Radiator Part 3

Fan Frustrations, Metal Fab, Expansion Tank Madness

Fan Frustrations:

I did a fair amount of sitting and staring at the fan to figure out how to mount the thing. The 16 inch Spal fan has four mounting holes on the rim so you can bolt through to supports in front of it.

However, the bolt heads would be perilously close to the fragile radiator fins. Things vibrate, things twist, things shift. The radiator itself is on rubber mounts and can move a millimeter or three on its own. The further away the fan shroud is from the surface of the radiator the more air will short circuit and not flow through. I bought some foam gasket material from the hardware store… Nope, not going to stick to the rather narrow edge on the fan shroud.

I was thinking about trying to return the fan and was searching Summit for alternatives. By sheer chance I discovered Spal Fans has special gaskets for the things. They also have mounting clips of various lengths. There is no hint of either part as a “Required Part” or “Recommended Part” on the fan page (or any Spal fan page). Unless you are really “into” aftermarket automotive fans you would never know these parts exist.

Even worse, the mounting clips come in various lengths. But no dimensions are given (even on the Spal webpage). So, you have no idea which ones you want even IF you know they exist.

This is basically negative marketing. I bought the gasket and had to pay shipping which would have been avoided if it had been purchased with the fan. Very frustrating. I expect better from Summit.

By the way, the gasket works perfectly. If you buy one of these fans – You want the gasket. It can be touching the radiator core and should not damage it.

I ended up just using some pan head bolts rather than what is shown above. The pan heads sunk down in the zig-zaggy gasket a little giving better clearance.

