Ian F

MegaDork

10/25/16 6:53 a.m.

Another thought - since the posts are portable, I can't imagine why you couldn't install anchors in more than one place to better suite the particular car getting serviced.

I still plan on a Max Jack for my future shop - mainly for the portability. Being able to get that inside post out of the way when not needed (which would be 95% of the time) is more important to me than being able to walk under the car.

In reply to Ian F:

Yes, that's part of the plan. The layout of the holes means that drilling three extra holes moves a post in about 5 1/2 inches. Two sets of three will move it in 11 for super narrow cars. This may also be the reason I set one tower very close to the outside wall. When not in use I can unbolt the inner tower and store them together against the wall.

Lots of planning.

It's not about the width of the car, it's about the space between the wheels. Longer vehicle means closer columns.

Right, every car makes a rectangle with it's lift points and I have to be able to hit those within the arc/in out of the arms. I need to draw some pictures.

mazdeuce wrote:

Right, every car makes a rectangle with it's lift points and I have to be able to hit those within the arc/in out of the arms. I need to draw some pictures.

If you can send me a sketch of the garage "room" you are putting the lift in, and the dimensions of the lift points for every car you have. I can autocad it for you and get you a good pretty picture that tells you where the posts need to be to hit the most lift points.

(I'll also need the jack arm lengths/reach)

Will do! It might be a couple of days. In-laws are coming into town tonight. Still lots to do. Just have to install drawer slides and I'm ready to build a base to move the first three cabinets into the kitchen. Too many projects going at once.

I went back to post number 1 of this thread a couple days ago and am now on page 41. Best build thread ever!

On May 24th, 2015,

mazdeuce wrote:

Every car I own is under covered parking. Kind of a big deal for me. 27 months ago I had no covered parking at all. Now I could park 9 with a bit of efficiency. 11 if enough of them were compact hatchbacks.

I read this thread every day when it was new, and I shed a tear of joy when you got to this point. Today, 1.5 years later, I arrived at this post while rereading the thread and I shed another tear of joy. I will probably read the whole thing again when I finish it this time.

Thanks for that. It's sometimes hard to see the road behind me when there is more to do every day. As far as a garage goes I'm technically on finish work, but holy cow is there a lot of that to do.

I'm having a lift installed at my place and the installer talked about keeping the posts away from the seams in the concrete.

Maybe having several sets of holes a few inches apart is ok but maybe it isn't. I'd double check with someone who knows (unless that person is you :) )

The good thing is there are no seams in my concrete. I only need to drill the holes for the anchors 4.5 inches deep but I'll drill one as deep as I have a bit for (8 inches I think) and make sure I really have as much concrete as I think I do.

