How to change a Sector shaft seal in a 1987 Toyota 4x4. By Hungary Bill

1) find out your seal is leaking. See that little drip there? don't be fooled. this thing pisses fluid like a beer-filled college student.

2) Borrow a Pitman arm puller from your local Oreilleys.

3) Remove nut and lock-washer and attach Pitman arm puller on your Pitman arm. Tighten the puller until that puppy is TIGHT! Keep tightening that beast until you're sure that by now you've put waaaaaay too much pressure on it and it's going to break. Now start whacking the side of the Pitman arm with whatever you have handy.

4) try prying a bit between the arm and the shaft housing with the flat side of wrenches, crow bars, etc. You should probably tighten that Pitman arm puller a little more just to be safe. Do so by bracing your foot against the passenger tire, and PUSH while PULLING with both rag-wrapped hands. Be sure to wince and look in a safe direction to give yourself that false sense of security that you'll save your pretty face if this thing decides to pop off right now.

5) whack that Pitman arm bit more, but this time do it for release of anger. Not so much with the idea that it's going to help anything.

6) go inside the truck and turn the key to release the column lock on the steering wheel. Turn the wheel side to side slightly and listen for the "POW" that sounds a lot like a gunshot! Leave any notion that you're going to get your deposit back from Oreilley's here.

7) find a couple screws (I found one holding the corner light bulb holder in its housing)

8) Screw in screws until you feel them bite the seal, then start pulling on them with anything handy (vice grips, channel locks, robo-grips, tweezers). Don't worry if it's not working. Your sole goal here is to slip off the screw and smash your elbow on the ground.

gooooooood

9) get a very small, and very long, flat-head screw driver and start prying at that seal until it comes out. This should take no less than 4 hours. Get creative using the screwdriver as a removal tool by twisting it in such a fashion that there is MUCH friction between it and the seal, but not so much that there is any friction between the seal and the housing. Pull 1mm, go 180-deg off and do the same. Repeat 100 times. Be sure to accidentally push the seal back in on accident a few times with the screwdriver.

10) insert new seal using a combination of sockets, closed ended combination wrenches (30mm), allen key heads, that same screwdriver, hammer, etc.

11) check if leak persists by starting the engine and turning the wheel side to side a few times.

12) when you are sure it is "dry as a bone" be sure to tell all your friends.

Celebrate

13) Check under the truck the next day to see that a small leak still exists.

Job complete. Well done

Meh, good enough for government work. I'll probably get a small piece of tubing to set that seal in there a bit better though. I think some PVC pipe I have laying around should to it.

Good times!

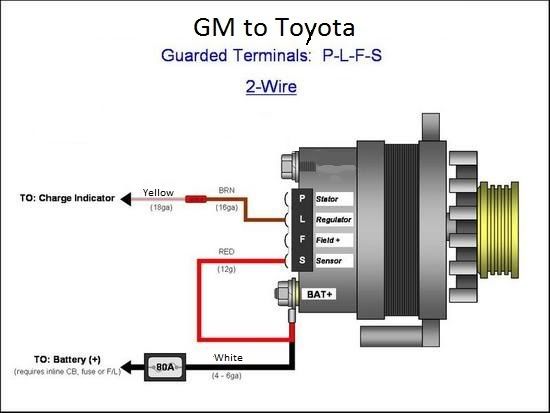

In which case the field wire appears to be an actual field wire for "smart charging" functions, or perhaps just diagnostics, and should apparently be left disconnected if it is to be used as a dumb alternator.

In which case the field wire appears to be an actual field wire for "smart charging" functions, or perhaps just diagnostics, and should apparently be left disconnected if it is to be used as a dumb alternator.