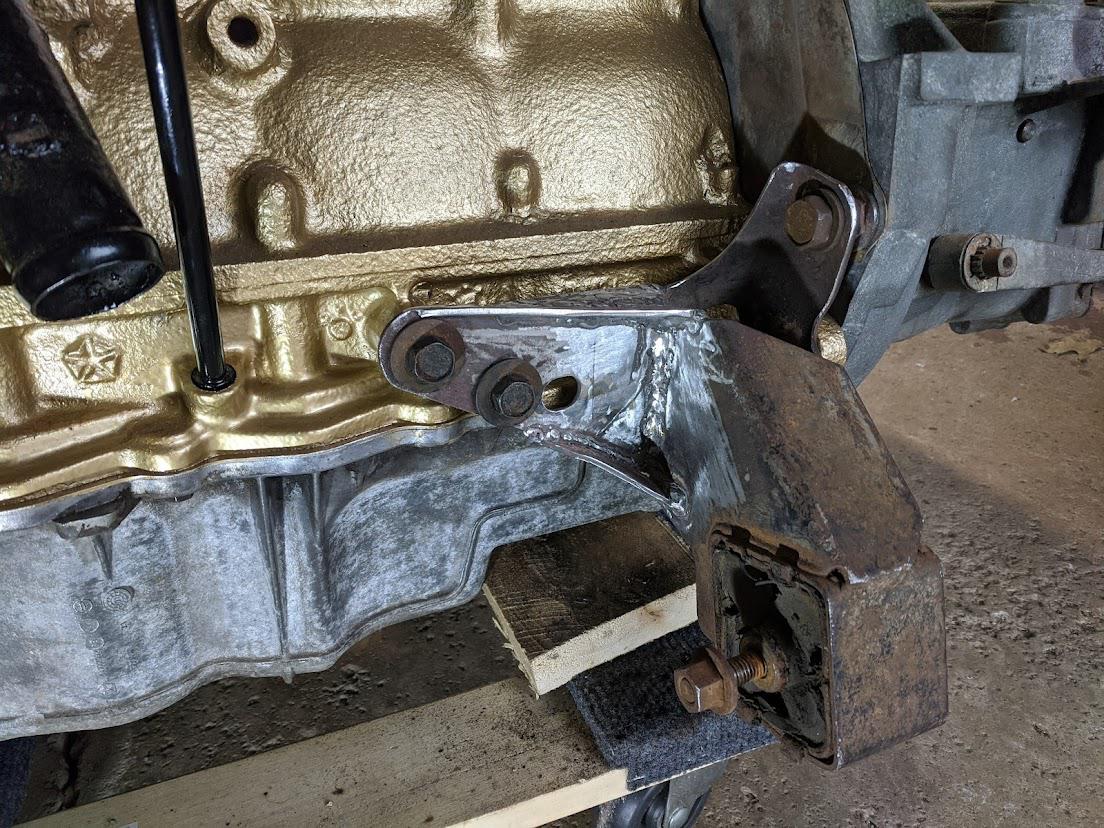

I started on the front engine mount by chopping up the back side of the bracket to fit over the engine contour. Then I cut the ear off so I can use two engine block holes. One wasn't used for anything in the PT, but already had threads cut in it, so I cleaned them up and put a bolt in finger-tight. We'll see if it will torque up, but if not I'll have to go next size up. The other one maybe had a power steering line support bracket or something. Need to connect the dots next.

Modified front engine mount is pretty much done. I cut all the metal used from this old transmission mount.

I was going to take photos along the way, but ended up just working straight through.

Welded on the drilled out nut I was using as a spacer for the top bolt, and a pad to push the block ear against the trans mating surface.

Will probably put a little more time into smoothing it out before I paint it, but I'm hoping to test fit the engine in the Rampage tomorrow and take a look at the passenger side mount.