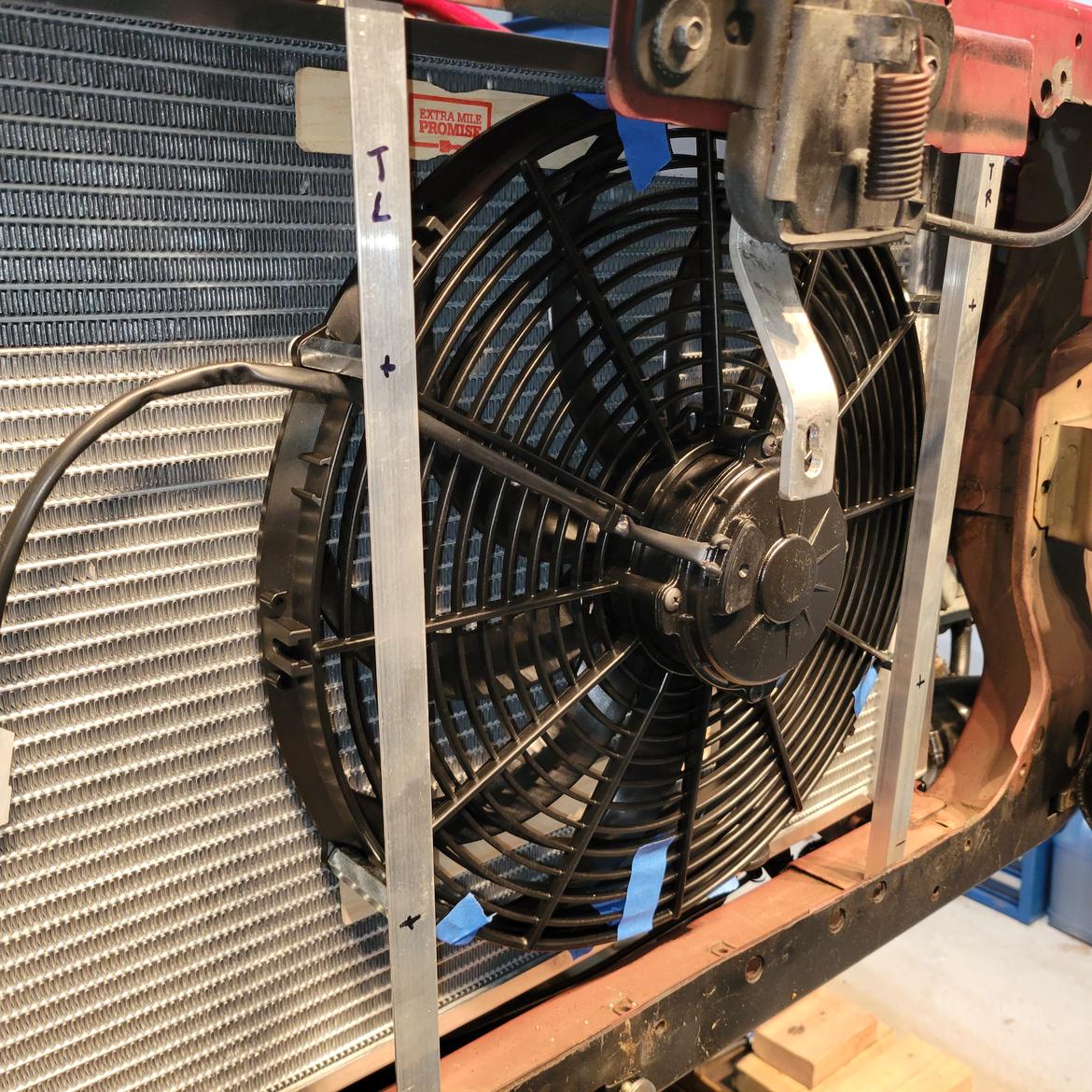

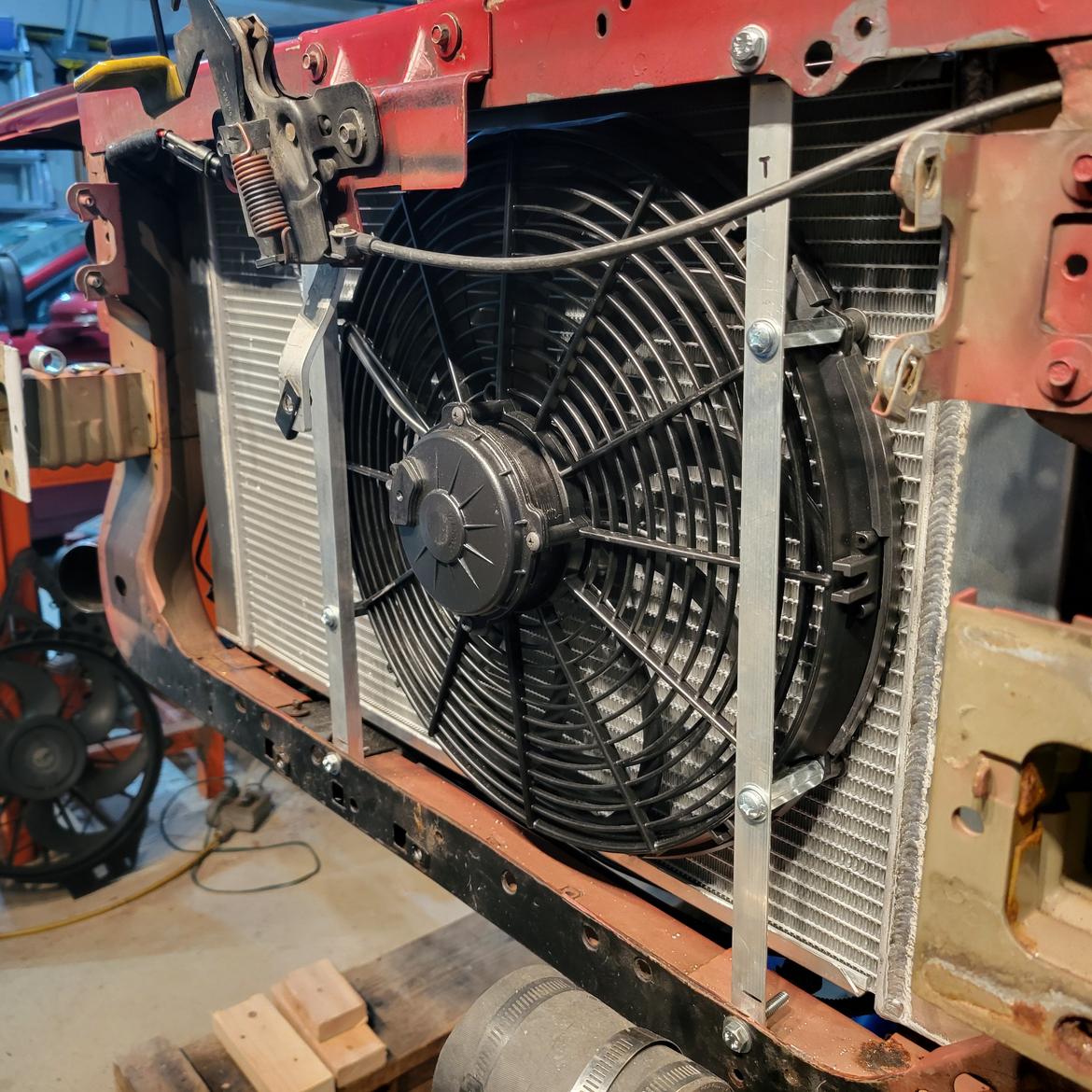

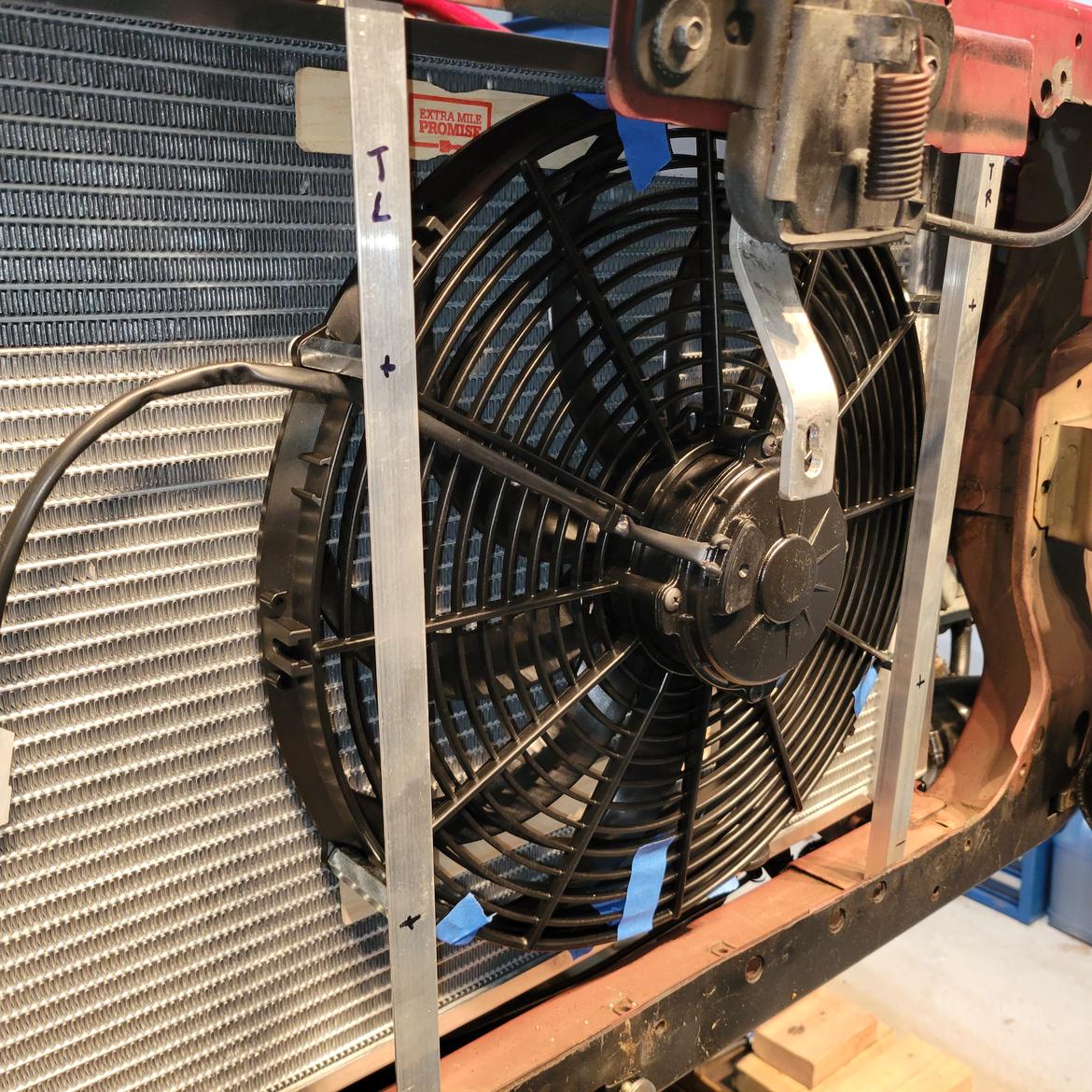

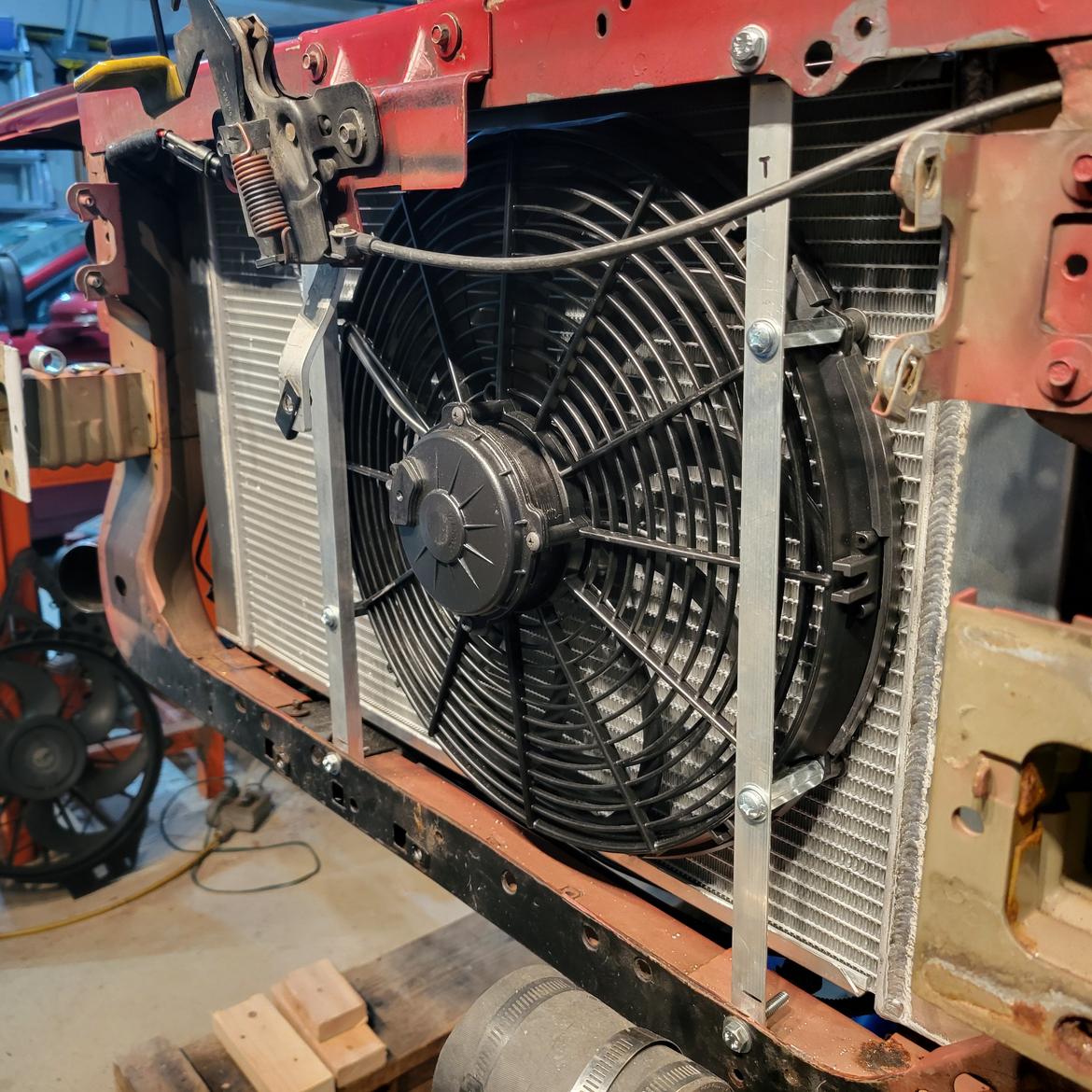

Using two aluminum angle pieces I did some test fits and figured out how to mount the fan. Note the photo below does not have the fan gasket installed.

I drilled mounting holes in the frame being careful not to drill through the radiator (that would be a bad day).

That brings back a memory from about 1972ish – Patching radiators… I remember soldering a thin piece of copper patch on the top tank of my 1968 Mustang. Blow torch, steel wool, solder, flux in a little tin, and a little piece of copper strip about the size of a penny. We were on a ski trip up north. It was snowing. It took a couple of attempts to patch the radiator. But we got home from the trip. Yeah, we used to do stuff like that. Did not think twice about it. I think I went back later and brazed it to make it permanent. I think when I brazed it I got it too hot, melted a bigger hole, and had to start all over. One thing I absolutely remember though: We did not buy a new radiator. We fixed it. We fixed everything (eventually).

