I call that one "The Grassroots"

Day 14, 15, and 16 (Today)

So we start the weekend with day 14 (Saturday). The kid went down for a nap and I fell asleep too. Except I woke up after an hour, and the kid usually sleeps for three so I high-tail it out to the garage. My mission? Tires, fluids, and choke wiring.

The tires took me an hour. The front two rims were still wagon wheels that had been painted. I didn't like them so I thought I'd trade them for that "Toyota" set that came with the truck when I got it back. Not only does the air compressor I have move at glacial speed, but the passenger front tire has dirt in the bead and wont hold air. So a slap a wagon wheel back on in its place. I figure I'll run by a used tire shop or the auto hobby shop later and clean that out.

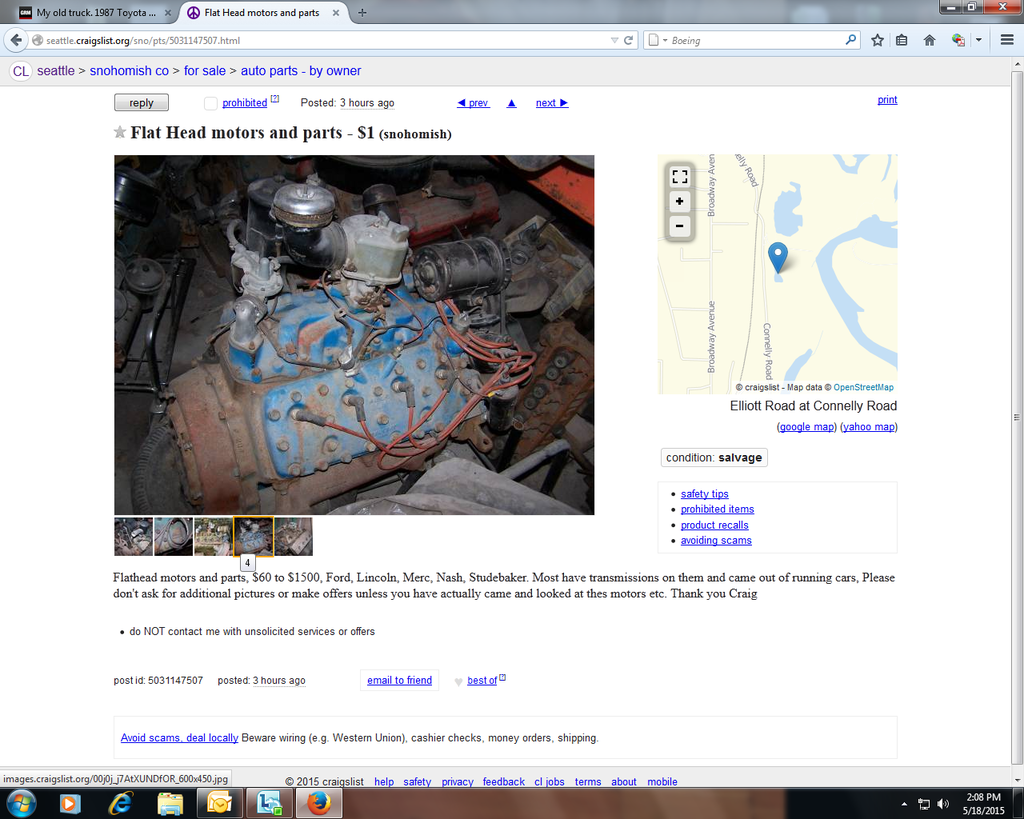

On to the choke wiring: I hook the wire up and touch it to the battery. I understand this choke is supposed to operate by slowly heating an element to open the choke. I let it sit for a while and nothing ever happens.

I'm not sure if you remember (its a few posts back) but I mentioned I could spin the tab that is the electrical connector 360deg. This tells me it's probably not going to do anything but I spin it anyways. Internal arcing ensues. I figure sparks inside the gas-filled carburetor are a bad thing so I remove the wire. Shucks.

I wrap it up here, and go back inside before the kid wakes up. You would think I'd learn by now that bad days in the garage are proportionate to how deep you delve into the engine, but I'm pretty thick. Later on we have company over and they ask about the Toyota. "It runs!" I tell them, and to prove it I start it (with the exhaust installed).

Thats when I hear the noise. It sounds like a clack, but not a very strong one. Definitely RPM related, definitely #4 cylinder, but is it a clack? Is it just a loud rocker?

I shut it down and leave it for the day, and make the post about the knock after drowning the issue in a PBR.

Day 15:

I start the truck for the wife. The clack is still there, but she doesn't hear it. I'm starting to second guess myself now as the "clack" is more like a loud TAP. Still #4, still RPM related (of course). But it's definitely softer.

what to do?

well, I guess first things first a compression check on #4

120psi.

A leakdown check shows more case venting than the good cylinders.

That does it for me:

The head inspection shows that the valves on cylinders #1 and #2 are a little too tight, but #3 and #4 are ok. I adjust accordingly.

Cam is within time...

The engine was hard to turn when #1 and #4 were reaching TDC so I was wondering if the new piston was hitting the head? Now when I turn it, it's like butter.

Nothing on the spark plugs...

Hmmmmmmmmm

The piston shows no signs of contact with anything. Nothing shows any signs of contact with the piston...

The cylinder wall looks good, but there is a TINY portion of a ridge that the ridge remover left behind. Not sure how I missed it, but it covers less than 1/4 of the cylinder wall, transitions smooth (no sharp edges) and is pretty mild. I get a ridge remover and hone from Oreilley's again and drop the pan and pull the piston.

Courtesy ream of the cylinder follows.

Ring gap's good, bearing clearance is good, can't get any movement between rod and wrist pin... I'm kind of at a loss here.

So!

Day 16

Lots of cleaning and re-installation follows. Not much to tell (it's a road pretty well traveled by now). But total time of tear down to turn key? 6-hours

I thought I heard the rattle, but I think it was just the exhaust flanges bouncing around.

Again, I'm well into the time I should be in the shower, but around the block I go! Hood-less and open header! She seems a bit weak at first, but seems to pull strong by the time I get back.

Proof of travels?

(sorry for the blurry shot. Greasy fingerprint on the cell phone camera)

and just for good measure:

Tomorrow I'll hook up the exhaust and remove that choke. It's warm enough here to run without it for a while I guess. I'll probably put that on order while I buy a few other doo-dads to get this thing 100% legal.

But pending tomorrow's start"