I was hoping for about 160hp with peak power closer to 6000 rpms and 170-175hp after the header, intake, and exhaust. Over all the engine feels snappier and I can get a little wheel spin while messing around in the parking lot. Looking forward to seeing how it does on track in a couple weeks.

Pattyo

Reader

4/23/18 7:46 p.m.

In reply to PseudoSport :

A couple weeks!? I don't want to wait that long! Isn't there a dyno near you?

Worked on a couple minor things this past weekend. Hood is back on and lined up the best we could. It's a little tricky because the front is smashed and rusty plus I welded the hood to the hinges. Next we installed a new starter from a 280zx which is a gear reduction style. Engine cranks over way faster then the old dying starter. Hopefully as an added bonus we will no longer have to hit this one with hammers to make it start.

The other project we finally got around to was mocking up a rear bumper. Something we've been meaning to do since day one. Its nothing crazy, just a little added protection to the gas tank and it gives something for the tow truck to push against other then the tail lights. At some point I will wrap the ends around some then cover it with a beat up 240z bumper.

Installed a 280zx master cylinder since it has a larger bore and should work nicely with the new 4 piston front calipers. We had to adjust the booster pushrod length since it needed to be a little longer but not a big deal. Also while we were at it I adjusted the play out of the brake pedal under the dash so there is no more weird clunk when you first hit the brakes. For the first time since I've owned the car it actually has a solid pedal.

Moved onto working on the rear brakes only to find out we ordered the wrong rotors. Apparently there is a Canadian 300zx which has smaller rotors. Ordered new rotors locally which will hopefully will be in before we leave. Also the driver side rear caliper is still weeping brake fluid but no were locally can order a replacement. Might have to run it unless I can track down a replacement in time. For now we pad slapped the rear and called it good till parts show up.

The car has never been washed after I painted it so its long overdue for a bath. There is actually mold growing on in. Made a quick pass with a scrub bruch which helped but didn't touch a mold or other grease stuff. Pat's wife suggested we try a magic eraser. On a normal car it might dull the paint but on the Datsun it worked great! It still has all the kicked up rubber marks, scuffs and scrapes since I didn't want to put in the effort to clean it up that much.

Ignore my goofy datsun washing face.

Car looks great!

did I miss it or were you planning on dropping that l28et in it at some point?

Thanks! I thought about dropping in the L28et but didn't know how reliable it would be in lemons. Also if the judges saw the turbo engine then we might get bumped into class A. Instead I built up a L28 and kept it stock looking. If that blows up then yeah, its turbo time. I've been hording a bunch of turbo parts for lemons and a future challenge build. I even went to look at a 260z parts car on Sunday. Later this summer I hope to start working on the burnt car or whatever usable shell I can find.

Loaded the car on the trailer a day early! Didn't see that coming when the engine was in pieces all over my basement floor a few weeks ago.

Normally we don't run open test day since its just another change for the car to crash or blow up. Since we made a few changes we are going to run Friday to sort things out. Hopefully the engine runs well and we can get brake bias dialed in.

Saturday I'm going to try and live steam the first 4 hours (if the car survives Friday) on our facebook page: www.facebook.com/NuthinButAZThang

Good luck!

