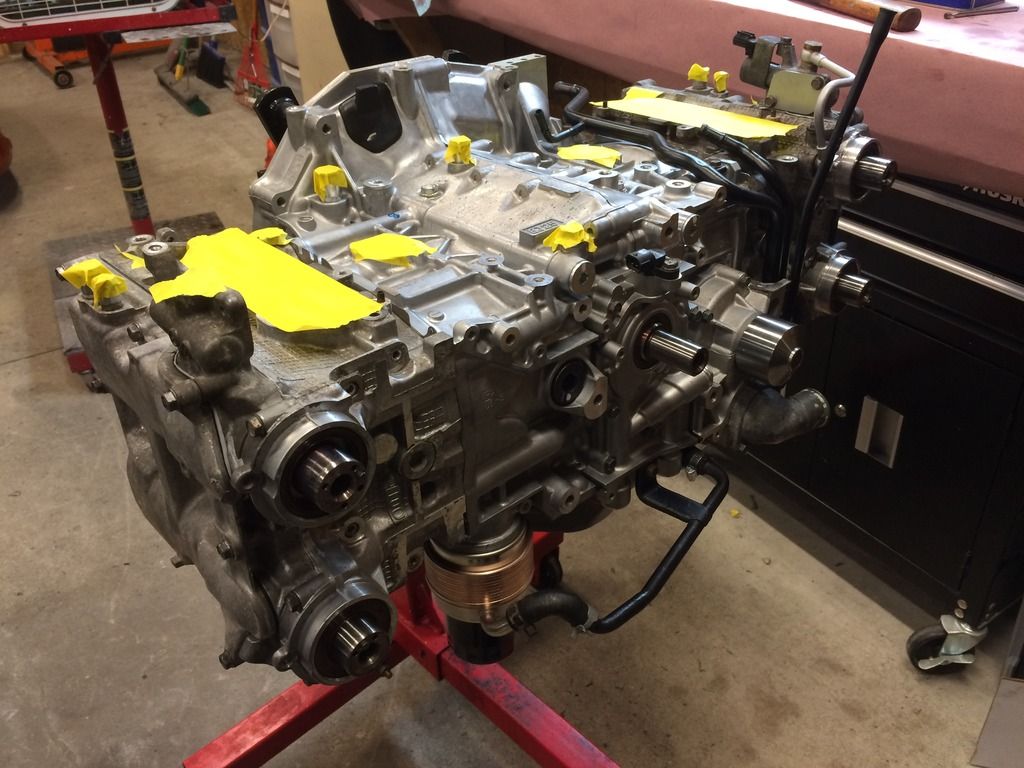

Using the old timing belt looped about various components, I installed the freshly cleaned cam sprockets. These are really torqued on there, so I was careful to make sure there wasn't any slippage. I used a paint pen to mark the torque angles specified by the service manual and went to town with a large breaker bar.

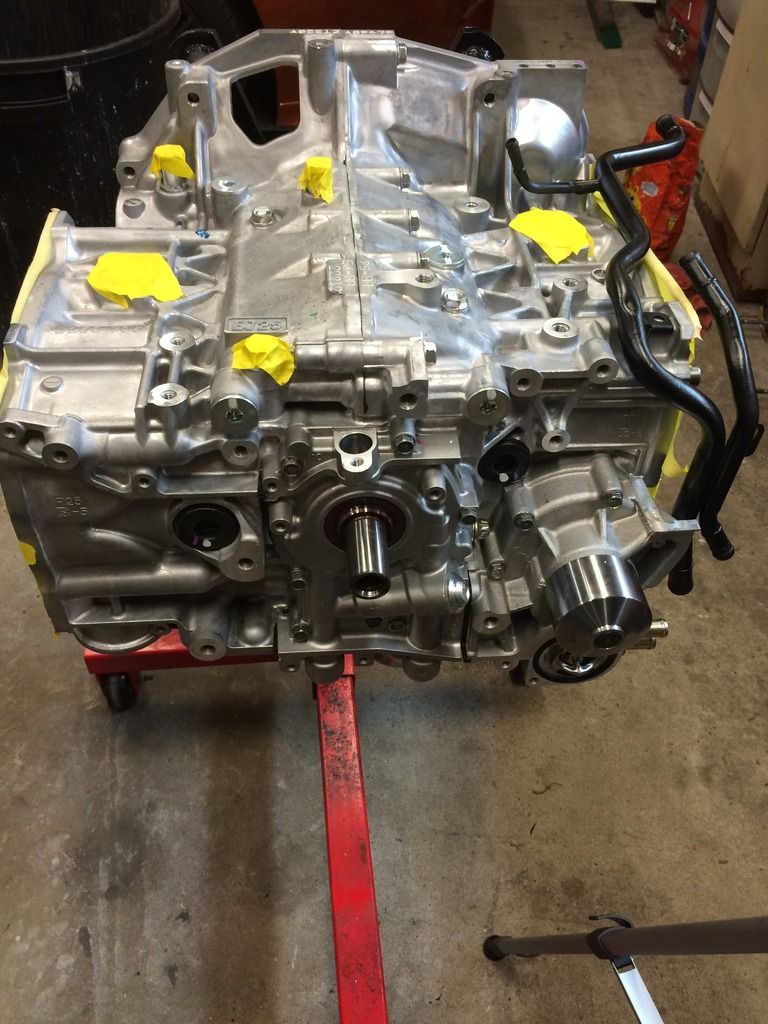

I then installed all the new timing belt tensioner and pulleys that were included in the Gates timing belt kit. I had installed the water pump early on when working on the short block.

