That's such a neat trick for tube fit-up! Definitely filing that one away into my memory.

¯\_(ツ)_/¯ said:captainawesome said:It's too bad you can't send that pipe to the passenger side. Is it possible to build or modify the stock water neck to exit the other direction similar to the K swap layout?

Certainly could, or even weld something up to make it go through the valley under the intake- ultimately I decided that the solution that doesn't have any welds on cast parts or more complex fabricated bits was probably the simplest.

I like the thought process there. Also, technically extra fluid capacity with a longer pipe, and that's not a bad thing.

¯\_(ツ)_/¯ said:captainawesome said:It's too bad you can't send that pipe to the passenger side. Is it possible to build or modify the stock water neck to exit the other direction similar to the K swap layout?

Certainly could, or even weld something up to make it go through the valley under the intake- ultimately I decided that the solution that doesn't have any welds on cast parts or more complex fabricated bits was probably the simplest.

I like the thought process there. Also, technically extra fluid capacity with a longer pipe, and that's not a bad thing.

The backyard engineer who has broken a lot of stuff in me thinks that's a lot of overhung weight levering against the water outlet and would like to see the tube broken up with a hose somewhere near the back. Or more sturdy mounting. (I can't tell if the hose in the initial fit up is a temporary hold-it-here fixture or a permanent part of the plan)

It'd suck to crack that at a rally.

In reply to Pete. (l33t FS) :

The tube at the back of the heads? There's another P clamp spot back there near the coupler, should be ok.

Wait are we talking about the new pipe or the stock water neck casting?

I see no problems with how you've supported all of that. It looks great too. I did far, far worse things to the Free Europa's 2GR coolant plumbing.

Could there be room for a silicone 180deg bend piece on the outlet at the back to bring the tubing around the other side of the engine? The 180 would add some flow resistance but it would also remove 2 90deg bends.

I cut the whole middle of the firewall out, there's room for anything! But, I don't think the flow will be a big issue since these do fine in Evoras and MR2s with an extra 10ft of tubing and whatnot.

After careful consideration, I decided the whole shifter was too close to the driveshaft and moved that part of the tunnel up:

I'm leaving the weird step at the back of it for the moment, seems like it may actually come in handy to mount something in a way that elbows won't get smashed later. We'll see.

I failed to take pictures of the fitup around the water reroute, but I made some more firewall based on that after pulling the engine again- just waiting on my access panel from sendcutsend and I can finish this:

Then, I went to the back of the car to stare at something else- I've always disliked the huge parking brake and near-useless internal vanes on the BRZ rear rotors, and the L2wd car goes through rear pads at an alarming rate, so I got this WRX rotor to try:

The parking brake drum bit is a good amount smaller, which is fine since I plan to use the hydraulic handbrake instead, and the offset is slightly different, but the cooling vanes actually have an inboard area to get some air from and it fits great with the 2 piston WRX calipers I'm planning to use, provided I do something with the backing plate:

If we look from the back, it's obvious that I've only used one bolt to attach it, but I think this spacing actually works out such that I can make a combination adapter/shield/wheel scraper mount that just attaches to the lower one. There are adapters on the market but they all use the BRZ rotor, and none of them include all the little other things I'd like to have here because this is a rally car:

Hi, I had to make an account to say this build looks sick, and hopefully fish for some information. I'm actually in the process of swapping a 2GR-FSE into my 1IS, and through a miscalculation of a unicorn part, have ended up attempting to use the TL70 from the BRZ/86. I stumbled into this thread after having already gotten a transmission, and fortuitously found most of the information I needed. But I was hoping you might have a contact at SPEC or more info on your flywheel, so I could have one made? And if you can confirm the thickness of your adapter plate. I'm going to have to have a custom one, and it will differ from what you needed, but the thickness piece of the equation was helpful to find.

I saw some CAD stuff in the early posts about an oil pan, do you have something made yet? I'm curious what solution you came up with.

