Thanks, I'm curious about the dip in the beginning. I think it when a little rich when the Dyno loaded up around 3000 RPMs but over all there is more power everywhere.

Thanks, I'm curious about the dip in the beginning. I think it when a little rich when the Dyno loaded up around 3000 RPMs but over all there is more power everywhere.

Last race went pretty well for the most part. When we arrived we unloaded and when through inspection without and problems. We replaced the brake pads since they arrived right before we were supposed to leave then sat around for the most part. It was kind of weird, nothing was broken or needed to be cobbled together for the next day.

There was also a lower number of cars then we are use. Instead of the 120+ there were only 60 cars signed up. We got Dave loaded up in the car and were one of the first car out on track. Dave had a couple slow laps to clean up the brakes and get a feel for the course before it when green. So far so good. After the course when green and a couple laps in Dave radios in saying there is something in the front moving around. Car turns fine left but not right. We had him come into the garage and check things out. Everything was tight up front so we sent him back out. We lost about 20 min doing that and were close to last place. He spent the next hour fighting the front end till it was time to pit for fuel. We checked the car again but this time found marks from where the driver’s side control arm was moving around on the part we recently modified. Since the bolt was already tight and still moving in the slotted crossmember I opted to borrow a welder from another team and weld the bolt in place.

Jeff was out next and said the car felt great.

We continued with our 1 hour and 20 min stints and our pit stops were pretty quick. We were slowly climbing back up in position when we noticed that Dave would have to pit for fuel with 30 minutes left in the race for the day. We radioed to Dave and told him he would have to take it easy and conserve fuel. Apparently he didn't here us and turned his fastest laps of the day. Like we though he radioed in with 45 minutes left saying he was getting fuel cut. We looked over at them empty fuel jugs and told him "too bad, keep racing". Besides just wanting to be jerks and laugh at Dave turning slow laps we were only 1 lap ahead of 3-4 other cars. If we could stay out we would be in much better shape the next day.

Now we get fuel cut in hard turns with 8-10 gallons left in the tank. We can normally keep racing for another 10-15 min as we get ready to pit but have never pushed it beyond that. As time went on Dave said it would cut in every turn. Eventually he couldn't accelerate hard or it would cut and he had to keep it under 4500 RPM. With about 15 min left he said he was down to 3500 rpms but was able to finish the race and only lost one position.

Sunday went smoothly for the most part other than us fighting over the wipers. Dave is short and has trouble seeing over the wipers so he removed them on Saturday. Sunday afternoon it started raining right at the end of my stint and we had to reinstall the wiper for Dave during the pit stop. Drivers wiper worked fine but no one checked the tightness of the passenger one and it stopped working a few laps in. It then slowly worked its way up the windshield until it got bound up with the other one. We captured Dave’s WTF moment on the GoPro. Next pitstop we fixed it for Jeff but then it spit out the passenger blade in turn one.

Over all it was a lot of fun racing on a new track and meeting some new teams. We placed 17th over all and 6th in class B. Looking at the results we were faster than the other 5 car in front of us in class B and second fastest in our class. The only other B car quicker than us was a 240Z. They came over to say hi and we talked briefly but it was in the middle of us welding suspension bits and we were a bit distracted. Wish I had a chance to talk more. Only thing I gathered was they were running a high compression 2.8L with carbs but were having some trouble early on with it running too rich.

Stole this pic of the Z's from Ron Vickers if you can't tell.

Man, I think what youre doing with this car is great. Curious, what ended up needing welded that first day? You said a bolt, but what specifically?

In reply to 4cylndrfury:

Oh right, forgot the details. We slotted the lower control arm bolt hole on the crossmember more on the drivers side then reinforced that area so we could get more camber out of that side. (Passenger side has plenty after last years crash). The bolt has a cam on it that use to ride against another piece of metal for adjustment. Now that we moved the bolt farther over the cam doesn't ride against anything. Even though we cranked the bolt down it was still moving in the slot changing camber and toe in turns. We didn't see any movement after a couple laps and confirmed that it was tight. After an hour or so when the car came back in the metal around the bolt was shiny from where it was sliding. That was handy since it gave me a clean surface to weld to.