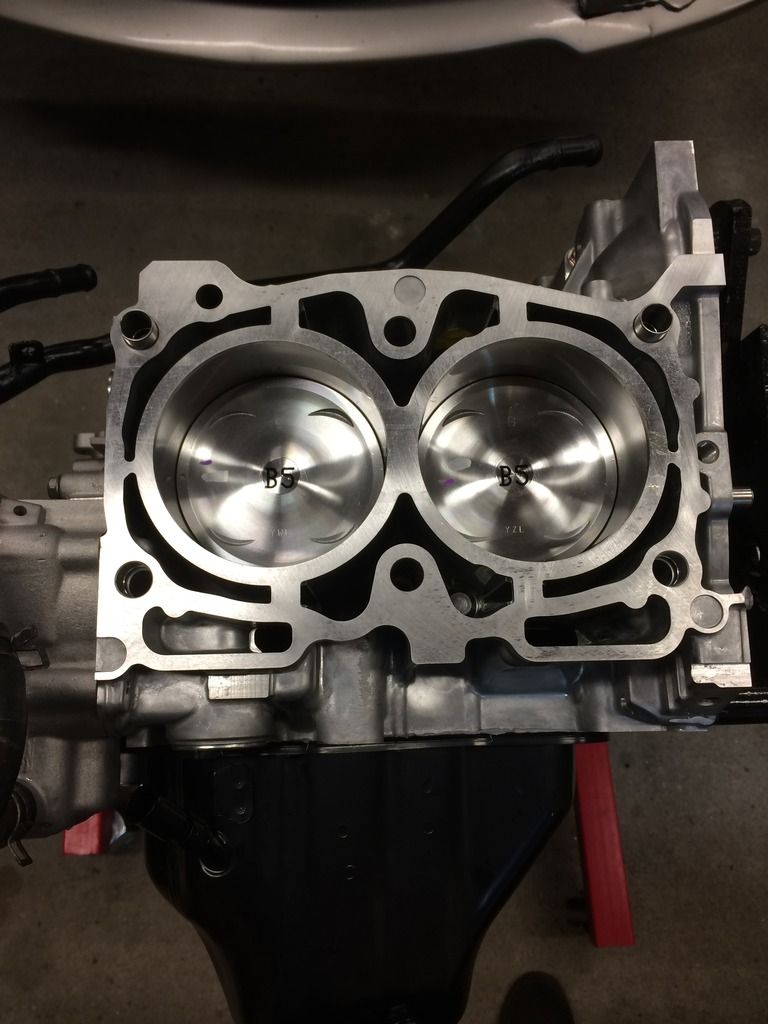

I triple checked that everything was aligned properly, sprayed a little oil down each cylinder, and then checked that the engine would turn over by hand. All good!