Don't forget to have fun-

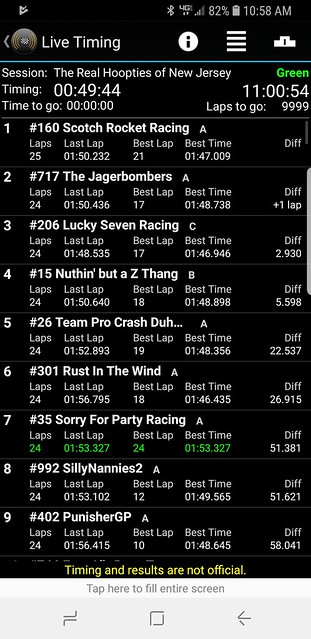

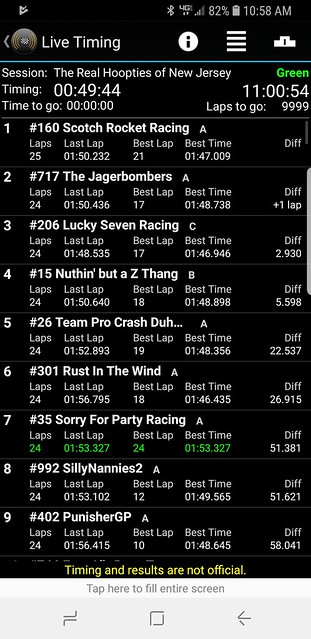

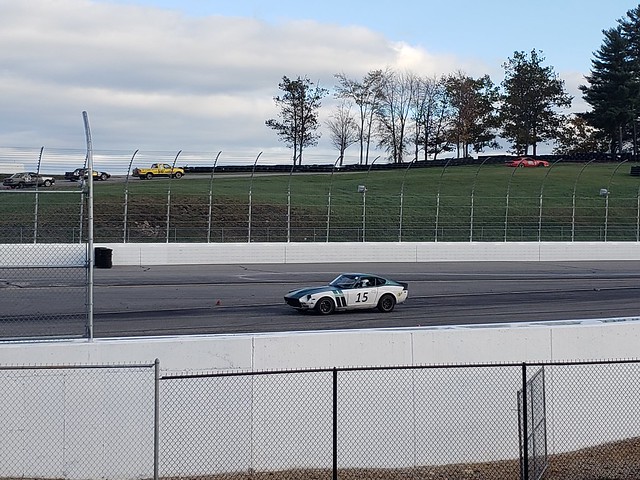

Well berkeley. Things started out ok and the car was quick. We jumped up to 4th place over all but that didn't last too long.

About 1.5 hours into the race Dave radios in and says he hears a noise from the front of the car and that he was coming in. As he is pulling up to the garage I can hear the engine knocking. Even with the new engine oil pressure was dropping at high RPM's like our last one but this time we spun a bearing.

Since we were far from home we packed light and didn't have a spare engine or bearings. We called around and the closest place that head rod bearings was 4 hours away. We found one other engine but the guy wanted $1,600 for it. berkeley that! So we found another team running a Datsun 510 and asked if they had any bearings. For some reason they saved a bag of spun bearings from their last engine. One pair look pretty hammered but it hadn't spun yet so we cleaned that up and spent all day Saturday cleaning up our crank and installing the used bearing.

Our bad bearing left, used 510 bearing middle, next best 510 bearing right.

We knew this wasn't going to work out well but there was not much else we could do. Crank actually cleaned up ok but the rod bearing cap was pinched smaller now and didn't want to fit on the crank. I sanded down the bad bearing sides then tapped the cap into place. It fit tight but the engine rotated over so we started putting everything else back together. While we were under there we shimmed the oil pump to give us higher oil pressure. Figured that couldn't hurt.

While waiting for the RTV to set we started drinking heavily then fired up the engine around midnight. Engine sounded quite and had decent pressure so we called it a night. Next day we slept in because we were hung over then went out for breakfast. We arrived at the track 2 hours after everyone had started racing. I suited up and took the car around the parking lot. Engine was still quite so I went out on track and did 1 very slow lap then came back. Surprisingly it was still quiet so i headed back out to see how many slow laps I could do. the Answer is 10. I tried to keep RPM's down but move fast enough as to not be a hazard but on my 10th lap I heard a faint knock going down the main straight. I came in and we called it a day. We thought about going out for the last lap but decided to pack up and head home early.

I had a 7 hour ride home to think about what went wrong. Oil pressure is only dropping on the main straights after extended high RPM pulls. Are we getting oil starvation and empting the pan? Oil temp is too high? Drain back issues? We also noticed that oil was already 1.5 quarts low when the bearing spun but there were no leaks or blue smoke. Guess all I can do is pull apart the engine and see what I can save.

Friday night I decided to pull the engine and see how bad things are so that I can stop thinking about it.

With the tight quench and the spun bearing I had a feeling that the piston might have hit the head. Once I opened it up that theory was confirmed. Fortunately the valves look ok and the combustion chamber only has a slight mark.

Block has been stripped down and looks to be in good shape. Crank needs to be machined but i'm just going to swap one in from the old engine. #3 rod and piston are junk and will be replaced. Hopefully I can get one piston instead of ordering a full set.

Sorry for your troubles :(

Hope you can get them sorted.

What RPM are you running to?

We spin it to 6000 sometimes.

Parts are back from the machine shop. #3 rod from original engine has been resized with a new piston, original crank has been cleaned and polished, and the head has been drilled and tapped for an extra oil return. Leftover junk has been added to my desk at work. Only out another $130 for machine work so not bad.

