Project LS2 S14 at present:

img_4303 by eric.burnett09, on Flickr

img_4303 by eric.burnett09, on Flickr

Current mod list:

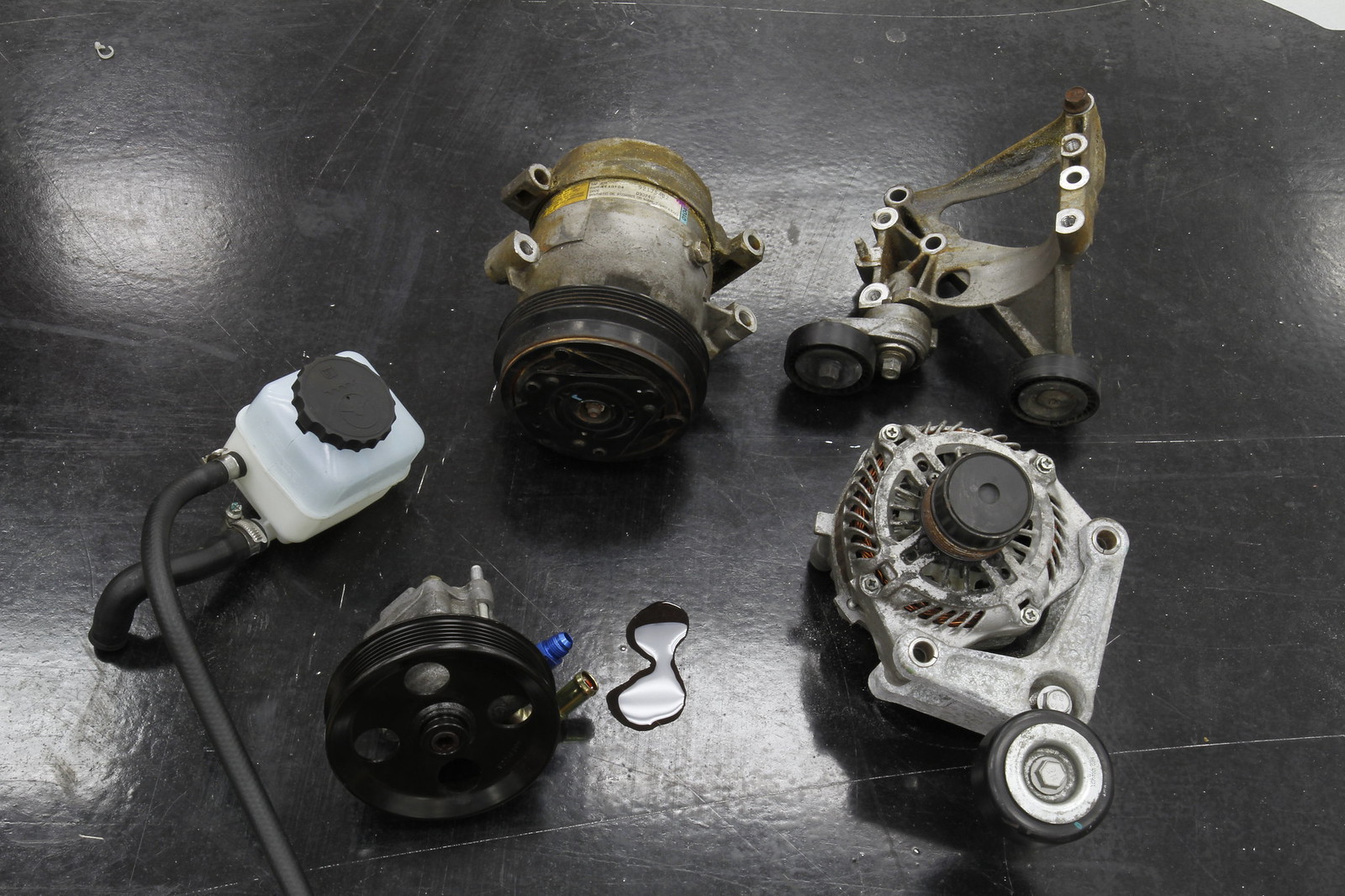

Powertrain: -LS2 engine rebuild by Richard Holdenor out of Cali-forged pistons and rods from CP and Carillo -Brian Tooley Racing Camshaft-Hooker S14 Engine Mount Swap kit-Hooker Stainless S14 LS 1 7/8'' swap headers, Y into 3'' single out with Hooker Aerochamber Muffler-OEM LS7 clutch/pressure plate from Scoggins Dickey -RAM flywheel (19 lb) -Engine Management: Holley Dominator EFI - Holley Billet LS Fuel Rails -Hurst T56 Shifter -CTS-V Front Drive Accessories-Street Elite Performance Clutch Master Adaptor Kit--K&N 4'' open element air filter-

T56 trans was recently rebuilt by American Powertrain with a race tolerance spec, it is now fortified with carbon synchros, billet fork pads, and heavy-duty slider springs. Torque is transferred through an OEM LS7 clutch mated to a 19-pound Ram flywheel.

