mndsm said:

No, but I'm pretty sure you had another nova was way earlier in challenge history, and I'm pretty sure it was that nova that made me read grm.

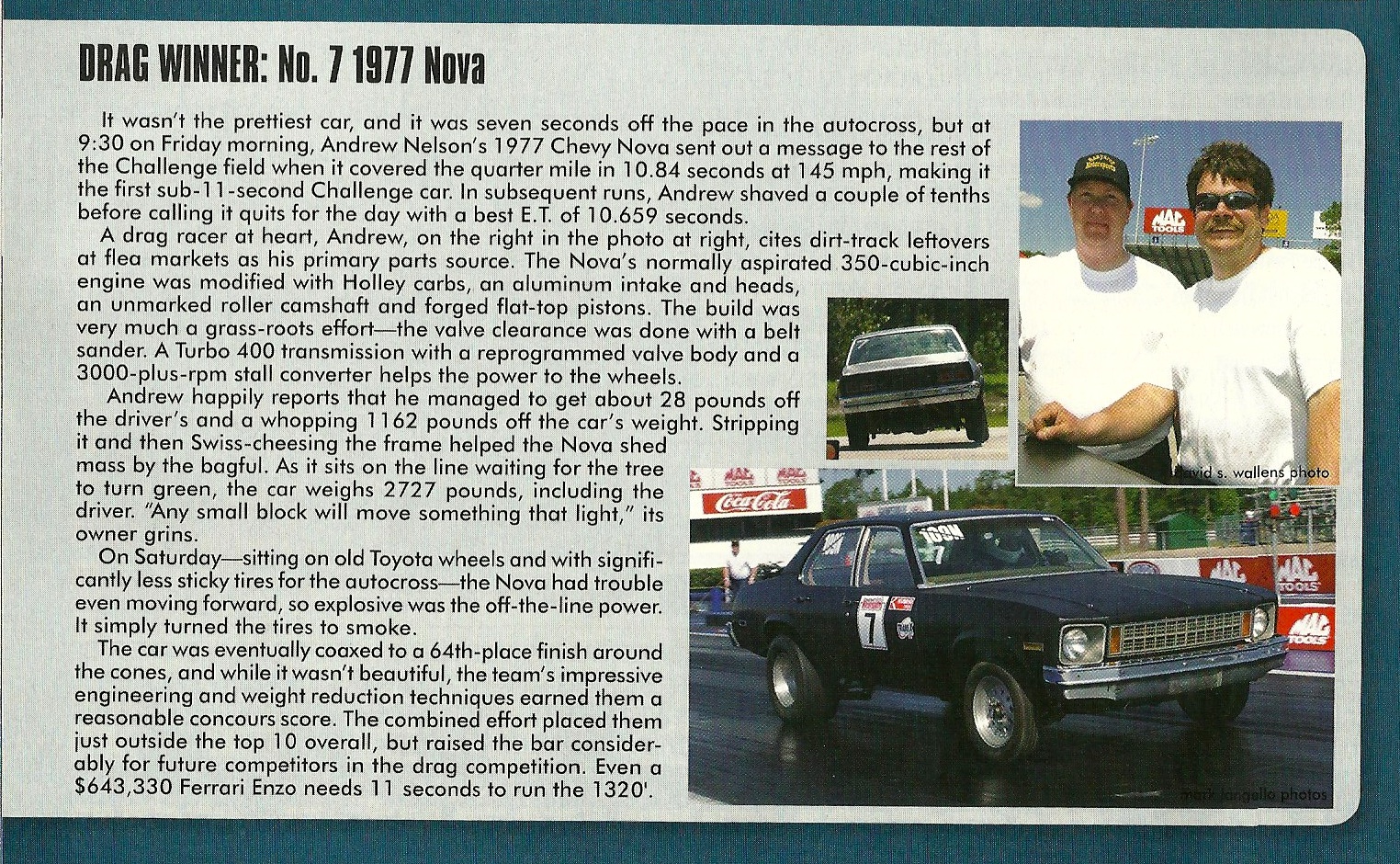

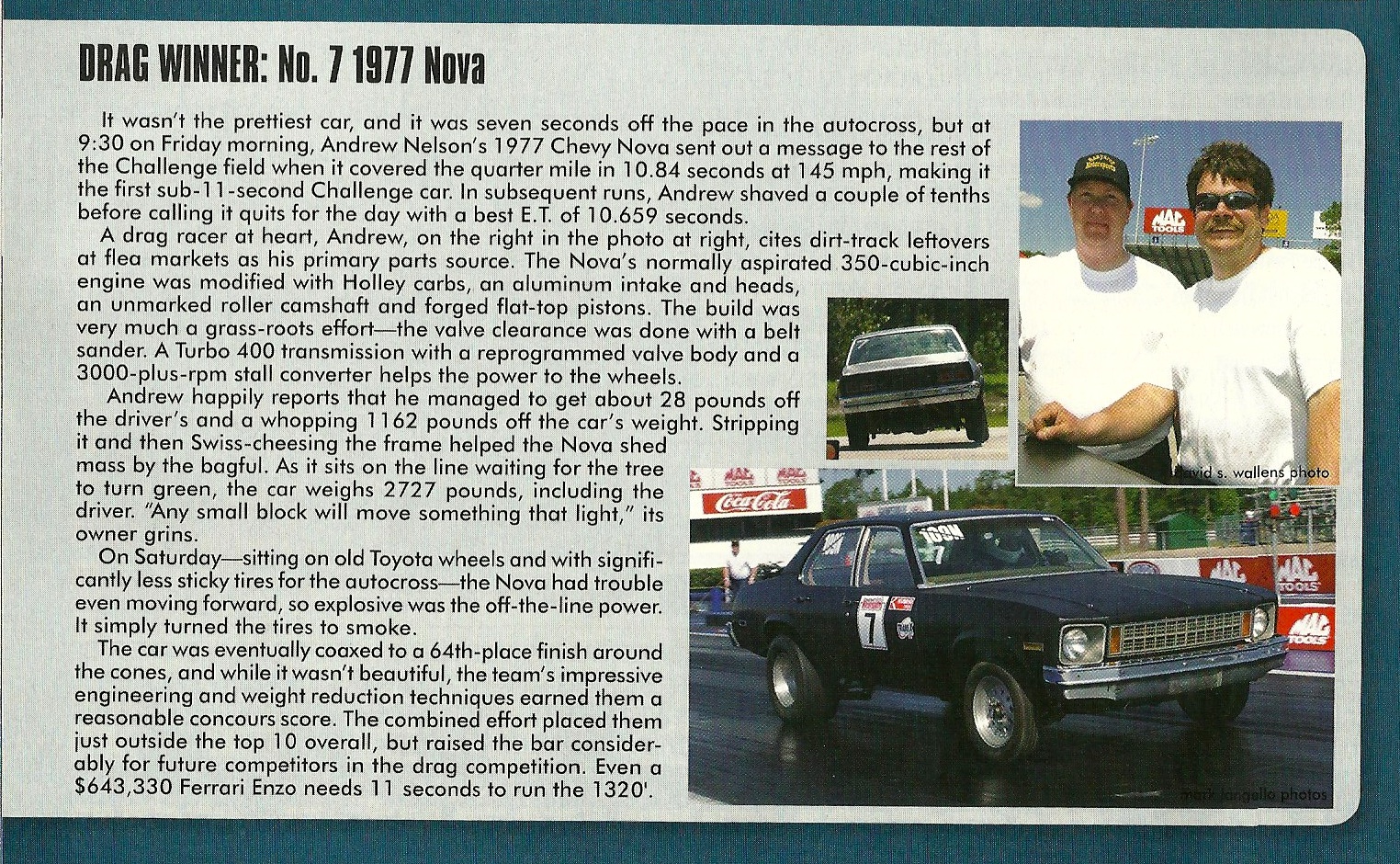

That's cool! We brought the 1977 Nova More-door to the $2004 Challenge. It was known as the "Tetanus Express ".

mndsm said:

No, but I'm pretty sure you had another nova was way earlier in challenge history, and I'm pretty sure it was that nova that made me read grm.

Me too, my first car was a ‘75 Nova 4 door I got in ‘01. At the time (and rarely today), no one was doing anything with that gen x-body, especially 4 door, so a huge inspiration to me.

Carson said:

mndsm said:

No, but I'm pretty sure you had another nova was way earlier in challenge history, and I'm pretty sure it was that nova that made me read grm.

Me too, my first car was a ‘75 Nova 4 door I got in ‘01. At the time (and rarely today), no one was doing anything with that gen x-body, especially 4 door, so a huge inspiration to me.

Two thumbs up!!! We are more-door fans and orphan fans (Studebakers, Henry J, etc.).

From my point of view, I think most GRMers are car enthusiasts first with a brand loyalty second. But the brand loyal purists are sprinkled into the mix.

I forgot you had this. I cannot wait to see a full-tilt Nova build from you guys! And that fiberglass front clip was a steal and a half!

My father in law had one of these when my wife was born. I just told him about it. He's excited to see where you guys end up.