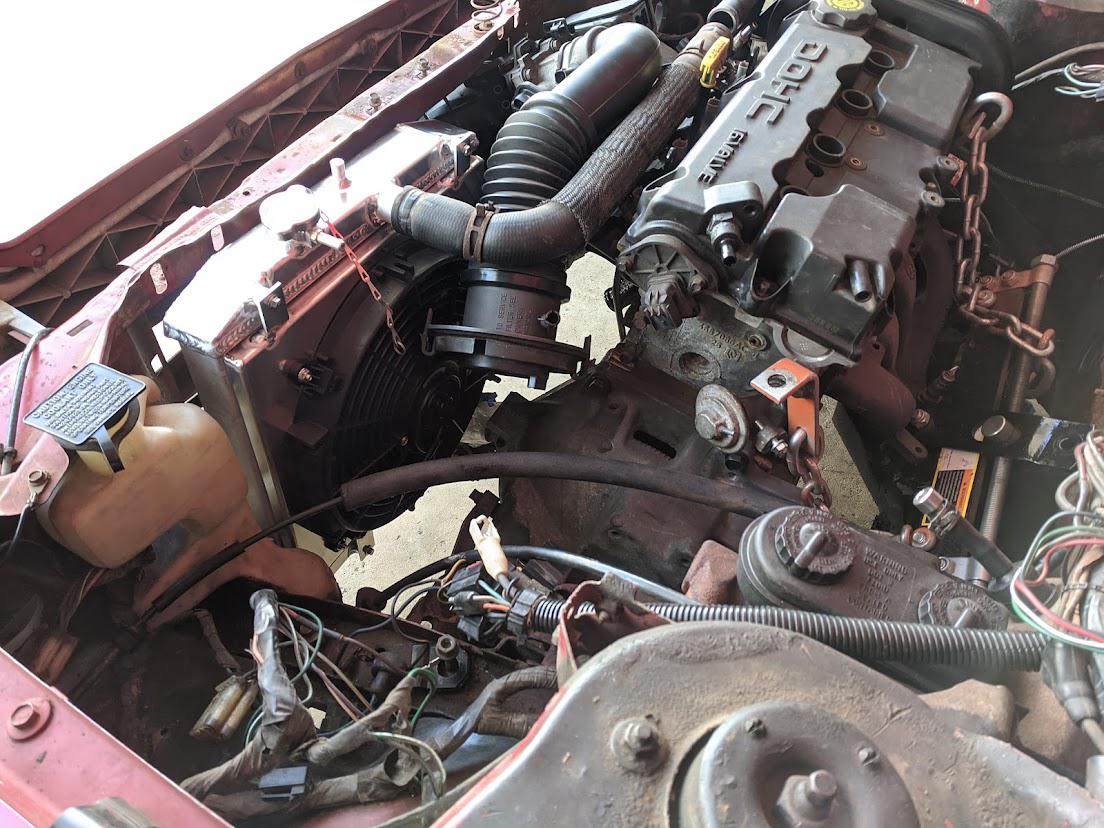

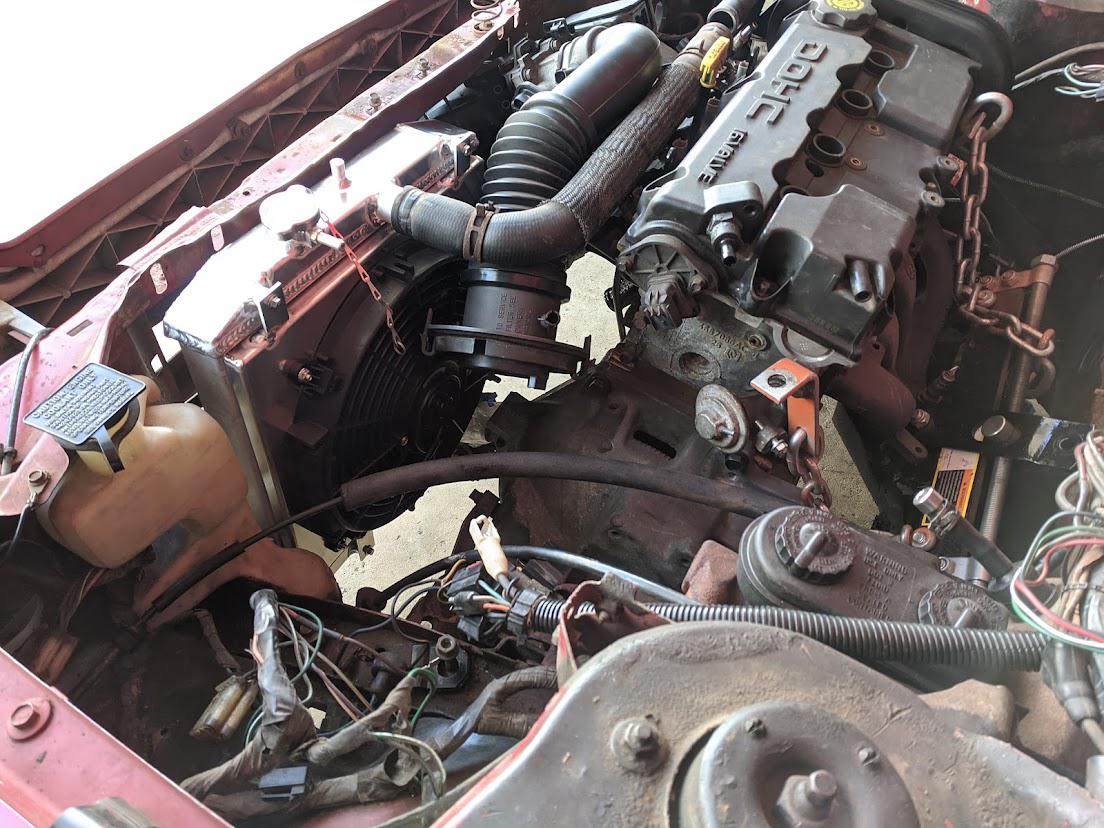

Test fit today was pretty successful. I tried dropping engine and trans together through the top, but just couldn't seem to get the angles correct. Engine from the top and trans from the bottom is the way to go. I switched the main engine mount bracket from the PT one to a Stratus one that is way smaller and lighter, and it lines up surprisingly well with the stock mount location. I cut apart a Stratus mount to bolt to the bracket and the engine is actually just resting in place. That's part of the original Rampage mount sitting on top of the Stratus piece.

The alternator had to come off though, as it's running into that rail a bit. I don't think much clearancing will be necessary.

Very cool stuff, Mopar content is good content.

Yesterday I made a trip to Pull-A-Part to look at Stratus parts. It turns out PT intake manifolds are way too tall to clear the hood, so looking at my options, I like the second gen Stratus / Sebring intake. I grabbed one of those with throttle body. I also got alternator and ac compressor and brackets from a first gen Stratus, which puts alternator in front. I will need to get a Stratus damper to match, but I'll get that new on RockAuto. I did have to take a little material off the alternator bracket for manifold clearance, but otherwise everything just bolts on. I like that this keeps the thermostat housing separate from the manifold, which isn't the case for first gen Stratus and Neon, and has pretty long runners like the PT.

But... it looks a lot smaller in a Stratus engine bay. I cut that center core support rib and bent the top out of the way a bit, so I'll turn that into a bolt in piece. I also had to cut out a little bit of sheet metal in the front. I was surprised to find the fuel rail mounts weren't in the same spot on the manifold. The hood closes, and the latch bracket all fits back in no problem.

So this eats up a bunch of my radiator space. I know there's a Neon half-rad out there, but I don't see it listed in RockAuto. I could maybe use a narrow Civic one too; apparently the Neon rad bolts right into Civics per some Honda forum posts. Would anyone have concerns with using a small radiator in this car? I really don't think I'll drive this thing hard ever, just want to have confidence in it.