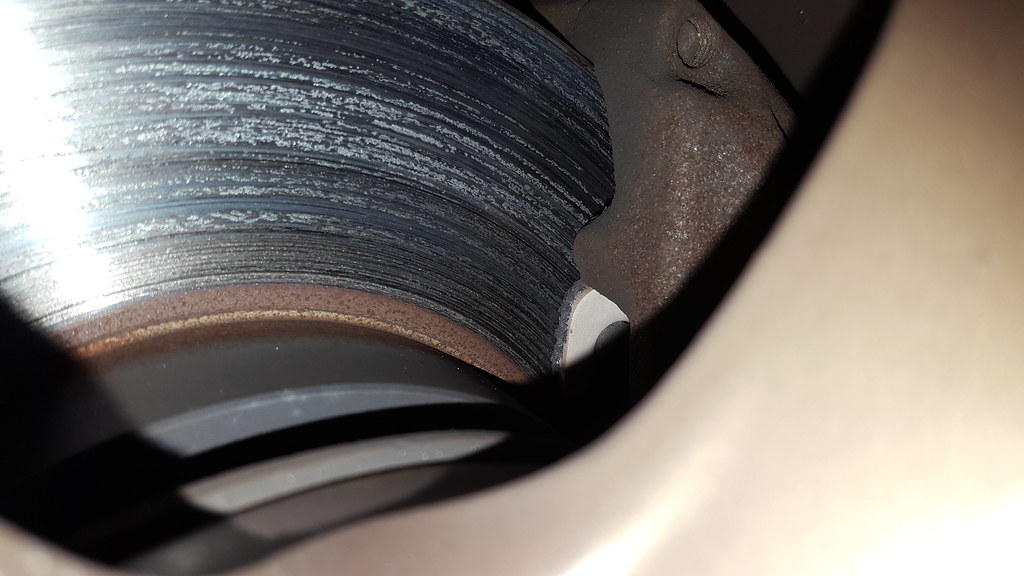

Next race is Aug 12th. Finally got around to working on the car again and it was nice to not have any major repair this time. We did front bearings, rotors, flushed brakes, fuel pump, new cool shirt controller, and redid the PTT buttons on the steering wheel.

One problem I found when doing the bearings is that the the outer race was loose in the hub. I tried installing a new one and that was loose as well. Decided to junk the hub and use another. New races and bearings went in without issue.

Our last race at CMP really beat up our tires so we swapped on a new set. Normally we can go 2 or more races.

"it was nice to not have any major repair this time"....yeah, so Pat changed the oil yesterday and noticed it was a little chunky.

Oil pressure was dropping to 10 psi last race on the main straight at 5k rpms. We have a suspicion that could be related. Engine still runs fine and doesn't make any noise. Current plan is dig out the spare untested engine and bring that with us. For fun we are going to cut open the oil filter tonight and take a peak at what it picked up.

With the writing on the wall, why not go through the spare motor and then install it in the comfort and convenience of your garage with the ability to test and address any issues that come up?? Just bring the current along as a spare :)

With the time and $$ involved with getting to and in a race, you'd be spending a lot to swap the unknown motor in at the track. While it makes for a good story, I'd prefer to turn laps>wrenches.

In reply to jfryjfry:

I totally agree with you but the timing of everything is difficult. Parts needed to refresh the spare from Rockauto wouldn't be here till next Monday which doesn't give us much time. We're afraid if we rush the refresh and engine swap we might not have everything sorted by next Thursday and will be in worse shape.

Tonight I'm at going to get the spare engine on a stand and at least check the bearings then order parts to have them on hand.