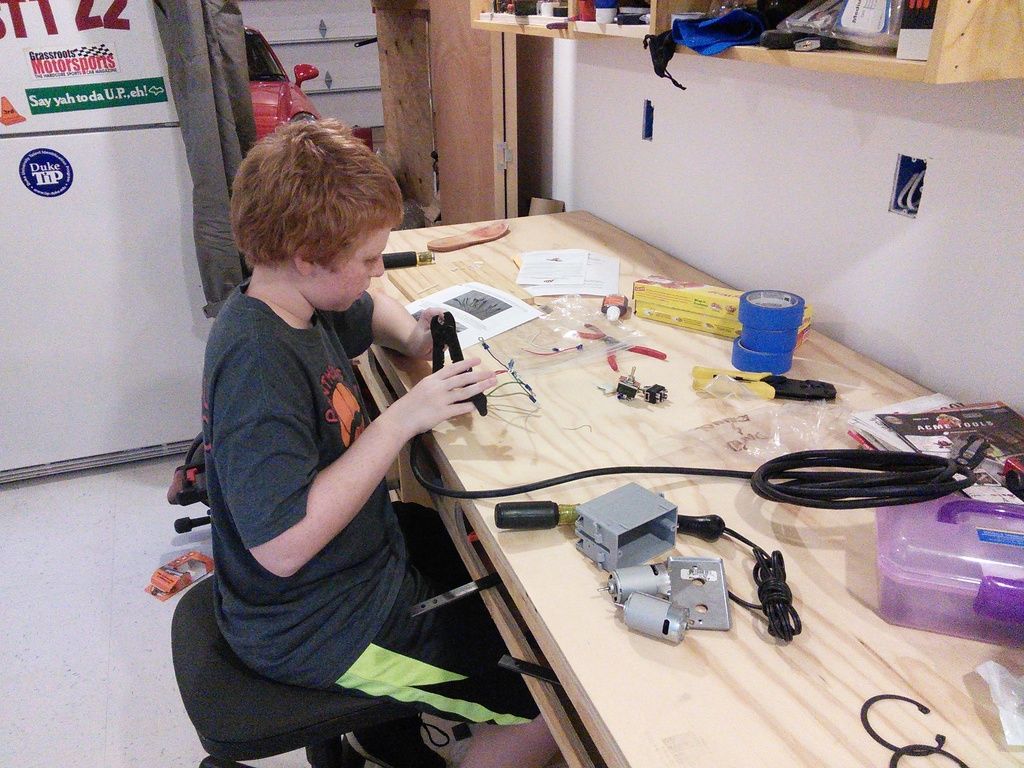

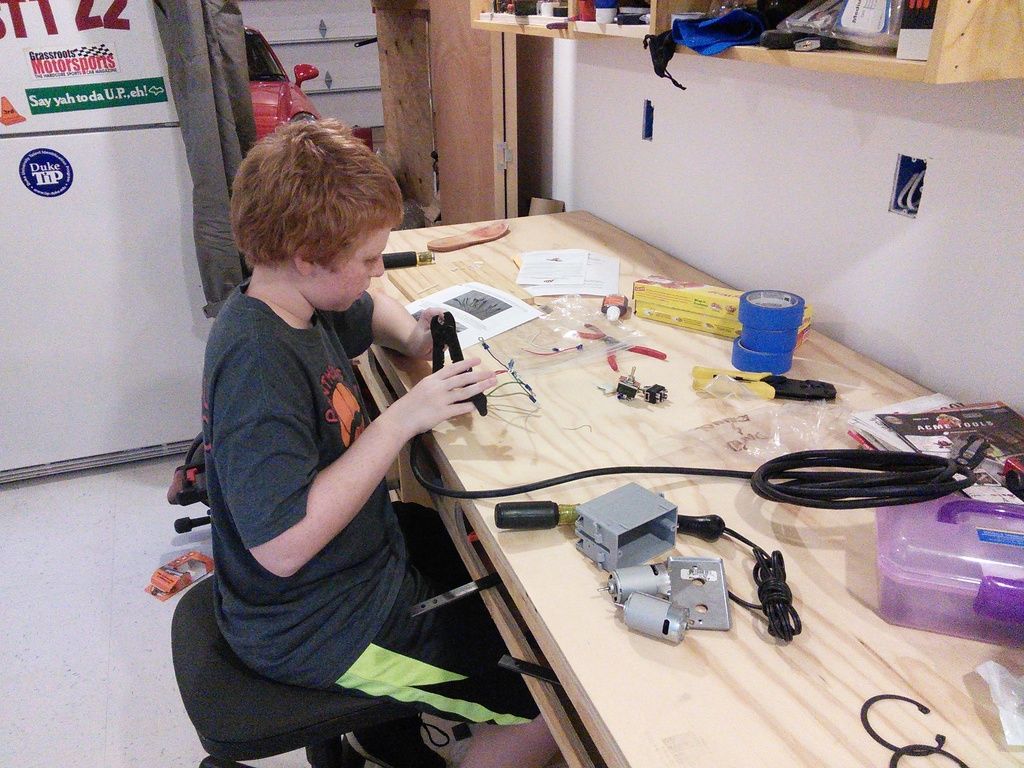

Deucekid#2 brought home the wiring for his robotics project, headed out to the workbench and cranked up some tunes. This whole clean well lit workbench thing is kind of cool.

