There is just something about a rats nests of wiring that makes me cringe. I can't say it's my fav part of a build.

There is just something about a rats nests of wiring that makes me cringe. I can't say it's my fav part of a build.

The car has been deemed to now be 60% done. Wiring and fine tuning the bolt-on parts continues. First on that list is getting the alternator mounted in the correct orientation. If keeping the belt on the motor is a goal, no better time than now.

The fine tuning of the front of the motor includes...

Having the Davies Water Pump mounted so it will line up with the hard lines in the car.

Next, confirming that the ...

The front engine mount will work with the new locations for the WP and Alt.

Close up of the details,

The finished hardware is in place.

Now, as it should be.

Wiring, in this case it's to create a stand alone engine loom. "If" removing the engine has to happen in the future, all you have to do is disconnect one plug.

The goal was one point of gathering the components...

\

\

Then..

more fine tuning...

Your goal is to have all the wire end up in the connector...

The attached picture is not going to give you a true inkling of how scruffy the car is, amount of time it sat in the paint shop did it no favor. The combination of oil, coolant, bondo dust and fiberglass is everywhere.

You can see the the large metal tube, that runs under the car to the front mounted radiator. The fuel lines and fuel pump are next on the list to be refreshed.

Today was more wire, taping and getting it in the car.

Getting it started looks like....

When success looks like this...

The car is actually cleaning up really well. The layers of accumulated stuff gave up with the application of effort.

When progress can be measured by what is no longer littering the floor, it starts like this.

Then under the car it looks like this.

Pulling more wire and reinstalling the loom for the engine and the run to the rear trunk looks like...

The more you pull into the car, the nest that is left looks like...

What is starring at you will end up under the dash and then finish at the front of the car.

The slope of the bulkhead between the engine compartment and the passenger area gives you no room to mount an alternator in the tradition location. When the motor goes back in the car the valve covers are right against that same bulkhead.

The motor in fact will sit at an angle, nose/ crank pulley down in the car. The motor could be mounted higher, the challenge is keeping the carburetor and air cleaner under the engine cover.

The new manifold is not the optimum for the motor, but the packaging of this combination is providing a number of choices and compromises.

David

This is a picture of what the drive train looked like before all the effort. Transferring the water pump to the passenger side of the engine has to do with the hard line routed under the car.

The other thing the new coolant system helps with is the increase in flow of fluid into the motor. The 90 degree fittings that bolted to the motor at the water jacket restricted the system.

Reassembly starts with staging the components.

The engine and transmission are bolted together, that will end up on the legs on the hoist. Then rolled under the car and lifted into place using the hoist.

This is what the goal looks like.

The engine did get rebuilt at some point in the past. The details were not passed on to the current owner. It was a running car but other than getting it moved from location to location it has not been enjoyed, as a driver.

Having the transmission gone through confirms its condition, now knowing the shifter is going to be in working order will make the car much easier to drive. The car was built and driven in Northern California on the coast. Now that it is in Southern California it is going to be able to survive in a much warmer climate and being driven in traffic. Based on the the cooling and oiling system, given the improvements.

All the research done on this conversion leave one to believe the weak link is the shifting of the gear box. The 901 was not built to work with the combination of horsepower and torque of a SBC, but you can drive the car. First gear has been deleted, one less opportunity to shred something when you are getting started!

First, the end result of a combination of parts that someone has pulled together might end up producing a master piece. Or a workable compromise. This combination of 914 and sbc are a lot of both. The parts that are a kit that has been available will put the motor in the car and will end up getting them combined. I do not know if they have evolved their blend of components. The motor and transmission have been in and out twice to fine tune the new fitment.

The engine, when it is in the car will be sitting with the front of the motor lower than the back end. The front of the crank shaft, just behind the cam sprocket cover might be pooling oil. This is a test for the crank shaft oil seal in the front cover. In our case the old seal had in fact, failed. The crank pulley for this kit starts off as a two grove item that was oem for a Chevy 250 6 cylinder. It gets worked to fit this application and it creates a path for oil to escape. Lots off it.

If they made an oil seal 30% wider, and they might, it would be perfect. Putting a new seal in the cover and not setting it 100% is the current fix. We shall see.

Making room for the water manifold requires removing sheet metal that would be used for the anchor for the tin used with the air cooled 4 cylinder engine. The shelf of metal is also used to run the oem wire harness. That has now been adjusted.

The room for the new water pump manifold is framed by the wire harness. What could go wrong?