I started on the passenger side mount too by cutting the Rampage one and adding onto it. I somehow made it too long by about half an inch, so need to shorten it and build in spots to use the other bolt holes.

I got the passenger mount finished up. Will blend on it some more like the front mount when I'm ready to paint them.

I laid under the car and stared at the fuel tank area for a while today, planning for fitting the PT one in there. I think I'll work on that next.

I am probably going to go with a Civic half rad. There are a bunch of aluminum ones on ebay; does anyone have any experience with a particular brand they'd recommend?

I was going to suggest the stratus alternator, but it looks like you are already on it. Carry on!

In reply to bgkast :

Appreciate it! I love that all the Stratus parts are aluminum and way lighter than PT steel stuff too.

I got a Civic half rad in this week, and like how it looks in there. The thermostat housing cap is higher so I'll keep that one, and I guess look for a locking cap for the radiator. The overflow port on the rad is a threaded fitting, so I can plug that. PT upper rad hose almost fits, so I'll have to look for same thing but longer on both ends.

I have been working on fitting the PT gas tank since my last post, which has taken more time than I expected. PT tank straps fit the Rampage slots and extend back toward a crossmember under the bed. I cut some sheet metal humps that located the Rampage tank, and had to hammer up some areas, but fits up in there pretty well. I didn't realize the driver's side of the crossmember was rusted quite so bad, so cut and patched some of that. I need to get some metal to make the rear tank strap mounts. Here's a photo showing the rusty areas I cut out. I welded in patches, but don't have a newer photo. The new strap mounts will be welded to the front side of the crossmember and extend down about 3".

Finished up making mounts for the PT fuel tank. I plan on trimming the driver side one back on the rear side and adding to the sides to tie it up into the crossmember. I'm not sure if I should gusset the passenger side one any more or not. Maybe a plate on the back to connect all the way up to the back side of the crossmember?

It's nice to have the tank out of the way in the garage now, so I'll leave it in there until it warms up more. I'm hoping I can drop just once more to finish everything up and paint.