When the engine was put together last time I noticed that the rings that came with the pistons were chrome. I didn't think they would be a problem since OEM was chrome but they don't like to seat right away. I'm thinking that since the engine didn't have a lot of run time before we went racing that the rings might be why we had oil consumption problems. This time around I'm going to use something else. Cast iron rings would seat quickly but don't hold up to racing well and my machine shop said to avoid them. Also the rings that I put in the original engine were cast which shattered. Decided i want to run a Moly ring in either ductile iron or steel but the only vendor that sells them is Total Seal and they want almost $200 for a set. After spending a day digging through ring catalogs I found that a Dodge 2.7L engine has the same bore and uses a 1.5mm Moly steel top ring. Unfortunately the other 2 rings were not the right size so I'll have to mix and match sets. For $35 I found a set of Mahle 41855CP .040 rings that should work. It was cheaper to buy that set then order the top rings by themselves.

While I'm waiting for the rings to show up I then dragged the block outside and honed it with 280 then 400 grit stones then washed it all out.

I also ported the rough casting around the oil drain hole in the back of the block. Sorry all I have is the before picture.

With the block cleaned out I can now start assembling everything again.

Nice sleuthing on the rings-

When's the next race? I'm not ashamed to admit living vicariously through your Z racing :)

damen

Thanks, next race is Aug 11-12. Crap that's coming up soon. Hopefully I'll have the short block together this weekend. Still waiting on the crank scraper which I ordered a month ago but the seller says it's being built now. Only other thing I'm waiting on is having a custom oil pan built by my teammate. I still need to give him our old pan and the one off the parts car in my yard.

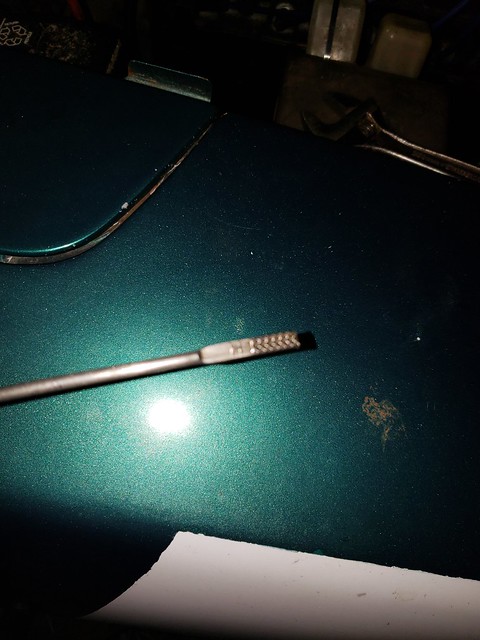

Going to be cutting it close. After waiting 8 weeks my crank scraper finally arrived. It still needs some adjustment to fit better but hopefully I can finish that up tonight or tomorrow.

Rest of the engine is pretty much together.

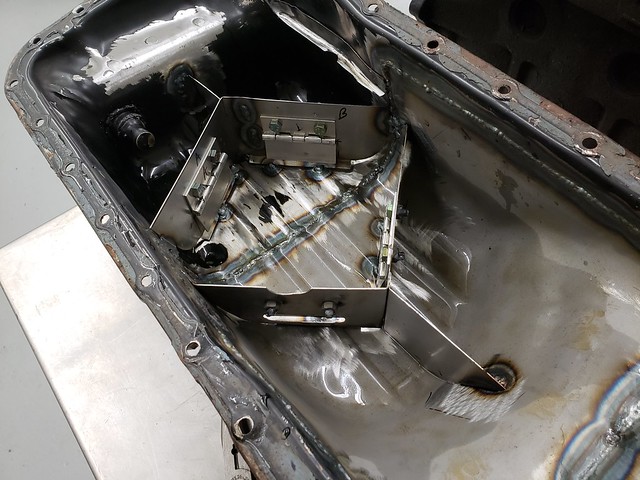

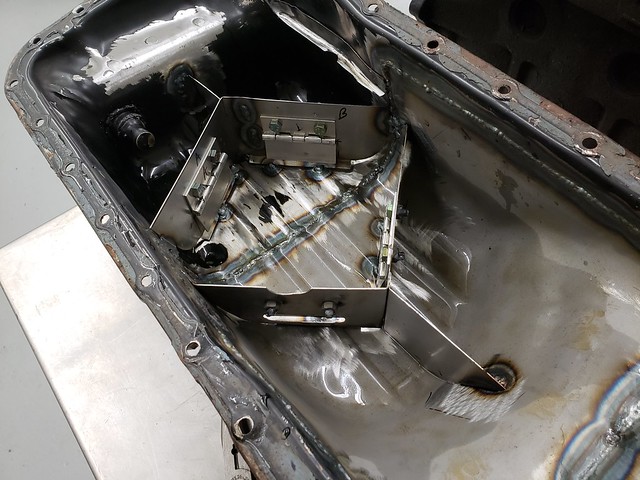

Main thing I'm waiting on now is the oil pan. Took me a while to find time to pull the 280zx pan out of the parts car so that set things back. Reason I wanted that pan is its rear sump where our stock pan is mid sump. There is plenty of room to go back so my though was to cut and weld the pans together to make a larger capacity.