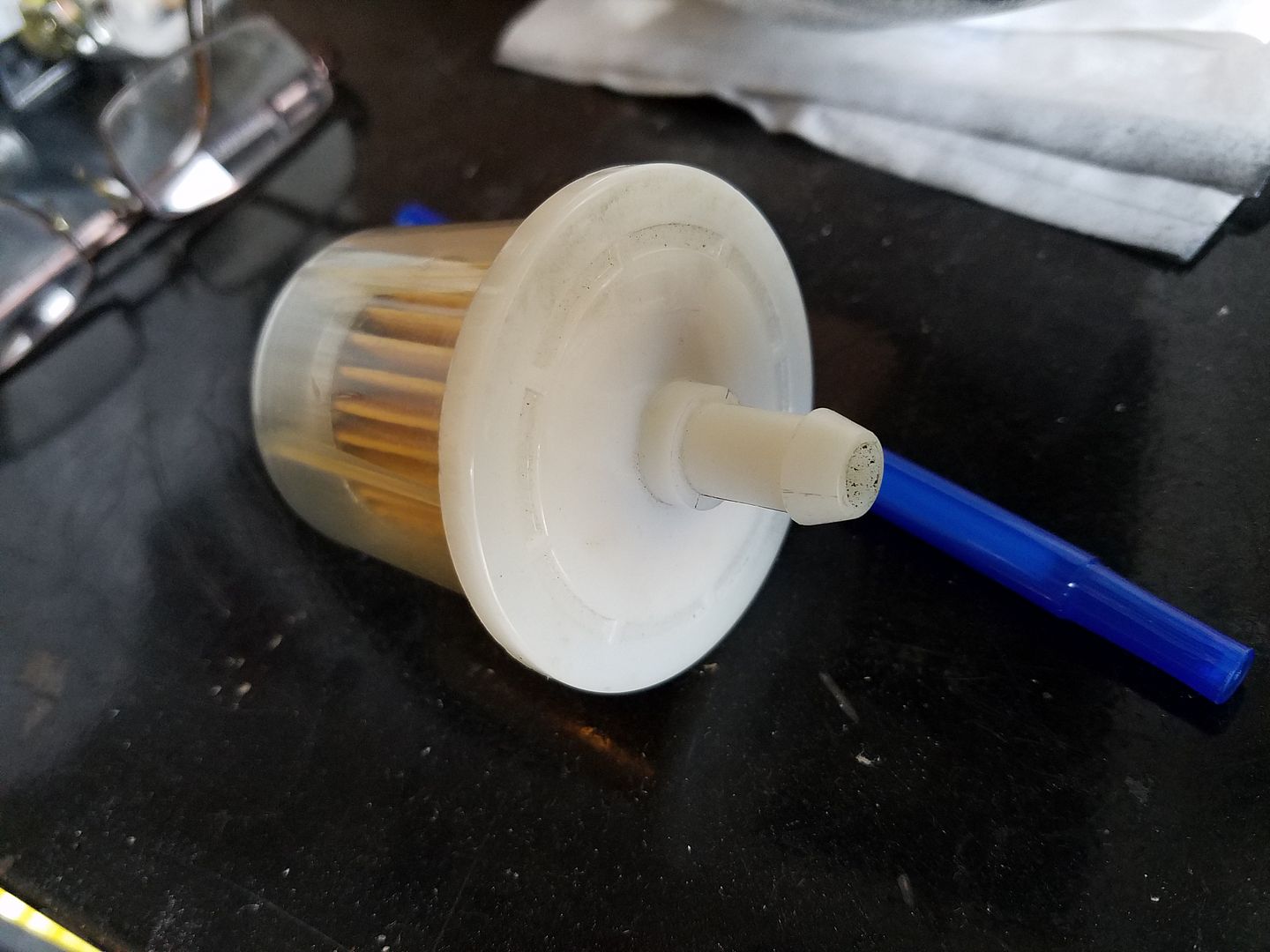

The fuel pump, filters and hard line are in place.

Now it's back in the car, like it fits. After you cut stuff to make room for everything.

That run of hose from the pump to the hard pipe are almost an affirmation of how this should be done. With the kit. That and the new metal on the engine mount protecting the oil pan.

The car is almost a driver. The details of buttoning up the installation include adding the ability of tuning the carburetor. To that end an O2 bung has been added to the exhaust system on the driver side of the car.

The new, larger oil pan and the side shifter for the transmission look to be a workable combination.

The driver side muffler, exhaust pipe, half shaft and the side shifter look to be close but they will not be in each others way.

The system for both sides is in place and with any luck it will be running, tomorrow.

Something about symmetry. That, and anticipation. I hope to be helping to tune the carb, requiring that I have to drive the car and that might include putting a number of miles on the updated combination. Yes, I am a willing victim.

Finishing up the installation and getting it running continues.

The cooling system required 4.4 gallons of fluid.

