Couple people have asked for some misc. Fabrication stuff. So I'll post what I can. Not everything I can post (Ridler builds and the like, due to their regulations) but... I'll throw some stuff up here and answer questions if people have them.

Long (ok, short) of it is I work at a pretty well known custom shop, Rad Rides. Been there going on damn near a decade now. I do a ton of chassis work, exhaust work, some sheet metal fabrication, a lot of logistical packaging as far as under dash, accessory packaging, retrofitting new tech into old vehicles, do our 3d printing, do some paint and body when needed, final assembly, help with tuning and electrical & troubleshooting and on and on.... and overall, whatever the hell is needed, when its needed kinda E36 M3. Been doing cars and bikes my whole life. Almost 39. So you can do the math on that. Had the privilege to work on some well known projects and race cars. Been a part of the world's fastest piston powered streamliner, our own streamliner shooting to go 400, off an NA small block, fastest flathead powered street roadster, and on and on and on, not to mention a bunch of standing mile & drag week with the twin turbo belvedere (208mph and in the 9's at 148/149mph, in street trim) and such.

So...anyway. enough chatter. Have some pictures.

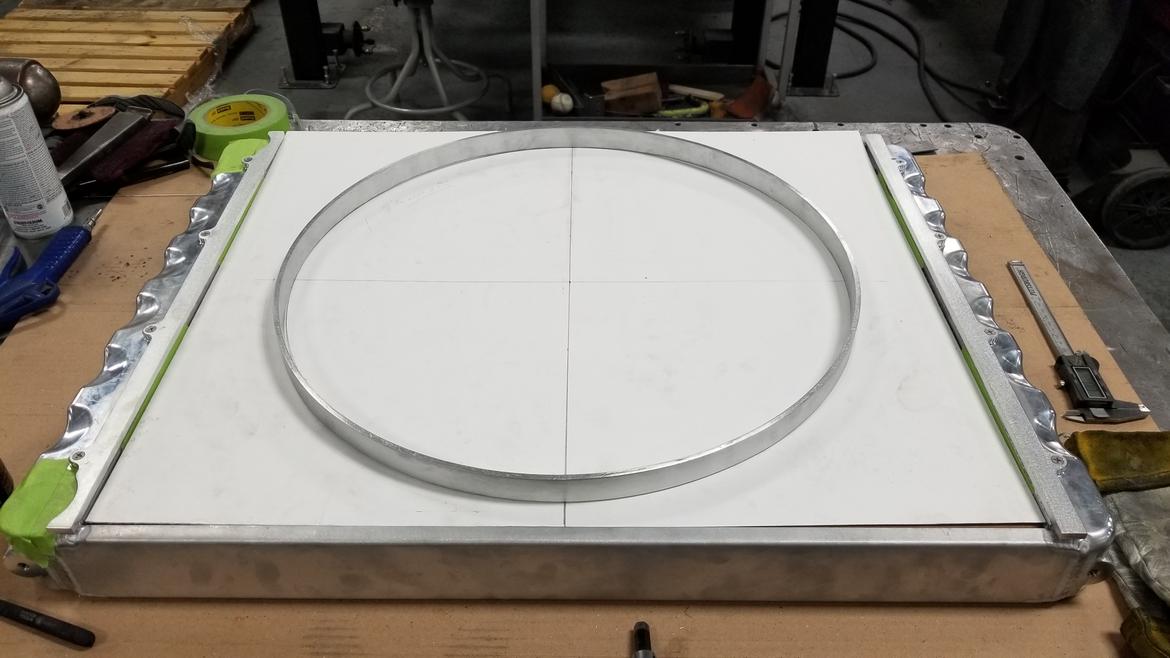

Shroud I did for the stroker gen v direct injected lt1 / 10 speed in the 41. I'll throw some frame pictures up next.