Power Steering: -KRC LS Power Steering Pump- Earl's power steering cooler and Earl's lines and fittings.

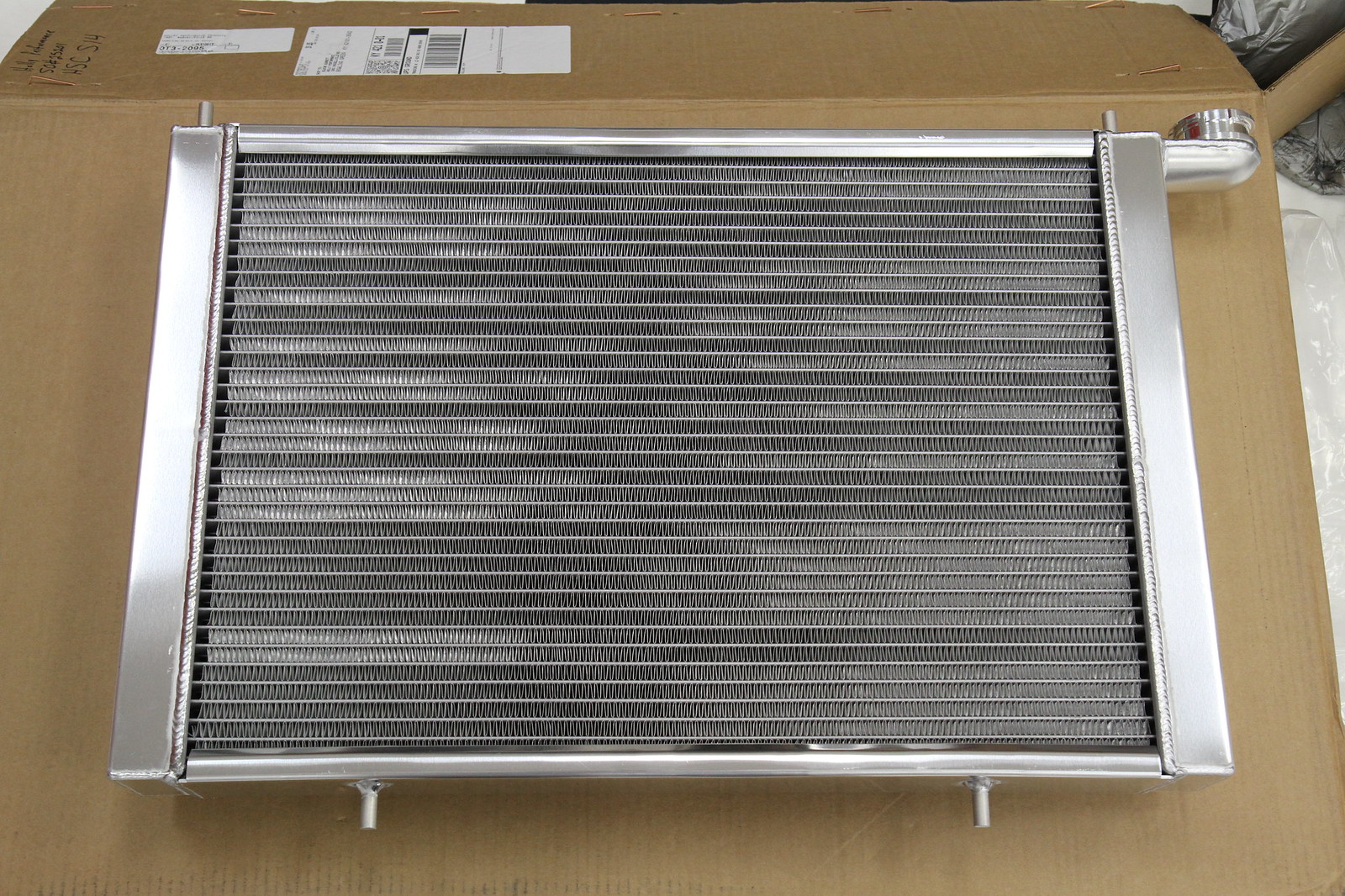

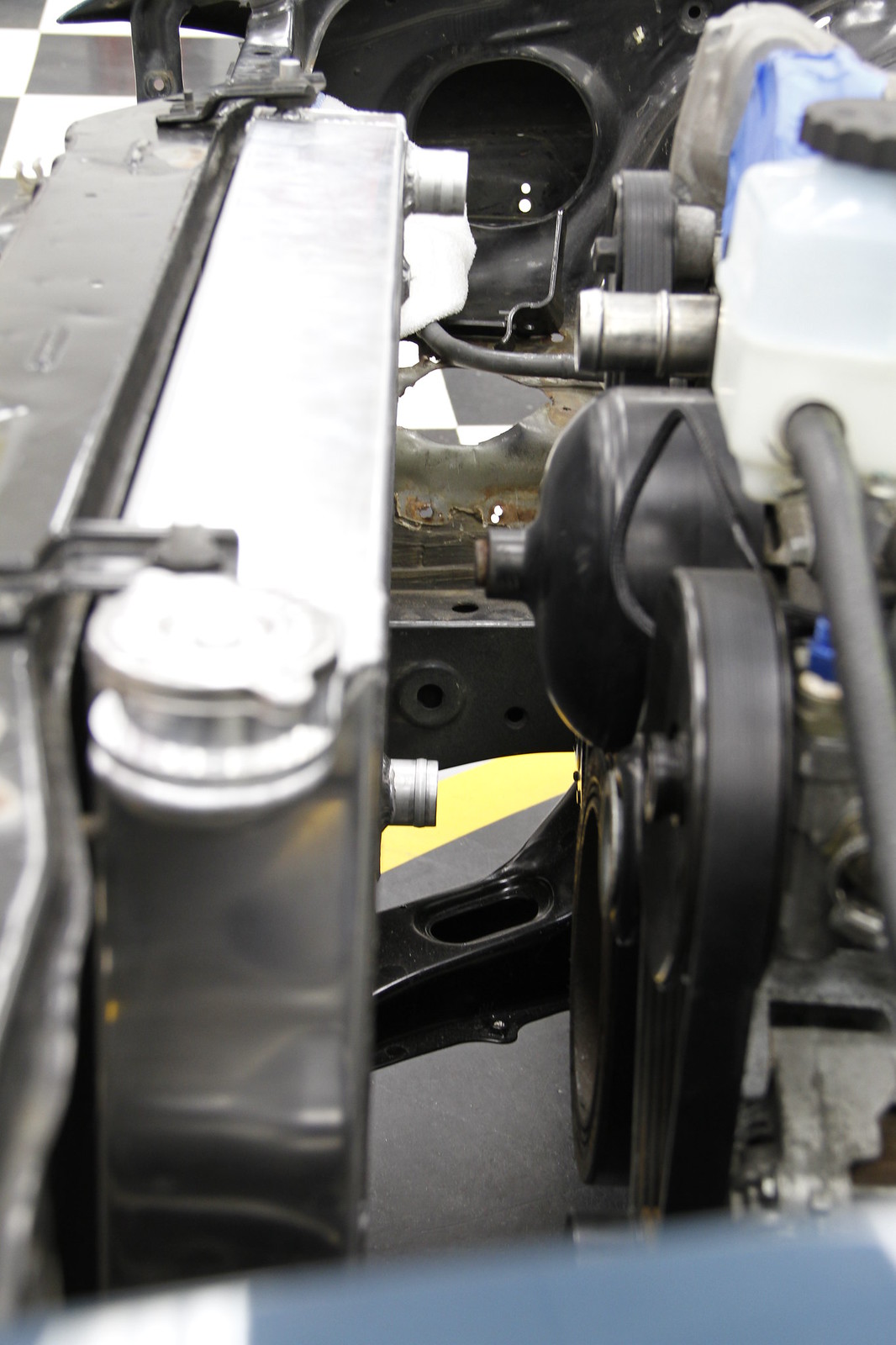

Cooling: -Hinson LS S14 Radiator kit- Custom fan shroud fabricated by Level 7 Motorsports out of Marion, IL. Single 15'' SPAL fan. Earl's oil cooler and Earl's Ultra Pro hoses and fittings.