Here is the completed fan assembly. The fan is mounted on 2” long spacer couplings (hardware store) with the gasket barely touching the radiator. The spacers are mounted to the angles. Everything has some blue thread locker on it. There are some little nylon spacers where the angles mount to the frame. All the fasteners are ¼-20.

I noted in the last post the car was not wired for the two speed OEM fan even though the fan was two speed (as well as the programming).

For grins here is the OEM fan and plug:

And the OEM harness (note the missing connector in the center):

I still think it is comical that the car came with programming for a feature it did not have. And that I have had it for 22 years and never noted that the fan never went to high speed even on the hottest days.

I cut the plug that came on the Spal fan off and used one from Amazon. Apparently Spal and Summit carry matching plugs but I could not find them and did not want to pay shipping again anyway. Negative marketing. No sale.

Metal Fabrication

The OEM radiator was fairly well “boxed in” both with factory parts and some additional parts I made some time ago. Boxing in forces air coming in the front of the car through the radiator rather than spilling out around everywhere under the front cover. I used some flexible plastic storage dividers and gorilla tape to do this work. Gorilla tape is great stuff and you can fold it on itself to make flexible gaskets and seals for this purpose.

The OEM set up used a large electrical harness to keep air from running between the top of the radiator and the frame. It worked well and is an efficient design. It would work again for the new radiator but for two things:

Thing 1 – I needed something to mount the expansion tank on.

Thing 2 – I wanted to direct some cold air onto the engine air intake. The filter is right behind the top of the radiator. It galls me a bit that I lost my cold air intake with the supercharger kit.

So, after some sitting and staring and messing around with cardboard I came up with a plan ( I would know later if it was a good plan or not).

The Plan:

- Move the harness down in front of the radiator (above the fan). This will allow air to pass through over the radiator (about one inch clearance).

- Fabricate a sheet metal cover over that one inch gap with a hole in it to allow a limited amount of cold air to blow on the air intake filter and provide a basis to mount the tank. I might later make a shroud for the filter to better contain the cold air.

My Neandertal metal working skills would be put to the test!

I started with making a template with some card stock. After a few false starts I was able to come up with a simple “bendiment” about 6 inches wide and 30 inches long.

I bought a piece of aluminum and while it was shipping made a crude brake on my workbench out of some angle iron. One angle was screwed to the bench top and the other screwed on top of that with the aluminum clamped in between. It is an old bench – Just drive screws into it.

The brake was a bit too crude. I had to score a groove on the underside of the bend to get a sharp edge. Most of the trimming was with a vibrating multi-tool. It was not perfect but serviceable.