The wiring to get the car to start was completed and it did in fact run. Finishing the wiring in the car is continuing. What you see behind the motor is just a small part of what has been removed and replaced.

First, the motor is running. It sounds great, in fact you will not miss it as it passes you. If I can figure out how to link the video I will post it.

But the details of completing the project continue. One of the items that cause no end of grief for mid engine water cooled projects is getting the unwanted air out of the cooling system. This car compounds the issue given that the motor does not sit level in the car. The front end of the motor is almost an inch lower than the distributor/back end. Yes, adding some sort of bleeder/petcock to the back end of the intake manifold would do the trick. But having coolant potentially leaking around the distributor and having to explain what a petcock is and does leads to other ways to fix the issue.

Shall we call it a "Binky" bracket?

The object is to mount the radiator cap/fill point as high in the engine bay as possible. With the cap above the level of the back end of the intake manifold.

The coolant overflow bottle is an addition to the system and yes it does have it's own bracket.

As a reminder of how these are usually built, the carburetor is usually mounted backwards and the original throttle cable is used to pull the system open. The combination of reverse mounting, angle of the carb and acceleration of the V8 combine to create a fuel starvation issue that you can not Band-Aid. If you ever get to go for a ride in one of these, the owner will confirm the issue. That and they run warm, see above.

The fix involves a wedge under the carburetor. Think V8 in the back end of your garden variety speed boat that runs a V-drive. The motor does not sit level in these applications ether. The carb is also subject to fuel sloshing around given it lives in a fluid environment and when you nail the throttle the bow reaches for the sky. Just like a dragster/funny car. The gentlemen doing the work on the car is an old hot rodder who works outside the box and has come up with a set up to provide some solutions. The first was to add an extension to the original throttle cable to extend it to the other side of the motor. Check out the brackets welded to the valve cover tension mounts.

The driver side of the motor now looks like the carburetor is level in the car and the action to open the throttle is as it should be. In the back end of a 914. With a small block making some awesome noise .

Now, back to the wiring.

I dont want to sound like a dick, but that air filter has caused me more grief if the past, especially with holley carbs than i want to admit, the major prob with them is the foam breaking down, clogging the vents or dropping bits of foam down the vent stacks.

I know you will be challenged with space, but i would strongly recommend an alternative, if possible

The air cleaner is only on the motor during this phase of the build. The alterative evolves creating modified sheet metal, that is still being done at this time.

I'll also say get rid of that air cleaner. I've seen them catch fire more than once and a buddy had a serious fire of dual carbs on a Pantera. When pumping gas to set mechanical choke or "prime" the gas splashes up and gets soaked up by the foam. Then all you need is the slightest backfire and poof!

Also I noted the use of the clear plastic fuel filter. The problem with those filters is that although they're made for a 3/8" fuel line the opening fuel flows through is actually very small because of the thickness of the plastic needed. It won't flow enough fuel to run a 350 wide open and you'll run lean and maybe burn a piston or several. Have seen it happen. Swap it out with a metal inline WIX filter as cheap insurance better for fire also.

[URL=https://s240.photobucket.com/user/NOTATA/media/20160901_163355_zpsmz9urj2m.jpg.html] [/URL]

[/URL]

And we have a driver. Yesterday was a spontaneous drop by and check out the car visit. As it turns out the details of the build will follow, but with the carb and timing dialed in using an air flow meter, it was time to roll out the car. For the first time under its own power.

First impressions, oh ghees. Fine tunings of things like finding gears in the transmission will come, but it does it scoot. With very little weight in the front and lots of "go" in the back end my first thoughts are have it pointed where you want to go before you unleash the beast.

More to follow, we are clear to add the miles needed to fine tune the driving experience. Darn, someone has to sacrifice.

First view as a runner.

https://www.youtube.com/watch?v=McYeQgPtl68

With this view you can see that the motor is moving around, front to back under acceleration and deceleration. That is going to be next on the list to be addressed.

Lingering oil leaks, during a shake down from a long term rebuild are a nuisance. Not that oil will find any opportunity to escape where it belongs and end up leaving that mess on things that will do nothing but collect dirt. It's when you leave off a bolt that might have you shaking your head.

To be fare, moving stuff from one side of the motor and installing it on the other might help in some respects and it could have a residual impact on the finished installation. Moving the bracket for the alternator bolted on the block from the passenger side of the engine allowed the electric water pump to line up with the hard lines in the car. It tuns out the mechanical fuel pump mounting flange that you have blanked off for this application has one galley that might intersect with a bolt on the front of the motor.

That use to have a bolt used to mount the alternator bracket. That sealed the "not under pressure" pathway for oil to escape the motor.

So, if you ever work around an old school small block, you have been warned.

You'll need to log in to post.