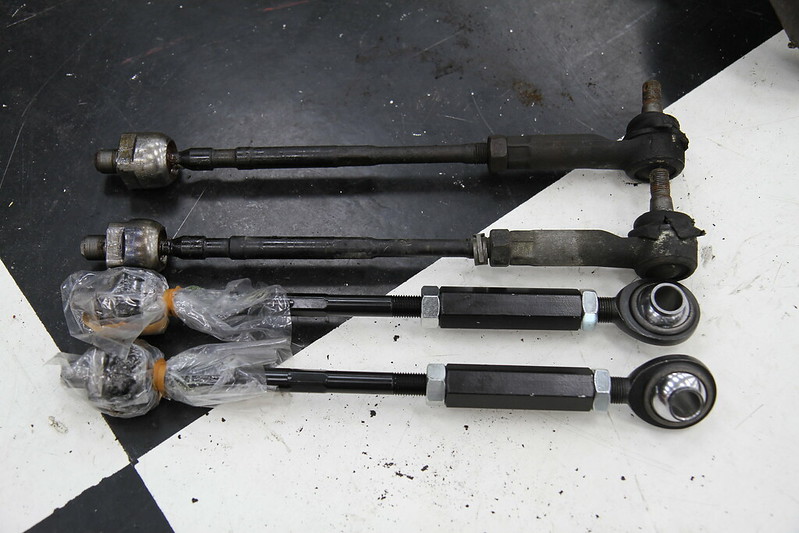

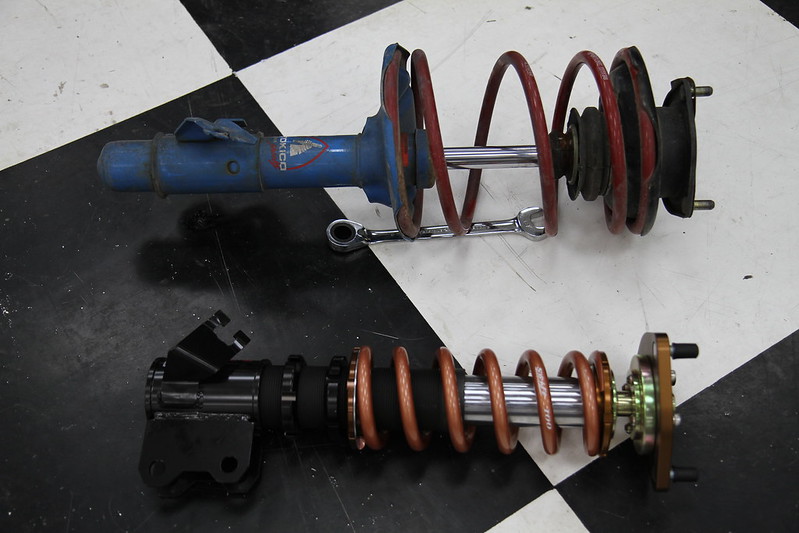

Suspension: -Driftworks Geomaster 3 drop knuckles front and rear - SPL tension rods- http://www.splparts.com/chassis-S14.html-SPL outer tie rods- -SPL rear eccentric lock-out -Feal 441 Single Adjustable Coilovers-Extended Travel version-Circuit Sports rear toe rods and traction bars (will most likely be going SPL on these before all is said and done. I had these laying around from my last car). New Setup: -Advan TCIII wheels Front: 18x9''+25mm with 10mm spacer. Rear:18x10''+35mm -Falken RT615K tires, square setup: 275/35/R18 Old setup:-275 section width Nitto NT-05's mounted on 17X10 FNO1R-C's in the rear 235 width NT-05's on the 17x 8 FNO1R-C's

Interior/Safety: -Autopower roll bar with bolt-in harness bar, welded extra material to floor to bolt it to for more roll over strength- http://www.autopowerindustries.com/rollbars.asp -Sparco Evo 2 seats with Planted Engineering seat brackets-Willans harnesses -S15 steering wheel (always like how nice those looked) -Racepak IQ3S dash behind steering wheel- Holley EFI touchscreen to monitor engine parameters, etc. installed where radio previously resided. -Racepak's solid state Street Smartwire PDM (power distribution module) unit has replaced the entire OEM body harness, reducing weight, removing the need for fuses and relays, and increasing the car's reliability overall.

*Read on below to see how things have progressed since the genesis of this project.* I've been scouring this site for quite some time, posting and learning as I go. I have finally reached the point it's worth showing what I've been working on for the last year or so. I've taken the time to take quality pictures of everything I've done so if what you see here doesn't take care of a question let me know and I'll see if I can help you out. It's been slow but I've been trying to build it the way I want it instead of what would've been more affordable. This car will most likely be the only car that I build for quite some time to have fun in so I want to enjoy it. I'll be using this build thread to show you all some new S13/S14 swap products from Holley as the build progresses. I had a white S14 for a while and it got totaled. I replaced it with the S14 below. It's a '96 and came with a S14 SR20DET swap in place and ran great until I pulled it out. Got it an hour and a half away down in Murfreesboro, TN. Owner reported it to have a broken trans. I had a spare, so I bought it, trailered it home, and discovered it was missing the bolts connecting the axles to the diff. Pulled them from the parts car and I had a perfectly running S14 SR car. After driving it for a while and dealing with multiple exhaust leaks due to the less than stellar intercooler piping job, and having to cross-reference parts with Nissan Sentras to get replacement parts I was ready to take the plunge on an LS swap. The plan is to end up with a car that can hold its own on the drag strip, road course, autocross, and still be relatively comfortable on the street for events such as Hot Rod Power Tour, Somernites Cruise, etc. I started working at Holley Performance Products after college and the bug for more displacement bit me even more. I found a buyer for the S14 motor which gave me what I needed to start the swap.

64447_724470857842_7953205_n by eric.burnett09, on Flickr

64447_724470857842_7953205_n by eric.burnett09, on Flickr

An LS2/T56 was sourced out of a wrecked 2005 GTO and the powers that be were gracious enough to let me use an area of the shop at work to get everything installed and running.