280zx top and 280z bottom

Took some trimming but Dave got them to fit great and should weld nicely.

We need to extend the tray forward and close it up some around the pickup to keep oil from splashing out. Also we plan on adding some trap door baffles but everything needs to be done by Friday so the engine can go in Saturday.

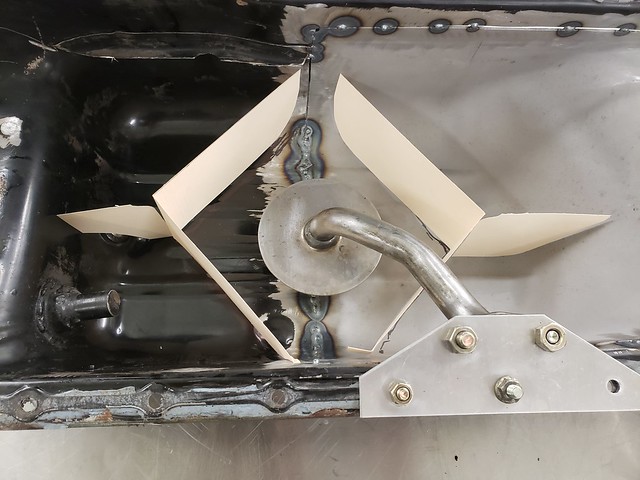

Dave started welding the pan and made a bracket to hold the pickup in the same position it was on the block so we could mock up baffles.

Man, I’m so happy to see this thing still kicking around, and very very jealous.

Thanks, project is still going strong. Its been a constant cycle of break, fix, repeat. Still having a lot of fun with it.

We had to hide the block from Dave's boss till we could work on it again the following night. Took him a whole 5 minutes to notice the following morning. Think the box bought us a couple seconds though.

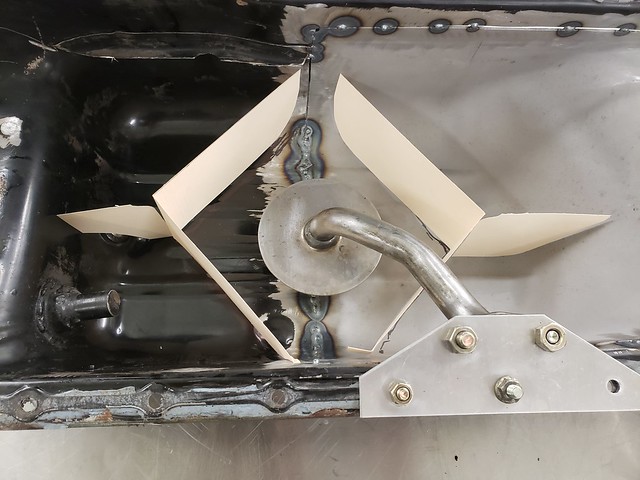

Baffles and trap doors were mocked up.

Final product. Hinges are from Improved Racing. They are designed to only open 60 degrees and hang slightly open. So far total investment for hinges, metal, plus a -8AN bung is $52. Not bad.

For the tray we combined the one from each oil pan then added a small section to keep oil from splashing out in a turn.

Quick video of it in action.

https://www.youtube.com/watch?v=xY9Ds3MdYxk

Kinda behind on updates. Couple days before the event I installed the oil pan and dropped the engine back in the car.

New pan fit great with plenty of room but one thing we forgot about was the dipstick. Went to check oil and "clank"! Dipstick hits the metal we added to close off around the pickup.

Fortunately the stick had some extra that could be trimmed off and still be usefully.

Next day I finished the engine and fired it at 11pm. Following day (now Thursday) I installed the new fancy oil pressure gauge and ran the engine a few times to check for leaks in the day light. Everything looked good so I made a couple passes down my street to seat the rings. No blue smoke like with the chrome rings and oil pressure was 75-80 psi cold with the new DL Potter oil pump springs.