So, here's the plan. The car is about half way done. We normally like to keep our cars under wraps until the challenge, but we decided to go public with this particular build. Given PACC Racing's history with Novas, we figured you guys would get a kick out of this one. Plus, we have other cool surprises in the works for other future challenge cars.

Therefore I will release one day at a time. until we catch up to current. Challenge Nova 2.0 is a go.

Day 1 - October 15, 2016

Pulled subframe and cut firewall. This is what the firewall looked like when we got the car, and is why the Nova was $50.

Day 2 - October 16, 2016

Began welding front subframe to body. Used 2 pieces of box tubing at 2#-8.2oz each @ $0.25/#. Moved frame up in body to lower the car and retain original suspension geometry.

Day 3 - October 17, 2016

Began cutting out spot welded flanges in A pillar area. Removed 3 mouse hotels from the rocker panel boxes. Nasty Nasty.

Day 4 - October 20, 2016

Trimmed cowl area and removed the frame mounts.

Is it wrong that I'm looking at that and thinking about how I could weld a fwd vehicle and a trailer together?

In reply to Stampie :

Wrong? No

Weird? Yes

But that's ok. We like weird.

In reply to TheV8Kid :

And that's why I like you guys. Helps that you're nice also.

Day 5 - October 22, 2016

Removed rear differential. Began mini tubbing left rear wheel tub.

Thanks for the assembly pictures. Is the point of permanently attaching the front subframe to the rest of the car to strengthen the whole thing when a cage is attached? I need to spend more time looking at the details of your cars next year and asking questions.

mazdeuce - Seth said:

Thanks for the assembly pictures. Is the point of permanently attaching the front subframe to the rest of the car to strengthen the whole thing when a cage is attached? I need to spend more time looking at the details of your cars next year and asking questions.

Strength and being able to keep functional factory suspension geometry while lowering vehicle. Think of it as a body drop. Otherwise any sort of drop springs just limits travel by that amount or more. Plus if you're planning to weld in a cage and subframe connectors on an F/X body it's very silly to leave rubber bushings between the frame and floor before welding everything up.

Patrick said:

mazdeuce - Seth said:

Thanks for the assembly pictures. Is the point of permanently attaching the front subframe to the rest of the car to strengthen the whole thing when a cage is attached? I need to spend more time looking at the details of your cars next year and asking questions.

Strength and being able to keep functional factory suspension geometry while lowering vehicle. Think of it as a body drop. Otherwise any sort of drop springs just limits travel by that amount or more. Plus if you're planning to weld in a cage and subframe connectors on an F/X body it's very silly to leave rubber bushings between the frame and floor before welding everything up.

What he said. Plus the front factory subframe mounts are gone. The firewall in the car has been moved back about a foot. Engine setback as you will see soon is 8.75 inches. More weight to back tires = more traction at launch. Plus it should handle better too.

As you see the cage come together, you will see the unitizing of the whole chassis. Give it time.

Old Firewall location:

New Firewall location:

The firewall was so hacked, we basically had to remake the whole thing, so why not do an engine setback while we were at it.

mazdeuce - Seth said:

Thanks for the assembly pictures. Is the point of permanently attaching the front subframe to the rest of the car to strengthen the whole thing when a cage is attached? I need to spend more time looking at the details of your cars next year and asking questions.

Rubber bushings are HP magnets. The system (the car) has the unload and reverse load the bushings on launch. By making everything stiff all the power is used to accelerate the car. Then you use your springs, dampeners and tires to tune the system (the car) for maximum traction with minimum pitch rotation.

We also took the time and effort to raise the subframe 1-1/2" up into the car to lower the car body and maintain the suspension geometry.

Thanks for the explanation. I don't have anywhere near the experience to think of these things early on in a build. I'm always impressed by (what appears to be) the clear vision you guys have when starting with a bare shell.

In reply to mazdeuce - Seth :

We have a couple of builds under our belt. Let's just say, we've learned what not to do.

I forgot about the Swiss cheese Disco Nova.

For those of you who are out of the loop:

So I was thinking, there seems to be a whole lot of stuff (fenders, radiator, grille, bunch of shiny stuff) that's now 1.5 inches higher than the middle part of the car. Is it as simple as moving the core support down? Or are you fabricating that anyway due to the fiberglass front end?

In reply to mazdeuce - Seth :

If we were going to use the original core support, yes it is as simple as notch the core support and move it down. In our case, we are going to fabricate all that stuff. You'd have to mess with your bumper brackets too since that mounts to the your frame as well. Also, you'd lose some hood clearance. There are a lot of things to consider, that we are simply re-engineering.