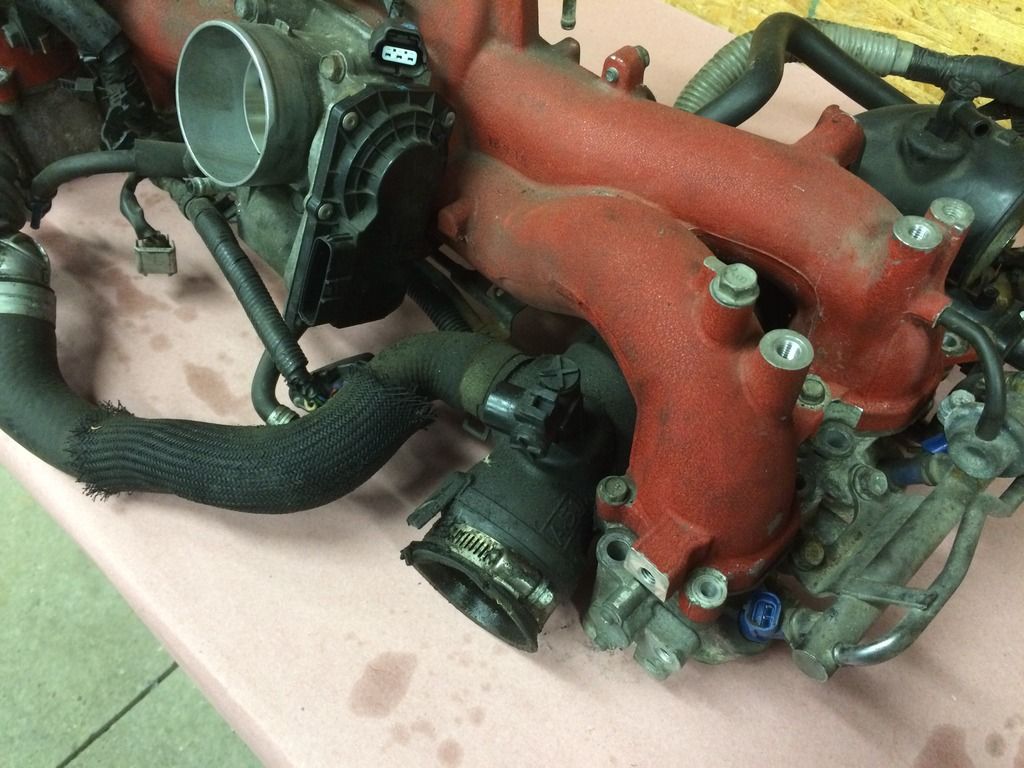

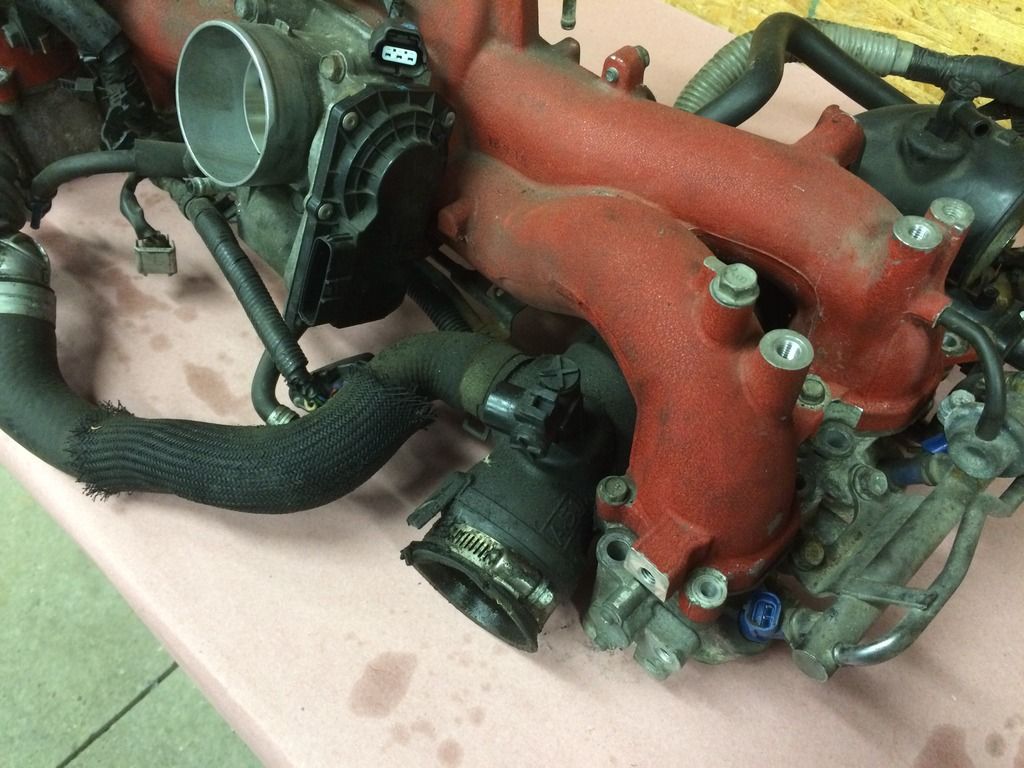

I was then ready to install the intake manifold assembly. However, it seemed a shame to bolt on years of grime to a very clean engine. I decided to disassemble it to clean, extract a few broken fasteners, and test operation.

As you can see, there is a lot more than just a simple intake manifold in this assembly. Included is the throttle body, four tumble generator valves, TGV motors, fuel rails and injectors, a wiring harness, and a whole bunch of rubber hoses and ducts. It was a mess. I started by disassembling everything.

Removing the actual intake manifold was easy enough, but some of the small bolts were corroded and snapped off. You can probably spot a few of them in the following picture of the TGV/fuel rail assembly.

Essentially what you have here is 4 separate butterfly valves. Each bank is individually controlled by the attached motor. Somebody more versed in emissions controls can probably explain the purpose of all these additional points of failure better than I.

I removed all the fuel lines, injectors, and rails. I cleaned them all meticulously, installed new gaskets on the injectors, and set them aside. I then tested the TGV motors to verify that they were working properly. Once satisfied, I cleaned all four TGV valves and the motors. I cleaned the intake manifold thoroughly and then replaced all the rubber hoses. I removed all the old tape and plastic that was falling off the wiring harness and rewrapped it almost exactly as it left the factory. Satisfied that everything was new and/or clean, I reassembled the whole thing and set it aside.

I realized that the large air duct going to the turbo was slightly torn. I decided to replace it now, as it would be a major pain to get to once installed in the vehicle. This is one big piece of hard plastic and molded rubber which was kind of annoying to replace as it wasn't cheap.