Race weekend we had a couple small issues but the engine ran great the entire time. Oil pressure was rock solid all weekend too! Like the past couple races we started off great but its was a wet and sloppy race both days. On Saturday our borrowed driver spun the car then a few laps later overcooked a turn and went off almost hitting a wall. The black flags and forced driver change dropped us from 10th down to 50th. We climbed back up to 36th with 2 hours left in the day but Jeff noticed the water temp start climbing and came in. Turns out a rock or something hit the radiator and it started leaking. I drove an hour back and meet up with Harkins to pick up a spare radiator but by the time I got back everyone was done for the day.

We also noticed the front was a little banged up. Dave said someone might have bumped us but didn't think much of it till he saw the headlight bucket. One of these days we'll build a front bumper.

Speaking of bumpers we got to test out the new rear one. During my stint I was at the back of a group of cars that came to a stop for a yellow flag. Car behind me couldn't slow down enough and hit the Datsun pretty good. Bumper took most of the impact and is slightly bent but the car continued under the bumper and actually hit our gas tank! For the next race we'll be extending the bumper a little lower.

Rest of the day was very wet but we drove cleanly and didn't have any more issues. Dave had the worst stint with a lot of standing water and zero visibility.

Other then a couple small things we should be ready to go for the next race in Oct.

My teammate installed a lift in his garage last week. No more rolling around on the ground prepping the car!

Like always we found more issues that need to be addressed before the next race. First we found some spot welds above the sway bar bushing that were failing. We rewelded them, ground them down, then welded in a reinforcing plate.

While we were going over the front end we also noticed the tack welds on the camber bolt broke so we had to reweld those again.

Also found that the fuel sending unit was leaking. tank much not have liked getting hit last race, Hopefully the new o-ring I ordered will be here by Thursday.

To prevent the tank getting hit we took an extra door bar and welded it to the bottom of our bumper.

Rear brake hoses also had slices in them from making contact with the body. Must have happened when the car when off track last race. We clearanced the body where they had hit and ordered new hoses. Hopefully those will be here wednesday. Once the hoses and o-ring are installed we should be good to go for this weekend.

Very cool - good luck in the race!

damen

Friday went ok. We fixed the fuel leak at the sending unit and replaced one questionable fuel hose to an injector. Also found the 2 new brake hoses in the rear were weeping so we tighten those and rebleed the brakes. Car didn't need much else so we hung out and relaxed.

Saturday got off to a rough start. In the middle of the stint there were 2 Miatas that were over driving battling each other. They got bunched up and one locked up the brakes then took a sharp turn into our car. Pat went in for the black flag and I ran over to check out the damage. Miata didn't take much damage but their wheel hit us pretty good. It looked like they missed our rear wheel and everything was cosmetic so I sent Pat right back out. Labels were added after the race for driver shaming.

Rest of the day went pretty smoothly and we climbed up from 97th place to 24th. Sunday was a tough fight but we worked our way up to 14th over all and 3rd in class B. We had 2 hours left and one pit to go and were pushing to try and take 2nd in B. Jeff radioed in saying there was a major vibration coming from the back of the car and that he needed to come in. Then he said he couldn't accelerate and wasn't sure he would make it back.

He was able to limp the car back to our pit but couldn't accelerate up our 2x6 wooden ramp. By now there was weird clunking and grinding. I stuck my head under and saw one axle spinning but the wheel wasn't moving. I could then see the axle moving though the center cap of the wheel but the the lugnuts were tight and wheel didn't fall off. None of us could wrap our minds around what was going on till we took the wheel and rotor off.

