¯\_(ツ)_/¯ said:

It sounds like it's running great in the video!

Thanks! It definitely sounds way better outside the car. Inside all you really hear is the resonance of every body panel.

Oh, and I think we might have found some bondo, as the magnetic number wouldn't stay stuck to the 1/4 panel right behind the driver's door.

In reply to engiekev :

That's a cool trick! I don't think mine has that lip, but I can use a hose clamp or something.

Huh, yesterday's results were posted, even with a cone I somehow managed to beat Aeromoto, and despite being on 3-year old street tires if I'd had a clean run it would have been fast enough for 2nd in XP. I'm pleasantly surprised by that.

1SlowVW

HalfDork

6/22/20 11:02 a.m.

engiekev said:

Awesome progress! Glad to hear its off to good start for first test.

For the dipstick tube, a popular mod is to add a spring if the tube is blowing out a little due to high crankcase pressure.

Helps keep the pressure in so you can press your crank seal out instead.

1SlowVW said:

engiekev said:

Awesome progress! Glad to hear its off to good start for first test.

For the dipstick tube, a popular mod is to add a spring if the tube is blowing out a little due to high crankcase pressure.

Helps keep the pressure in so you can press your crank seal out instead.

4G63 have a very robust front and rear main seal, and the crankcase venting is fairly adequate. If the dipstick is held shut, excess pressure would likely pass from the block up into the cylinder head through the oil drain ports and then through the baffled valve cover. The next restriction there is the valve cover breather port, many open that up to a large size and add AN fittings to a catch can to improve flow. Only extremely high HP (600+) 4G63 need crankcase venting through the block, and add that point a dry sump becomes more desirable to address crankcase pressure issues.

Popping dipsticks is a fairly common problem on DSMs. That picture is an Evo, but they encounter similar problems.

You could also a try a thicker o-ring, the o-ring on there is probably well worn out and not doing much at this point!

In reply to engiekev :

That's good to know, I've never had a 4g63. But I used to hear of vw turbo diesel guys that would pump the boost to them and have issues with pushing seals out.

1SlowVW said:

In reply to engiekev :

That's good to know, I've never had a 4g63. But I used to hear of vw turbo diesel guys that would pump the boost to them and have issues with pushing seals out.

Wow, that is not a good problem to have!

Could the need for left foot braking be reduced with some suspension tweaks? You're swapping the rear springs anyway, maybe go a little stiffer? Wider front tires? Rear toe out?

In reply to ¯\_(ツ)_/¯ :

It definitely needs more roll-stiffness, especially in the rear. The only factory adjustment in the rear looks like it affects camber more than toe. If I have room in the budget, and more importantly time, to install the rear toe-eliminator setup then I'll be able to dial it in. At this point I'm thinking if I have the budget & can find a set of used swaybars, that may be the best option though.

If this is what the rear wheel bearing looks like, can you shim it for some rear toe out (maybe more camber too)?

In reply to Robbie (Forum Supporter) :

I didn't even look when I installed the shocks lol.

In reply to Robbie (Forum Supporter) :

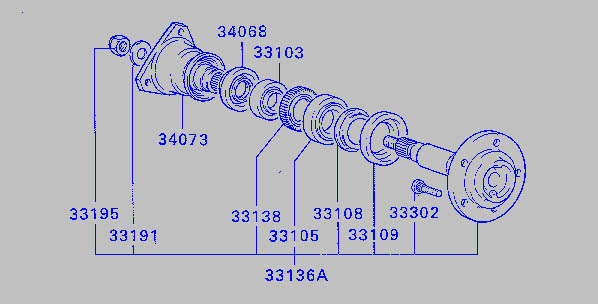

1G Rear wheel bearing is not a bolt-in unit, pressed onto the shaft and the hub passes through to an axle cup that goes over the threaded part shown.

Unfortunately the only way to adjust rear toe any significant amount is with the rear toe eliminator kit, shown below the threaded heim joint. From the factory it is a rubber bushing that flexes during compression and reduces toe-in. The factory attachment point does use eccentric bolts for rear toe, but again with the "active" toe stock joint it will toe-in during compression, and there is not much room for adjustment. You can see the eccentric bolt above where the heim joint attaches to the subframe.

Best bet for the most simple rear stiffening (that sounded odd) would be a used thick sway bar for sure. 1G DSMs suffer a lot of the same ill handling characteristics of other front engine mcstrut AWD cars like Subarus, and anything to stiffen the rear up helps in reducing understeer. 2G DSMs improved a lot with double wishbone suspension but still were tuned to push quite a bit from the factory.

Much of it is driving technique. You aren’t going to tuck the nose in under power. You need to already have the car rotating and have enough power available to keep it there. Trail brake or lift throttle to get the tail loose, give it power to keep it there. What kind of shape is the rear limited slip in? It contributes a lot more than you would expect to the handling under power. A bigger rear bar will amplify this, it will make it transition quicker and to a greater degree. It sounds like you have plenty of negative camber in the front. Were you able to remove enough from the back?I was never big on left foot braking, I had a hard time being consistent. But other successful DSM autocrossers back in the day swore by it. It may be a bit more necessary with a big turbo.

In reply to Boost_Crazy :

I've not measured rear camber yet. When I got the car it probably had about -4* in the rear with the E36 M3ty lowering springs. The coilovers don't go as low though, so there's way less camber at the rear than the front right now. Just guessing I'd say probably between -0.5* to -1* right now.