IMG_5703 by eric.burnett09, on Flickr

IMG_5703 by eric.burnett09, on Flickr

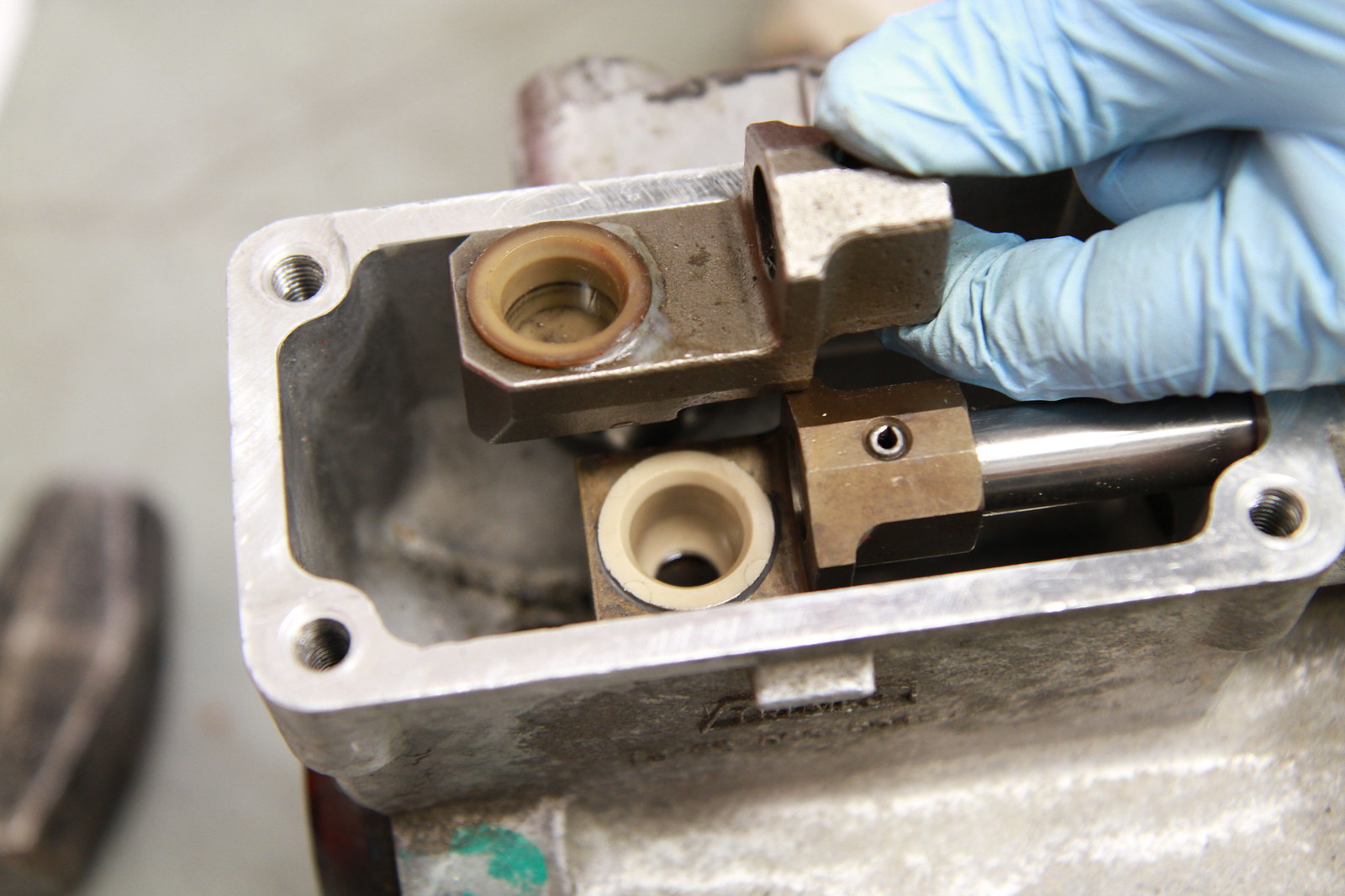

Before test fitting the engine it is necessary to remove the shifter. A good idea is to fit it with masking over the top of the mating surface so you don't scrape it on anything underneath the car. I also discovered that you can use an F-body shifter on the GTO transmission as long as you swap out the shifter receivers inside the rear of the trans as pictured below (this forum has awesome information). I got mine from www.thegearbox.org.

Here's the part # you'll need:

IMG_1635 by eric.burnett09, on Flickr

IMG_1635 by eric.burnett09, on Flickr

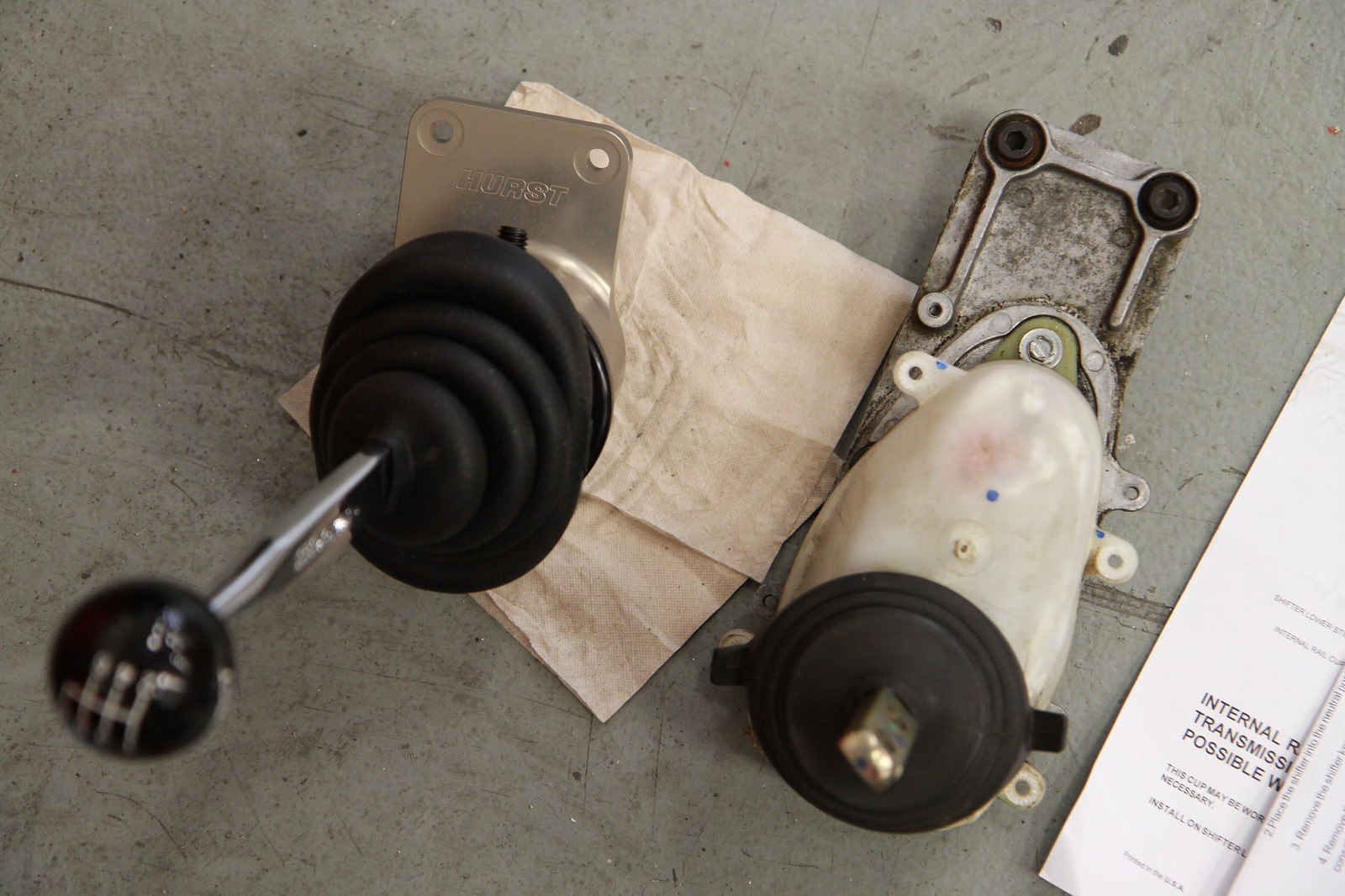

Old vs. new:  IMG_9506 by eric.burnett09, on Flickr

IMG_9506 by eric.burnett09, on Flickr

Hurst F-body shifter vs. OEM GTO shifter

IMG_9511 by eric.burnett09, on Flickr