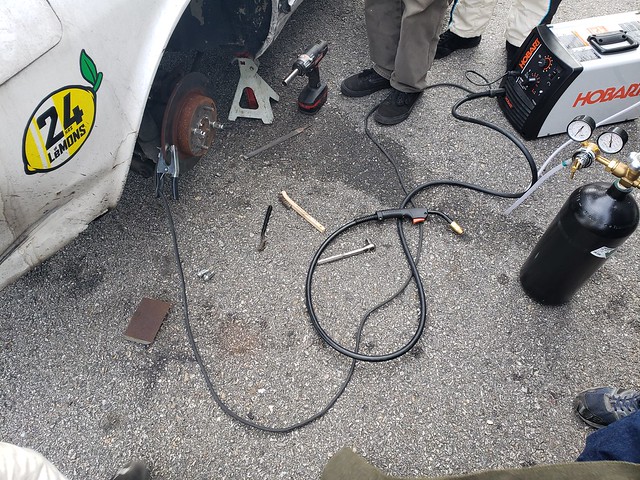

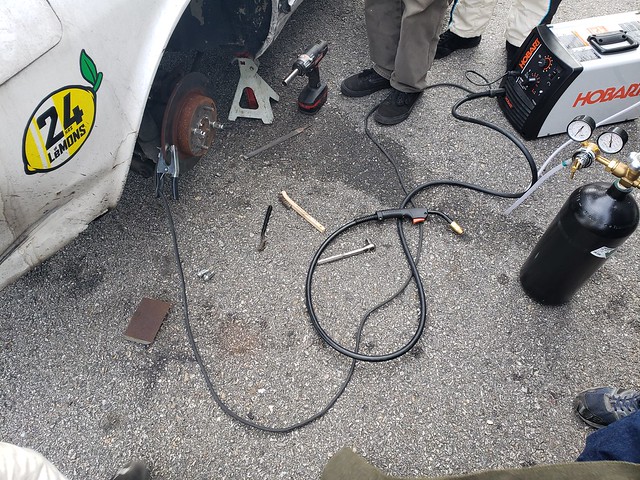

Somehow we broke the flange off the axle. Fortunately since we upgraded to rear disc the wheel didn't fall off. With 2 hours left there was not much we could to. I don't have a spare flange and to swap that out takes forever. Defeated we went back in the RV and started eating cheeseballs since we couldn't start drinking till 5pm. Watching as our place dropped down one by one on the race app, we started to come up with bad ideas. We talked about welding the flange back to the axle but then we would have to grind it down so the rotor would fit. More cheaseballs were consumed then I thought, why don't we weld the rotor to the center of the axle? Axle will drive the rotor and the rotor will turn the lugnuts. To avoid grinding we will bolt the wheel on first and weld through the center. Before we had time to rethink this terrible idea Jeff went off to find a welder. So with about 40 min left here's what happened.

Step 1: Clean up rotor with a grinder

Step 2: Clean up stub axle

Step 3: Mock up parts to weld

Step 4: Pull wheel to center it, hold ground strap to the back of rotor since it won't clamp with wheel inplace, and weld rotor to flange.

Step 5: Don't share pictures of your terrible welds on the internet

Step 6: Convince driver there is only a small chance of him dying

Step 7: Dominate!

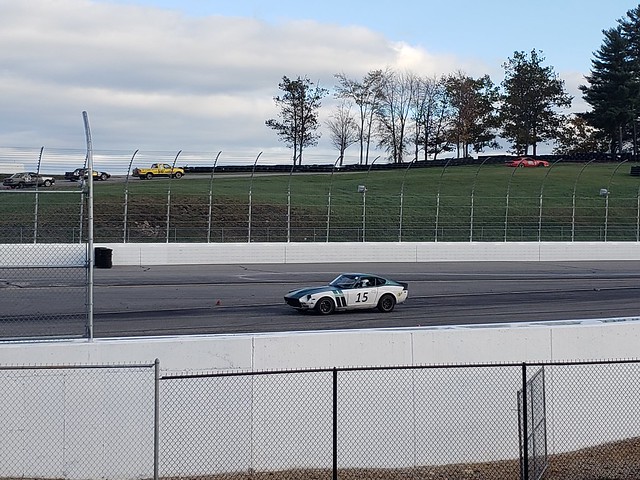

Any by dominate I mean turn 10 really slow laps till it breaks again right in front of the checkered flag and not finish, lol. Over all we had a great weekend will have the car fixed up for NJMP in May

At least with it broken again it should be easy to get everything apart to fix.

How do you like the Falkens? Have you run the RS-4 to compare to? I'm looking for new track tires in the spring having run RS-4s for the past two years and wondering if the Hankooks are worth $100 more for the set.

Adam

We like the Falkens a lot. Life, wear, and grip have been great. Normally we get about 2 races out of a set. There might be some sticker tires but for the price they are hard to beat. We wait for one of the big Discount Tire sales and get them for $300 after rebates. Right now they are $100 off on ebay. For a couple of races we tried the Nitto NT05's and didn't like them. They wore funny and greased up fast if pushed. You would get a couple good corners then have to dial it back for the rest of the lap. I haven't seen many other teams running the RS-4 but I wanted to try them since they offer them in a 225/45/15. Some of the fast teams really like the Dunlop Direzza. They say they grip better then the falken but don't last as long.