First three kitchen cabinets are dry fit. They can't go tight against the wall because the outlet for the microwave is behind them. It will get moved up when I do the drywall. Still using the classy left over plywood for the counter top. I'm considering buying an 8 foot counter top from Ikea just to make it kind of nicer for a while. They're not perfect. Still need doors and drawer fronts and the shelves are getting poly right now. Need to build five more boxes and 10 more drawers. I'm happy so far.

mazdeuce wrote:

Still using the classy left over plywood for the counter top. I'm considering buying an 8 foot counter top from Ikea just to make it kind of nicer for a while.

Im not sure if theyre out there by you, but we have Habitat for Humanity Re-stores around here, that sell used or offcuts of re-sellable building products. Ive donated laminate countertops far longer than that in the past. A fine jigsaw blade will produce a clean edge if prep the cut line with some masking tape first. Probably cost you all of $25.

Otherwise, its fun to take a break from the Grosh for a moment, and see some of that kitchen work coming to fruition!

Back in January 2016,

Keith Tanner wrote:

I was lucky enough to spend some quality time with my grandfather before he passed. He wasn't a grease monkey, but he did do a lot of ham radio, lathe work and the like. His house was full of old stuff and I have one of his toolboxes.

What I noticed wasn't that his tools and other possessions were inherently high quality, but that he cared for them. <>

There's a lesson there. Mechanical empathy. I hope I learned it.

Mechanical empathy is what I preach to whoever will listen. I love that term.

In reply to 4cylndrfury:

Habitat is a great idea! We're taking in the dishwasher that hasn't been hooked up for 10 years that we use to hold baking sheets. I'll have a look around. Thanks.

In reply to mazdeuce:

Ikea AS-IS section is pretty awesome for stuff like that.

Ok, so I measured all the cars and got out the graph paper and figured some stuff out.

If I mount the columns 115 inches apart (outside base plate dimension, for some reason this is the reference point MaxJax chooses) this is what I get for the Porsche which has the smallest jack footprint at 50x52 inches. As you can see, the arms are all the way in. This means that I don't have ANY wiggle room in positioning the car.

This is the arm position for the R63 which has a lift footprint of 75x62. The arms are a bit over halfway out.

This is the arm position for the R63 which has a lift footprint of 75x62. The arms are a bit over halfway out.

The footprint of the truck is 68x41 and the narrower width means that the arms need to come out a couple more inches. Not all the way, but getting there.

The footprint of the truck is 68x41 and the narrower width means that the arms need to come out a couple more inches. Not all the way, but getting there.

So I think that's where I'm going to mount them. I still haven't been able to find the extra Woody recommended fittings locally so I'm going to make a run down into Houston proper and see if I can get them and the proper size drill bits and get this thing going.

In reply to mazdeuce:

^McMaster Carr for the fittings.

Max Jack is the semi-permanent one, right? Move it out of the way when you don't need it?

If that's the case, maybe two sets of holes for one of the legs? A narrow car set and a wide car set?

Yes. The 115 inches will be the narrow setting and I'll drill another set wider if I need them.

Sent my dishwasher and the oven that I've been saving to use as a powder coat oven for almost five years to Habitat for Humanity. No countertops at the store.

Also only about half the fittings I needed were in stock at Grainger so I'm finally going to take Woody's advice and order them from McMaster Carr. I may not get in the Grosh at all this weekend and I'm gone three days next week so it won't exactly slow things down.

Also only about half the fittings I needed were in stock at Grainger so I'm finally going to take Woody's advice and order them from McMaster Carr. I may not get in the Grosh at all this weekend and I'm gone three days next week so it won't exactly slow things down.

Marked out the holes and started to drill initial 1/4 inch holes.