I'd also like to offer a little transmission context for anybody coming through who may be curious, as I've spent a lot of time on it the last several months. The transmission in the BRZ/FRS/86 is the TL70 variant of the Aisin AZ6. This is a new variant for this chassis, but as mentioned, AZ6s have been used in many other chassis through the years. However, it was not ever paired with a GR engine. It was used in first generation IS200s, and Altezzas in other markets, but not in the IS300 available in the US. The 2008-2012 (I think) second gen IS250 was available with a 6 speed as well, which is the RA62 variant of the AY6 transmission. Completely different transmissions, and likely what OP had, although I think he would have the same fitment issues, given the bellhousing pattern differs from the RWD GR engines to the FWD variants. The reason I'm here, is because the RA62 is basically non-existant, and terribly hard to find, while the TL70 is a $500 transmission available down the street. And the gear ratios are very close.

In reply to Stockish :

PM me and we'll get a detailed conversation going on this stuff, but here are some quick answers:

Spec flywheel PN should be SU20S-2GR, although it's worth mentioning that I haven't really proven this works yet. If they act confused I'll get you a contact to talk to.

Adapter plate is 1.344" thick.

Oil pan is ongoing, friends are helping me out with that one since I don't have CNC access- it'll be a machined upper and a welded lower piece and probably won't make sense anywhere that didn't previously have a subaru engine.

Well, the first of the "off-the-shelf parts I had hoped to use but couldn't" has arrived. The Frankenstein Motorworks stainless cast manifolds look awesome, but the driver side wants to share space with the steering shaft support:

As much as I'd love to just cut stuff until this fits, I really don't want the exhaust and the steering this close together and there's no real reason to package the header this way on this car, so my backup plan of some other V6 headers and 2GR flanges and cutting and welding is now being kicked off instead.

Got my sendcutsend order so I guess I'm ready to finish the firewall. This thing is steel with a 1/8" aluminum cover plate I failed to take a picture of- seems like it should let me reach the things I need to reach through here, which will hopefully almost never happen:

An important clearance check indicates this is big enough:

check Z32 rear calipers too I'll have to get some measurements for you as those lugs are deeper so it may help with fab. brb in 10

Zap, then arts and crafts template time, cut some metal, bend some metal, then zap more and we have a firewall:

I did all of the welding with the cover plate installed to minimize warping- the excessive number of fasteners are intended to keep it from coming off in a crash bad enough to move the tunnel, but they also keep it nice and stiff when installed.

I'm pretty happy with how this came out:

And paint:

While the paint was drying, I messed with some adjustable trailing arms. Laser time!

So, with the 25mm lowered trailing arm mount point, a trailing arm adjusted about 9mm longer than stock gets near-zero toe change across the full travel. Neat! I locked the setting in and marked the arm accordingly:

I don't like how much thread is sticking out at this length, and I have another set of tabs to weld to a subframe for 50mm of trailing arm mount drop, but this is progress and tells me I'm in the right ballpark. Once I confirm the approximate length with the other trailing arm tabs, I'll chop up and modify the arms to be a little longer and beefier.

Once the paint dried I plopped my seat back in in the intended position:

Not much further back to go from here:

Steering being the next thing, I first liberated the "rally steering column support" from the factory dash bar. Most OEM parts have a racing part hiding in them if you just use enough sawzall and cutoff wheel to find it:

Ok yes I'm definitely sitting a little too far away now:

So I cut that up a bit more and zapped a piece of rectangle tube into it to get things in the right spot:

That'll get a mount to the cage dash bar when the time comes. I also added an angle iron support for the steering quickener, although I'm becoming increasingly skeptical of the idea of using it. We'll see, good to have the option:

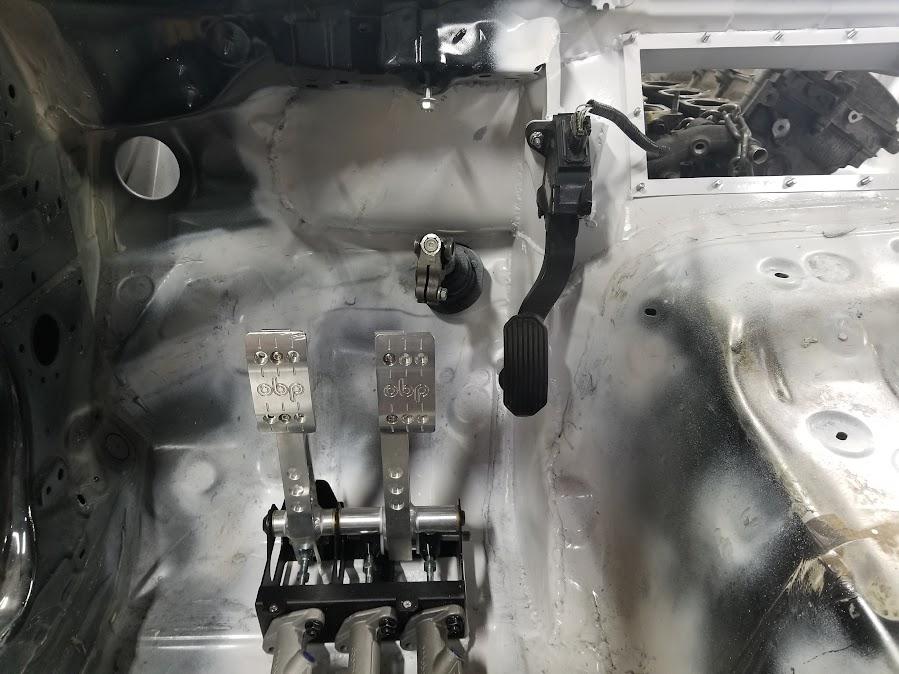

Then I stared at the pedal box a lot. Clearly it needs to go about here, but things like the angle relative to the floor and the seat seem easy to screw up so I want to make sure I'm relatively happy with the plan:

I think I'm going to do something like this with the drive-by-wire pedal- probably needs an extended pedal face to make heel-toe easier, but this packaging would be a lot simpler than trying to put it down on the floor. I do have a couple pedal options, the Sienna pedal looks best for this layout:

Pedal box base welded up and welded in- I hate welding stuff to this floor, it loves to blow through, but this little thing lands right on the top side of the unibody rail where it ties to the front subframe support under the car so it should be strong. I may tie it in further once the cage has been welded in, but don't want to put any ties to the rocker right now since they'd probably go right through where the front cage foot wants to be. I used my MR2 as a reference for spacing since those are the pedals I'm most comfortable with.

The one stud in this setup is for alignment, and because the floor interfered with a weld nut there:

Time for the other pedal. I decided it'd be cleaner to mount the Sienna DBW throttle in its' intended orientation than to flip it (or the RAV4 pedal I have as an option) over and/or adapt to the pedal box. The mount ties to the tunnel and the steering column support on the firewall, plenty stiff for what it needs to do. I welded the lower stud in but left the upper as a nut and bolt in case I need to shim it to fine tune the fore/aft placement later:

And made an adjustable stop with a weld nut and a bolt with a washer welded to the head- DBW throttles hate going past 100% so this should be helpful to dial in the proper travel:

Paint:

And there we have it, minus the false floor that I'll have to make at some point in the future:

Very comfy for various rally car footwork, although I may make it an extended face to make it even easier to hit with a heel in bumpy braking zones:

After all the pedal stuff, I "rewarded" myself with an exhaust project- after discovering that the Frankenstein manifolds wouldn't clear, I purchased a set of 2GR header flanges and a cheap pair of scratch and dent VQ headers on ebay:

After an immense amount of cutting and welding, I ended up with this:

The header had to be angled outwards by extending the front cylinder's tube, and then the two cylinders behind that had to be brought closer because the port spacing on the VQ is wider than the 2GR by a bit. Amusingly, this brought the staggered lengths of the original design all into the 17-18" range so I accidentally made it a nearly equal length header.

Then I did it all again on the other side, which proved to be more difficult even though I'd made myself a "kit" of cuts on my way through the first- I don't think they were actually perfectly mirrored to start with. Now I just have to figure out how to get these turned around and packaged; I think using the empty space down low next to the block makes sense for the catalysts, it'll be tight but I'm certainly not putting anything else in that spot so it'd be a nice way to tuck things where they won't get hit. If I can't fit the cats there maybe I'll add some tiny resonators instead, since things like that seem to be more effective the further upstream in the exhaust they are.

You'll need to log in to post.