Being a vlsd I'm not sure this is conclusive, but I rotated one rear wheel while the car was in the air, in neutral, and no other wheels turned. That said, I didn't have any wheel spin at the autox.

I worked late tonight & didn't get out to the garage until after 8, so I decided to work on the shifter instead of checking/setting the timing.

The builder of the car told me he'd had some custom work done to the shifter. I thought he said his uncle had turned some custom brass bushings for it, but it still has plastic ones(that probably need replaced). It actually looks like someone did some cutting & welding of the entire shifter, but without any idea of what the OE unit looks like it's hard for me to tell. However, I'm pretty sure it didn't come like this from the factory...

Yes, that's some MIG wire stuck to the top of that bracket.

I greased, shimmed & tightened everything as much as I could, but would still allow movement. It seems a fair amount less sloppy, but there's excessive clearance in almost every pivot point, and a lot of the friction is either internal to the cables, or to the transmission its self.

My 2nd gen Eclipse GST had horrible shifter slop. Honestly just about anything you do is bound to be an improvement if the 1g is anywhere near as bad.

In reply to trumant (Forum Supporter) :

It seriously reminded me of an old 78 GM box truck I used to drive with the granny-gear 4-speed.

Pete Gossett (Forum Supporter) said:

In reply to trumant (Forum Supporter) :

It seriously reminded me of an old 78 GM box truck I used to drive with the granny-gear 4-speed.

You could try replacing the factory plastic bushings, but some shifters are so worn out it might not help much, that's why a lot get "custom" brass bushings made for the dimensions of their shifter. I had good luck on my 1G with the plastic bushings, but another VR4 was still pretty sloppy afterwards.

They're pretty cheap, but may not be worth it in your case for challenge budget.

https://extremepsi.com/store/OEM-Shifter-Bushing-Gearshift-Link-Mitsubishi-Eclipse-1991-1994-Only-Requires-6.html

Pop cables off transmission to see if there's still friction, if so hang them vertically and hose E36 M3 into them from the top until they work smooth?

In reply to Patrick (Forum Supporter) :

That might happen. I sprayed plenty of Freeze Off down them from the interior last night, but the trans side has crimped on boots.

In reply to engiekev :

I'll definitely be doing that sooner or later. I also don't like the rubber bushings holding the shifter mechanism to the tunnel. There's way too much flex in the whole assembly.

I didn't have much free time this weekend, but I did change the oil last night. There were no chunks or metal flakes in the oil, and just a bit of ferrous material on the drain plug. There was a pretty big chunk of something on the oil filter lip, but I think it was remnants of an old paper gasket that had been soaked in oil for a very long time. Who knows where that came from.

Unfortunately switching to 40-weight didn't help my idle oil pressure, I'm still at 9-10psi. I was told the balance shafts were "removed correctly", but I'm wondering if that may be related.

I found a boost-tester fitting in the box of parts, so I hooked it up & checked it out. There's a pretty significant leak at the back side of the throttle body, but I'll have to do more investigation in better lighting to track it down.

Pete Gossett (Forum Supporter) said:

In reply to engiekev :

I'll definitely be doing that sooner or later. I also don't like the rubber bushings holding the shifter mechanism to the tunnel. There's way too much flex in the whole assembly.

Very common those are flexy, one of the original cheap mods is to replace the bushings with metal bushings. The true GRM solution would be to use stacked washers, it works!

http://vfaq.com/index-main.html

https://machv.com/products/mach-v-quick-shifter-kit?_pos=31&_sid=f5ef78414&_ss=r

Another "flexy bit" is the bushing where the shifter cables attach the trans shift arms, those can be replaced with brass bushings or even roller blade wheel bearings tack welded together (also GRM worthy).

https://machv.com/products/precision-bearing-shifter-cable-bushing-kit

Once those two are replaced, all the linkages between the shifter and transmission are solid.

Pete Gossett (Forum Supporter) said:

I didn't have much free time this weekend, but I did change the oil last night. There were no chunks or metal flakes in the oil, and just a bit of ferrous material on the drain plug. There was a pretty big chunk of something on the oil filter lip, but I think it was remnants of an old paper gasket that had been soaked in oil for a very long time. Who knows where that came from.

Unfortunately switching to 40-weight didn't help my idle oil pressure, I'm still at 9-10psi. I was told the balance shafts were "removed correctly", but I'm wondering if that may be related.

I found a boost-tester fitting in the box of parts, so I hooked it up & checked it out. There's a pretty significant leak at the back side of the throttle body, but I'll have to do more investigation in better lighting to track it down.

That's definitely too low, 10psi/1000rpm absolute minimum.

If the balance shafts were removed correctly, the front balance shaft bearings need to be clocked to cover the oil hole or solid bearings need to be installed:

https://www.youtube.com/watch?v=LR-1adDayQY

Unfortunately, it will be hard to check without pulling the timing belt and oil pump and then inspecting the bearings. Other potential areas for pressure loss:

- Oil pump pickup seal to pump

- Failing oil pump - usually you would hear this as the DSM oil pump starts to eat itself and wear into the front case

- Oil squirter loose or fallen off - these are one of the first passages after the oil pump, so a leak here will drop a lot of pressure. Have to pull pan to inspect, but possible to address without removing engine.

In reply to engiekev :

I'm thinking I'll just raise the idle :)