IMG_9511 by eric.burnett09, on Flickr

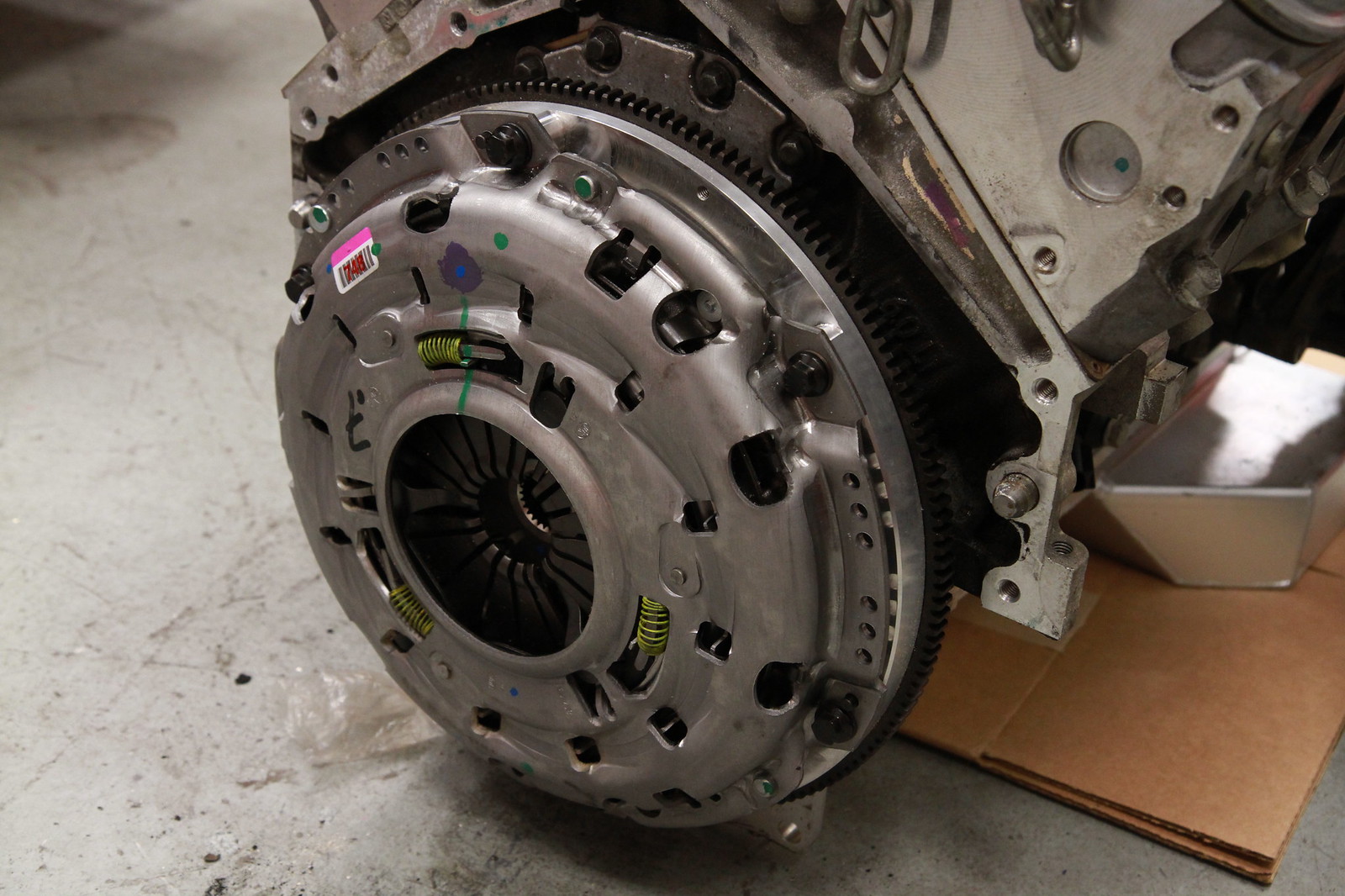

While the trans was out I went ahead and installed some new goodies I got from www.sdparts.com. LS7 clutch kit with RAM 19.2 lb. flywheel.  IMG_9420 by eric.burnett09, on Flickr

