You really do need a better ball joint. Those things fail quick on the 124, and your upright is shorter, so load is not as light as the lower car weight would suggest. The arm is beautiful, if maybe too strong. I would rather bend an arm than a chassis, and I don't drive perfect, who does...Maybe use breakaway bolts on the ball joint?

Trent

PowerDork

11/2/23 1:24 p.m.

Sometimes you gotta treat yourself.

Or in this case, when the very last NOS fender on the North American continent is available AND yours is in pretty rough shape, You opt to pay a fee to save time later on.

JoeTR6

SuperDork

11/2/23 4:27 p.m.

I had 25 y.o. British Motor Heritage fenders in the TR6 pile of parts that I bought. They alone were worth what I paid for the entire pile of parts. Literally just required a small amount of filler along the front edges.

That is prescious. Congrats!

NOHOME

MegaDork

11/3/23 9:29 p.m.

This thread delivers the goods. I will eternally be jealous of those who have a milling machine to make stuff.

Trent

PowerDork

11/4/23 6:16 p.m.

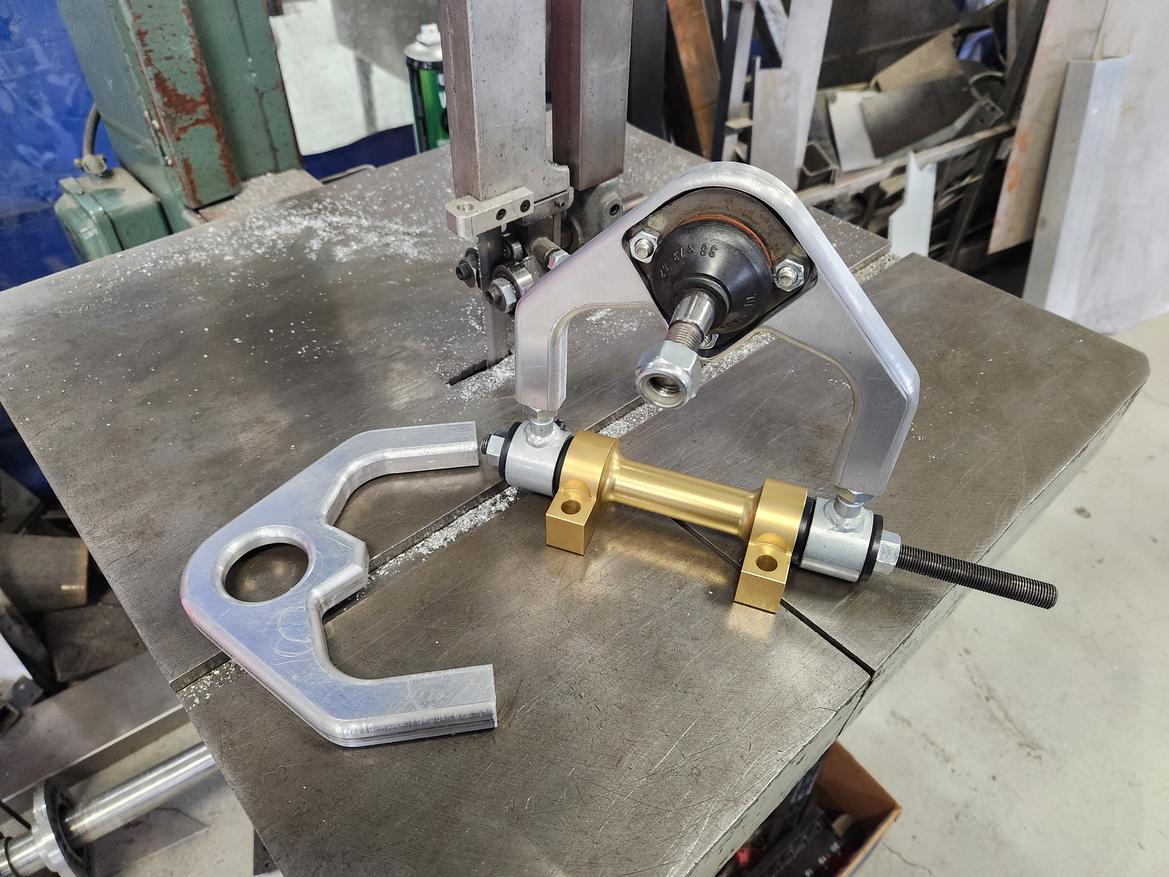

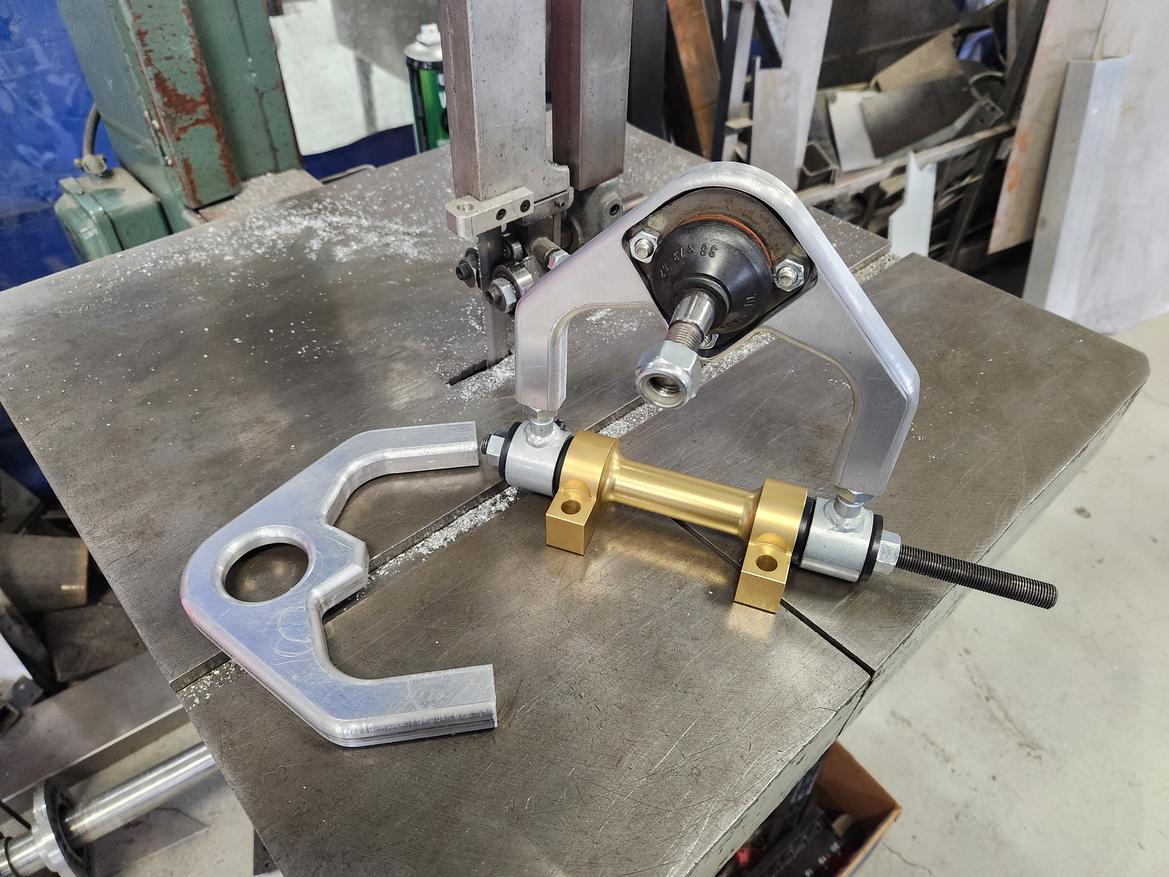

Just a bit of mockup.

The hero jig from the rear crossmember has been cut up and repurposed into a new jig for the front subframe.

The threaded rods indicate the axis and centerline on which the inner pivots must reside. The temporary "lower control arm" tubes hold the ball joint in its location.

Now I have to decide on a lower control arm layout so I can plan the subframe design.

Forgive my ignorance, but is that spindle upside down?

Trent

PowerDork

11/5/23 10:05 a.m.

In reply to Shavarsh :

Looking at the king pin inclination angle, you are correct.

Which means I have some investigating to do. One of my measurements is apparently wrong somewhere

Trent

PowerDork

11/5/23 1:30 p.m.

Somewhere there must be a difference between the 600 and 850 chassis I have not accounted for. When I flip the upright the upper arm needs to be significantly shorter.

Measuring to happen tomorrow

Or the lower ones longer?

Are you sure the hub isn't on upside down, and/or reversed with the other side?

All the extra eyes on your project probably just saved you a few days. You would have caught it, but how many extra steps would need to be reversed...I missed it on first exam too.

ddavidv

UltimaDork

11/6/23 5:20 p.m.