Got the spare engine on a stand last night. I was told it was a low mile engine but it was in the storage unit of questionable Datsun parts a bought a few years ago and has been sitting in the corner of my basement since.

I pulled the intake and exhaust manifolds off since there was some small damage to both. Under the valve cover looked fairly clean and I could still see the paint marks on the cam. Pulled one rod and main caps and the bearings looked ok. It was late so I didn't pull any more. Over all it was pretty clean with no sludge or build up. Valves didn't even have carbon build up on them.

My only concern is that there is some discoloring from heat around some of the rod journals. I pulled the cap on the one that looked the worst but didn't see any issues. Maybe its from the factory heat treating of the crank since the rod was not discolored?

well, there doesnt appear to be any deep scoring, so you might be right about the factory treatment. But, Ive never seen it that pronounced before. We are talking about a car that remembers when Reagan was just an actor, so, things may be a bit different nowdays. Any idea on what year that crank was manufactured?

The engine is either a 1975 or 1976. I have a couple 240z cranks kicking around an none of them show discoloration. They are also not as clean as this one. I can also dig out my other L28 short block and check that one too.

I ordered some plasigage from a local parts store and will check bearing clearances tonight. If everything is in spec then I'm tossing the pan back on and calling it good.

So I learned that if you leave plastigage on the front seat of your car on a hot day it will melt. Ordered more and when I went to check the bearings my torque wrench didn't want to click anymore. Borrowed a friend's torque wrench and that one was acting up too. Went out and bought a new one and was finally able to check the clearances. All bearings measured at .002 which is within spec.

Weird thing I noticed about the engine is that one of the crank weights had green paint on it. Looks like the factory marked an imperfection and there was a light grind mark on the crank. Guessing there was a slight balance issue? Motor looks like it's never been opened up and I've never seen this on any of my other Datsun cranks.

With the bottom end back together I reinstalled the oil pan and valve cover then scraped the gasket surfaces. It should be ready to go if needed. Now I just have to get it out of my basement.

Yup, must be a lemons race coming up because my basement is a disaster.

As for the motor in the car Pat finally cut open the oil filter to see how bad things are. There was a lot of metal in the filter but none of it looked liked bearings since it was dark and magnetic. Oddly that makes me feel a little better. I didn't get to take any pictures and Pat is not sharing the results with the rest of the team till we are at the track. Guess he doesn't want the rest of the team to worry about it all week. Meanwhile I'd at least like to remove the valve cover and see if it's something like a wiped cam lope. Can't think of anything else that would put that much metal into the filter that's not bearing.

Edit: I guess Harkins has seen the filter too. That just leaves Dave and Jeff since they live north of Boston. We are going to take some before pictures of the filter then load it full of metal and other stuff just to mess with them.

Last weekend was our best yet. We placed 18th out of 111, 6th in class B, and turned 477 laps. Best part is nothing broke! Even the engine held together all weekend as we beat the crap out of it. After 9 hours of racing on Saturday we changed the oil expecting the worst. It had a shimmer plus a couple copper flakes but but no chunks this time and inside the filter was clean. It didn't exactly heal itself as oil pressure was dropping to near zero on the main straights. Our solution for Sunday was this:

That plus some 20W50 and a quart of Lucas.

The biggest improvement this race was scheduling our pit stops. We know we get fuel cut after about an hour so we pitted every 1:15. The stops themselves were getting faster too and we are down to 3.5 minutes. The car was fast but in order to do any better we need to stay on track longer. Top teams were doing 3 hours stints.

Only minor issue we had was someone used the Datsun to slow down.

VW went too fast into a turn and hit our quarter panel almost spinning us. Jeff was able to catch it and went in for the black flag. Other team admitted it was their fault and we were sent right back out. Nothing important was damaged and the other team came by later to apologize so all was well.

There was also a light tap up front on Saturday too but it was still minor. I'll probably have both spots banged out with fresh rustoleum for NH.

