Hello Everyone

Long time lurker , first time poster. I never posted about my projects till about a few months ago. I realized I need to document what I'm doing, at least for bookkeeping sake. I started a build thread on ClubLexus and Supraforums, since the platform is a Toyota/Lexus. But I figured I should be really posting here, since the car is going to be track focused after all.

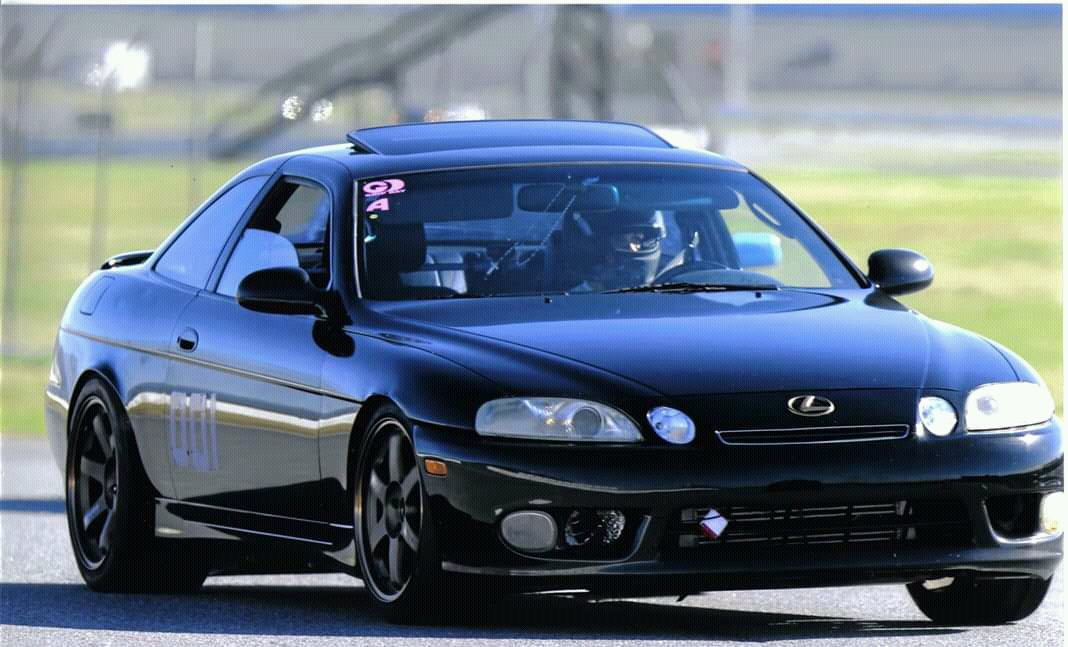

The car is a 98 SC300. It has a list of modifications already:

- Built 2JZ short block (rods, pistons, bearings...etc)

- VVT i Head with springs and retainers

- Borg Werner 8375 S300sx Turbo

- R154 5 Speed conversion

- Fuel Cell

- Full Re-wire

- AEM EMS

- Bosch 044 Fuel Pump (for now)

- 6 piston calipers brakes (porsche calipers, ISF rotors, brackets...etc)

- Turbo Supra LSD

- AC-Heater Delete

- Other supporting mods like oil cooler, PS cooler, fuel lines& rail...etc

The driver is meeeeeeeeeeeee ![]() Aerospace Engineer with 2 toddlers and an insatiable love for speed. I work as a stress analyst but after work....I'm a "hardcore" DIY enthusiast. To give you an idea, I made a carbon fiber hood from scratch (mold, layups, vacuum bagging...etc) without having any background in composites. This was before Youtube had any tutorials on how to do any of that lol Details here https://www.clublexus.com/forums/sc-1st-gen-1992-2000/550751-the-latest-of-my-insanity-home-made-hood.html

Aerospace Engineer with 2 toddlers and an insatiable love for speed. I work as a stress analyst but after work....I'm a "hardcore" DIY enthusiast. To give you an idea, I made a carbon fiber hood from scratch (mold, layups, vacuum bagging...etc) without having any background in composites. This was before Youtube had any tutorials on how to do any of that lol Details here https://www.clublexus.com/forums/sc-1st-gen-1992-2000/550751-the-latest-of-my-insanity-home-made-hood.html

Everything I post here was/is/will be performed by myself.

Most of the modifications above were performed between 9-12 years ago. Since then, I mainly focused on graduating, career, getting married, kids....etc Basically life took over . I recently just started getting back to it and wrenching on the car. It is difficult to do a lot when 2 toddlers are involved, but I do enjoy it.

My objective is to develop a time attack car. The car is not street-driven anymore (although it's still registered). My approach is to start from the front and work my way to the back in the development process. I'm going to avoid making compromises regarding street vs track use. If any, the scale will be tipped heavily in favor of track use. Still I'd like to drive the car every once in a while in a non-track setting.

My plan is do a full iteration to address/restore any mechanical modifications related to Engine, Drivetrain, Fuel System...etc. Then, address Suspension and Chassis. And Finally, address my Aero (BIG PLANS HERE).

Here's what the car looked like before;

Auto Club Speedway, Fontana

I'm going to condense posts I've made, the last couple of months, on other forums, first, for bookkeeping purposes.

Will change it later

Will change it later