I know where you got that fender, because that's my Sharpie writing of the fitment.  I spent a day in that "attic" ID'ing as much sheet metal as I could because he had no idea what anything was that didn't fit a 124 Spider. Those were the days.

I spent a day in that "attic" ID'ing as much sheet metal as I could because he had no idea what anything was that didn't fit a 124 Spider. Those were the days.

NOHOME

MegaDork

11/6/23 5:23 p.m.

In reply to Trent :

Where there is a redneck, there is a way....

Trent

PowerDork

11/6/23 6:27 p.m.

The upper arm inner mounting points are 10mm outboard of where they should be. That is primarily because of this reinforcement and flange

I trimmed the flange off but will likely have to shave the backside of the mounting pad for the rest.

The rest of the positive camber is likely a sine error when I measured the control arm length. I might have to shave a bit off the arms where the rod ends screw in to get that back

On a positive note the VW oil heat exchanger I have been thinking about using will indeed slip right in place on the block

I doubt I will have the space for a sandwich plate, thermostatic bypass valve, heat exchanger AND hoses. This solution is super compact.

Trent

PowerDork

2/8/24 2:42 p.m.

Spitfire steering racks are back in stock at most US vendors. A lot more expensive than they were 4 years ago! You gotta do what you gotta do though.

I did a tech tip post on this exact process some time ago here

I did decide to do it a little different this time though.

One genuine piece of trash 6061.

Machined into a reasonable analog of the bushing holder on the right side.

Pressed on and augmented with green Loctite .

Et voila! One significantly shorter steering rack.

Front subframe has been in process for a while now and was stymied by the lack of the rack, The mini sale, the Clubman repairs and the new toy E39 projects.

Of course now I have a new issue. It will likely require something like a steer clear drop unit. More on that in a few days

Trent

PowerDork

2/11/24 11:20 a.m.

Continuing with the theme of "Why do it the easy way and eventually finish the build when I can do it the way that strikes my fancy"

Front subframe has to start somewhere

So it is starting with 1"X1.5" steel bars and a rough sketch.

And lots of metal deleting later I have the end brackets that bolt to the chassis.

Which get bolted to the revised jig. All the important points are held fixed. Just need to tie it all together.

To the wood shop!

Just plain old 3/4" plywood.

Since the straight edge is.... well, straight I did that radius on the brake

Then to the vise

Which was trimmed, tacked, slotted and set in situ

Trent

PowerDork

2/11/24 11:28 a.m.

The end pieces proved almost impossible to hammer form what I had in mind so some chromoly started the bridge

But now it is at least one piece

Which means we can test fit

The ends will be plated over something like this.... I think

And then the rack mounts can be added.

Man, inspiring work as always. One of my favorite to check into!

"Why do it the easy way and eventually finish the build when I can do it the way that strikes my fancy" ...awesome!!

TurboFource said:

"Why do it the easy way and eventually finish the build when I can do it the way that strikes my fancy" ...awesome!!

Yeah, that one hit home with me too.

Trent

PowerDork

2/17/24 8:06 p.m.

Trent said:

Hey, remember when I spent a lot of hours making these nice control arms? It turns out they are trash!

While starting another project with those aluminum plates I noticed something written on one.

MIC6.

Wait .... a.... minu...

That is gauge plate! Cast and ground. I don't think it can take much in the way of any load.

I cut a 3/4"X3/4"X8" piece and went to the arbor press.

You don't want to know how little force it took to snap this stuff. my disappointment was palpable.

back to the drawing board. I was becoming increasingly annoyed by the rod end design anyway. Two adjustments is a terrible way to change length and they couldn't be used to change caster so why have the complexity and weight of the two?

So anyway this morning I made a trip to a place my dad has been telling me about. A "really neat scrap yard" he said.

Some $3 per pound aluminum. Those discs are 12 inches in diameter to give a sense of scale.

But it wasn't just metal. It was everything!, from motors to ball screws to antiques to linear actuators to stepper motors to bulk bearings to test equipment to..... it boggled the mind. Endless shipping containers and pole barns filled with goodies.

I could have spent hours but it was raining.

What I left with

Wasn't what I went looking for but they were nice billets and I wasn't making a 2 hour round trip to come home empty handed.

Cast iron pans polish into a decent hammer form...

In reply to TurnerX19 :

They're also extremely good for cooking food