The hole to direct some cold air into the intake was made with a hole saw and multi-tool.

To dress up this pig: Burnishing little spin circles in a pattern with the drill press. Little sander disks are from Harbor Freight. Easy to do and covers up a multitude of sins.

And the lipstick on the pig is to put 1/8” rubber edging (Bushwacker Fender Gimps 000040-01 from Summit) around all the cuts that are exposed (the multi-tool is not a precision instrument). You can see it around the cold air intake hole here:

Expansion Tank

The OEM radiator on the V6 model has the pressure cap mounted directly to it. This radiator is from a GT and does not have a cap so it needs an expansion tank and place to mount the cap. I wanted the expansion tank as high as possible. The OEM radiator cap was about 3 inches below the high point in the engine. This made filling and venting somewhat tedious. Raising the tank would help with this. But how high without getting into the hood?

With the car on the lift, I used a broom handle poking up through from the floor. I lowered the lift slowly until the handle was about to hit the closed (but unlatched) hood.

With the hood opened I marked the handle so I would know what height to set the tank.

With the tank height known I set about with new cardboard templates and made a support plate. The top of it is mounted on some 1 inch spacers from the radiator cover made above. The bottom is supported directly from the (now unused) OEM fan mount that came welded to the new radiator. I had to cut this down and then drill and re-tap it. A little trepidation clamping the new radiator to a vice and taking a hacksaw to it.

In for a penny?

And this would work well and look good. Hopefully I would not need to remember how to patch a radiator.

This fabrication was much smaller and easier.

The plate has a bend along the diagonal edge to add rigidity. This time I just used my wood vice and a ball pean hammer.

It is serviceable, does not block air flow, holds the tank properly and you really can’t see it anyway. In fact, once installed it almost disappears. I can’t even get a good photo of it.

Reassembling the front of the car required a few more "cut to fits" and "bumps to suit" to get everything to match up. The fiberglass assembly that mounts the headlights had to be trimmed in several places.

Nothing a little flat black paint won’t hide.

More Tank Madness

If your engine holds 2 gallons of water then the water expands about to about 2.2 gallons when heating from 60 degF to 204 degF. That is almost one quart. That is about 800 ml.

When shopping for aftermarket expansion tanks your choices appear to be limited to 800 ml, 1 liter, or 1.2 quarts (1.1 liter). After the first warm up I found the little tank would empty itself out the radiator cap to the floor. Fluid expansion on my engine is about 1.2 quarts. I must run with a non-pressurized overflow tank that siphons fluid back into the pressure tank through the cap on cool down. That means ALL of those overflow tanks on the market are too small unless you have a little four banger. All of them…

I ended up reusing the overflow tank that Procharger provided with the super charger kit. I think it is not quite 2 quarts. Works fine. I think it is actually meant to be a vacuum tank. It is mounted between the fan and the bumper next to the intercooler.

Summary observations:

- This was harder than expected. If I had bought only a two-pass radiator instead of a four I would still have had to move the fan. If I had bought a three-pass I would not have had to trim the air intake to the supercharger.

- If I had bought a thin profile fan I probably would not have had to relocate everything in front of it. But those fans don’t move as much air so I might have needed two of them which would cost more. Would have been much easier though.

- Even with the trials and tribulations above beveling the bottom of the bumper is providing much better air flow to the intercooler with little loss in strength.

- The steel used in a modern bumper is incredible stuff.

- The steel used in a Steeda Towel Bar Bumper is ordinary stuff. I look at it this way: I had my grandkids riding in this car at 90 MPH up the hill through the chicanes at Grattan Raceway last year. I want a #$%$ real bumper on the car please! One of them is now old enough to drive it at an event. Real bumper please!

- My metal working skills are still laughable and hidden behind swirls and rubber gasketing.

- Spal fans and Summit do a poor job at providing related part information for these fans. It creates frustration for customers and reduces their sales.

- Mistress should stay pretty cool this summer and I can concentrate on driving between runs instead of how hot the engine is. This should make us slightly faster. A little. Perhaps.