Any plans to help extend the runs? Larger fuel cell?

10:1 will really help get a boost out of corners! Have you had any problems with engine heat this summer?

Engine has always run nice and cool even when it was about 100 degrees last year. 10:1 is higher then I would like and we'll have to be careful with timing. Our current N42 head has a small but open combustion chamber. Great for bumping compression but poor for detonation resistance. Cheapest and easiest option is to reuse that head and have 10:1. My only fear is that we will have to back timing off so much that it will cancel out any gain from the added compression. Selecting the right cam might help things. The other option I have is a P90A head which has a quench pad and larger chamber. That would give us about 8.8:1 which is a slight bump from our current 8.4:1. I could have that head decked to give us anywhere up to 10:1 but it would then need custom cam tower shims. That would then need custom lash pads. Depending on how much is milled and what cam we use I could get around the custom lash pads by using the longer N42 valves. Yeah so a bunch of measuring, math, and added cost but its a better flowing head that would allow us to run more timing with higher compression. I'm not looking for crazy power, just want to fend off the occasional Geo Metro or Subaru Justy. Fuel cell might be this winter's project and we need to look into what setup we want to go with. FIA cell for more money and less work or cheaper cell that needs a firewall.

This is great- Just read through the whole thread and it's awesome. The lemons thing seems like a blast and it seems like a real quirky group of people hanging out and having a good time.

Keep it up!

Are you getting fuel cut because you're out of fuel, or because your pickup and/or baffles are ineffective?

In reply to Gunchsta: Thanks, I've been having a lot of fun with the car. Our team is certainly not as wacky as some of the others but lemons is a great time and everyone we've meet has been awesome. In reply to AngryCorvair: Tank holds 17 gallons but we can only use 7-8 gallons before we get fuel cut in turns. The stock pickup and baffles are terrible. We normally go 1 hr 20 mins before pitting. At CMP we stretched our last stint of the day to almost 2 hours because we didn't want to pit and if we did we would lose 3 positions. Not that we really cared and it was more of an experiment to see how far we could push it incase it takes extra time to get ready for a pit stop. That or the whole team decides to go to Wendy's and leaves the driver out there. (which has happened). I thought about running a hydramat but I'm not sure how we could get it in the stock tank since the pickup is not removable.

Also as a bit of an automotive hypochondriac I love watching this stuff NOT fail, get pulled straight, and generally kept going. I realize your car has had some mechanical trials and tribulations, but from what I read the thing seems pretty robust.

I also don't have the stones to tape over the oil pressure gauge, love it.

As for the stock tank- is there any way you could put a sump/swirl pot on it so instead of having to pick up gas from the stock pickup it can suck out of the lowest point in the tank? I know on a car I drag raced I put a sump on the stock tank and it helped fuel delivery a lot. Not sure if there's any advantage in Lemons to staying with a modified stock tank but it's an option.

We can't run a sump/swirl pot with a stock tank according to the rules. We would need to upgrade to a fuel cell first then add a proper surge tank and pump. Lemons wants either a completely stock fuel system or a properly built one.

The Oct NHMS race last weekend snuck up on us. I never got around to building the new engine or doing anything else to the car. Instead we loaded it back up on the trailer and headed to NH. We installed new brake pads Friday and changed the oil again with Lucas and 20w50. Still a lot of metal in the oil but whatever. Saturday we crossed our fingers and sent it out racing.

We had a rough start that morning. Pat was first in the car and spun halfway though his stint. Both him and the car were fine but he got a black flag then continued racing. Next up was Jeff who also spun halfway through his stint and came in for the black flag. When he got there they said he had also passed under yellow which we didn't know about and they even admitted later they were having problems with flag station 3. Still with the spin and 3 flags they sat us for 20 min.