I've been making steady process, but recently felt like I was going too slow, so I took last Friday off to dedicate work on the Rampage. I'll be doing the same this coming Friday. Since my last post, I figured out radiator mounts. The lowers are tacked in and need fully welded, and the upper could be considered done, but I'd like to make it look nicer. I drew with black sharpie where I might cut out windows. This upper rad hose is a Cadillac DeVille hose that I should be able to cut down. I bought a Plymouth Breeze lower hose that I thought looked right, but didn't pan out. I cut part of that and connected it to an old PT upper hose, and it looks decent, but I would prefer to figure out a one-piece solution. I don't have a lower hose photo for some reason, so I'll get one later.

I laid the PT wiring out in the bay to plot where to pass through the firewall. Then pulled the engine back out so I can drill a hole for that and finish welding up some stuff. I cleaned the K-frame and will paint that and the firewall soon.

I forgot I have the PT fuel line in there too, but need to finish that up too. A cut down PT fuel filler neck fits the Rampage, but I need to track down a hose to run to the tank that's 1" for the neck and 1.25" for the tank. With the engine out I installed the flywheel and clutch, so it was nice to confirm the Dodge Aries stuff actually fits.

I then modified the old Rampage rear engine to transmission brace to fit the 2.4 and switched to Dodge Stratus harmonic balancer so I can use the Stratus alternator. I measured for a belt (40") and cross-referenced one to BMW 228, and I think an Audi/VW, so need to order one of those.

So that's where I'm at. We are still planning on doing the Lemons Rust Belt Ramble rally in July, and I'm feeling ok-ish about getting everything done in time. Wiring, exhaust, instrument cluster, wheels/tires, and probably a million little things.

Really impressive fab work here. As a long-time El Camino owner, I certainly appreciate quirky little trucklets of all types.

In reply to maschinenbau :

Thanks, I appreciate the comment!!

Edit to add that I'm very flattered, having been following along on all of your builds going back to the Datsun wagon.

I got the lower rad mounts all welded up, and made a bolt-in brace for the core support that I previously cut out.

This weekend I cut the hole for wiring harness pass through and painted the bay and k-frame. Pretty half-assed, but better than it was.

I read about a shift feel improvement on an old forum post where you weld the rotating pin and replace bushings with sleeve bearings, so I went for that. There was a ton of slop in the pin that's removed now.

The engine started for the first time in the Rampage this weekend. Let's see if this Instagram link will work for video:

We are registered for the Rust Belt Ramble, team: The Parkers.

Took the car for its maiden voyage around the bock on Saturday. Engine bay wiring is all done and wrapped. I put the pcm down next to the battery, so had to extend all sensor wiring except cam position sensor, and some wires going into the cabin, but it turned out pretty tidy. I need to zip tie stuff into place still, and I have a multi gauge thing in the car to finish wiring.

Test drive was a success, but the exhaust rotated on itself and dropped the driver side down quite a bit, so I will add another hanger near the fuel tank. And speaking of fuel tank, got the filler all finished, but still need to go to a gas station to verify no leaks (fingers crossed). Turns out the egr leaks through the lower port if no vacuum on the top? Whatever, I ordered a blockoff plate from Modern Performance - not very grm to buy one, but I feel like I'm running out of time to make little stuff like this. There's a small oil leak at the tee for my pressure sensors that I need to fix too.

Exhaust is PT cat flipped 180* and the seam on one side ground off and welded shut to avoid hitting shift rod. Mid pipe is srt4 Neon piece that I had. Muffler is the cheapest 2.25 in/out that AutoZone had. It's listed for a bunch of older GM stuff, mostly 3800 v6 applications it looks like.

I attempted to replace the inner boot on the passenger axle, and failed. Two hours of struggling to stretch it over the tripod, then ripped it. Rockauto had a new axle, so hit the easy button on that.

Hopefully this week: wheels / tires, egr blockoff, fix oil leak, stuff interior wiring out of the way somewhere. Then wire the multi gauge and hopefully add cruise control before the trip.

Put the new wheels on and took it for its first drive further than around the block. Filled it up with gas since it still had whatever was in the PT's tank when I got it. It has about 30 miles on it now, but I plan for a longer test drive this weekend before we head up to Detroit for the road rally next week.

I 3D printed a reverse lockout pad. Let me know if you're an L-body person and need the file!

That thing is cool! Don't know how I missed this.

These old fwd Mopars are so cool in the weirdest ways. I can't wait to hear how the longer drives go for you!

Even an NA PT Cruiser motor should be a significant power bump for the Rampage. Glad to see one of those oddballs back on the road!

My grandfather has a convertible turbo pt cruiser with a manual trans. It has absurdly low miles. I'm not sure he's ever driven it lol.