IMG_9420 by eric.burnett09, on Flickr

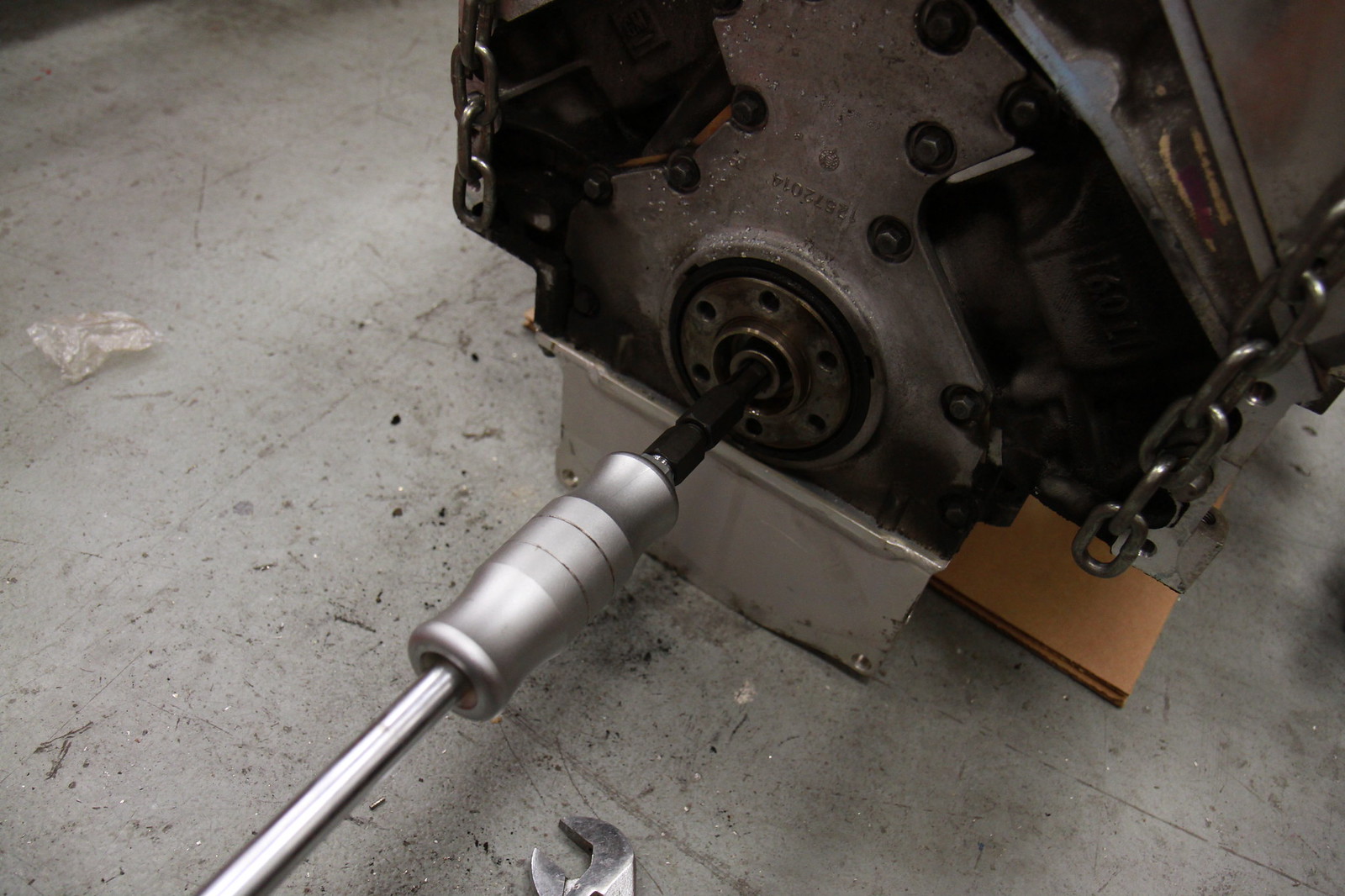

I removed the old pilot bearing with the following tool from AutoZone:  IMG_9529 by eric.burnett09, on Flickr

IMG_9529 by eric.burnett09, on Flickr

IMG_9527 by eric.burnett09, on Flickr

IMG_9527 by eric.burnett09, on Flickr

IMG_9513 by eric.burnett09, on Flickr

IMG_9513 by eric.burnett09, on Flickr

IMG_9527 by eric.burnett09, on Flickr

Then installed the new pilot bearing with this kit from AutoZone: IMG_9528 by eric.burnett09, on Flickr

IMG_9528 by eric.burnett09, on Flickr

IMG_9536 by eric.burnett09, on Flickr

IMG_9536 by eric.burnett09, on Flickr

Flywheel installed and torqued to the these values: 1st go round: 15 ft.lbs 2nd: 37 ft. lb. and 3rd: 74 ft lb.

IMG_9538 by eric.burnett09, on Flickr

IMG_9538 by eric.burnett09, on Flickr

Pressure Plate torque figures are: 1st: 7 lb ft. 2nd: 18 lb ft 3rd: 30 lb ft. 4th: 52 lb ft. Then you're done. If you're concerned about torquing the bellhousing back on correctly the torque spec is 37 lb ft.  IMG_9540 by eric.burnett09, on Flickr

IMG_9540 by eric.burnett09, on Flickr

The Clutch Master Adapter Kit from Street Elite Performance:  IMG_9850 by eric.burnett09, on Flickr

IMG_9850 by eric.burnett09, on Flickr

I took the opportunity to replace the throwout bearing with a new one (not pictured) while installing these lines. Make sure you get the lines tightened up enough because it's a pain to have to take the trans back off later and re-tighten them...say after you notice a leak and fluid from bleeding your clutch all over the shop floor....OOPS!!!:cry:

IMG_9808 by eric.burnett09, on Flickr

IMG_9808 by eric.burnett09, on Flickr

Next you have to transfer the rod from the OEM Clutch master over to the Wilwood piece because the new one is too short. Using snap ring pliers (hopefully better ones than I purchased), remove the snap ring holding the rod in on both masters and swap the rod out of the old one into the new one in the reverse fashion that you took it apart.

Do yourself a favor and purchase better snap ring pliers than these:

IMG_2599 by eric.burnett09, on Flickr

IMG_2599 by eric.burnett09, on Flickr

IMG_2601 by eric.burnett09, on Flickr

IMG_2601 by eric.burnett09, on Flickr

IMG_2595 by eric.burnett09, on Flickr

IMG_2595 by eric.burnett09, on Flickr

You should have something like this when you're done:

IMG_2606 by eric.burnett09, on Flickr

IMG_2606 by eric.burnett09, on Flickr

Wilwood Clutch Master Cylinder (included in Street Elite kit) installed:

IMG_9829 by eric.burnett09, on Flickr

IMG_9829 by eric.burnett09, on Flickr

That's all I have for tonight.

It wasn’t long until that ten millimeters fit just fine. These wheels are a +35 offset all around for anyone who’s curious. The main concern with rolling fenders is that you don’t want to crack your paint. It’s best to use a heat gun and a friend (father in this case) so that you can heat an area and then roll it. Repeat the process until you’ve completed an entire side. Then move on to the next. Just take it slowly and you should be fine depending on the condition of your cars paint and your ability. Testing for clearance throughout suspension travel after roll:

It wasn’t long until that ten millimeters fit just fine. These wheels are a +35 offset all around for anyone who’s curious. The main concern with rolling fenders is that you don’t want to crack your paint. It’s best to use a heat gun and a friend (father in this case) so that you can heat an area and then roll it. Repeat the process until you’ve completed an entire side. Then move on to the next. Just take it slowly and you should be fine depending on the condition of your cars paint and your ability. Testing for clearance throughout suspension travel after roll:  And a couple of shots before I headed home. Cannot wait until it's on the road!

And a couple of shots before I headed home. Cannot wait until it's on the road!