One was wandering just a bit so I decided to pull out the anchor bolts to see how much play I had to work with. Except there aren't any anchors. Crap. Emailed the guy I bought it from and he got back to me quickly to let me know the anchors were shipped separately because they were out of stock when the lift shipped. Ok, would have been nice ro know. Where did they ship to? Probably the same address as the lift which means that I get to drive 40 minutes one way to go get them. Awesome.

One was wandering just a bit so I decided to pull out the anchor bolts to see how much play I had to work with. Except there aren't any anchors. Crap. Emailed the guy I bought it from and he got back to me quickly to let me know the anchors were shipped separately because they were out of stock when the lift shipped. Ok, would have been nice ro know. Where did they ship to? Probably the same address as the lift which means that I get to drive 40 minutes one way to go get them. Awesome.

Also there is an issue with the locks for the arms. They don't actually contact the arms.

The instruction book shows a hole in the base plate where the rod should go. That would make them closer, but it still wouldn't fix it. Danmar is supposed to call me tomorrow.

The instruction book shows a hole in the base plate where the rod should go. That would make them closer, but it still wouldn't fix it. Danmar is supposed to call me tomorrow.

Lame quality control and customer service

The quality control does leave something to be desired. I got a call from the Danmar guy, he was nice, said sometimes the rods are too long so just cut them off to the right length. Ok. That'll work I suppose.

He was nice enough to swap the shipping address of the anchors to my house instead of the business I had the lift shipped to. That'll save me some time when they finally get here next week. If I wasn't so busy that I can't get it installed anyway I'd be pissed.

Looks like you're going to need those 90 degree fittings!

This is the arm position for the R63 which has a lift footprint of 75x62. The arms are a bit over halfway out.

This is the arm position for the R63 which has a lift footprint of 75x62. The arms are a bit over halfway out. The footprint of the truck is 68x41 and the narrower width means that the arms need to come out a couple more inches. Not all the way, but getting there.

The footprint of the truck is 68x41 and the narrower width means that the arms need to come out a couple more inches. Not all the way, but getting there.

Also only about half the fittings I needed were in stock at Grainger so I'm finally going to take Woody's advice and order them from McMaster Carr. I may not get in the Grosh at all this weekend and I'm gone three days next week so it won't exactly slow things down.

Also only about half the fittings I needed were in stock at Grainger so I'm finally going to take Woody's advice and order them from McMaster Carr. I may not get in the Grosh at all this weekend and I'm gone three days next week so it won't exactly slow things down. One was wandering just a bit so I decided to pull out the anchor bolts to see how much play I had to work with. Except there aren't any anchors. Crap. Emailed the guy I bought it from and he got back to me quickly to let me know the anchors were shipped separately because they were out of stock when the lift shipped. Ok, would have been nice ro know. Where did they ship to? Probably the same address as the lift which means that I get to drive 40 minutes one way to go get them. Awesome.

One was wandering just a bit so I decided to pull out the anchor bolts to see how much play I had to work with. Except there aren't any anchors. Crap. Emailed the guy I bought it from and he got back to me quickly to let me know the anchors were shipped separately because they were out of stock when the lift shipped. Ok, would have been nice ro know. Where did they ship to? Probably the same address as the lift which means that I get to drive 40 minutes one way to go get them. Awesome. The instruction book shows a hole in the base plate where the rod should go. That would make them closer, but it still wouldn't fix it. Danmar is supposed to call me tomorrow.

The instruction book shows a hole in the base plate where the rod should go. That would make them closer, but it still wouldn't fix it. Danmar is supposed to call me tomorrow.

Half of the anchors were set and one post is test fit. Awesome.

Half of the anchors were set and one post is test fit. Awesome. Slight delay today because the anchors that they promised were going to be sent to my house instead of the business I had the lift sent to.....were sent to the business. So that added almost an hour and a half of driving to the day. Grrrrrrrrr.......

Slight delay today because the anchors that they promised were going to be sent to my house instead of the business I had the lift sent to.....were sent to the business. So that added almost an hour and a half of driving to the day. Grrrrrrrrr.......