After they let us go we went back to the pit and check tire pressure. Rears were at 32 and fronts were at 30 psi. Earlier that morning it was 40 degrees and we didn't inflate he tires too much because we thought the pressures would come up more once things warmed up. Well we were wrong so we aired them up to 36psi and sent the car back out. at this time we were down to 67th place. Rest of the day we focused on driving cleanly because judge Steve said " you guys really don't want to see me again today". Car felt great with the added air pressure and we climbed back up to around 30th.

Sunday was uneventful till the last 45 minutes. I was in the car for the second to last stint and about halfway through the brakes started feeling off. They still stopped good enough on main straights but hard jabs didn't have the bite they use to. Figured I had over heated them so I took it easy the rest of my laps then passed off the car to Jeff with 30 left minutes. Right before we went out I did warn him the brakes felt off and to take it easy and leave some extra room. He finished his stint but was about 3 seconds off off his faster laps. After the last lap he pulled the car into our pit and right on the trailer. When he got to the end the car didn't want to stop and he slid into the bin on the end of the trailer. Apparently the drivers side front pad was completely worn out and down to metal. Passenger side was just about gone too. Guess we were a little harder on them Sunday and glad nothing more serious happened. Overall we finished 26th out of 115 or so.

Oh yeah we somehow lost one of the googly eyes on Saturday so we gave it one lazy eye.

With the race season over I've turned my attention to building a new engine for the car. Yeah its going to be kinda cheaty so shhh.. don't tell anyone![]() . The basis for the new engine is a 2.8L short block I've had kicking around. I was told its actually the original engine for the car that was removed because it had some bent valves which then sat outside in a barn for a few years. Its a little rusty and I've tried to give it away multiple times with no luck. I forgot to take a picture of the whole thing but here are what the main bearings look like. Also as a bonus there is some hair on the main caps from whatever animal might have been living in the block at one point.

. The basis for the new engine is a 2.8L short block I've had kicking around. I was told its actually the original engine for the car that was removed because it had some bent valves which then sat outside in a barn for a few years. Its a little rusty and I've tried to give it away multiple times with no luck. I forgot to take a picture of the whole thing but here are what the main bearings look like. Also as a bonus there is some hair on the main caps from whatever animal might have been living in the block at one point.

Rear main seal had been replaced at some point and the previous owner must have had some junk under the cap when they reinstalled it. I dropped off the short block bits at the machine shop long with the new pistons. Hopefully I'll find out next week if everything worked out.

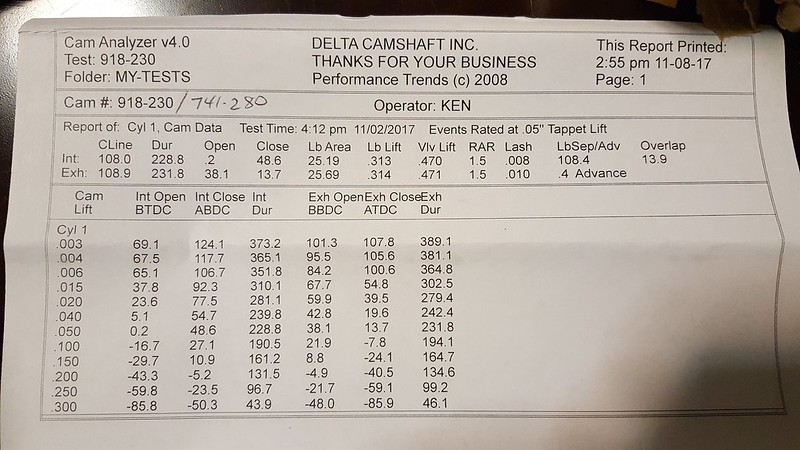

Cam kits are expensive for Datsuns so to save some money I sent out one of my spares to be reground along with some rockers. I gave them some engine info and what my plans are and they recommended their 280 grind. It was the largest they could regrind to and allow me to reuse the stock springs and retainers.

I still need to figure out which head I want to use. Probably going to be the one that's currently in the car unless I find a deal on something better.

You'll need to log in to post.