madmax98 said:

On another front, I started my sunroof delete.

I initially I thought that black trim (where the bolts are inserted) is metal. Upon further inspection, It seemed to be some kind of fibrous plastic composite.

Out went the composite panel and sunroof frame.

The composite panel, alone, still weighed over 9 pounds, so I decided to do some lightening :)

I was disappointed to see it weigh just under 6 lbs. That was a lot of work ... nasty work.. I was itching for a couple of days (there's probably some fiberglass in there).

Installed

Then comes the hard part: Making a fill panel instead of the heavy glass sunroof. I was kind of torn between a light lexan duplicate, or a carbon panel. I ended up decided on going the carbon route. To me there's no point of the lexan unless you really can't do without the sunlight shining on top of your head while you drive. In Ca, most people end up using the sunroof shade to block it (at least I did). So... what's the point ?! lol

Anyway... I started to make the mold. In an effort to not damage the original sunroof panel, I wrapped it with vinyl (the kind you wrap food with).

That didn't work out so well because the vinyl did stick enough to the glass. It ended up sticking to masking tape. Additionally, it formed bubbles near creases or edges of the rubber gasket. I tried to remove the rubber gasket but it wasn't a removable part (it was sealed with urethane).

So I took off the vinyl wrap and waxed the sunroof panel well. I then taped over the rubber part to further protect it from the gelcoat.

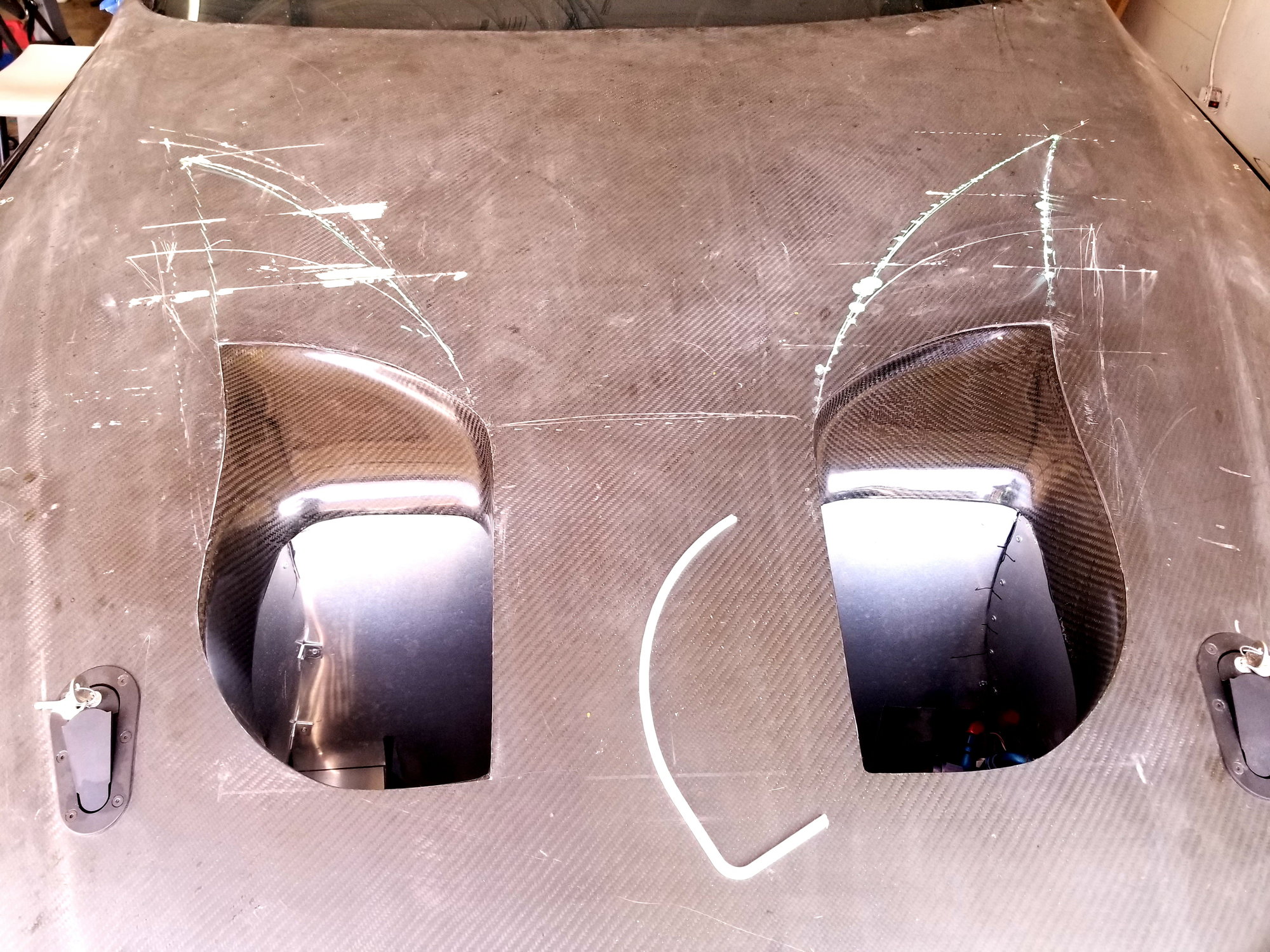

Last time I made a mold was making the one for my hood (you can see that HERE). That was quite a project, but it was also over 10 years ago. So I lost a lot of what I learned. I made a few mistakes. First, I didn't buy enough gelcoat. One quart was not enough to achieve proper thickness. So, some areas ended up thinner than others. I didn't have my support fiberglass cut beforehand so I was under the gun a bit. The resin was curing too quickly and the heat wasn't helping. Last, my flanges were not great, so I had to spend a lot of time making sure they hold vacuum.

Any who..

This was me starting to pop the mold a few hours later. That wasn't too difficult, but took about 30 minutes.

Mold out... looks like crap I know... It was a good surface though, with no problems. So that part I'm happy about.

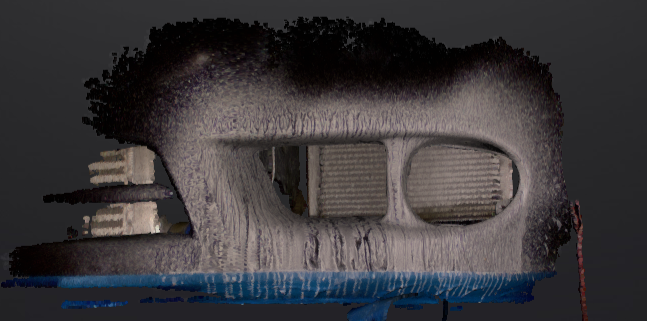

The flanges have to hold vacuum. That struggle I still remember from my first project with the hood. So, I decided to make sure the flanges have a good surface, that's big enough for sealing tape, before going forward.

I taped the area around th flanges and currently in the process of depositing polyster resin all around.

will report back with progress in this project.

Sunroof delete panel done... need to finish the clear coat.

.

.

.

.

.

Just gonna park this right here... weighs less that a pound (OEM glass alone weighs 12 lbs)